V0_2020-06-25

When selecting the site for your pool, take into account city by-laws regarding fences and utilities laws pertaining to electrical cables

as well as the landscaping which you are planning once the pool is installed.

Dear Customer

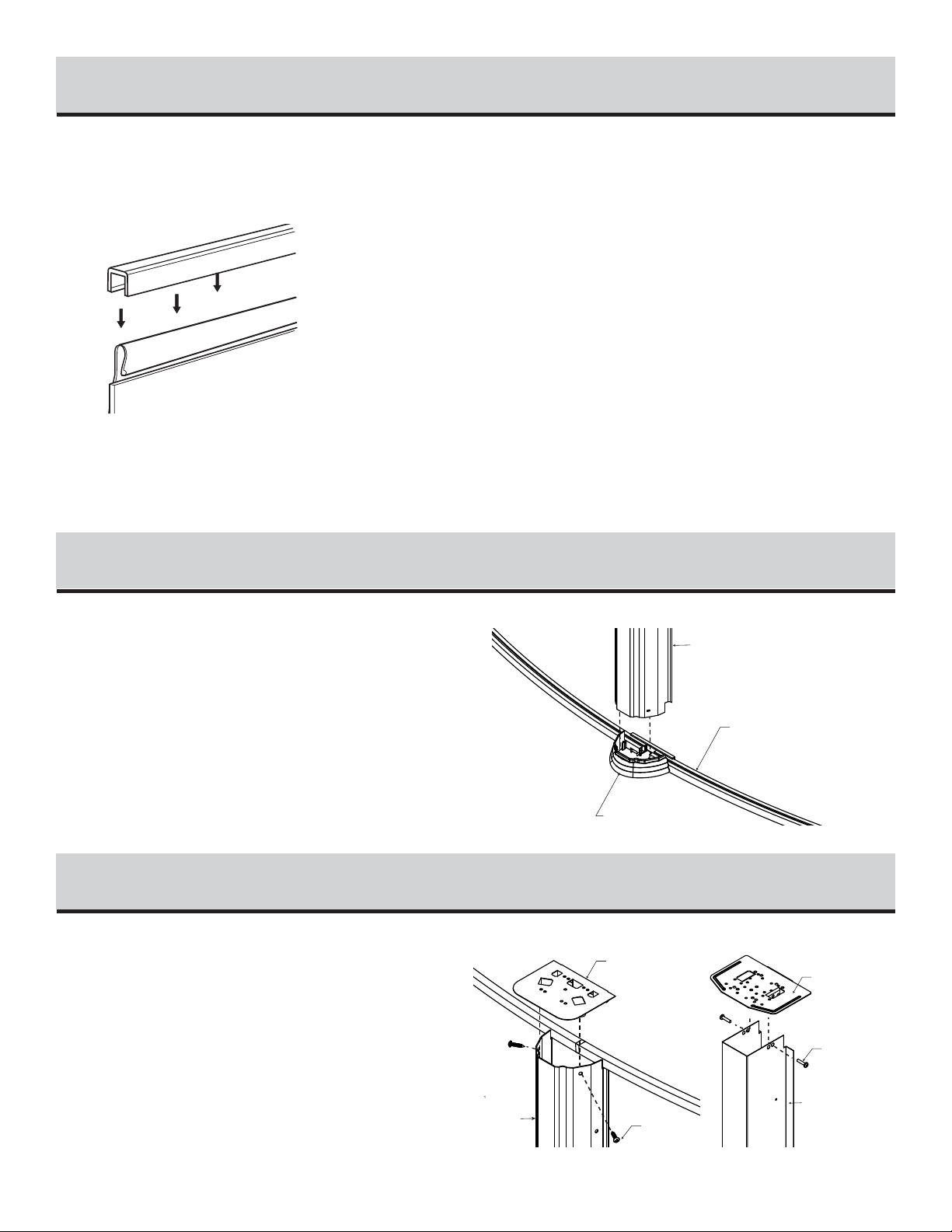

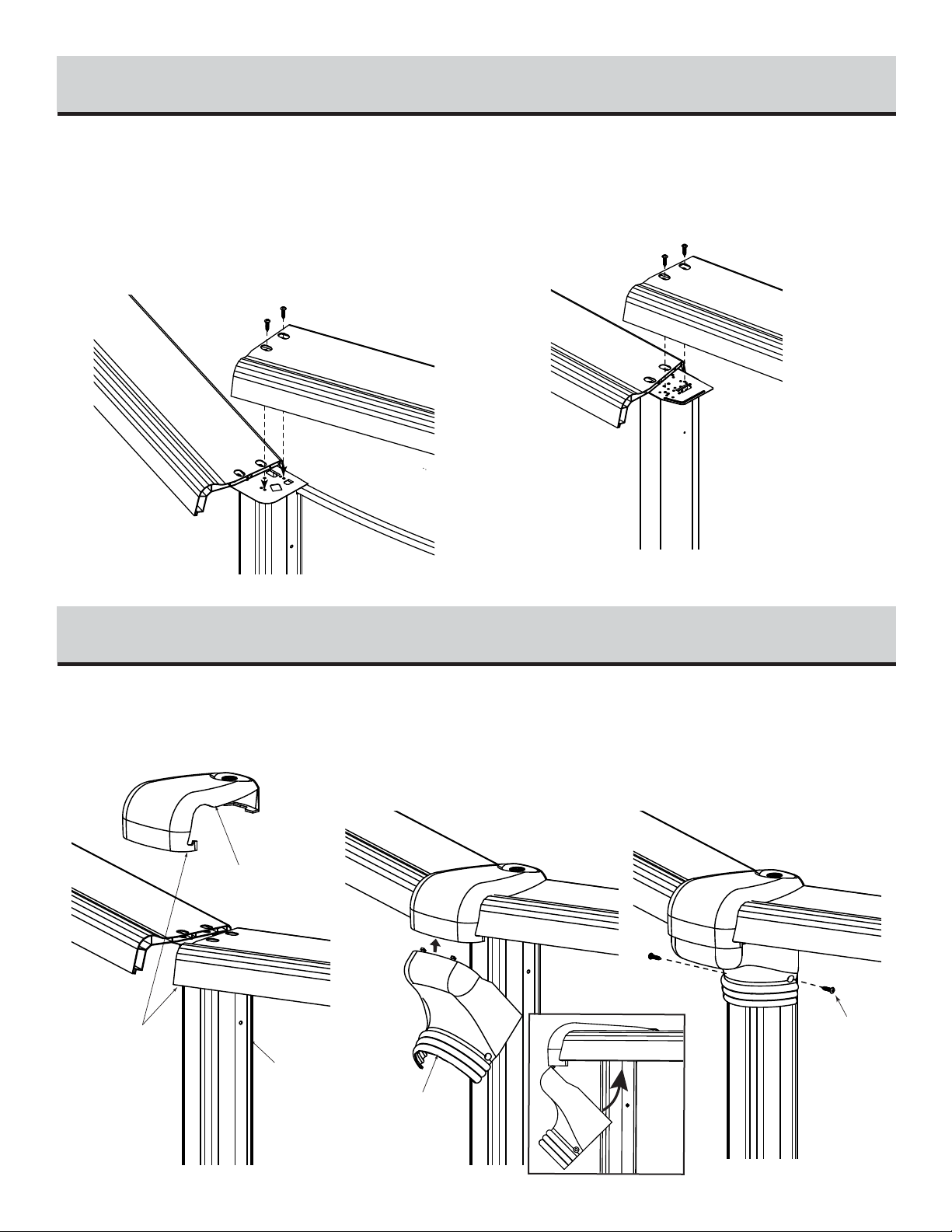

Congratulations! You have purchased a pool of superior quality and durability. To achieve the best possible results,

follow the instructions carefully. Failure to follow the installation procedures may result in damage to your pool or

property and void your warranty. We recommend that you make a preliminary study of the instruction booklet to

familiarize yourself with the different parts of your pool. Make sure that you understand each step thoroughly before

you begin assembling.

