Page 7

10.Press UP to select OUT 17.0V. Press NEXT to start. Wait for the

relays to sequence. Press UP or DOWN button to get as close as

possible to 17.0V on the DMM. Press NEXT to sa e the calibration.

11.Press UP to select DISP 17.0V. Press NEXT to start. Wait for the

relays to sequence. Press UP or DOWN button to get as close as

possible to 17.0V on the LCD display. Press NEXT to sa e the

calibration.

12.Press UP to select OUT 36.0V. Press NEXT to start. Wait for the

relays to sequence. Press UP or DOWN button to get as close as

possible to 36.0V on the DMM. Press NEXT to sa e the calibration.

13.Press UP to select DISP 36.0V. Press NEXT to start. Wait for the

relays to sequence. Press UP or DOWN button to get as close as

possible to 36.0V on the LCD display. Press NEXT to sa e the

calibration.

14.The next set of calibration steps require measuring the current flow

into a battery. Connect you DMM in series between the battery

negati e and charger negati e. Use the 200mA connections on you

DMM to get the maximum resolution. Connect a alligator clip wire

between the battery plus and charger plus. Set your DMM to the

200mA scale. Press UP to select OUT 0.05A. Press NEXT. Wait for

the relays to sequence. Press UP or DOWN button to get as close as

possible to 50mA on the DMM. Press NEXT to sa e the calibration.

15.Press UP to select DISP 0.05A. Press NEXT. Wait for the relays to

sequence. Press UP or DOWN button to get as close as possible to

0.05A on the LCD display. Press NEXT to sa e the calibration.

16.Reconnect you DMM to use the 10A measurement. Press UP to

select OUT 2.5A. Press NEXT. Wait for the relays to sequence.

Press UP or DOWN button to get as close as possible to 2.5A on the

DMM. Press NEXT to sa e the calibration.

17.Press UP to select DISP 2.5A. Press NEXT. Wait for the relays to

sequence. Press UP or DOWN button to get as close as possible to

2.5A on the LCD display. Press NEXT to sa e the calibration.

18.Press UP to select OUT 2.6A. Press NEXT. Wait for the relays to

sequence. Press UP or DOWN button to get as close as possible to

2.6A on the DMM. Press NEXT to sa e the calibration.

19.Press UP to select DISP 2.6A. Press NEXT. Wait for the relays to

sequence. Press UP or DOWN button to get as close as possible to

2.6A on the LCD display. Press NEXT to sa e the calibration.

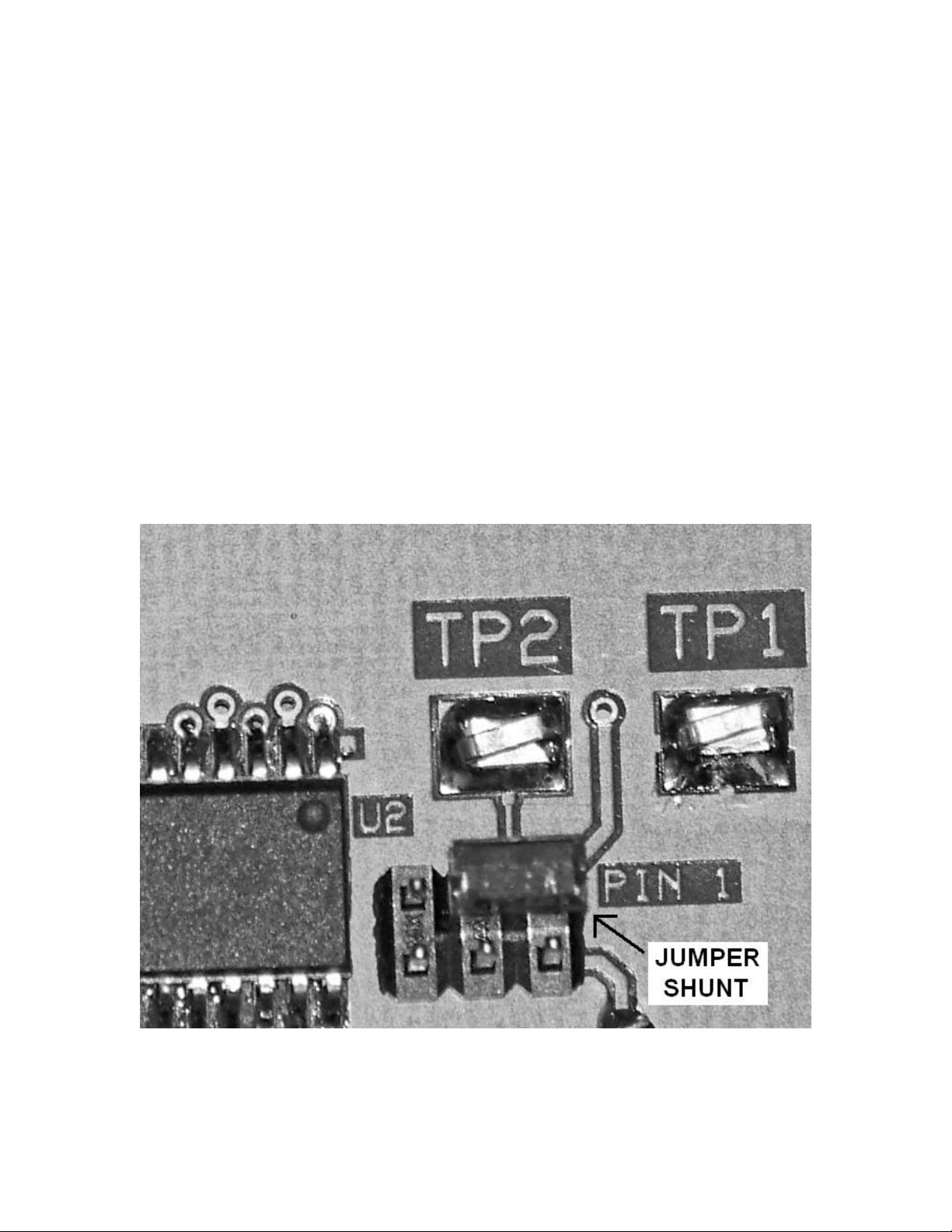

20.The next steps require the CF1 calibration shunt. Connect the battery

to the CF1 calibration shunt. Connect the DMM to the CF1 and select

the 200mV scale. 1mV will be 1A. Press UP to select OUT 25.0A.

Press NEXT. Wait for the relays to sequence. Press UP or DOWN

button to get as close as possible to 25.0A. Press NEXT to sa e the

calibration.

21.Press UP to select DISP 25.0A. Press NEXT. Wait for the relays to