7

Suitable Cable Lengths

The tables in this section show the approximate maximum cable

lengths for diering maximum required currents to achieve a

400mA/m eld strength.

Loop impedance (at 1.6kHz) should be less than voltage capability of

the driver (22V) divided by the required current.

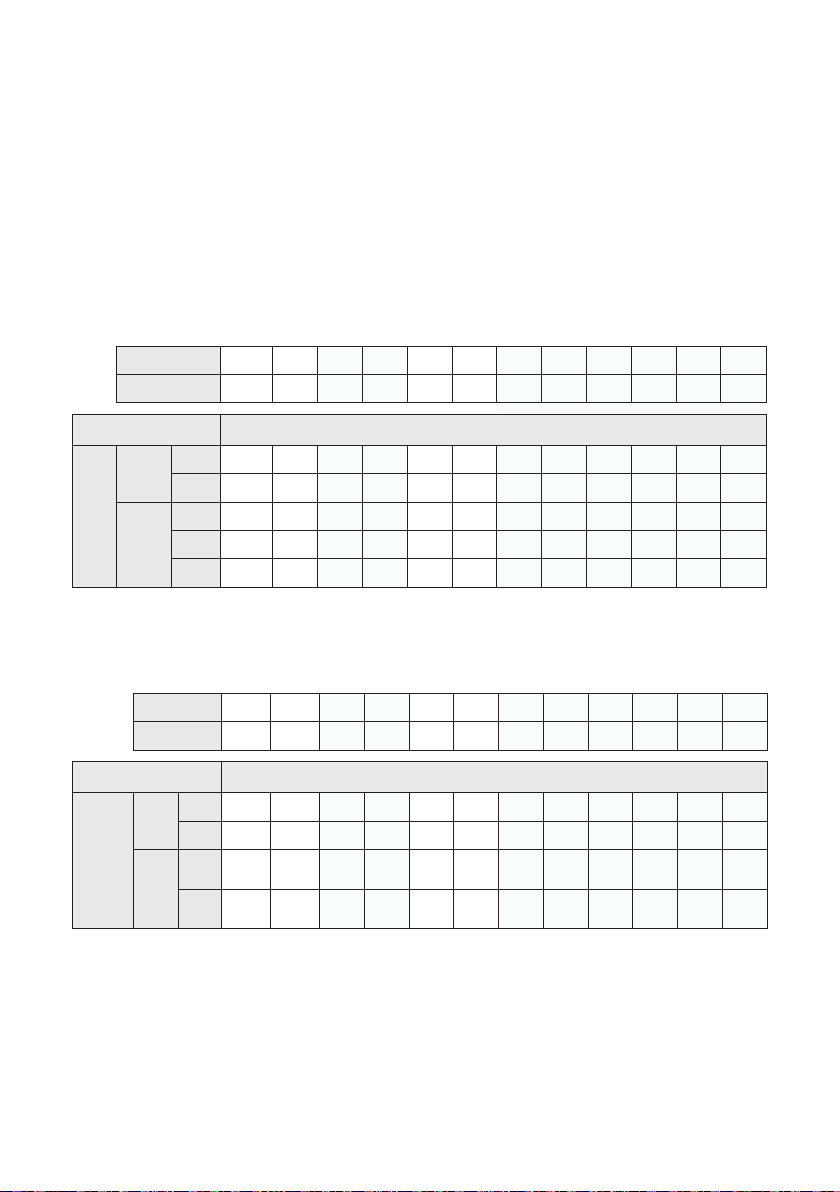

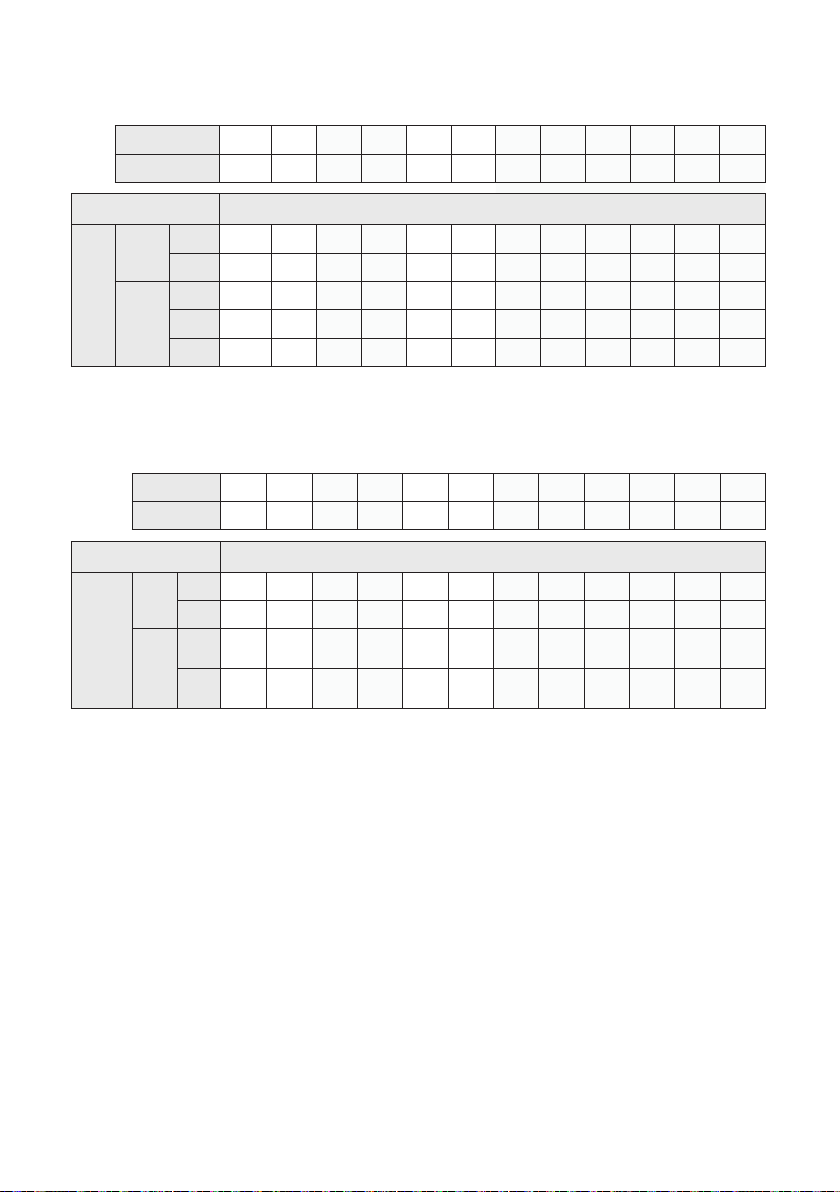

V22 Single-Turn (Metric)

Current 1A 2A 3A 4A 5A 6A 7A 8A 9A 10A 11A 12A

Impedance 22.6Ω11.3Ω7.53Ω5.65Ω4.52Ω3.77Ω3.23Ω2.83Ω2.51Ω2.26Ω2.05Ω1.88Ω

Cable Type Cable Length

Max.

Cable

Length

Round

Cable

(AWG)

1.5mm 970.99m 485.50m 323.66m 242.75m 194.20m 161.83m 138.71m 121.37m 107.89m 97.10m 88.27m 80.92m

2.5mm 1091.74m 545.87m 363.91m 272.94m 218.35m 181.96m 155.96m 136.47m 121.30m 109.17m 99.25m 90.98m

Flat Cable

(Width)

10mm 614.41m 307.21m 204.80m 153.60m 122.88m 102.40m 87.77m 76.80m 68.27m 61.44m 55.86m 51.20m

