Caution

1. Please read the Instruction Manual before installation and use.

2. Some Cole-Parmer Fluidised Baths can heat up to 700°C. High temperatures are dangerous and can

cause serious burns to operators and ignite combustible material.

3. Use care and wear protective gloves to protect hands and protective glasses to protect eyes.

4. Do not put hot objects on or near combustible objects.

5. Do not operate the unit close to inflammable liquids or gases.

6. Do not place any liquid directly in the unit.

7. Always ensure a suitable, adequate ventilation system is used when equipment is in use.

8. Always install fireproof metal ducting with sufficient airflow where applicable.

Maintenance

1. When performing maintenance, always disconnect from power supply and cool below 50°C.

2. Antylia Scientific Ltd recommend regular cleaning of fluidised baths. Externally, wipe with a damp

soapy cloth. No abrasive cleaners should be used. Care should be taken to prevent any water entering

the unit.

3. Regular internal and external inspection of extraction ducting is recommended to detect any damage

and ensure the internals are clean. Any build-up of particles or debris discovered in the extraction

ducting requires the ducting to be cleaned or replaced.

4. In fluidised baths used for polymer burn-off, please regularly inspect fluidising medium, remove any

foreign debris and replace with clean fluidising medium as required.

5. Never top-up a hot fluidised bath with cold fluidising medium. Always cool below 50°C first.

Please note:

1. Please ensure an adequate risk assessment is performed before use of a fluidised bath.

2. Please ensure the appropriate temperature is used for the application, always stay safely below the

combustion temperature of any material or sample in a fluidised bath.

3. Fluidising airflow must be switched on before heating a fluidised bath and left operational until the

bath cools to below 50°C.

4. Do not overfill fluidising media. When fluidized, the aluminium oxide level should be approximately

100mm (4”) from the top surface of the bath at your maximum operating temperature.

5. In fluidised baths used for polymer burn-off, always remove excess polymer from sample.

6. In applications where materials being treated produce acidic vapours during thermal decomposition, it

is recommended a fume scrubber is utilised to ensure fume emission from the plant conforms to local

regulations.

