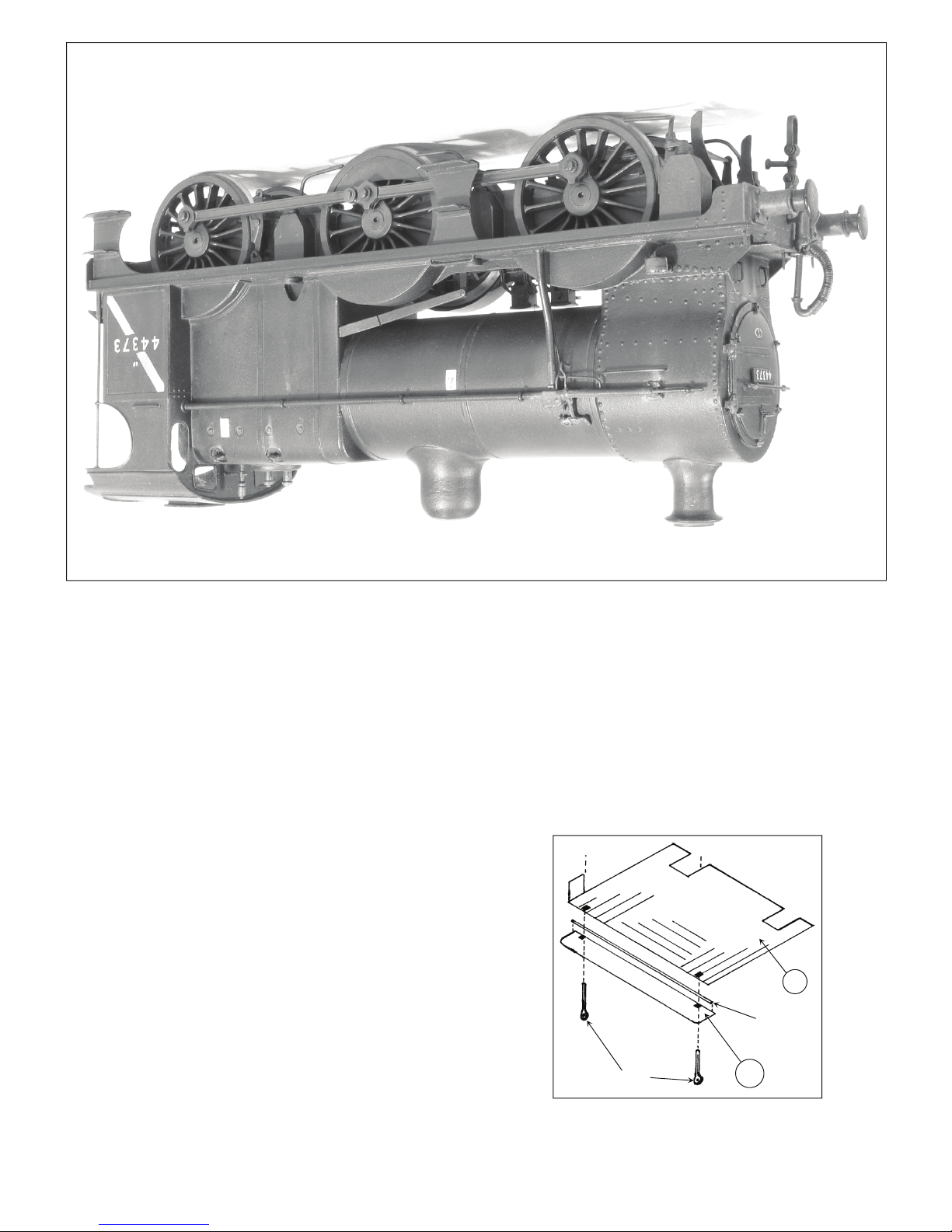

LMS 4F CHASSIS ASSEMBLY

9. Take the main frames (parts 48) and using a tapered

reamer open out the axle holes so that the turned brass

bearings will be a snug fit. If you are fitting plunger pickups

then also open out the holes for these so that the housing will

be a snug fit.

Take the frame spacers (parts 49) and where appropriate

fold them through 90°. The rear spacer is slightly tight on the

axle gear wheel and so you may wish to fold this one through

95° to give a little extra clearance.

Now pin one side frame down to a flat block of wood with

the top of the frame slightly overhanging the edge of the

block. Solder each spacer firmly into place. Fit second

sideframe checking with an enginers square that the two

sideframes are exactly opposite each other. Tack solder the

second frame at the tabs only and start in the centre and

work to each end. Remove the chassis from the wood block

and check that it is square and not twisted. Once you are

happy solder all joints solid.

