CommScope BUDI-M User manual

Other CommScope Enclosure manuals

CommScope

CommScope OFDC-B8G User manual

CommScope

CommScope FOSC-ACC-B-TRAY-12-RBN User manual

CommScope

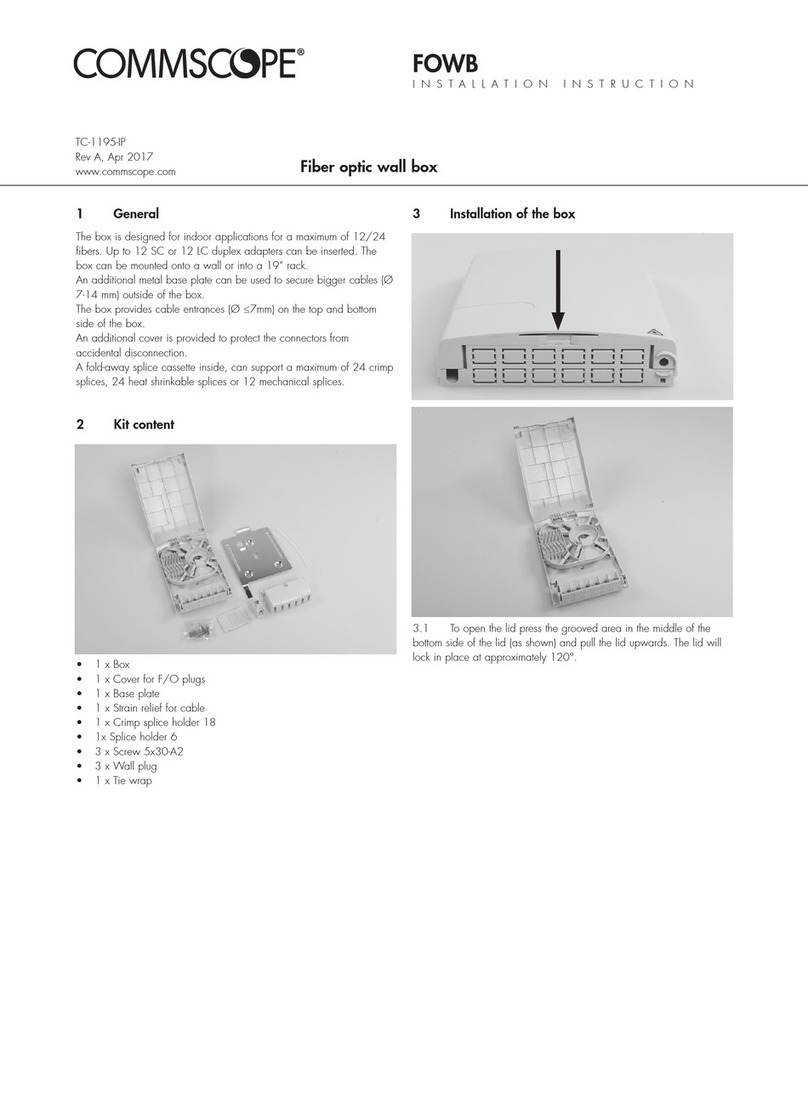

CommScope FOWB User manual

CommScope

CommScope Mini-OTE 200 Series User manual

CommScope

