Come.up Winch Seal Gen2 12.5rs User manual

Other Come.up Winch Winch manuals

Come.up Winch

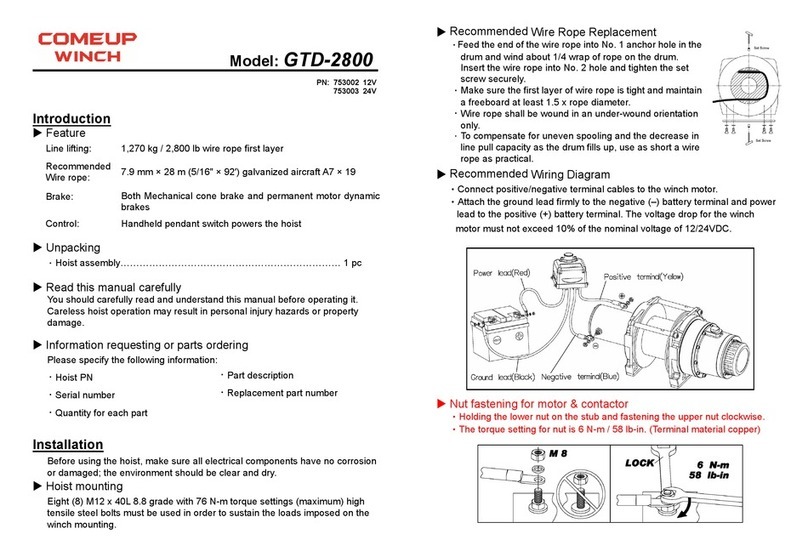

Come.up Winch GTD-2800 User manual

Come.up Winch

Come.up Winch DV-9si User manual

Come.up Winch

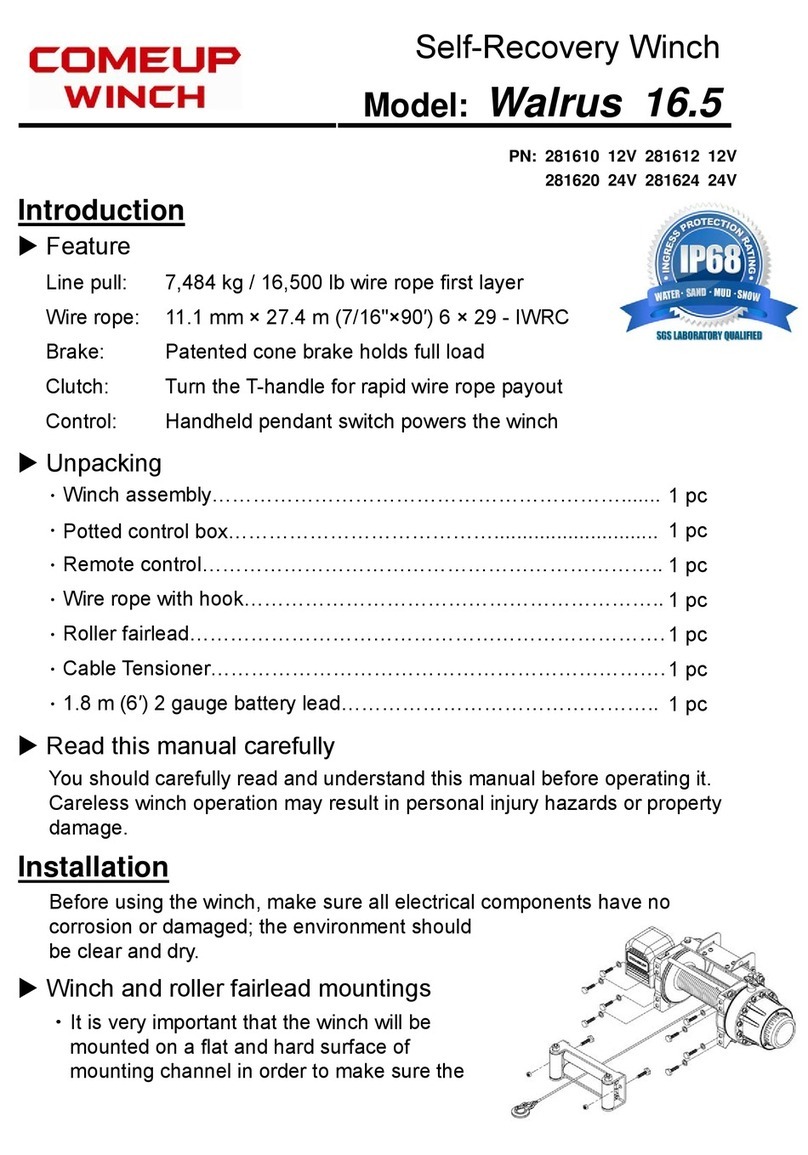

Come.up Winch Walrus 16.5 User manual

Come.up Winch

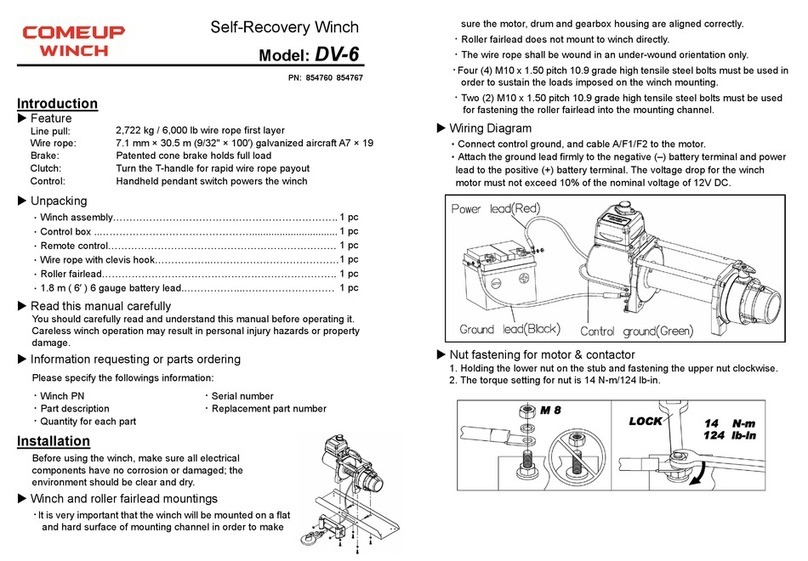

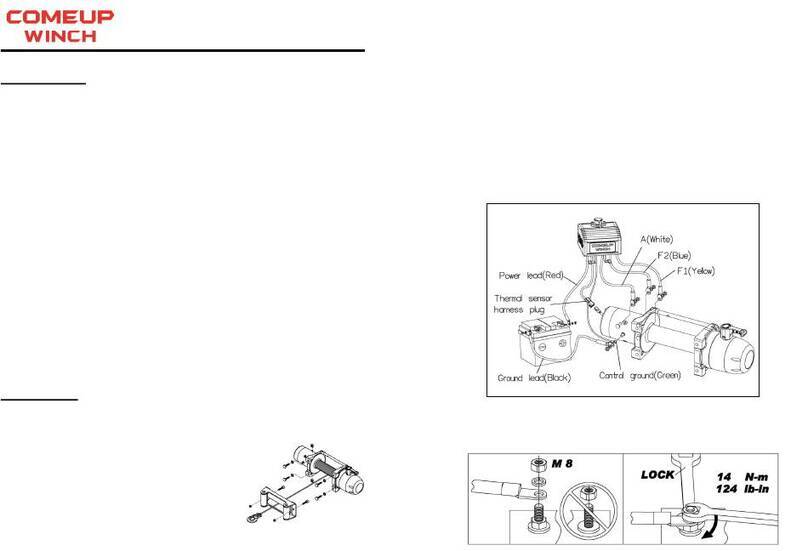

Come.up Winch DV-6 User manual

Come.up Winch