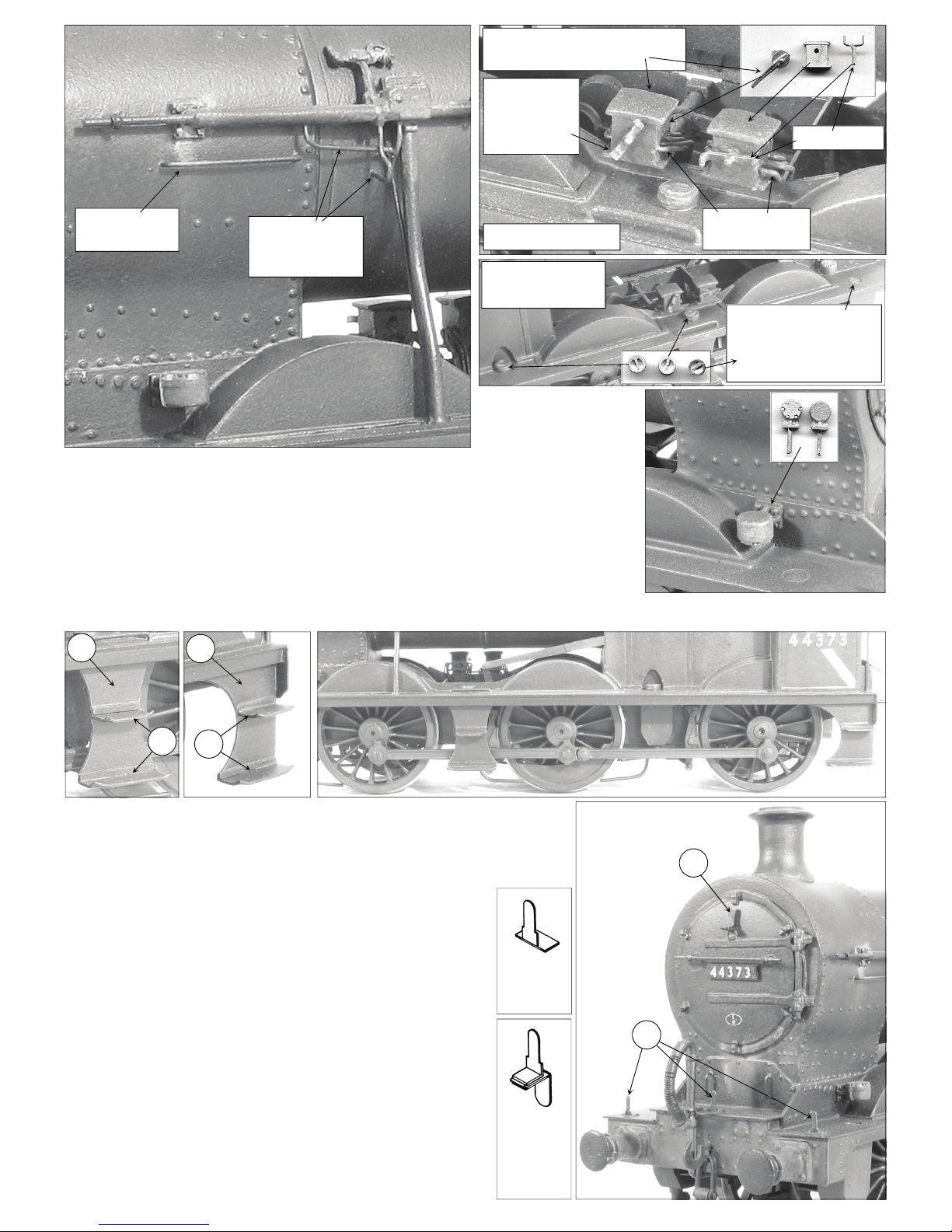

Fold the reversing gear weight shaft brackets that project

upwards from the top edge of the frames into inverted U

shapes and reinforce the folds with a spot of solder.

Laminate together the the reversing gear balance weights

(parts 50) and fold over the circular ends to form four metal

thicknesses. Cut a length of 1.5mm brass rod to a length that

will be a spring fit between the frame brackets and thread the

weights onto this and solder centrally 6mm apart. Fit a length

of 0.9mm brass wire through the holes in the ends of the

weights and trim down to slightly less than chassis width and

then solder the 1.5mm brass rod weight shaft solidly to the

chassis brackets.