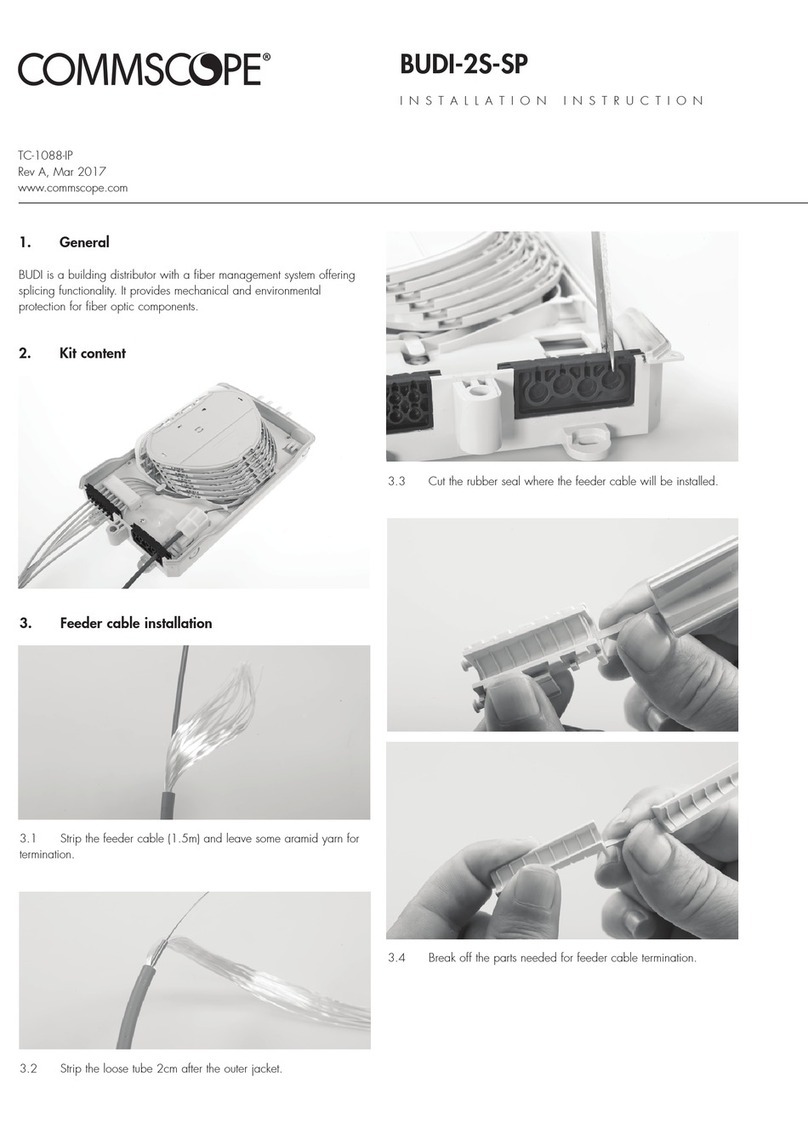

CommScope BUDI-2S-SP User manual

CommScope

CommScope AEKT User manual

CommScope

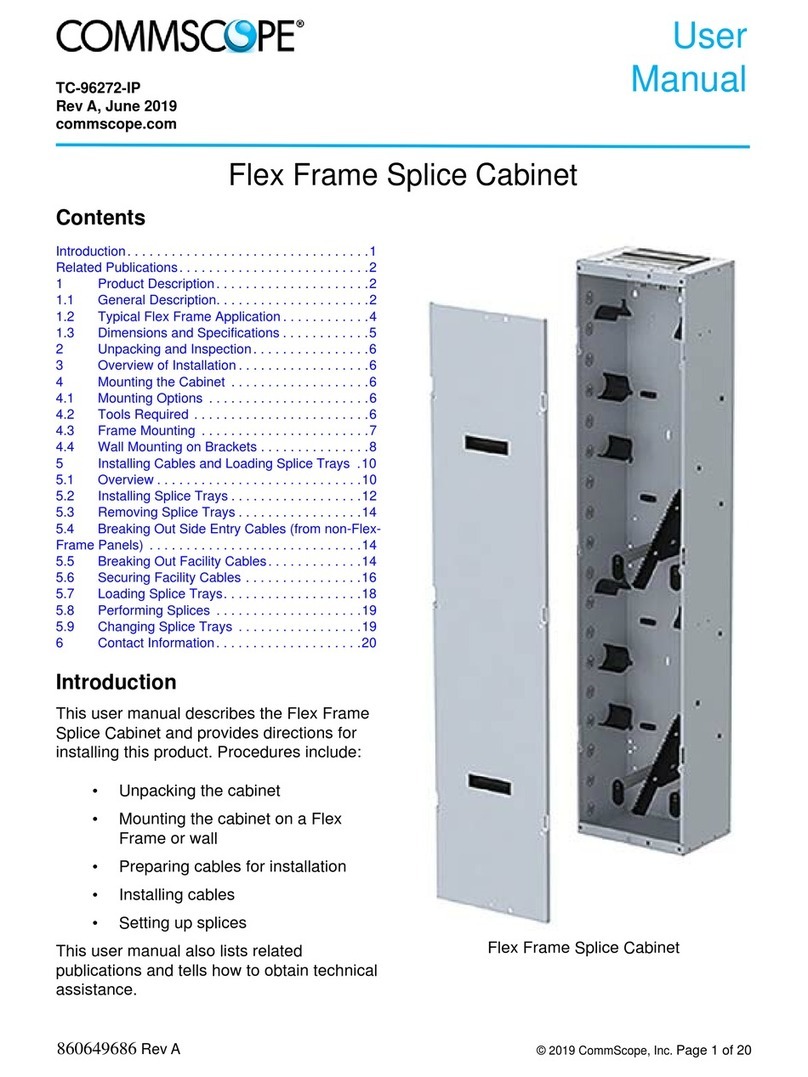

CommScope Flex Frame Splice Cabinet User manual

CommScope

CommScope FDH 3000 User manual

CommScope

CommScope CHD Series User manual

CommScope

