408-32067

2of 4

Rev B

— INSPECT BEFORE YOU CONNECT!

Before inspecting a fiber endface, DISCONNECT the

optical fiber from the power signal source. Always

clean and inspect a fiber endface before installing and

connecting the cable assembly.

— NEVER inspect the fiber endface when power is

applied to the optical fiber.

4. INSTALLATION PROCEDURE

4.1. Tools

The followings tools are needed for installation:

DANGER

STOP

— MTP/MPO In Bulkhead Adapter Cleaner 1918809-1

— LC/SC In Bulkhead Adapter Cleaner 2064500-1

— One Slot Reel Cleaner 1918803-1

(for MPO connectors and LC connectors)

— 200× Microscope Kit 1754767-1 fitted with:

— Universal Microscope Adapter 1754765-1

(for LC connectors)

—MPO Microscope Adapter 1828836-1

(for MPO multimode connectors)

—MPOA Microscope Adapter 1828837-1

(for MPO singlemode connectors)

To avoid personal injury, NEVER view an active

optical fiber using a microscope.

NOTE

i

Professional Fiber Optic Connector Inspection Kit

2064651-1 contains all of the above tools.

— cross-recessed screwdriver

4.2. Preparation

Before beginning installation:

Rails of Rack (Ref)

Facing Up

— The enclosure must be installed directly below

the switch (no gap).

—If desired, remove the rear brush from the

chassis; the rear brush cannot be removed after

the enclosure is mounted onto the rack or cabinet.

