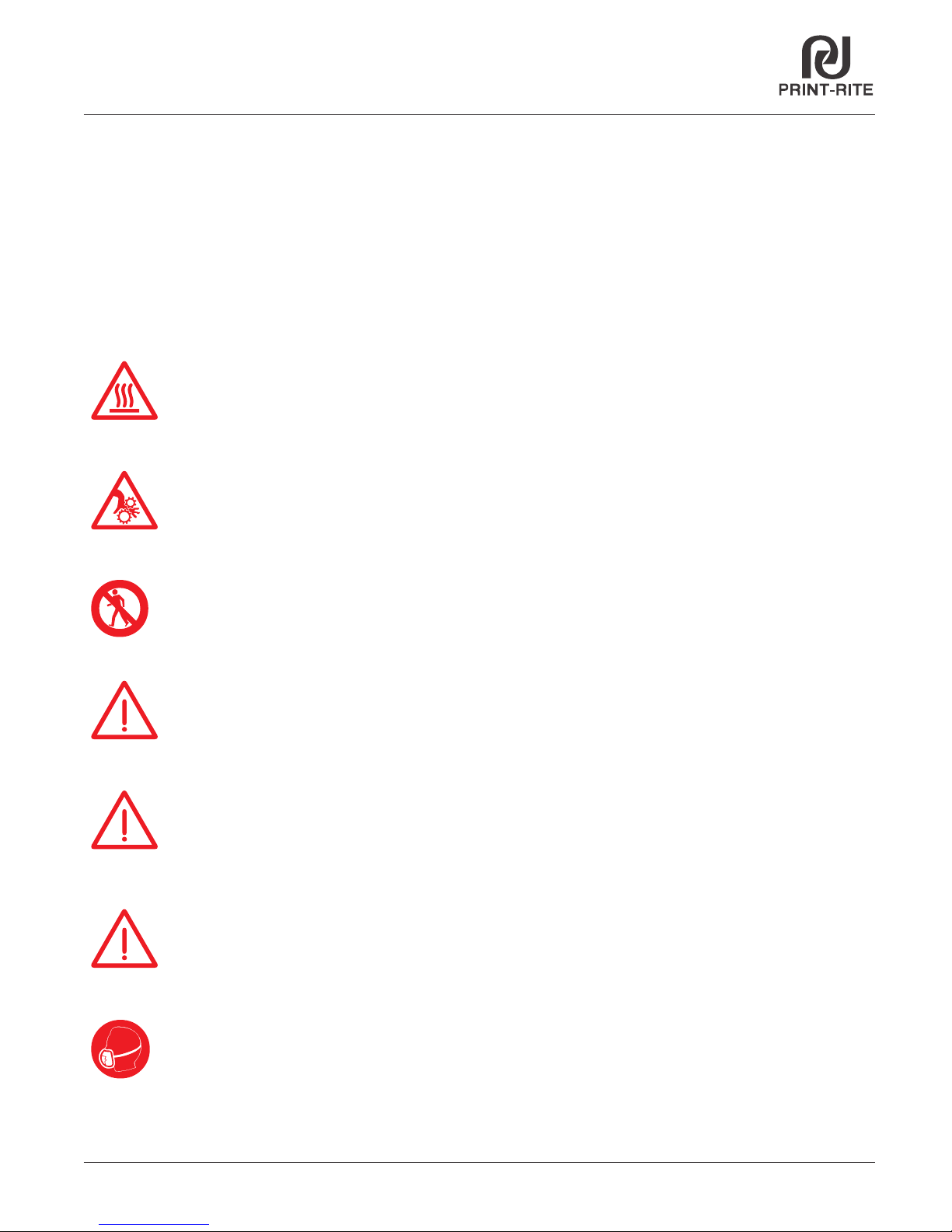

Safety Alert Symbol

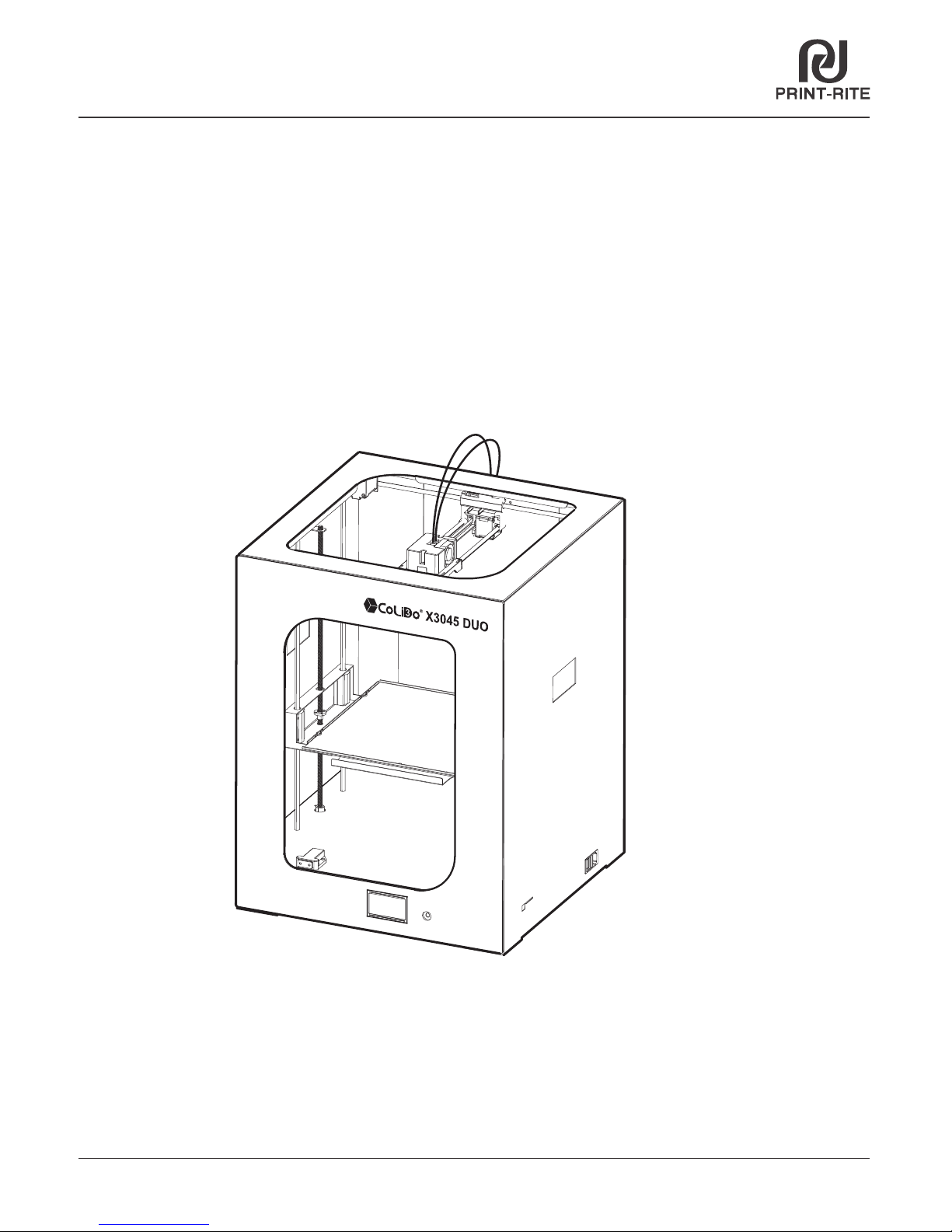

CoLiDo USER MANUAL

Index

02

Chapter 1 Introduction 03

Chapter 2 Safety and Compliance

04

Interference of Radio and Television 05

5.1 Unpack CoLiDo Printer

09

08

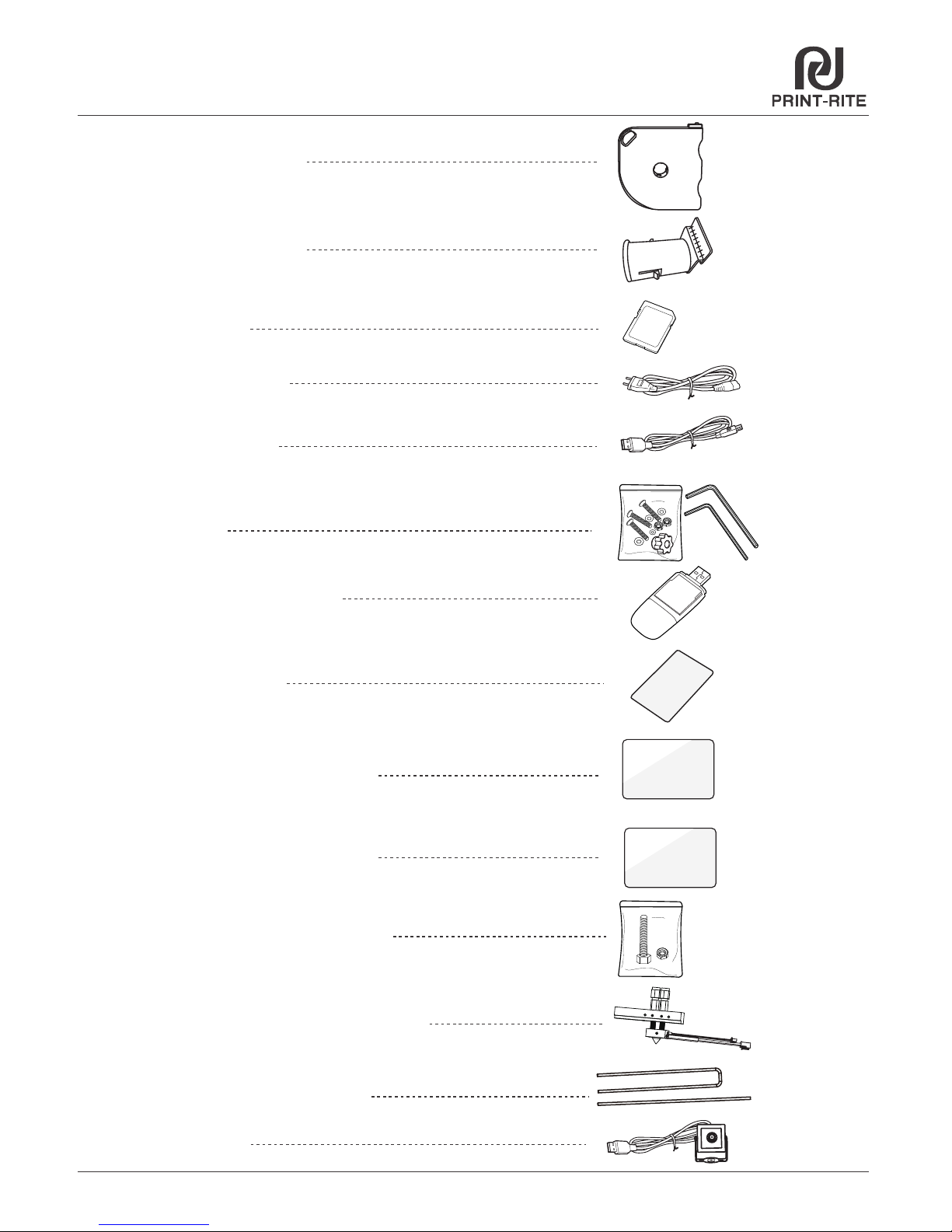

5.2 Accessory Checklist

10

5.4 Unlock Printer Head and Heat Table 11

