ENGLISH

CONTRACOR

®

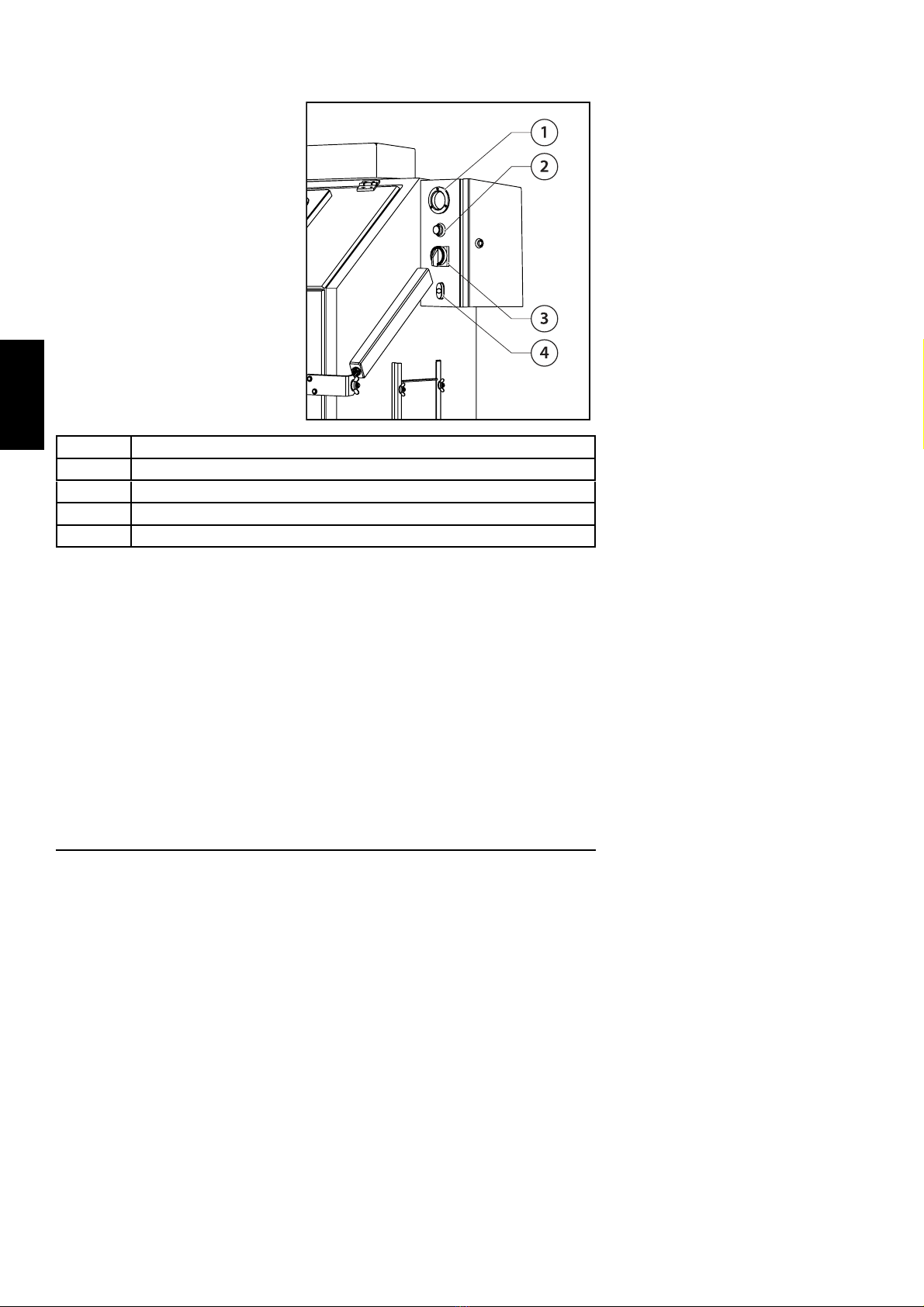

ECO-series pressure blast cabinets 9

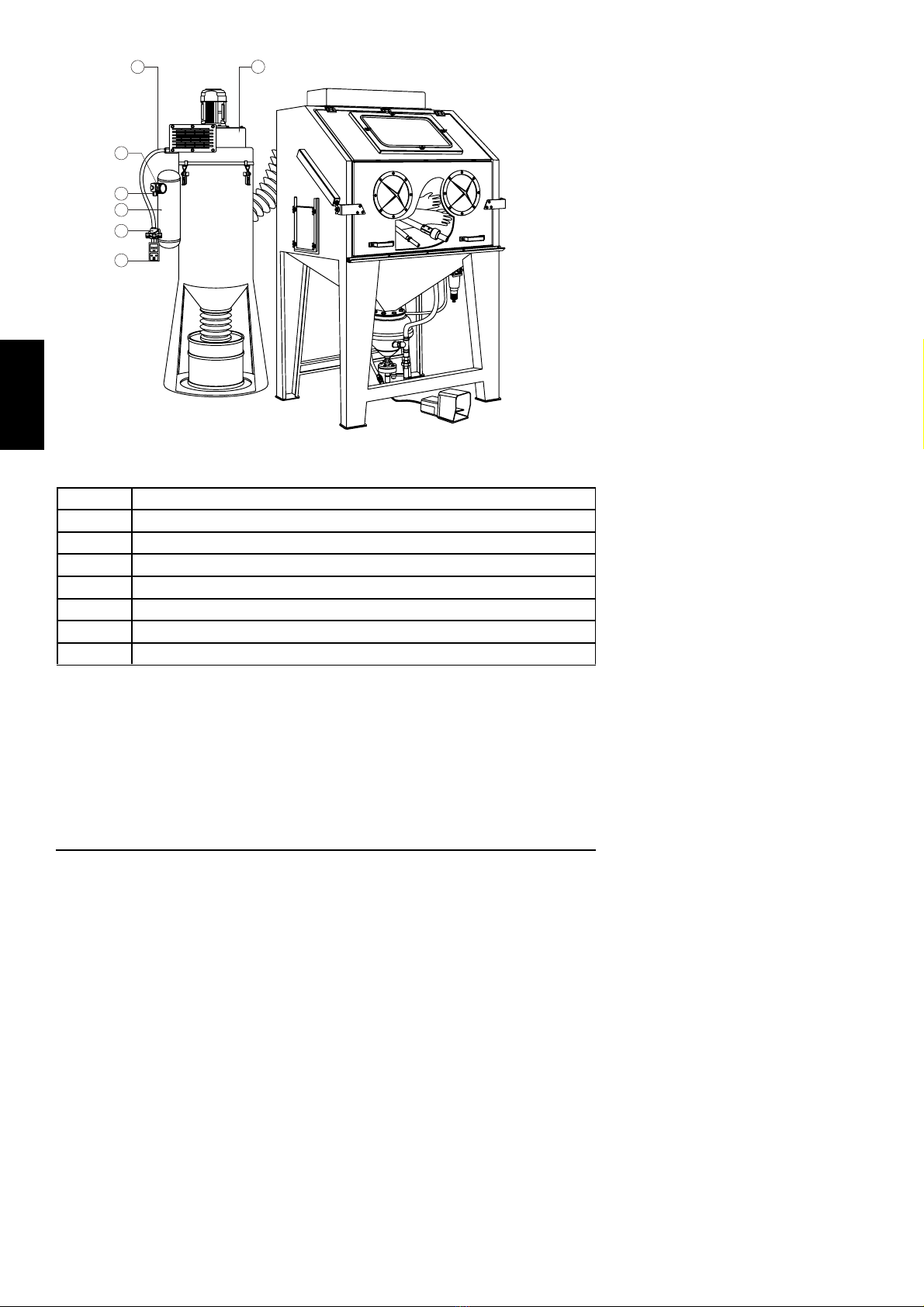

Order code Model Description, package

17201 ECO-80P Blast cabinet,completesystem,containing:

-Cabinet enclosure

-13 liter blast machine

-Cartridgedust collectorDC-370

Standarddelivery:

