3

Instructions for use

The compressed air unit of the VitoMat assortment for filling of aerosol cans is used for the

quick and easy filling of pre-filled ColorMatic cans with lacquer. The cans are already filled

with propellant and solvent.

Advantages of a VitoMat:

•Every customer gets the desired colour he wants within a short time even for just one

can. But the machine is also perfect for the filling of a larger quanity.

•Cleaning circuit-system, without manual cleaning, the thinner runs through the

machine and thereby cleans it

•No electrical connection needed

•Requires little space, relatively low weight

•Also suitable for waterbased lacquers

•Easy to apply and easy to clean

•Adjustable pedestals

•The bottom part can be screwed to the place of employment

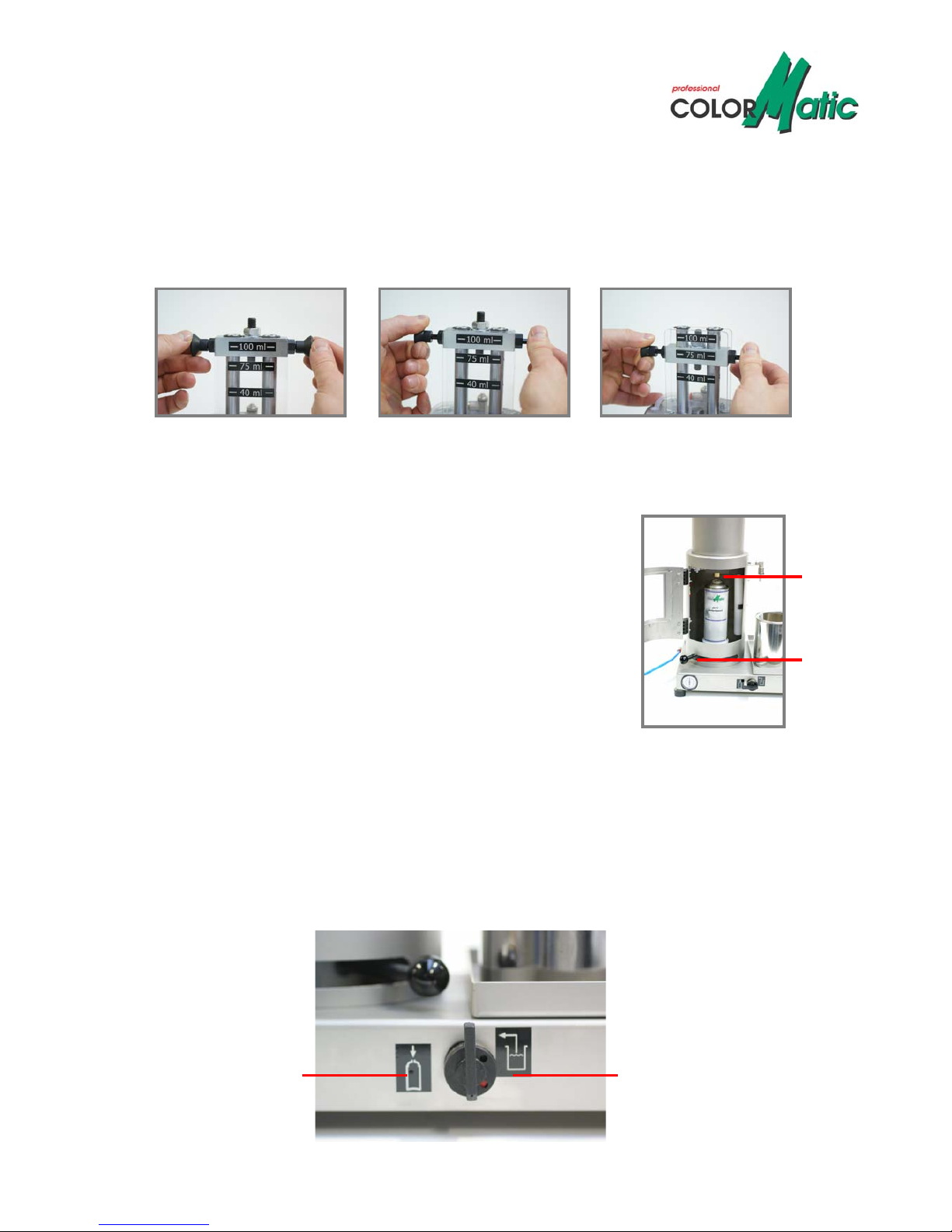

•Transparent inspection window made from solvent-resistant plastic for permanent

possibility to control.