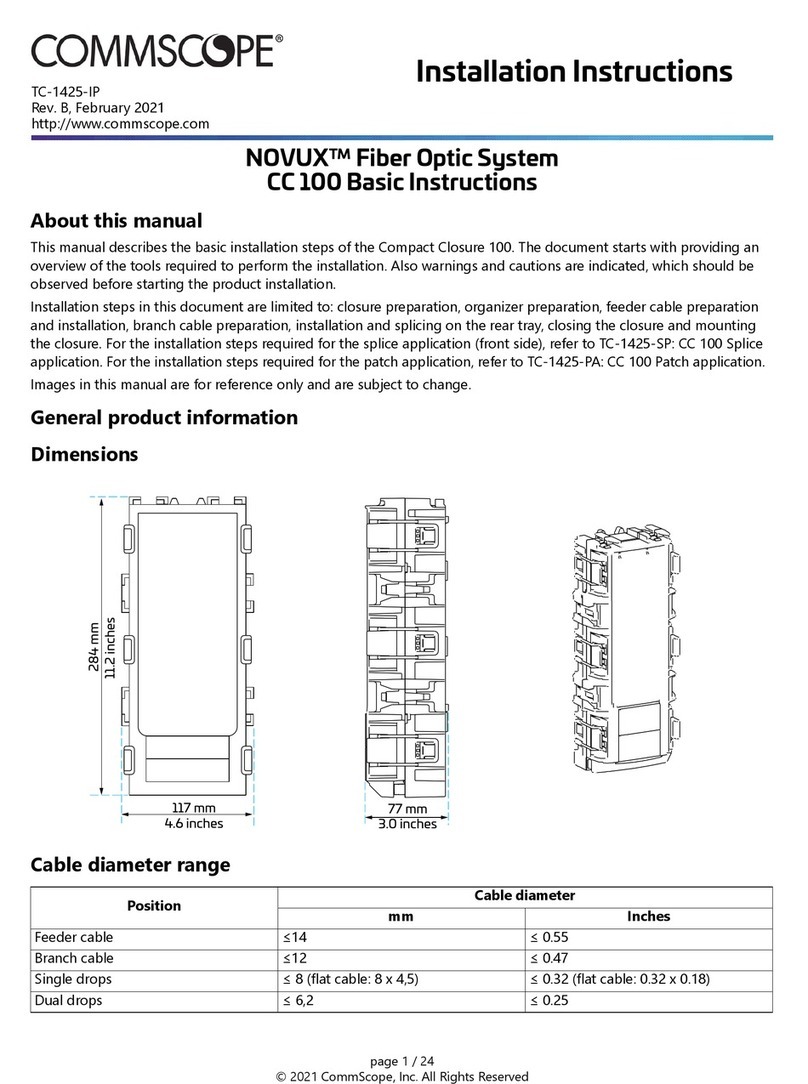

CommScope NOVUX CC 100 User manual

CommScope

CommScope TENIO User manual

CommScope

CommScope Mini-OTE 300 Tap User manual

CommScope

CommScope FOSC-500-AA User manual

CommScope

CommScope FTUO User manual

CommScope

CommScope MDCC User manual

CommScope