12.5mm 1161.97m 580.99m 387.32m 290.49m 232.39m 193.66m 166.00m 145.25m 129.11m 116.20m 105.63m 96.83m

25mm 1538.27m 769.13m 512.76m 384.57m 307.65m 256.38m 219.75m 192.28m 170.92m 153.83m 139.84m 128.19m

V22 Single-Turn (Imperial)

Current 1A 2A 3A 4A 5A 6A 7A 8A 9A 10A 11A 12A

Impedance 22.6Ω11.3Ω7.53Ω5.65Ω4.52Ω3.77Ω3.23Ω2.83Ω2.51Ω2.26Ω2.05Ω1.88Ω

Cable Type Cable Length

Max.

Cable

Length

Round

Cable

(AWG)

18AWG 2552.86ft 1276.43ft 850.95ft 638.21ft 510.57ft 425.48ft 364.69ft 319.11ft 283.65ft 255.29ft 232.08ft 212.74ft

14AWG 3408.47ft 1704.23ft 1136.16ft 852.12ft 681.69ft 568.08ft 486.92ft 426.06ft 378.72ft 340.85ft 309.86ft 284.04ft

Flat

Cable

(Width)

18AWG

(equiv.)

2871.76ft 1435.88ft 957.25ft 717.94ft 574.35ft 478.63ft 410.25ft 358.97ft 319.08ft 287.18ft 261.07ft 239.31ft

14AWG

(equiv.)

4538.17ft 2269.08ft 1512.72ft 1134.54ft 907.63ft 756.36ft 648.31ft 567.27ft 504.24ft 453.82ft 412.56ft 378.18ft