•High working security by solid construction and easy handling

•The filling time takes only a few seconds, depending on pressure (7-8 bar)

Directions for use for VitoMat III

1. Instructions für use

With VitoMat III filling machines ColorMatic pre-filled cans with solvent and propellant will be

additional filled with lacquers of different manufacturers and different paint qualities. These

cans are constructed for a fill quantity of 400ml and 150ml (for the filling of 150ml cans a

special adapter is necessary) and a test gauge pressure of 15bar. 400ml cans are pre-filled

with approx. 300ml (depending on the product) of a solvent-propellant-mixture and therefore

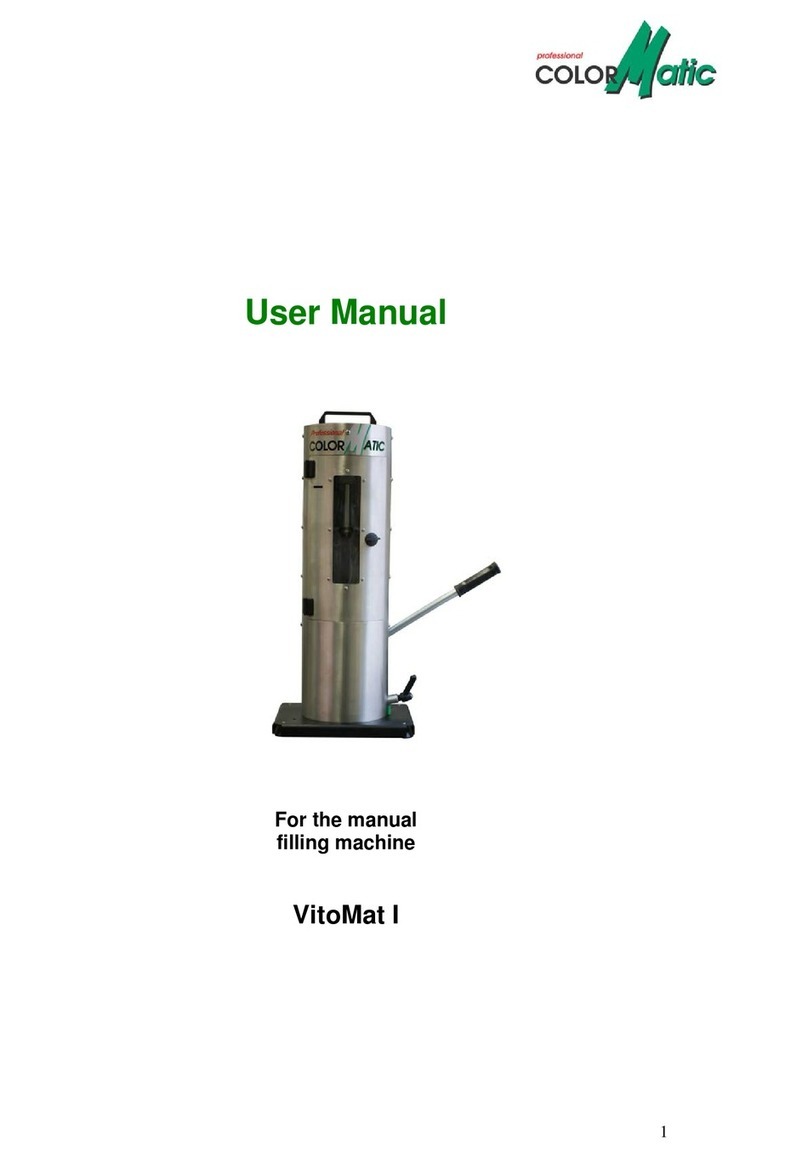

they have a free filling space of 100ml more or less. By means of a press-in construction this

lacquer will be additional filled into the cans.