C11 (Rev. 8) User Manual

Revision: 02/12/2008 http://cnc4pc.com/TechDocs/C11R8_User_Manual.pdf 2/18

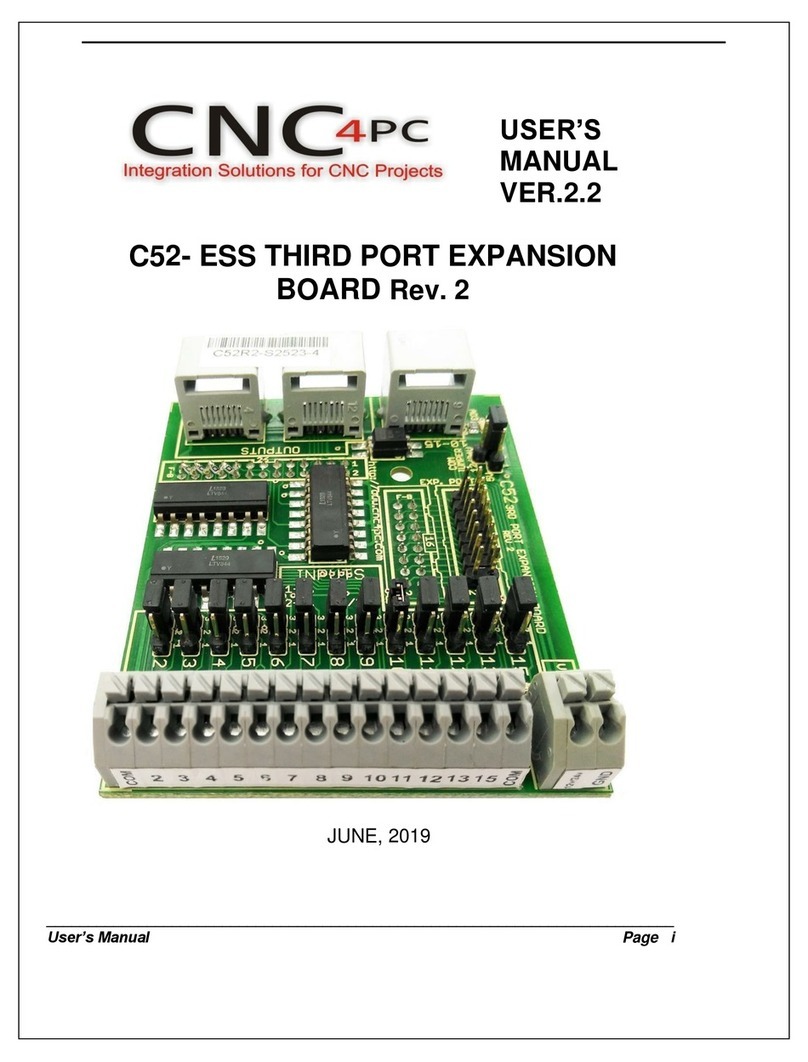

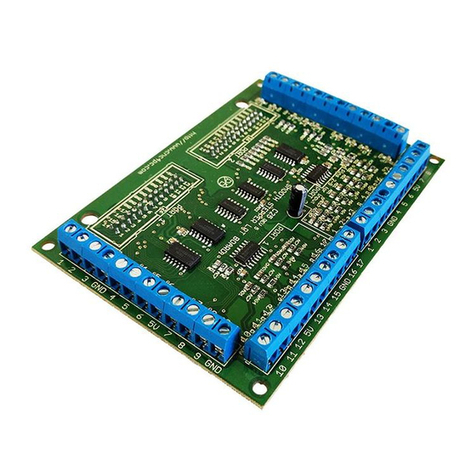

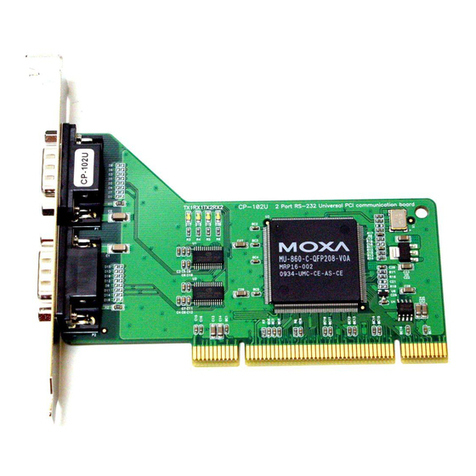

•Support for up to 150 KHz

optoisolation on step and

direction signals.