We wish you a most pleasant and refreshing summer.

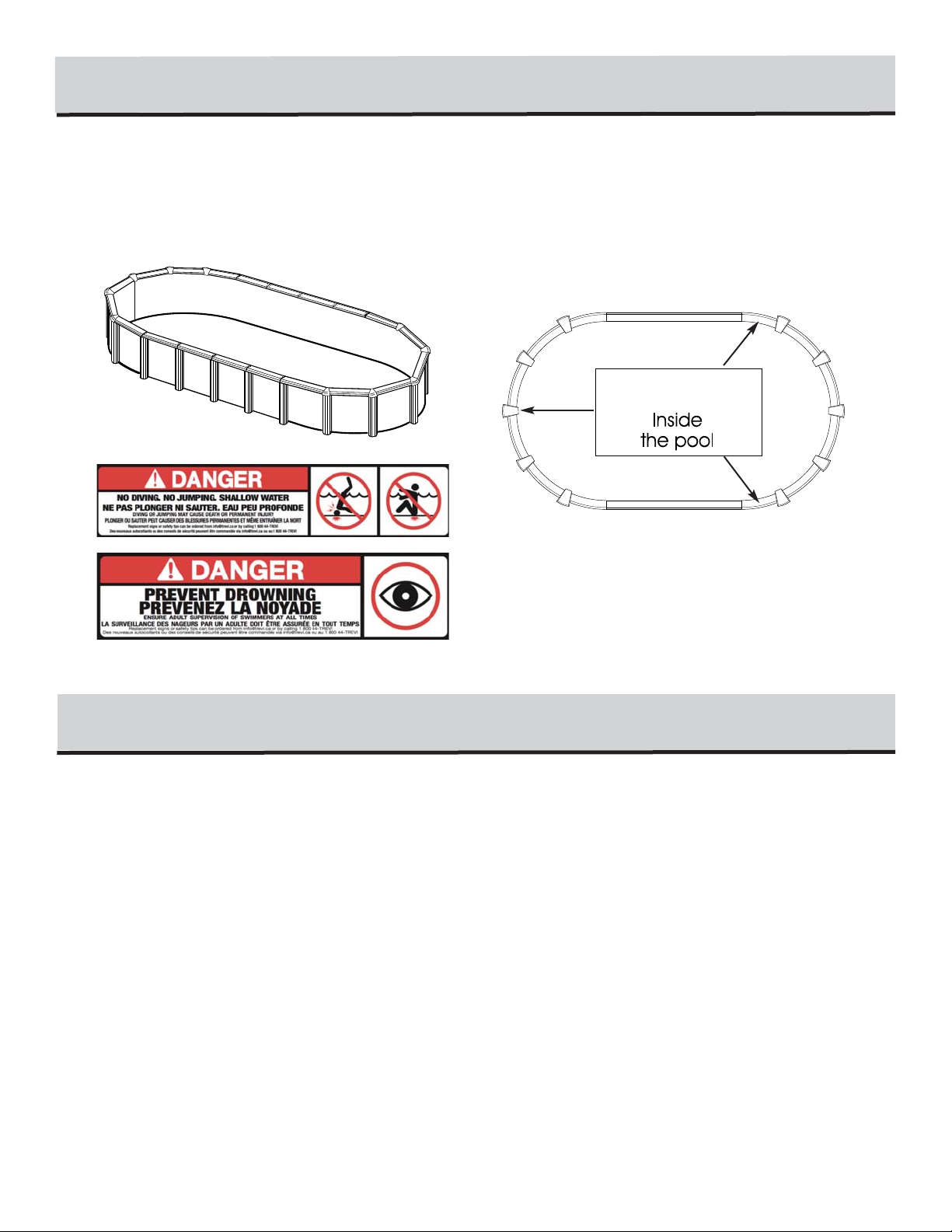

WARNING: Be sure you have read and understand the “Safety Information” sheets

before you begin your pool installation.

