CONTROLS, INCORPORATED

CONTROL SYSTEMS & SOLUTIONS

- 7 -

9) Controller Menus

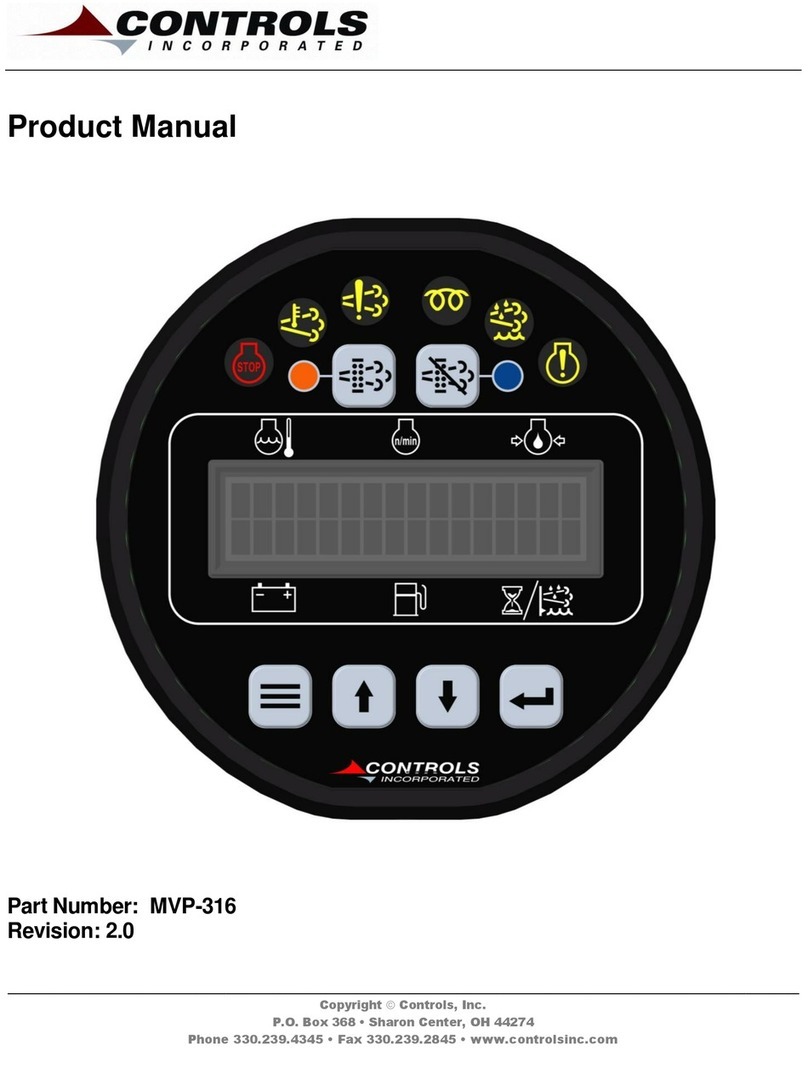

9.1 The control panel has menus to view engine and controller parameters. These menus are accessible via a

four-button pad located on the face of the control panel.

9.2 Available Menus

Sender Configuration: Speed signal and overspeed settings.

Control Functions: Glow plug and auto start settings.

Discrete Input Configurations (View only)

9.3 Menu Access & Navigation

9.3.1 Entering Menus

1. Press and hold the MENU key & simultaneously press the ENTER key.

9.3.2 Navigation

1. Press MENU to select the next menu category.

2. Press UP to view or edit the specific screen(s) in the category.

3. Use the UP and DOWN keys to move among the screens in the category.

4. Press MENU at any time within a category to jump back to the inner ring

9.3.3 Password Entry

The password screen is provided to restrict the edit of sensitive values to authorized personnel.

Not entering a password permits viewing, but no editing of restricted values. Upon encountering

the password screen, a series of dashes will be displayed. To enter the password:

1. Press ENTER to begin editing. The password zeroes will be bracketed.

2. Use the UP and DOWN keys to set the first (leftmost) digit, as you would for a cylinder

combination lock.

3. Press ENTER to freeze that digit and move to the next one on the right.

4. Repeat steps 2 and 3 until all digits have been set. After the final digit is set, the brackets

automatically disappear.

5. Press the UP key to proceed to the next screens.

If the correct password was entered earlier, navigating back over the password entry screen will

show the password as a row of stars. The password approval state is retained as long as the

panel is powered up.

9.3.4 Editing

Some screens permit parameter changes.

1. Press ENTER to start editing. The value on the screen will be surrounded by brackets. On

password-protected screens, brackets appear only when the correct password was entered

earlier.

2. Use the UP and DOWN keys to adjust the value. In the case of a selection list, the various

possible selections will be shown in a ring. In the case of a variable number, press the

appropriate key to step up/down. For larger changes, press and hold the UP or DOWN key.

(The value will step faster as the key is held down. Stepping will stop when preset value limits

are reached or the key is released.)

3. Press ENTER to save the new value. The brackets will disappear.

4. To skip the edit and retain the old value, press MENU instead of ENTER.

9.3.5 Exiting

1. Press and hold the MENU key & simultaneously press the ENTER key.

Leaving during editing will abandon the edit and the old value will be retained. Exiting has no effect

on the password approval. To clear the approved password state, power cycle the panel.