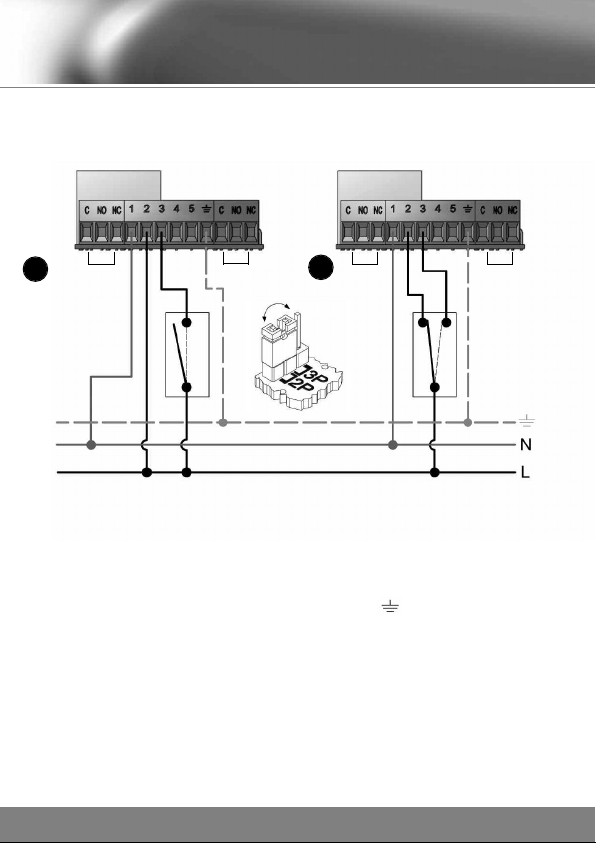

HOW TO INSTALL THE SPACER FOR INSULATION WITH LEVER FOR MANUAL OVERRIDE (2)

MANUAL OVERRIDE DIRECTION (1)

Push the button and rotate

the lever ANTI-CL CKWISE

Actuator with

90° rotation

Actuator with

180° rotation

ATTENTION

The valve can be manually operated only when

electrically disconnected or if the actuator is bro-

ken. If the valve is blocked, please follow below

instructions:

• disconnect the actuator

• remove the actuator

• try to move the ball using a screwdriver or a

wrench suitable for the valve rod.

We would recommend not to overstress the valve

to avoid damages to the body or to the actuator’s

connection. If the ball remains blocked, remove

and replace the valve.

CABLE GLANDS SIDE

Please proceed as per following instructions and be careful

to respect positioning of all components:

1.Place the actuator with cable glands oriented towards you

and put the spacer with the vertical connection piece on the

right side.

2. With the actuator in open position, fix the central rod

paying attention that the lever for the manual opening is

opposite to the cable glands.

3. Tighten the screws to fix the spacer between valve and

actuator.

4. Electrically connect the actuator and make it open and

close to test it works properly. Looking the actuator from

above, you will see the lever moving anticlockwise from

open to close position.

ATTENTION:

Not compliance with the provisions above may cause dange-

rous situations for operators and/or the system integrity..

Diamant 2000

Diamant

PRO

6

COMPARATO NELLO SRL