-Quality600 mmblast gloveswithinner fabriclining

-13x27 mmblast hosewithcoupling/nozzleholder

-TungstencarbideventurinozzleNTC-5.0

-FSV-0 meteringvalve

-MainairlineÀlerwith5 Àltrationgrade

-Pilot regulatedblast pressure

-Doorsafetyinterlocks

-Manual cleaned cartridge Àlter 8 m²

-Electrical connection0,50 kW,380V, 3 phase,50Hz

OverallDimensions(WxDxH),mm950 x680 x1660

Workingchambersize(WxDxH),mm750 x520 x660

Windowsize(Safetyglass),mm 476 x296

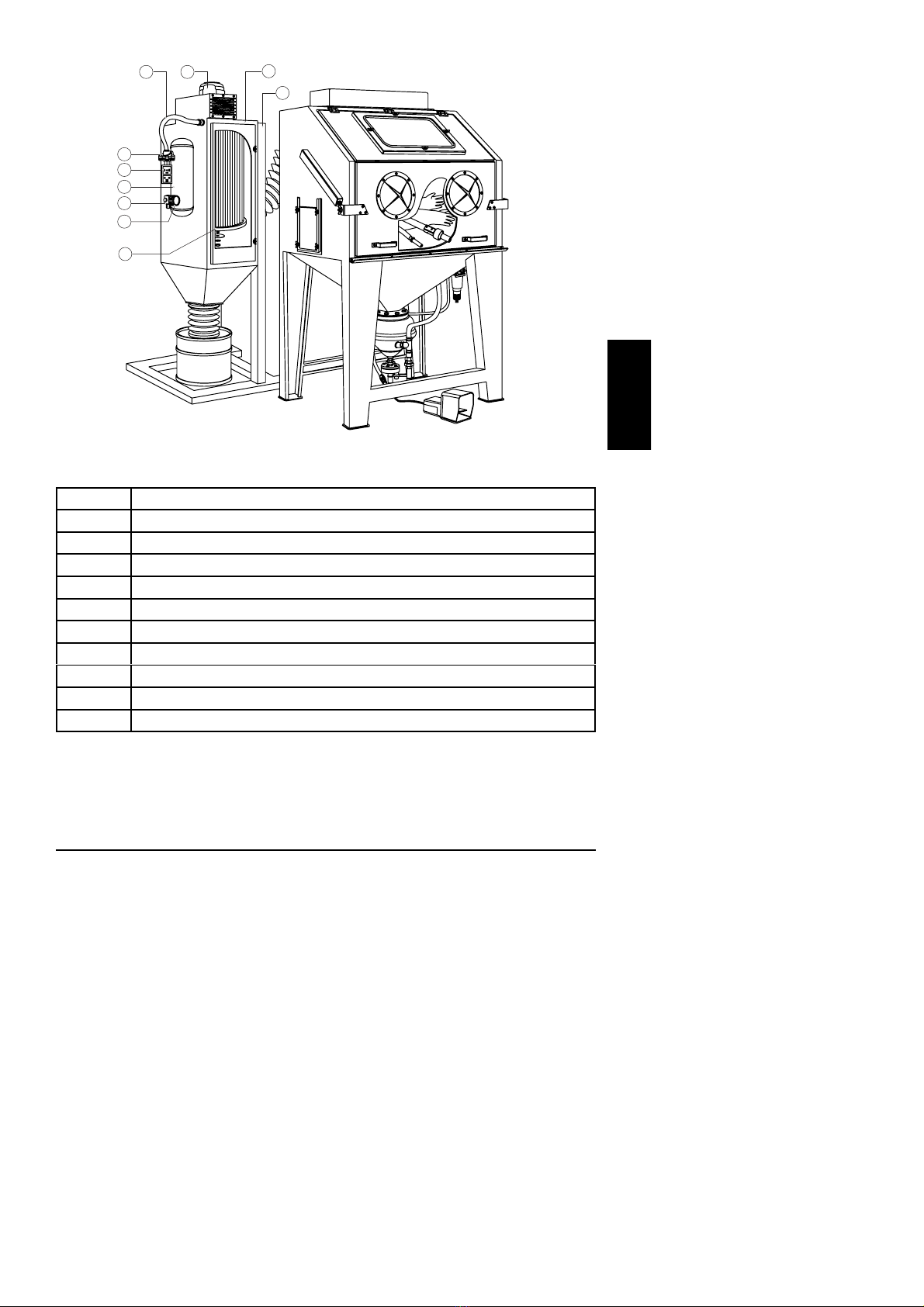

17202 ECO-100P Blast cabinet,completesystem,containing:

-Cabinet enclosure

-13 liter blast machine

-Cartridgedust collectorDC-370

Standarddelivery:

-Quality600 mmblast gloveswithinner fabriclining

-13x27 mmblast hosewithcoupling/nozzleholder

-TungstencarbideventurinozzleNTC-5.0

-FSV-0 meteringvalve

-MainairlineÀlerwith5 Àltrationgrade

-Pilot regulatedblast pressure

-Doorsafetyinterlocks

-Manual cleaned cartridge Àlter 8 m²

-Electrical connection0,50 kW,380V, 3 phase,50Hz

OverallDimensions(WxDxH),mm1150 x880 x1760

Workingchambersize(WxDxH),mm950 x720 x760

Windowsize(Safetyglass),mm 476 x296

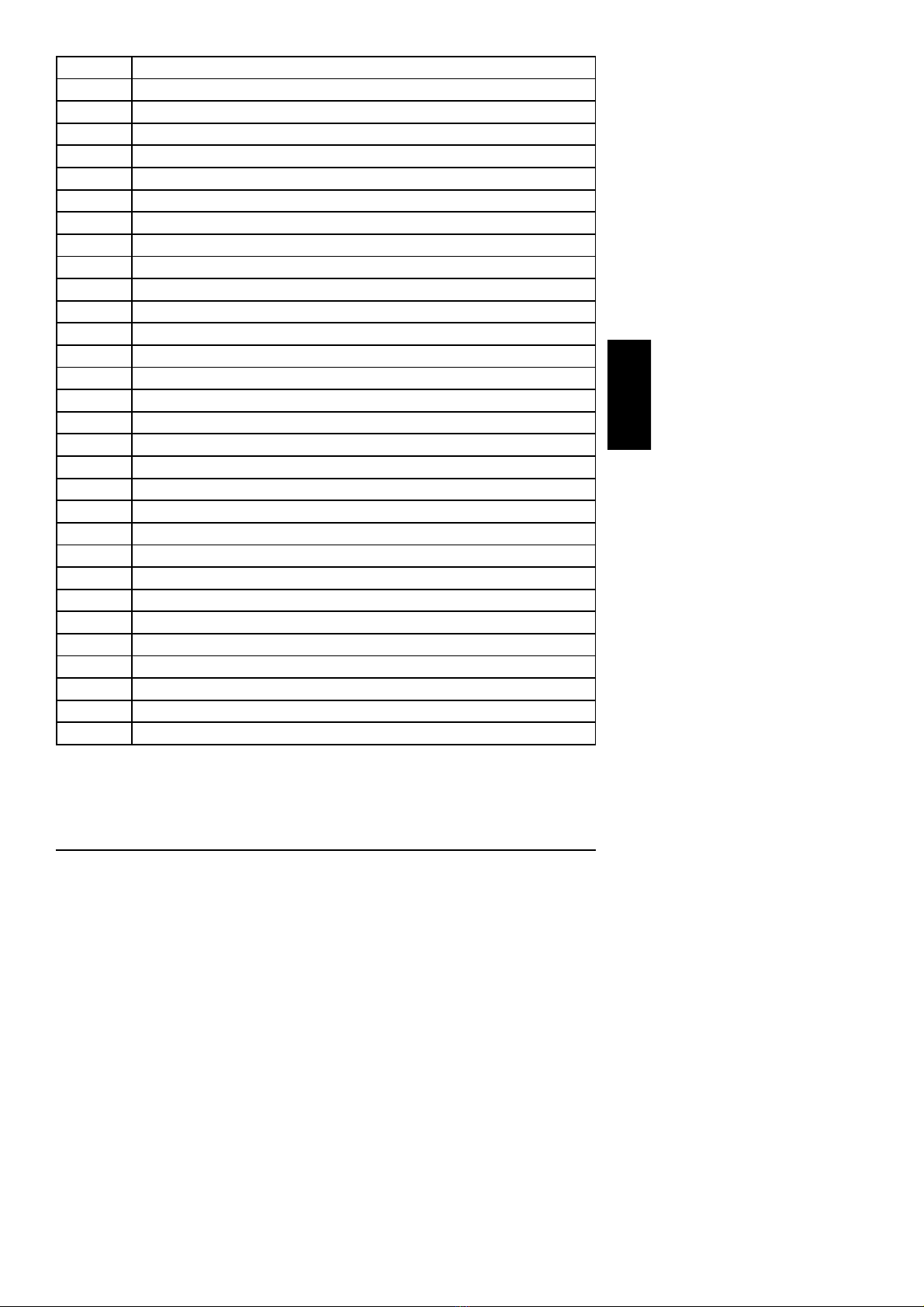

2.1. Package

Table 2.1