New on this revision is that the

optoisolation circuit has been

optimized and now supports full

optoisolation at speeds over 150 kHz.

•Built-in Passive Low Pass Filters

for the all signal.

This board includes low pass filters to

reduce the effect of the noise from the

drivers or other devices over the

signals.

•Microcontroller based SCHP.

This board comes with a

microcontroller that allows the

implementation of a complex

algorithm for sampling and analyzing

the SCHP signal.

•All TTL 5VDC signals.

Interface directly with parallel port

interface products and other CNC4PC

cards. 5VDC (TTL) cards are very

common among automation devices.

•Buffered outputs.

All outputs are buffered through the

use of high speed and high current

buffers, with the result that your

devices receive all the power they

need.

•Easy installation of an On/Off

switch. You can control the card

externally.

An On/Off or a Safety Charge Pump

can easily be installed to enable or

disable the card. CNC machines

could be dangerous and, remember,

safety comes first. This card is

provided with an extra pin (EN) that

allows you to control the card

externally by enabling or disabling

outputs. The card must have +5vdc

supplied to the EN terminal to enable

outputs.

•Status LEDs on all inputs and

output connections.

No more guessing. You can SEE all

your signals. Save valuable time and

brainpower for CNCing. To avoid

remaining current to the main load

(driver or other device), all the

indicator LEDs are driven by

independent buffers of the ones that

drive de output.

•Built-in Variable Speed Control.

It has an optoisolated analog 0-

10VDC output that will convert a step

signal into an analog signal that can

be used to command a commercial

VFD. This analog can be adjusted

using on-board potentiometer, so this

board can be adjusted to other

voltages.