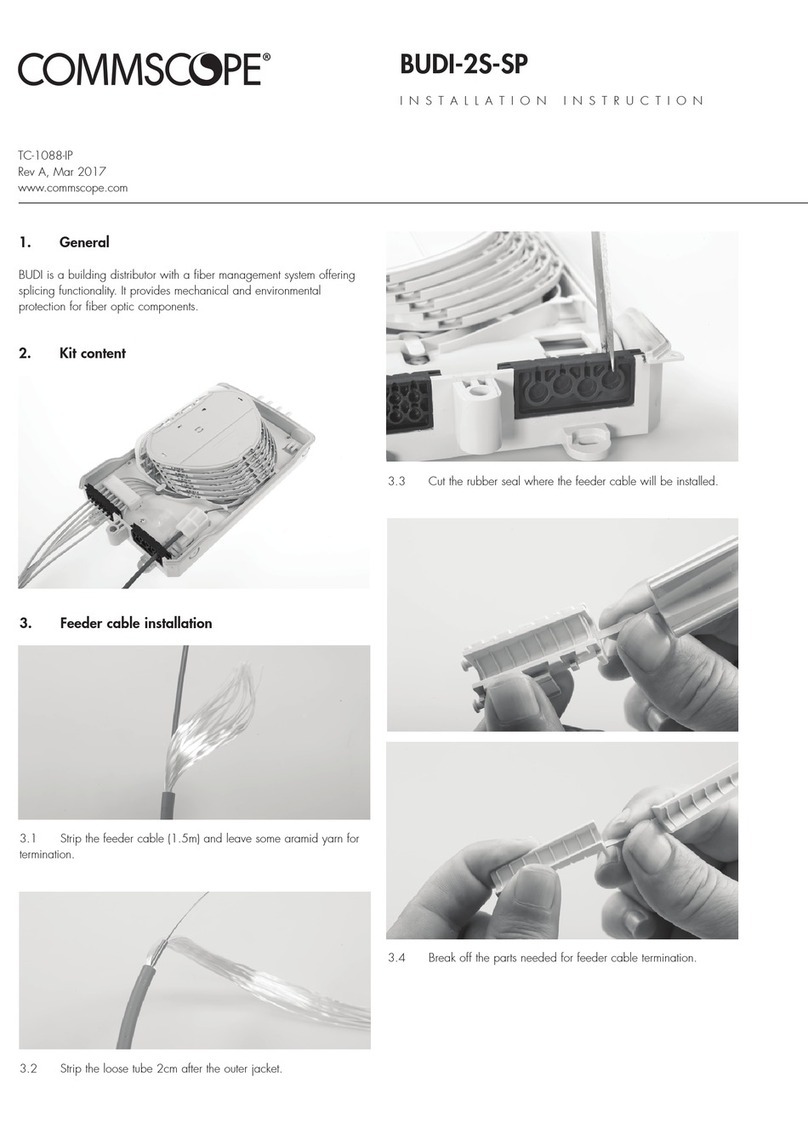

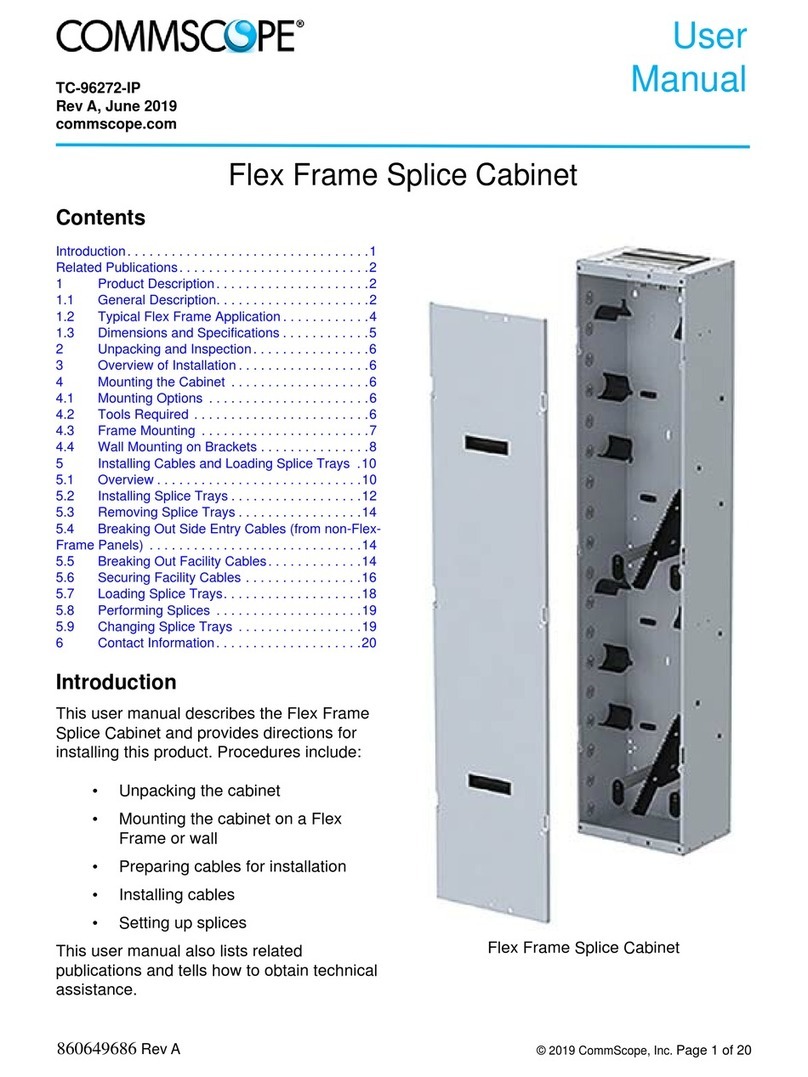

4.3. Mount the Enclosure

1. Determine the vertical and horizontal (flush or

protruding) mounting position of the enclosure in the

rack or cabinet.

2. Using 4 of the 12-24 UNC-2A screws, install the 2

rear brackets onto the rack or cabinet (2 screws per

bracket, 1 bracket per side of rack or cabinet).

Observe the arrow and “TOP” marking on each

bracket (shown in Figure 1) for correct orientation

for installation (the long cutout of the bracket should

be facing up). See Figure 2. DO NOT tighten the

screws at this time.

