Pag.2

Declaration of CE conformity

We Manufacturer IAG Room 2310-2311, Press Building, No 2 Shennan Zhong Road, Shenzhen, China, 518027

Declare that the product MP150 Spot DV is in conformity with 89/336 EEC-EMC directive and with the actual

required safety standars in accordance with LVD 73/23 EEC

Shenzhen, 01 October 2005

ATTENTION: carefully read the directions of this manual. Exclusively follow the safety rules in force and do not carry out assembly and/or

maintenance operations without taking all precautions as indicated in the different sections or without the necessary specialization.

This manual must always accompany the equipment, therefore it must be available and readable at any moment if necessary. Also in

case of sale, rent, change of place and/or ownership, these documents shall be enclosed with the relative equipment.

ADVICES FOR A CORRECT INSTALLATION

This equipment is destined to an exclusively Professional use.

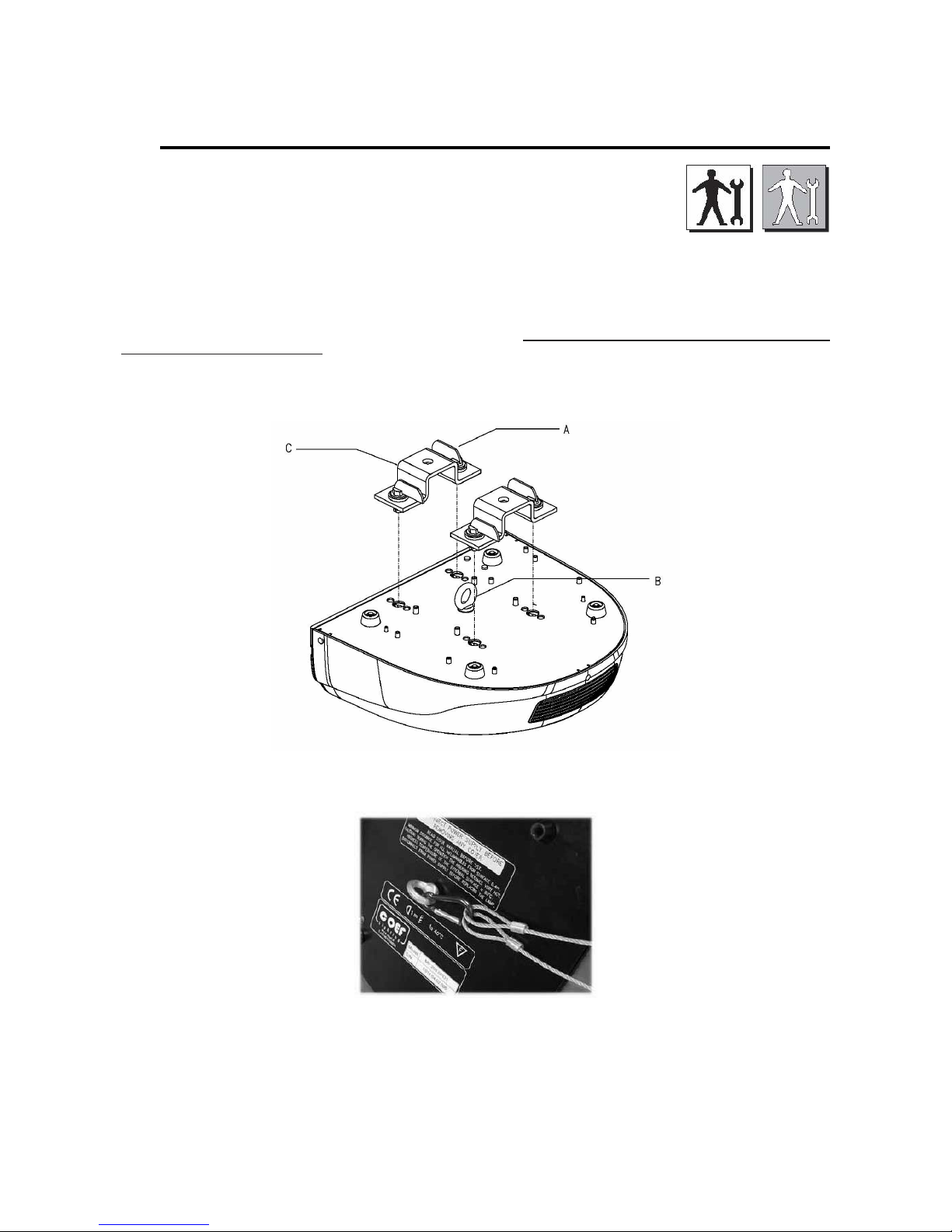

1) Make sure that all the fastening parts of the spotlight are in good condition. Regulate the proportions of the fastening accessories

(screws, bushes, nuts, supports, etc.) in order to be slightly over-dimensioned as compared to the actual requirements.