Come.up Winch Seal Slim 12.5 User manual

Come.up Winch

Come.up Winch Rhino 8 Pro User manual

Come.up Winch

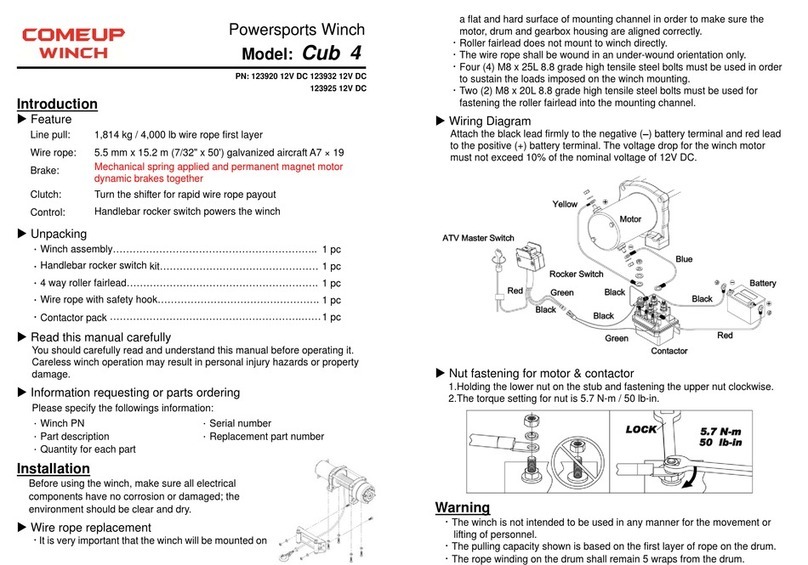

Come.up Winch Cub 4 User manual

Come.up Winch

Come.up Winch Seal Slim 9.5rs User manual

Come.up Winch

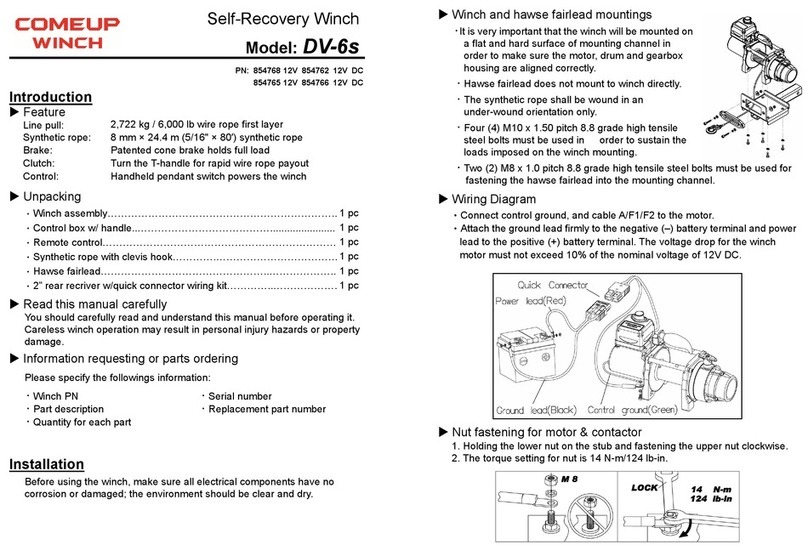

Come.up Winch DV-6s User manual

Come.up Winch

Come.up Winch Seal Gen2 16.5rs User manual

Come.up Winch

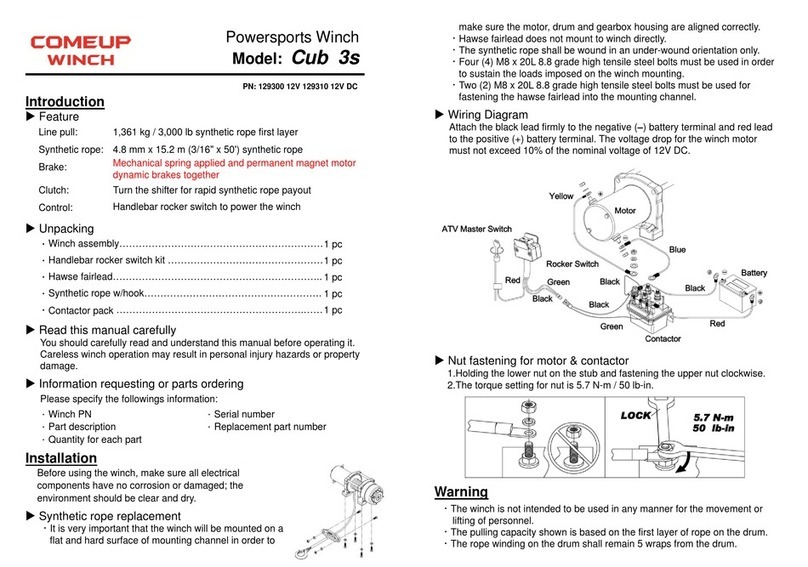

Come.up Winch Cub 3s User manual