Figure 2

Front Bracket Not Installed

on Chassis (Ref)

Openings for Adapter Plates

(Front of Chassis)

Front Bracket Installed on Chassis

(In Flush Mounting Position, Ref)

Short Leg of Bracket

Facing Forward

Figure 3

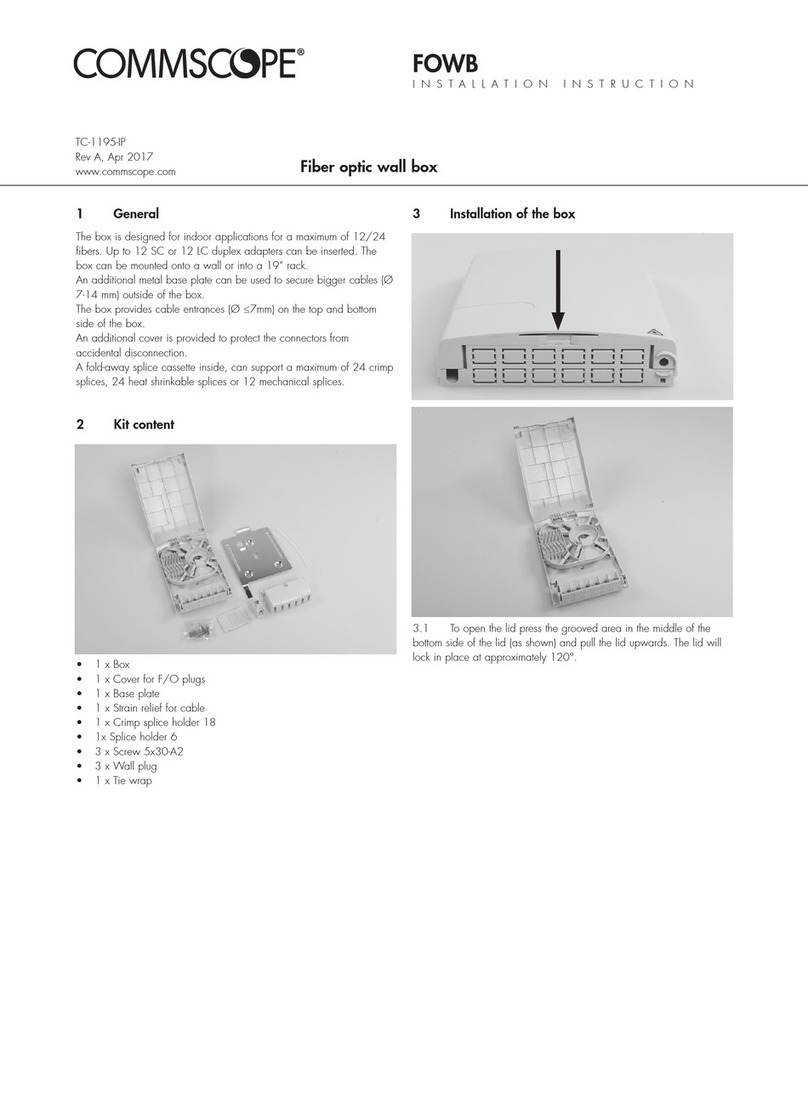

3. Using the 6-32 UNC-2A screws, install the 2 front

brackets onto the chassis (8 screws per bracket, 1

bracket per side of chassis). Make sure that the

short leg of each bracket is facing forward. Tighten

the screws. See Figure 3.

4. Align the back of the chassis with the back of the

legs of the rear brackets. Slide the chassis through

the rails of the rack or cabinet and onto the legs.

Make sure that the legs enter the guide channels on

each side of the inside of the chassis. See Figure 4.

5. Insert 4 of the 12-24 UNC-2A screws through the

holes in the front brackets (2 screws per bracket),

and secure the front brackets to the rack or cabinet.

See Figure 5, Detail A.

6. Tighten the screws of the rear brackets to secure

the rear brackets to the rack or cabinet. See Figure

5, Detail B.