Ver.1.01

CNT24-2(FIT)GY 3

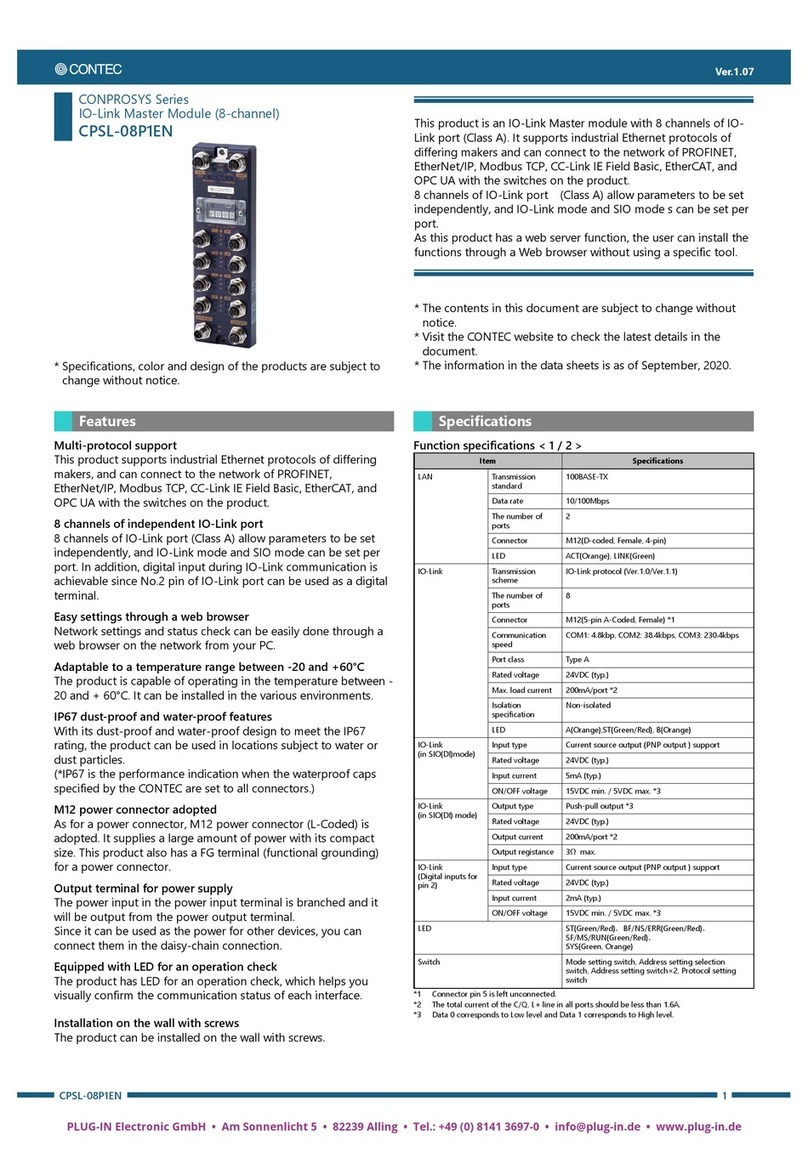

When connecting the Module to an external device, you can

use the supplied connector plug. When wiring the Module, strip

off approximately 7 - 8 mm of the covering for the cable, and

insert the bare wire by pressing the orange button on the

connector plug. Releasing the orange button after the wire is

inserted to fix the cable. Compatible wires are AWG 28 - 20.

Press this section to insert

the wire material.

7 - 8mm

CNT24-2

Device

ID

ABZD1

CH

PCOM

PA

PB

PZ

PD1

EQ.P

EQ

EQ.N

0

4

0

4

6

2

5

1

3

7

PCOM

PA

PB

PZ

PD1

EQ.P

EQ

EQ.N

CH

CH

CH

- Connector used:

2.5mm pitch, 9-pin type, 4.0A nominal current

MC0,5/9-G-2,5 connector (made by Phoenix Contact Corp.)

- Applicable plug:

Front-operable spring gauge type

FK-MC0,5/9-ST-2,5 plug (made by Phoenix Contact Crop.)

Applicable wire: AWG 28 - 20

CAUTION

Removing the connector plug by grasping the cable can

break the wire.

The Module can be connected to an external device using a

9-pin (1 group) connector that is provided on the Module face.

9

8

7

6

5

4

3

2

1

CH0

PCOM(0)

PA(0)

PB(0)

PZ(0)

PDI(0)

EQ.P(0)

EQ(0)

EQ.N(0)

N.C.

Plus common for channel 0 input signals

Channel 0 phase A input

Channel 0 phase B input

Channel 0 phase Z input

Channel 0 general-purpose digital input

Plus common for channel 0 output signals

Channel 0 count-match output

Minus common for channel 0 output signals

Not connected

9

8

7

6

5

4

3

2

1

CH1

PCOM(1)

PA(1)

PB(1)

PZ(1)

PDI(1)

EQ.P(1)

EQ(1)

EQ.N(1)

N.C.

Plus common for channel 1 input signals

Channel 1 phase A input

Channel 1 phase B input

Channel 1 phase Z input

Channel 1 general-purpose digital input

Plus common for channel 1 output signals

Channel 1 count-match output

Minus common for channel 1 output signals

Not connected

220

Opto-coupler

2.2k

Module External circuit

Input

pin

+5V

Plus common

External device

signal output

220

Opto-coupler

2.2k

Input

pin

+12V

External device

signal output

400

R

Plus common

CAUTION

The general-purpose input signal also has a similar circuit

configuration.

When an external power supply other than 5V is used,

insert a current-limiting resistor at position R. If PV

denotes an external power supply, the current-limiting

resistor R can be calculated as follows:

P - 5

20 < Rk<P - 5

15

For example, P = 12V will require the following resistance:

350< R < 470

When there is a match between a channel count and a

specified value, a one-shot (one pulse) match signal is output

to the outside. The signal output section has an open

collector configuration based on opto-isolation. Driving the

output of this module requires an external power supply.

Output

pin

Opto-coupler

Plus

common

Minus

common

Load External

power

supply

5V - 12VDC

Vcc Module External circuit

CAUTION

A surge voltage protection circuit is not provided on the

output transistors for this Module. Therefore, when

driving relays, lamps, and other induction loads using this

Module, a surge voltage countermeasure should be

provided on the load side.

For details, see the manual, chapter 3 “Surge Voltage

Countermeasures".

How to Connect an Interface Connector

Signal Layout on the Interface Connector

Connecting to a Opto-Isolated Input Circuit

Output Circuit and an Example Connection