7. If you have any questions, please contact cptechsupport@antylia.com.

WARNING HOT

SURFACE

IMPORTANT SUPPLEMENTARY SAFETY INFORMATION

Introduction

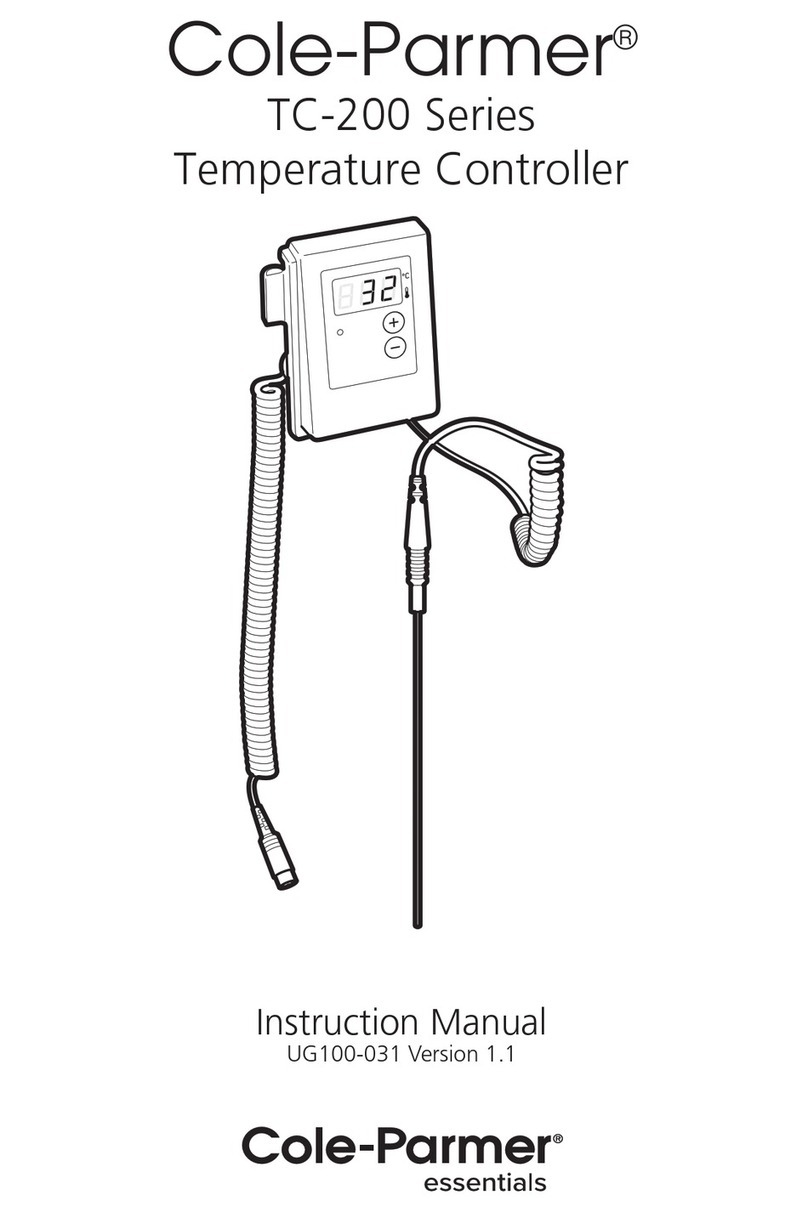

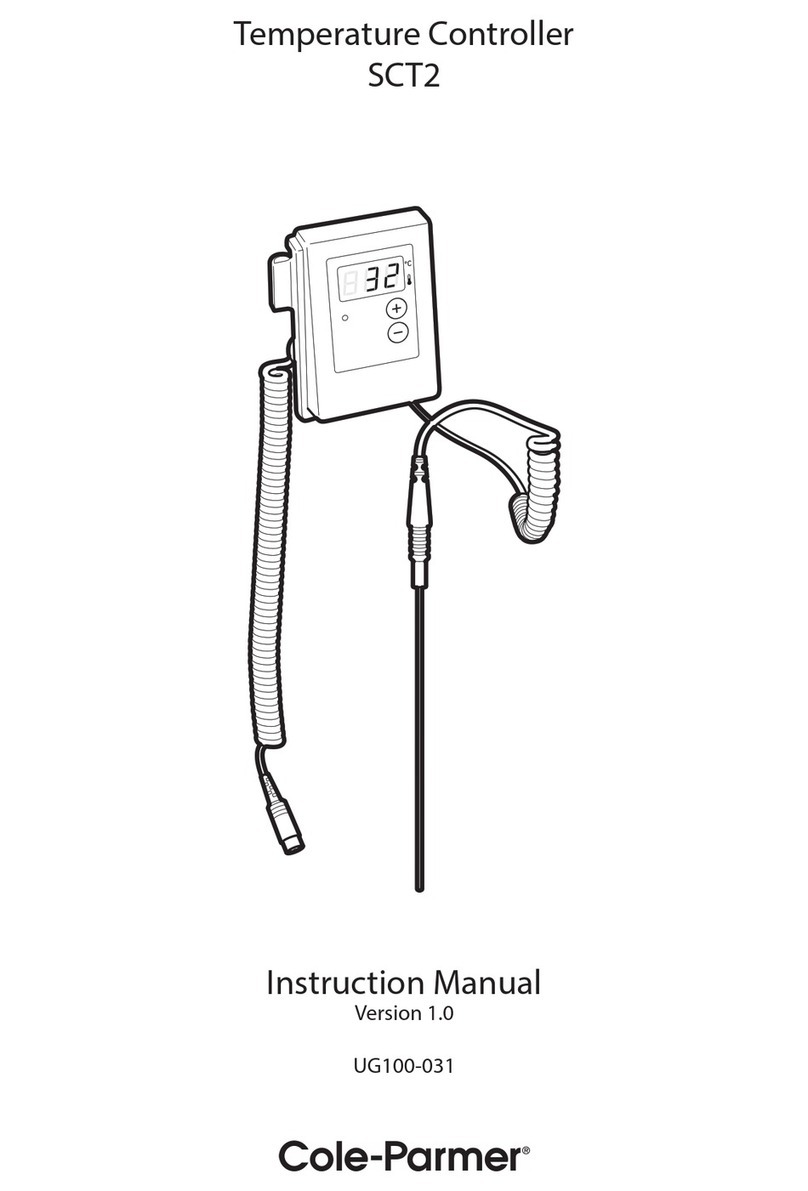

The FSB-200-TC Temperature Controller is designed as an alternative to the energy control provided in

the laboratory fluidised baths. It is supplied with a Chromal Alumel Thermocouple which fits into the

sheath built into the fluidised bath.

Symbols Defined

RISK OF

ELECTRIC

SHOCK

EARTH