50

Fold over to form shaft brackets

0.9mm brass wire 1.5mm brass rod

Fold up the ash pan sides (parts 51) and solder into the half

etched rebates on the inside of the frames

51

Note how cast spring fits to frame

PAGE 10

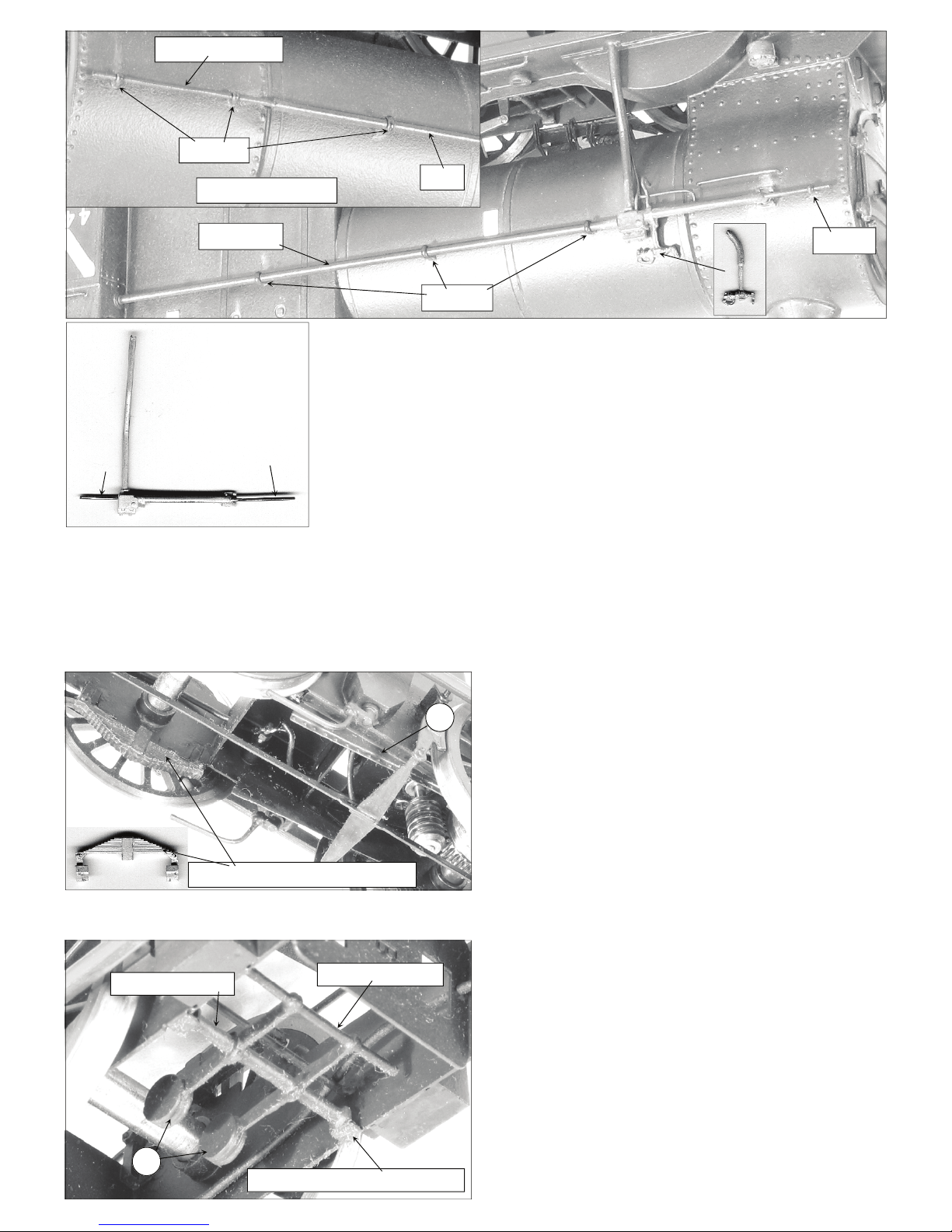

time spent working on the top surface with knife blade and

fibre brush removing part lines and casting blemishes will be

well rewarded. Any casting porosity marks can be filled with

70° solder and polished back smooth. Check that you are

happy with the way the roof fits and file or scrape the

underside edges if required. Solder the roof into place with

70° solder fitting two lengths of (tinned with 145°) soft wire at

the joints between roof and cab side. Using plenty of flux

allow a generous amount of 70° solder to flow over the wire

and around the joints. Then scrape back with knife blade and

clean up with fibre brush to reveal the wire rainstrips and

blend the cab roof into the sides with no sign of a joint. Drill

out hole in centre of cab roof and fit the roof ventilator.