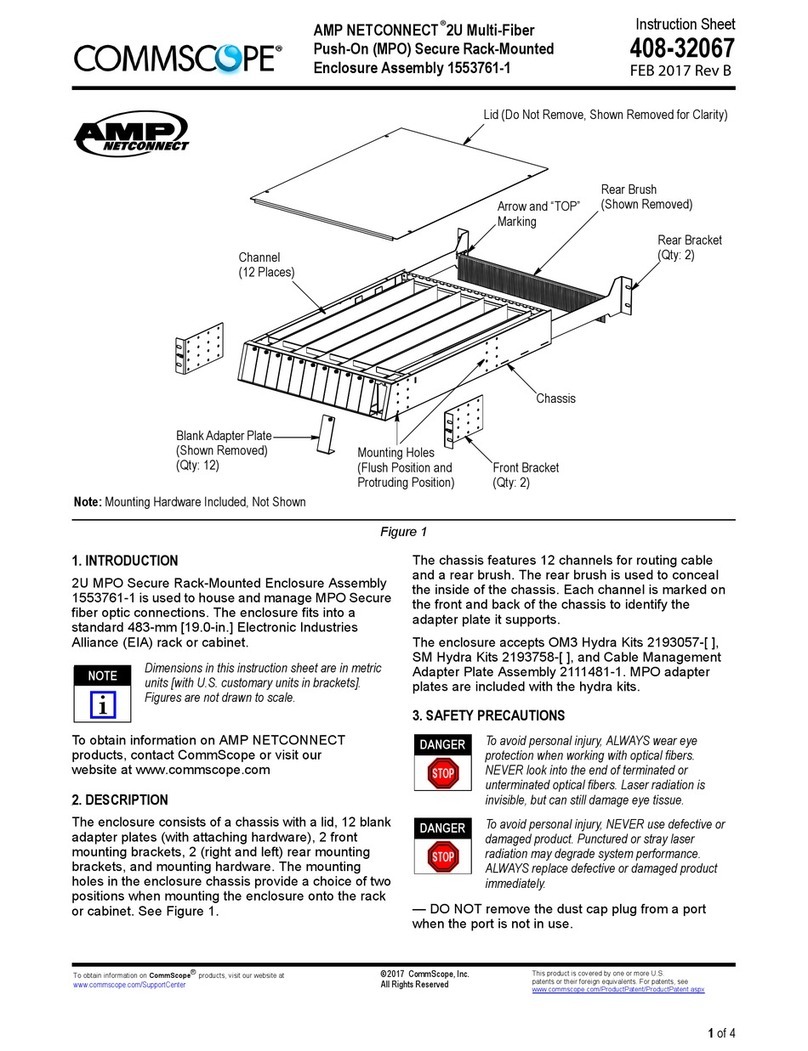

CommScope AMP NETCONNECT 2U Multi-Fiber Push-On User manual

CommScope

CommScope FOSC-450A User manual

CommScope

CommScope BUDI-M-FPS User manual

CommScope

CommScope FOSC-450-BS User manual

CommScope

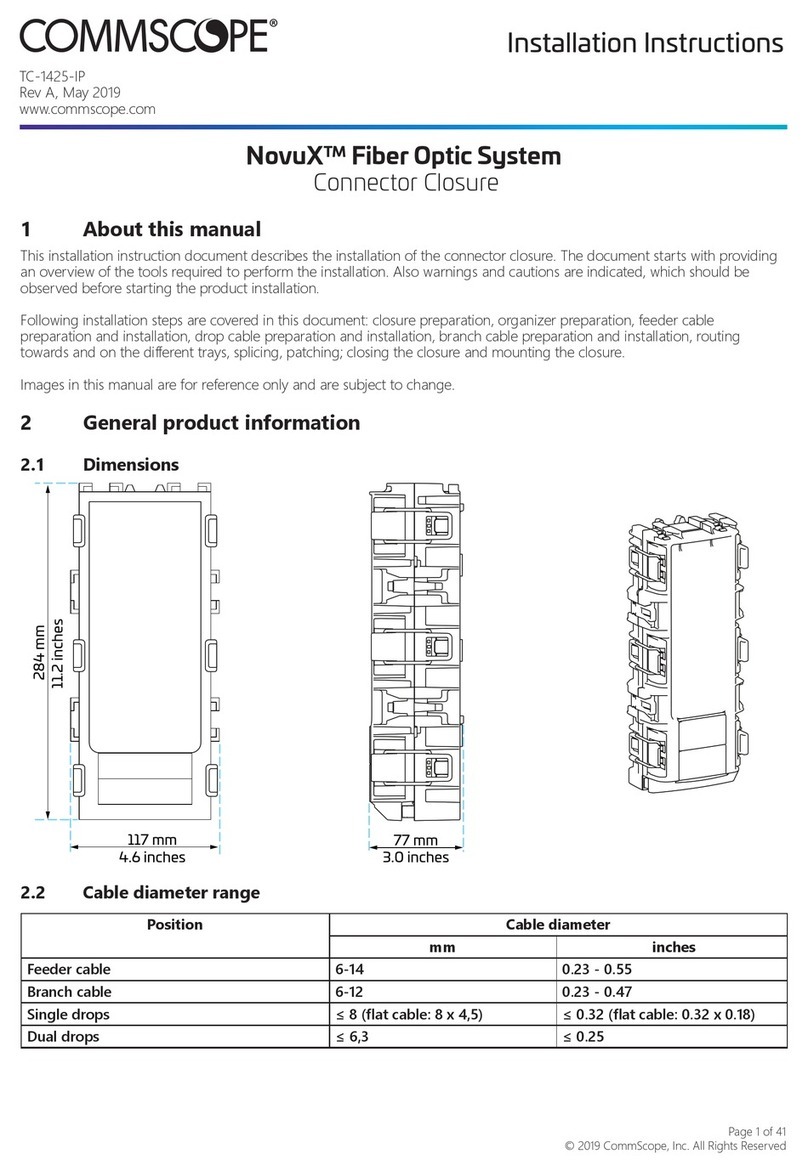

CommScope NovuX Fiber Optic System User manual