3

www.combisteel.com

6.2 Algemene stroomonderbreker ...................................................................................................................25

7. De deegmenger gebruiken ............................................................................................................................... 26

7.1 Kwalificatie operator................................................................................................................................... 26

7.2 Werkstation ................................................................................................................................................ 26

7.3 Inbedrijfstelling ........................................................................................................................................... 26

7.4 Standaard stopprocedure ........................................................................................................................... 26

7.5 Noodstop ....................................................................................................................................................26

7.6 De machine opnieuw opstarten na een handmatige noodstop .................................................................26

7.7 De machine uitschakelen............................................................................................................................27

8. Onderhoud........................................................................................................................................................27

8.1 Als het apparaat nieuw is............................................................................................................................ 27

8.2 Dagelijkse werking ...................................................................................................................................... 27

8.3 15 uur werk................................................................................................................................................. 27

8.4 Maand van het werk...................................................................................................................................29

8.5 Om de twee jaar .........................................................................................................................................29

8.6 Reiniging .....................................................................................................................................................29

8.7 Motoronderhoud........................................................................................................................................29

9. Probleemoplossing ...........................................................................................................................................30

10. Veiligheid ........................................................................................................................................................ 31

10.1 Veiligheidscriteria ..................................................................................................................................... 31

10.2 Gevaarlijke gebieden en restrisico's.......................................................................................................... 31

10.3 Veiligheidsmaatregelen voor mixers......................................................................................................... 32

11. Schakel het apparaat uit ................................................................................................................................. 33

12. Naleving van de regelgeving ...........................................................................................................................33

DEUTSCH

1. Warnung ........................................................................................................................................................... 34

2. Anleitung zur Vormontage................................................................................................................................34

2.1 Lagerung und Transport.............................................................................................................................. 34

2.2 Nutzungsbedingungen................................................................................................................................ 35

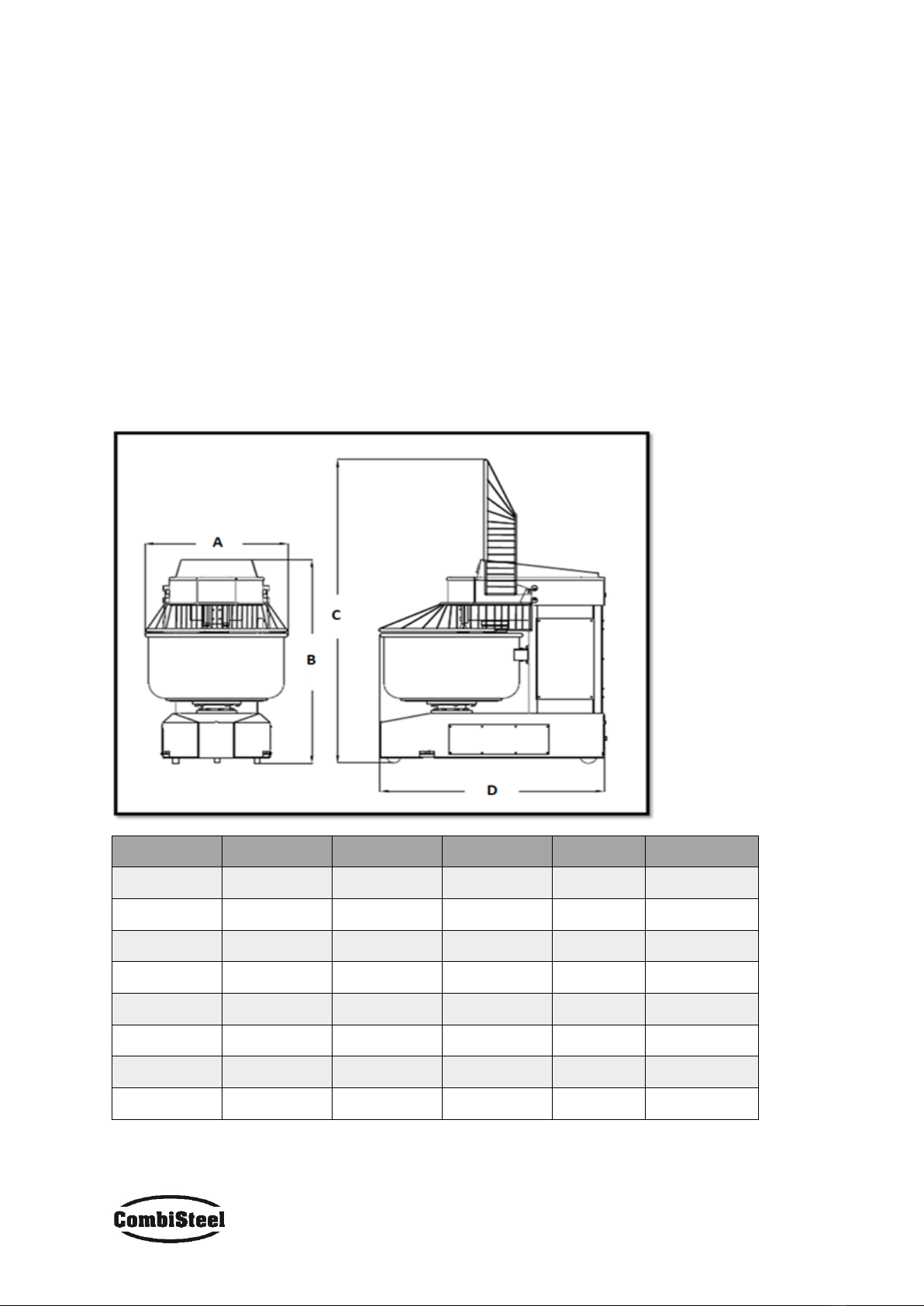

3. Allgemeine Abmessungen ................................................................................................................................ 36

4. Technische Spezifikationen ...............................................................................................................................37

5. Elektrischer Anschluss ...................................................................................................................................... 37

6. Use and Safety ..................................................................................................................................................38

5.1 Fundament.................................................................................................................................................. 38

5.2 Warnungen .................................................................................................................................................38

6. Mixer Funktionen..............................................................................................................................................39

6.1 Maschinensteuerungen .............................................................................................................................. 39

6.2 Allgemeiner Circuit Breaker ........................................................................................................................ 39

7. So verwenden Sie den Mixer ............................................................................................................................ 40

7.1 Bedienerqualifizierung................................................................................................................................ 40

7.2 Workstation ................................................................................................................................................40

7.3 Inbetriebnahme ..........................................................................................................................................40

7.4 Standard-Stoppprozedur............................................................................................................................. 40

7.3 Not-Halt ...................................................................................................................................................... 40

7.6 Erneutes Starten der Maschine nach einem manuellen Not-Aus............................................................... 40

7.7 Ausschalten der Maschine..........................................................................................................................41

8. Instandhaltung.................................................................................................................................................. 41

8.1 Wenn die Maschine neu ist.........................................................................................................................41

8.2 Täglicher Betrieb ......................................................................................................................................... 41

8.3 15 Stunden Arbeit.......................................................................................................................................41

8.4 Monat der Arbeit ........................................................................................................................................43

8.5 Alle zwei Jahre ............................................................................................................................................ 43

8.6 Reinigung .................................................................................................................................................... 43

8.7 Motorwartung ............................................................................................................................................43

9. Fehlersuche.......................................................................................................................................................44