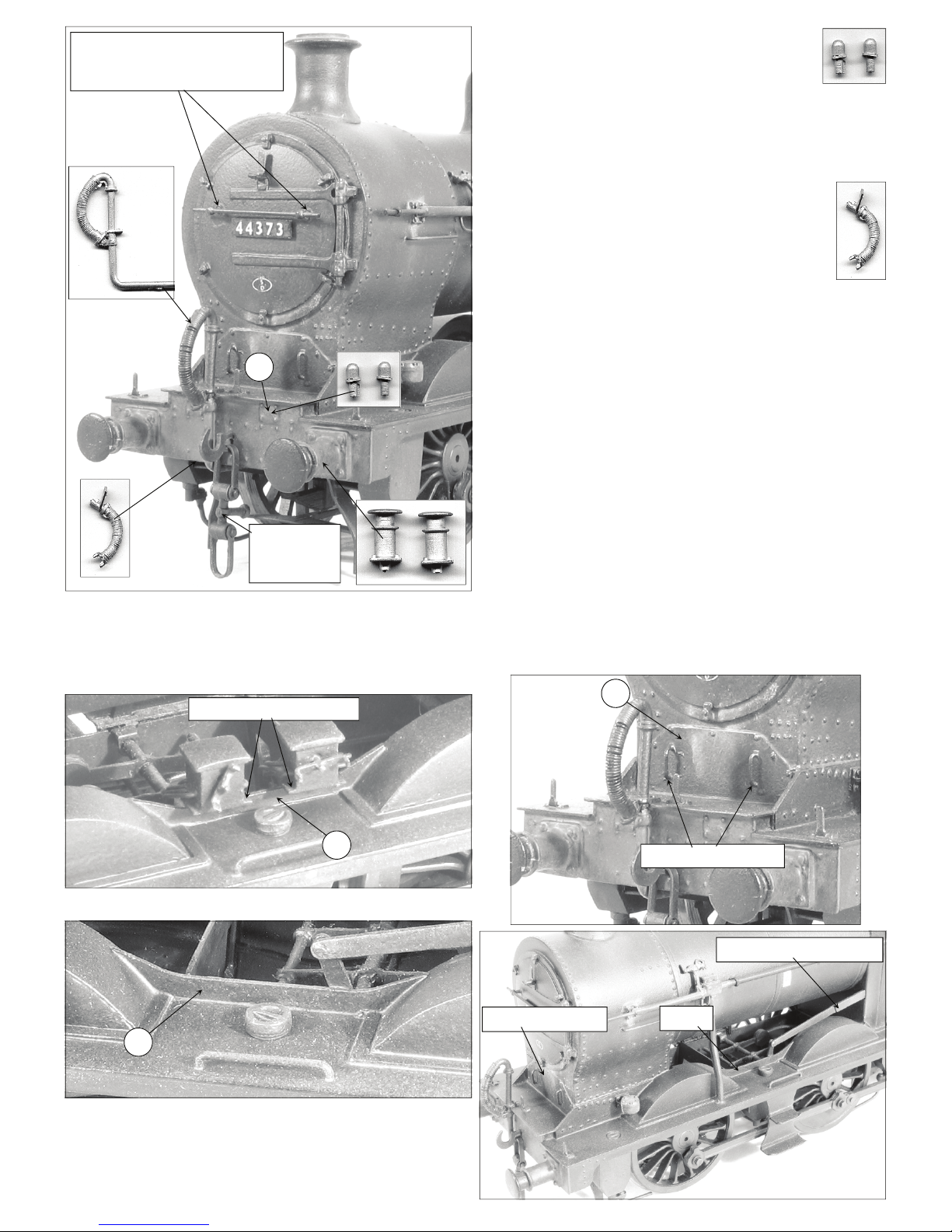

16. On the prototype loco the boiler handrails were

actually pipes the R/H one feeding the smoke box blower the

L/H one feeding the vacuum ejector.

On the model these are represented with brass tube cut to

length and opened out split pins threaded on. The split pins

are gently squeezed closed at the back so that they form

tightly around the tube and then mounted into the boiler. A

length of 0.7mm brass

wire is fitted into the

tube to continue the R/

H handrail along the

smoke box. The cast

vacuum ejector has

0.7mm brass wire cast

into it and this is fitted

into the L/H tube to

again continue it along

the smoke box.

Fit

into

tube

Continue along

smoke box

Right Hand handrail

Tube

Split pins

0.7mm Brass wire

Brass tube

Split pins

Split pin

PAGE 19