4

WARNINGS

1_SAFETY PRINCIPLES AND ADVICE FOR SAFE WORK

1. Read this instructions manual carefully before starting the machine and each time you have a doubt

about its operation. The best safety possible is in your hands. Using any type of machine involves

risks: you should keep this in mind. Diffuse and make its content known to the relevant people.

2. Only use the machine inside buildings.

3. Pay attention before starting any work.

4. Only work with all guards planned in their place and working perfectly. Avoid placing hands near

moving parts.

5. It is strictly forbidden to by-pass, remove, modify or make inefficient any safety device, guard or

control on the machine, no matter where it is located. All safety devices and guards must be kept in

perfect and constant efficiency.

6. Before operating the machine, ensure nobody is in the risk zones.

7. During the work cycle, operators must be kept outside the risk zones.

8. Do not leave the machine unguarded when on.

9. Never work on different materials, in quantity, shape or type, to that planned for the machine in the

design phase.

10. It is strictly forbidden for anyone to use the machine for use other than its expressly intended and

documented use.

11. Completely stop the machine before proceeding with its cleaning and before removing any guards to

carry out maintenance.

12. During the research and removal phase of any cause of malfunction or inconvenience relating to the

machine, implement all the suitable precautions to prevent any damage to people or property. Cut

electrical power (sectioning the machine from the electrical mains) before accessing the guards.

13. At the end of any intervention that leads to removal or by-passing of any safety related part (barriers,

sensors, guards, etc.), restore and ensure correct positioning and efficiency.

14. Do not allow unauthorized and qualified staff to operate, adjust or repair the machine. Always refer

to this manual for the necessary operations.

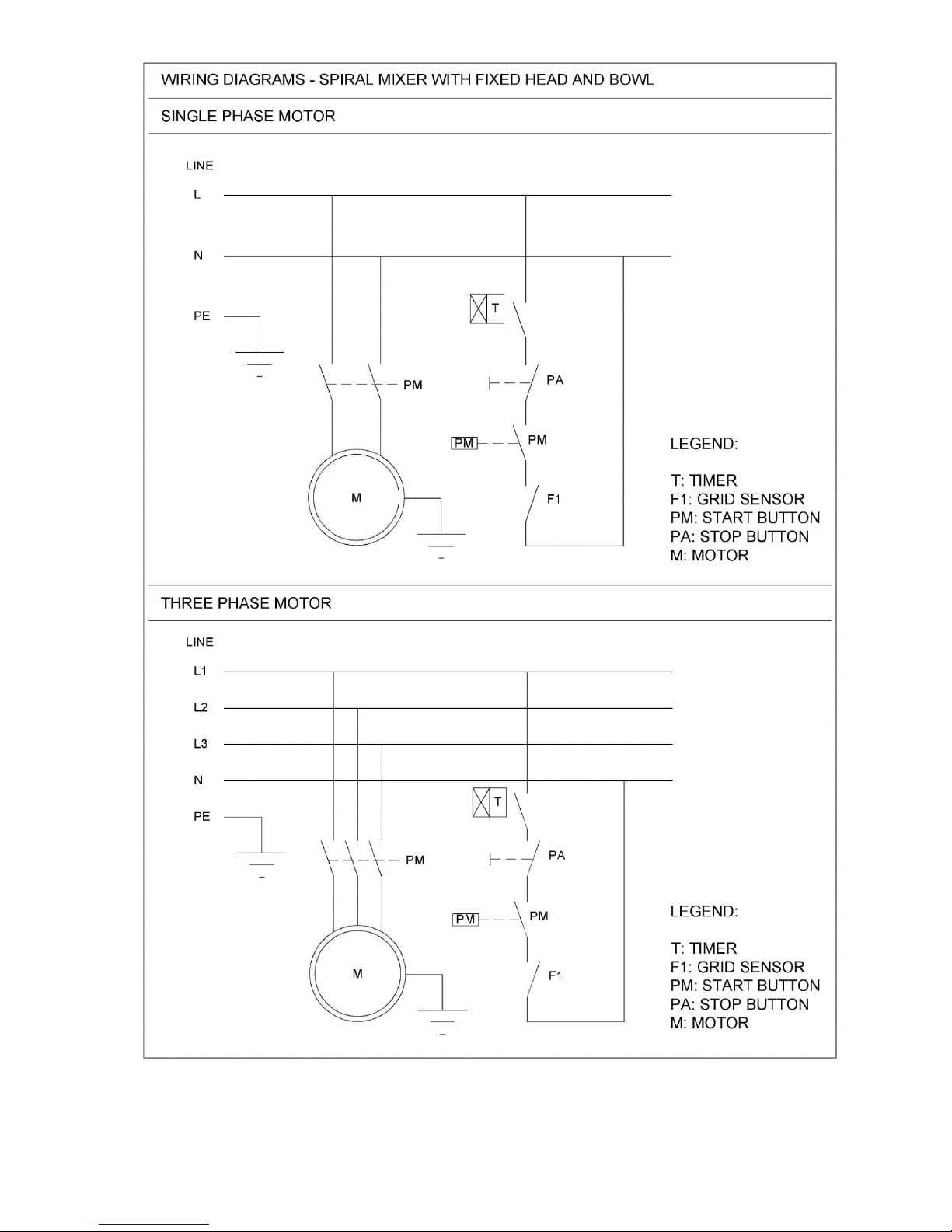

15. The electricity supply system must have an automatic release system upstream of the main switch

on the machine and a suitable earthing system that meets all the industrial standard requirements

for accident prevention.

16. If you have to work on the main switch or near it, cut power to the line on which the main switch is

connected. All controls and maintenance operations requiring removal of safety guards must be

carried out by specialist and authorized technical staff.

17. Pay utmost attention to the plates on the machine each time you work on it or nearby.

18. It is compulsory for the user to always keep the plates legible.

19. In the event of machine malfunctions or damage to parts, contact the maintenance manager, without

proceeding with further repair work.

20. Never carry out repairs in a hurry or leave repairs incomplete which could compromise good

functioning of the machine.

21. Any tampering by the user relieves the manufacturer of any liability and makes the user solely

responsible for the competent bodies for accident prevention.

22. These safety standards integrate and do not replace the safety standards in force in the place of

machine installation.