ATTENTION:

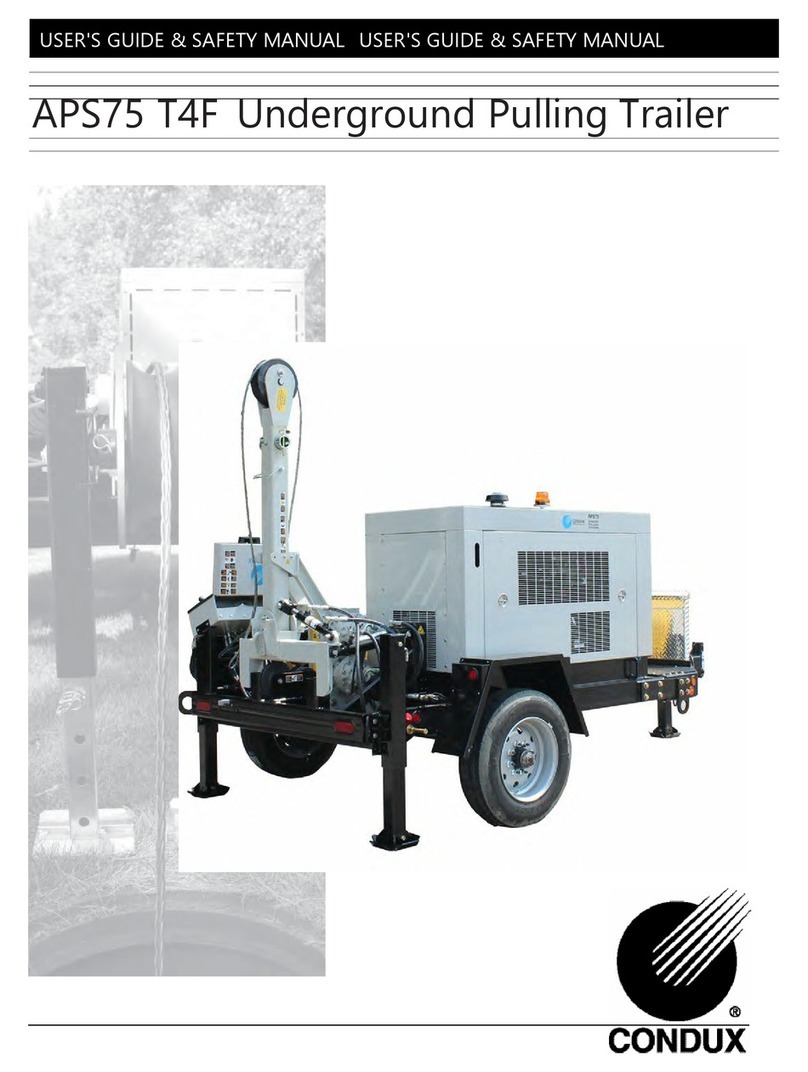

This guide is designed to be used for quick reference and machine setup. Please take time to review the

complete manual for this machine before operating. The machine has many other options and menus not

covered by this guide.

You can download a manual pdf at any time for free by entering the machine serial number or trailer VIN number at:

https://conduxtesmec.com/manuals/

BASICS OF PULLING OPERATIONS

PAGE 8 of 8 www.conduxtesmec.com 1-888-980-1209

SETTING THE MAXIMUM PULL FORCE

Setting maximum pull force will limit the maximum allowable force the machine will apply to the pulling rope. When

set the unit will not pull with anymore force than programmed. If the machine reaches this level all motion will stop.

This knob on the controller is used to adjust the maximum pull force setting.

RECOVERING or PAYING OUT ROPE and/or CONDUCTOR

It is important not to make abrupt control inputs or direction changes. Slippage of the rope on the bull wheels may

occur, ease into the pull and gently increase speeds in either direction. When paying out rope, the rope will need to

have some tension on it to avoid slipping on the bull wheels. Damage will occur to the sectors if wire rope is allowed

to slip on the bull wheels.

NORMAL and LOW RANGE OPERATIONS

When using the unit as a puller described in this quick start guide there is no reason to use low range. If the display is

showing values less than the rated range of the machine it may be necessary to change settings REFER TO THE OPER-

ATORS MANUAL. NEVER CHANGE THE TRANSMISSION SETTING WITHOUT CLAMPING OFF THE CONDUCTOR

OR ROPE!!! Very dangerous conditions can occur if this process is handled incorrectly.