COMBI PCS 110 DUAL

User’s manual

Version: 1.0

Page: 2 of 30

Date: 24.04.2022

Contents

INTRODUCTION..............................................................................................................................................5

GENERAL INFORMATION...............................................................................................................................5

SYSTEM DESCRIPTION..................................................................................................................................7

FunctionalDescription..................................................................................................................................7

ProductionDescription2A0388...................................................................................................................7

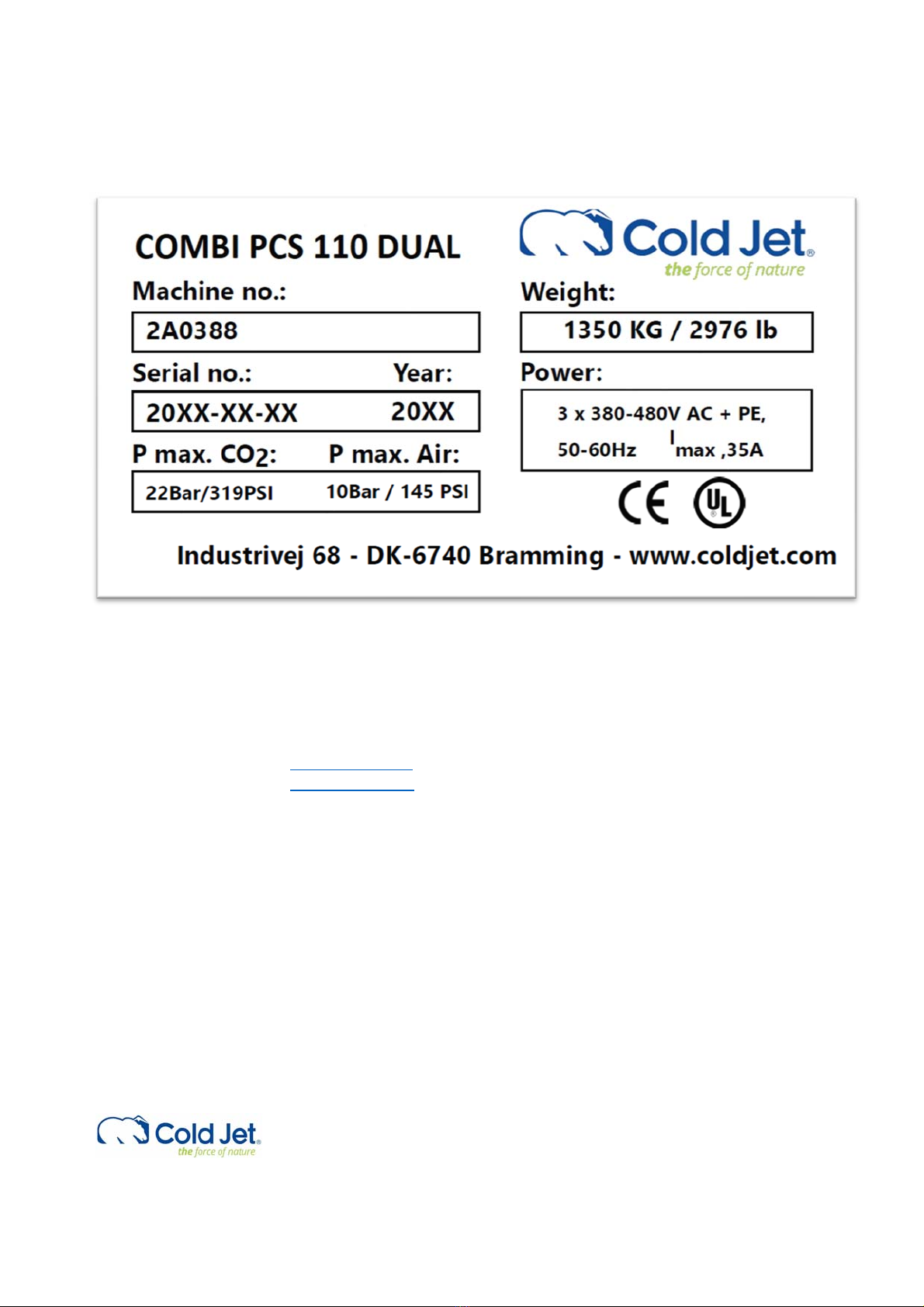

SYSTEM IDENTIFICATION.............................................................................................................................9

SupplierResponsiblefortheEquipment.....................................................................................................9

TECHNICAL DATA.........................................................................................................................................10

SAFETY REGULATIONS................................................................................................................................11

GeneralMeasures.......................................................................................................................................11

PersonnelQualifications.............................................................................................................................11

SecurityandRisk.........................................................................................................................................11

C02Safety....................................................................................................................................................11

ElectrostaticDischarge...............................................................................................................................12

SafetyLabels...............................................................................................................................................13

DangerofSuffocation.................................................................................................................................13

StaticElectricity...........................................................................................................................................14

DangerofCongelation................................................................................................................................14

WearProtectiveGloves..............................................................................................................................14

SAFETY OPERATION.....................................................................................................................................15

EmergencyStop..........................................................................................................................................15

MachineSafety...........................................................................................................................................15

LiquidCO2Leakage......................................................................................................................................15

StopProduction..........................................................................................................................................15

DailyCheckupBeforeStart‐up...................................................................................................................15

MACHINESTRUCTURE.....................................................................................................................................16

MACHINECONTROL........................................................................................................................................17

FrontPage...................................................................................................................................................17

StartUp.......................................................................................................................................................18

ChangeofUserLevel..................................................................................................................................19