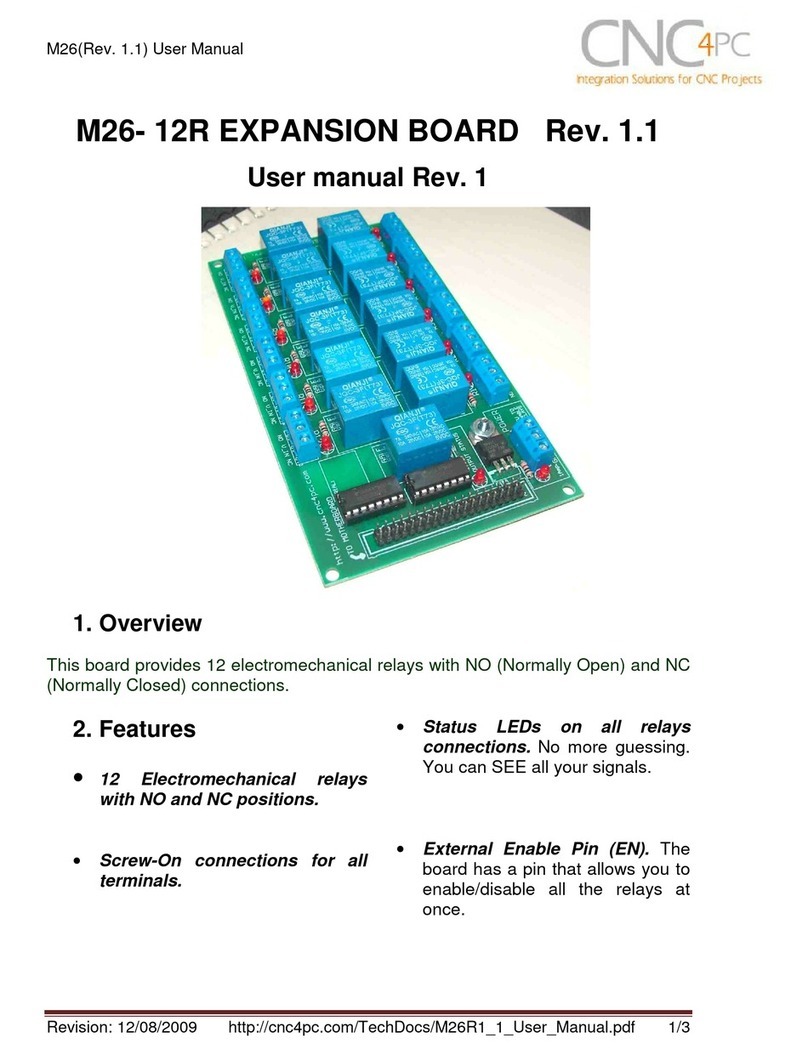

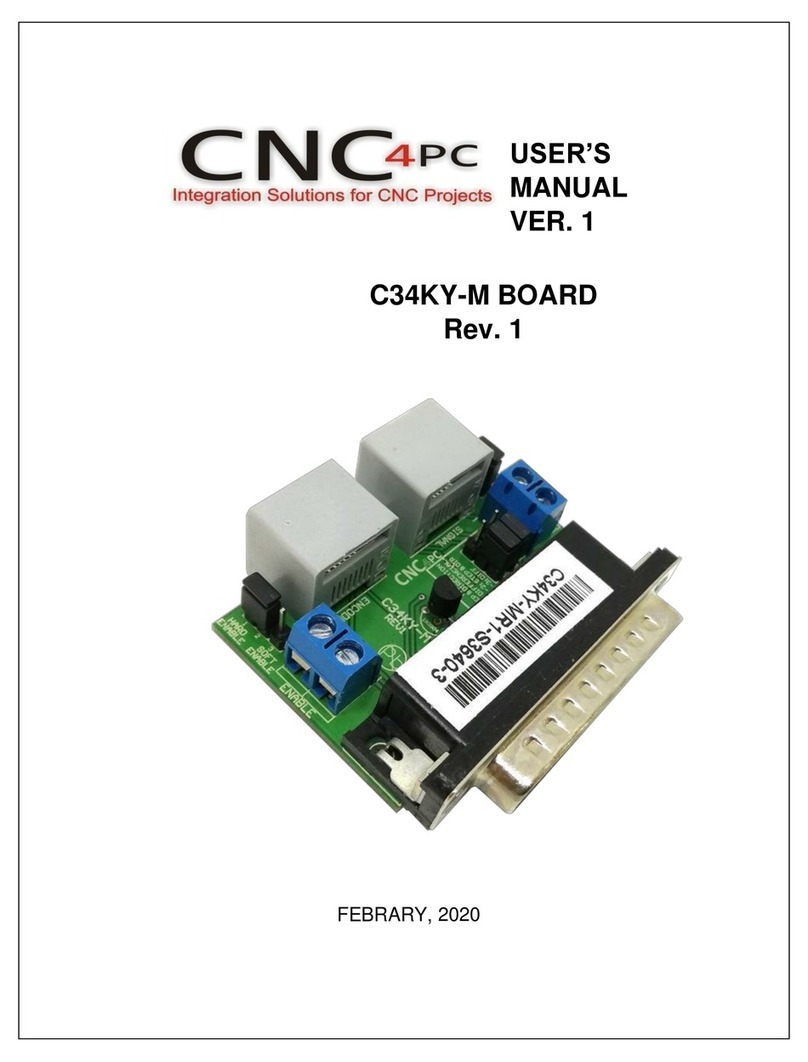

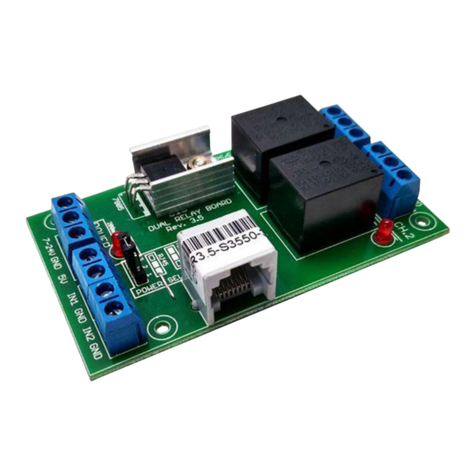

•Two Built-in Electromechanical

Relays with NO and NC

positions.

•All pins can be used in a

concurrent manner.

You can use all the input or output

pins in a concurrent manner. For

example, if you are using output pin

#1 to control the Built-in

Electromechanical Relay, you can

also access that signal from the

output pin on the board or from the

DB25 connector for output. Each

connection will not affect the other

current from the other connection.