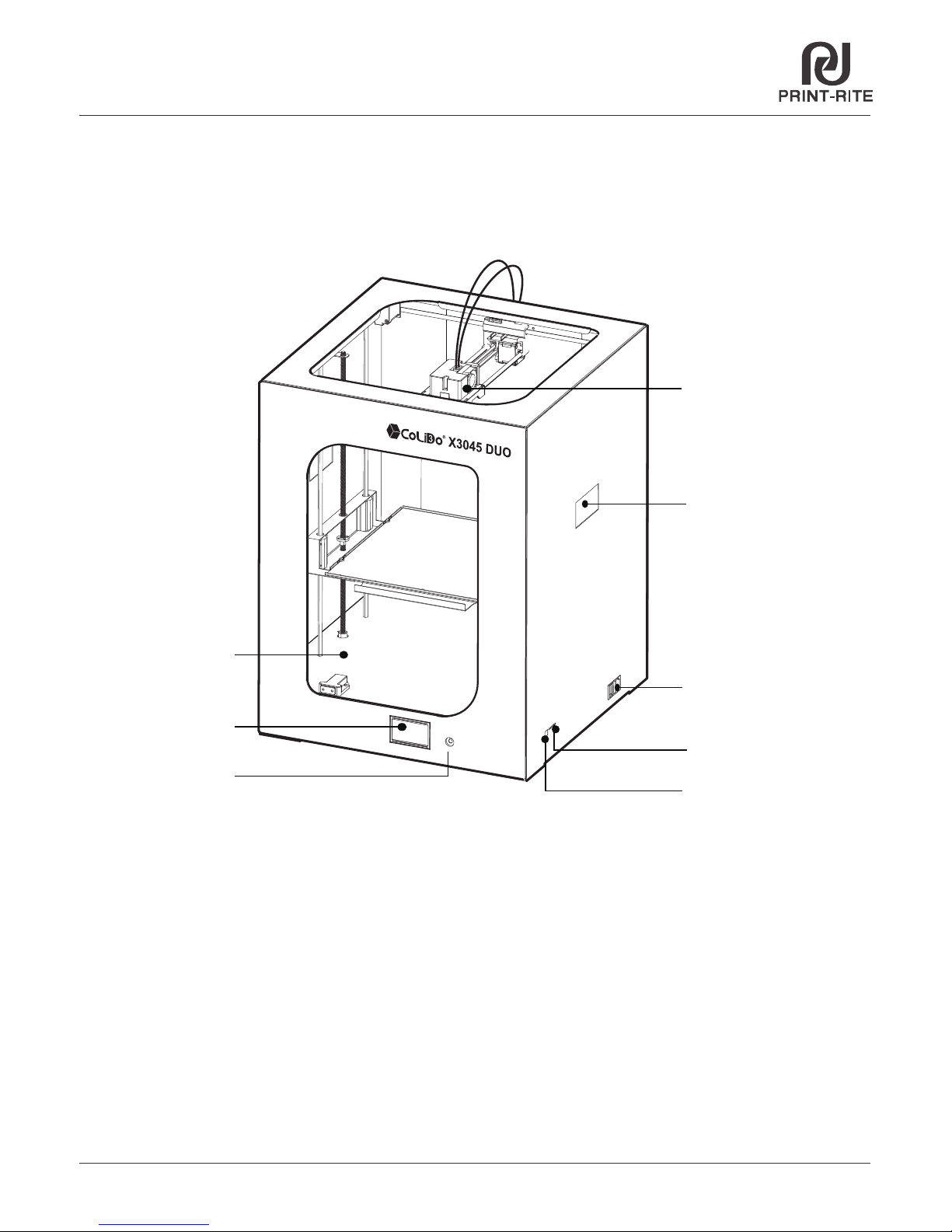

5.3 CoLiDo X3045 Duo 3D Printer Structure Illustration

12~14

5.5 Install Glass Platform

Chapter 3 Specification 06

Chapter 4 Print Principle 07

Chapter 5 Set up CoLiDo Printer

TM

15~175.6 Install Filament

6.2 Calibrate Mode 20~22

23~24

6.1 Main Menu 19

6.3 Nozzle & Filament Test

25~26

6.4 Print test with SD Card

27

6.5 Prepare Menu

28

6.6 Choose Nozzle

31~33

6.8 Color Mixing

Chapter 6 CoLiDo Printer Calibrate and Test

Chapter 8 Maintenance 78

Chapter 7 REPETIER-HOST Setup, Slice and Print

7.1 Install REPETIER-HOST 39~42

7.2 REPETIER-HOST Setup_Single Color/Color Mixing 43~44

7.3 Slice_Single Color/Color Mixing 45~46

Chapter 9 Troubleshoot 79~81

29~30

6.7 Change Filament

7.4 Printing_Single Color

7.5 Printing_Color Mixing 50~51

36~38

6.10 Print from SD Menu

34~35

6.9 Control Menu

47~49

7.6 Repetier-Host Setup_Two Color/Two Material 51

7.7 Slice_Two Color 52~53

7.8 Slice_Two Material 55~57

7.10 Repetier-Host Basic 3D Printing 70

7.11 Repetier-Host Advanced 3D Printing 71~77

185.7 Install camera

7.9 Printing using WIFI communication 58~69