2) Carefully check the contents of the packaging and the completeness of the components. If any of the parts listed hereunder is missing,

please contact your Dealer immediately.

3) Do not install the projector outside where the influence of atmospheric factors could damage the unit working (rain, wind, intense heat

etc.) or indoor if there is a high percentage of humidity.

4) Do not clean the projector using water jets or immersion in different liquids. Scrupulously follow the indications given in the chapter

MAINTENANCE.

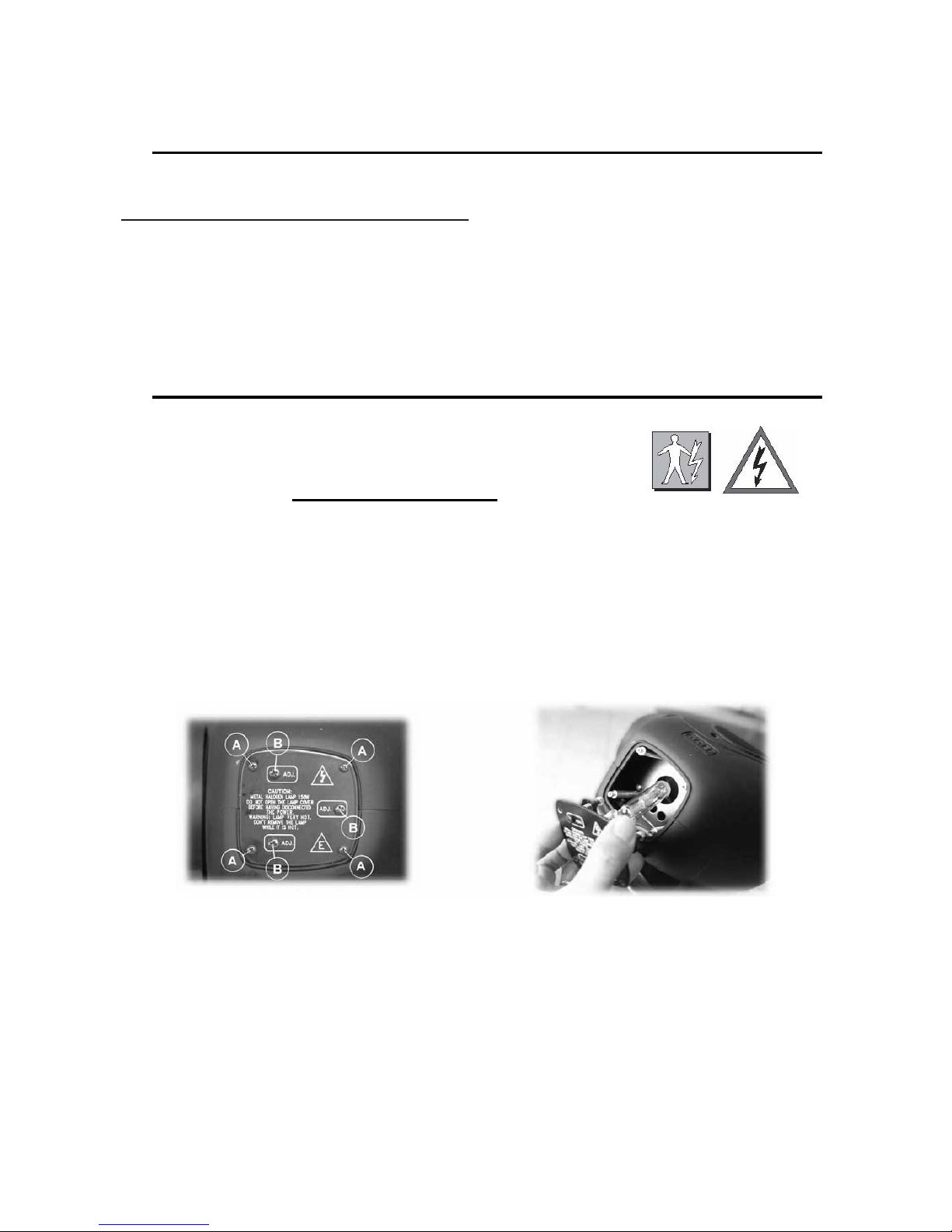

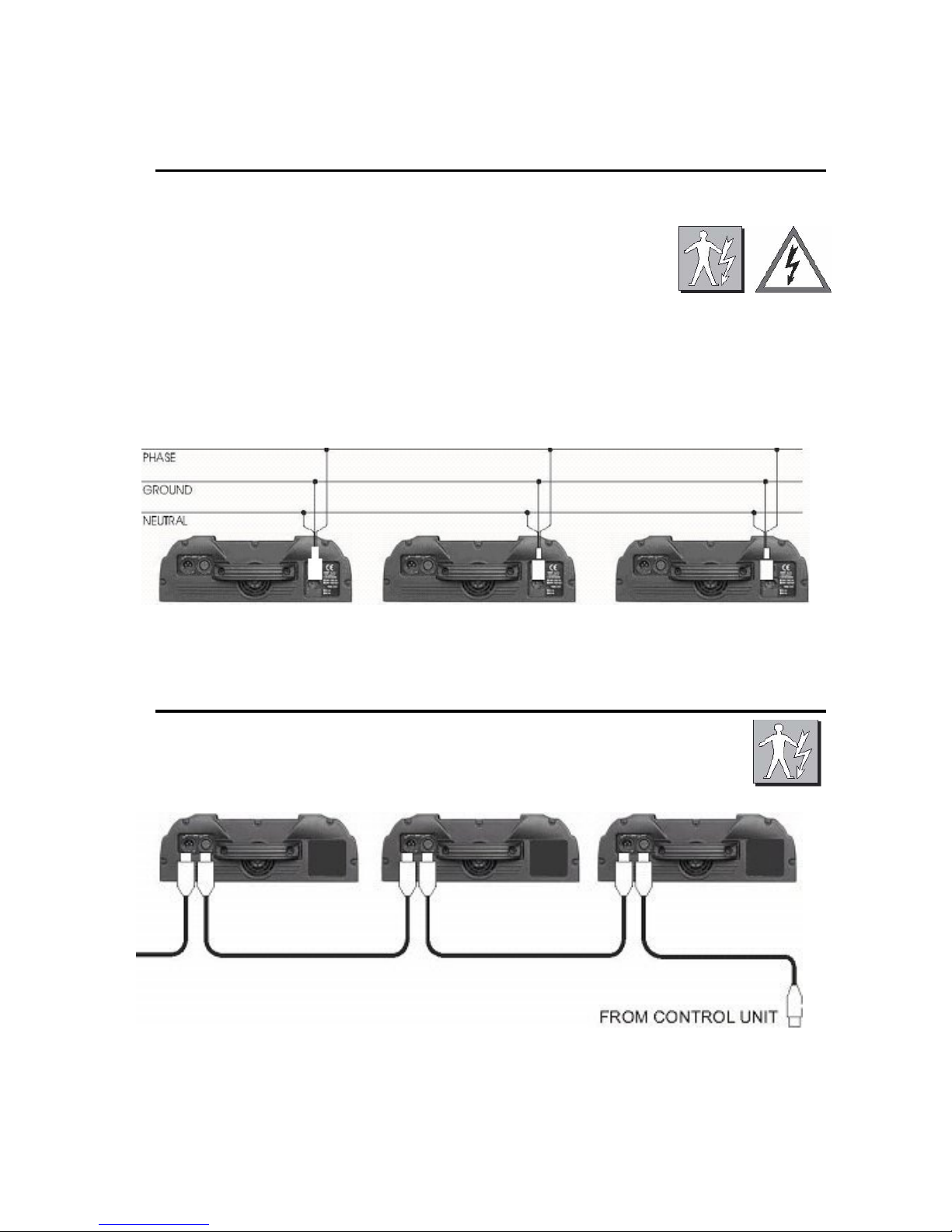

5) Make the electric connections and the installation / replacement of the lamp after having disconnected the power supply and after haved

positioned the power switch to OFF.The apparatus is classified as belonging to Class 1 type of protection against electric shocks. Its

connection to an earthed mains unit is compulsory. The equipment must be protect by an adeguated magneto-thermal switch. You are

recommended to equip the system with aptly dimensioned differential switches.

6) Do not touch in any case the internal and external parts of the projector without previous authorization of the constructor and make

modifications only by the intervention of qualified staff.

7) Make sure that the projector is correctly fixed on the support as indicated in par. 3.3

8) If the bulb explodes, the particular design of the apparatus prevents the splinters from going outside the projector. All the parts, therefore,

shall be complete and perfectly assembled. The lenses, if visibly damaged, shall be replaced by original spare parts.

9) Minimum distance from illuminated objects: The projector must be positioned in such a way that objects struck by the light beam are

located at least 1 metres from the projector objective.

10) Minimum distance from inflammable materials: 0.4 meters

11) MAX ambient temperature: 40° C.

12) MAX external surface temperature:80° C.

13) Don’t look directly the lamp trough the lens.

14) We recommend not to look at the lamp without wearing a proper protection; also ensure that the covers are assembled to

the equipment.

15) Inside the equipment there are high temperatures and tension/current values which might be very dangerous. It is necessary to

disconnect the equipment from the mains before removing its protection covers and wait for 30 minutes at least before touching any part

inside.

16) Do not switch on the equipment if its lamp is not inserted.

17) Leave sockets and air outlets free from encumbrances and clean them periodically (see “Maintenance” section).

18) Do not leave the packaging elements (polystyrene, nylon, metal parts, etc.) unattended; they might be dangerous for children.