Come.up Winch

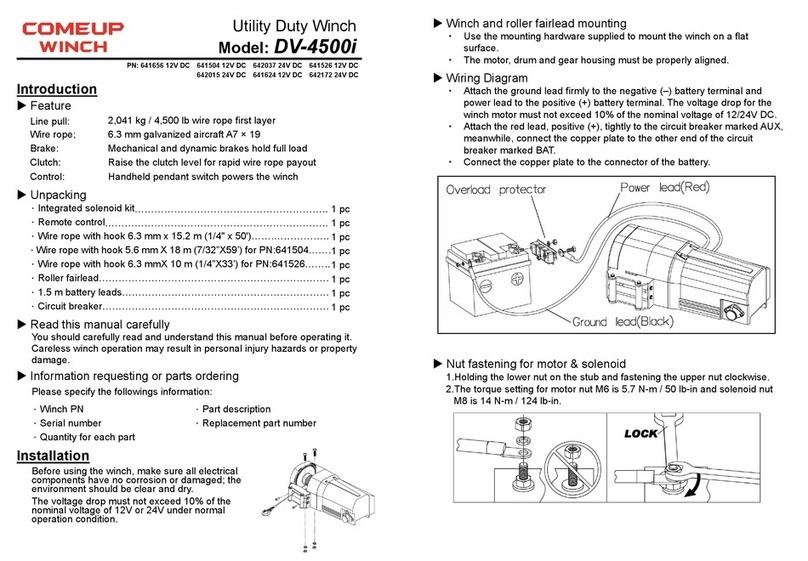

Come.up Winch DV-4500i User manual

Come.up Winch

Come.up Winch GIO 100 User manual

Come.up Winch

Come.up Winch SOLO 12.5rs User manual

Come.up Winch

Come.up Winch Rhino 15 User manual

Come.up Winch

Come.up Winch DV-9s User manual

Come.up Winch

Come.up Winch Seal Slim 12.5rs Instruction Manual

Come.up Winch

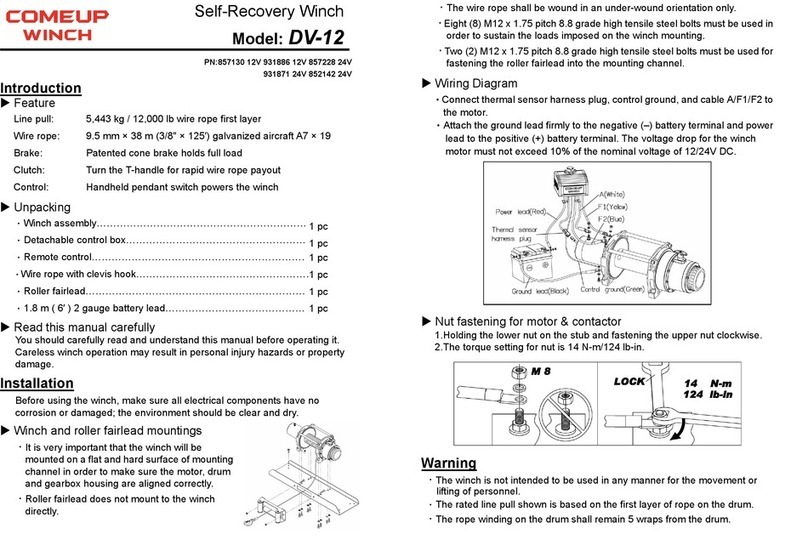

Come.up Winch 857130 User manual

Come.up Winch

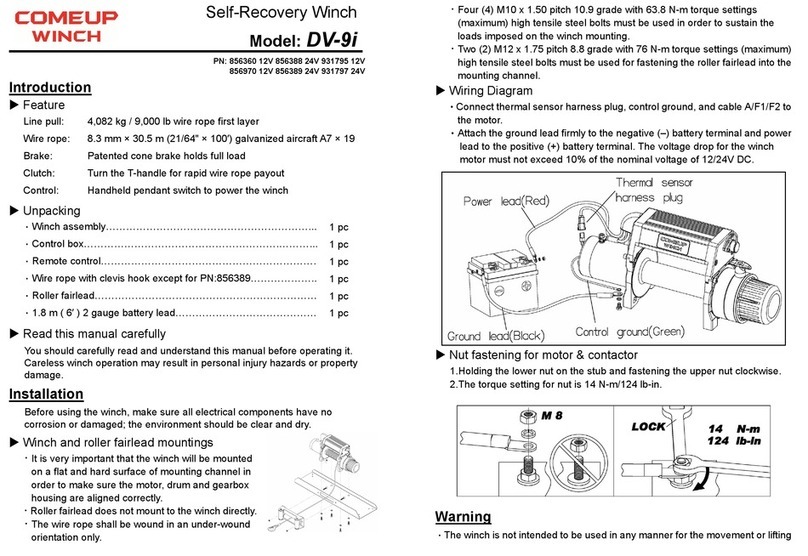

Come.up Winch DV-9i User manual

Come.up Winch

Come.up Winch GTD-800 User manual

Popular Winch manuals by other brands

Comeup

Comeup DV-9 manual

Orvea

Orvea Italwinch 805 Installation and user manual

Prowinch

Prowinch PWJTHF300 user manual

Clas Ohlson

Clas Ohlson LD2000-A manual

Runva

Runva EWD8000 Assembly & operating instructions

Ingersoll-Rand

Ingersoll-Rand LIFTSTAR FG 1500/CN Series Parts, operation and maintenance manual