WARNING: For your safety, your pool is not designed for diving and/or jumping head first.

Please do not dive. Diving may result in permanent injury or death.

ASSEMBLY INSTRUCTIONS

OVAL POOLS

MODEL NH

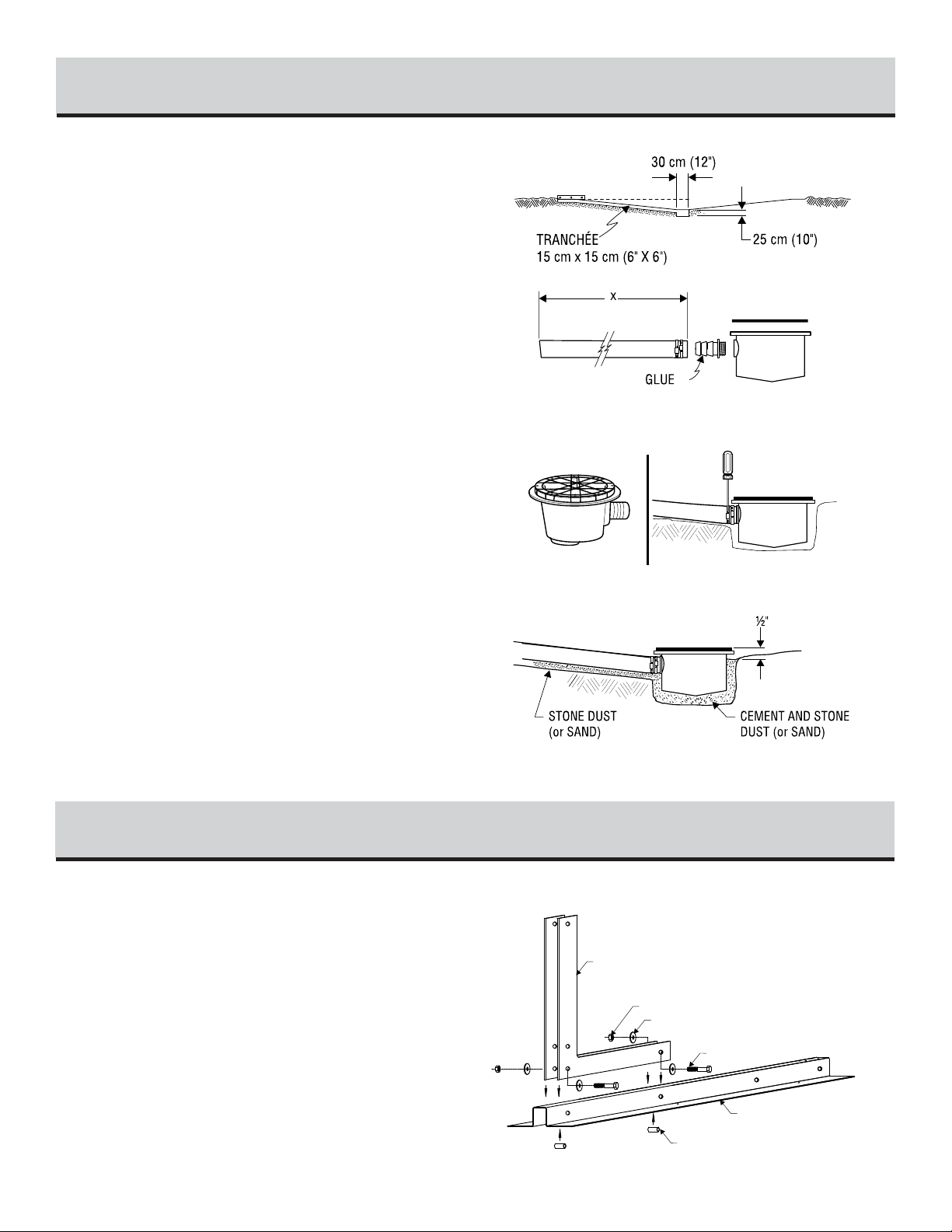

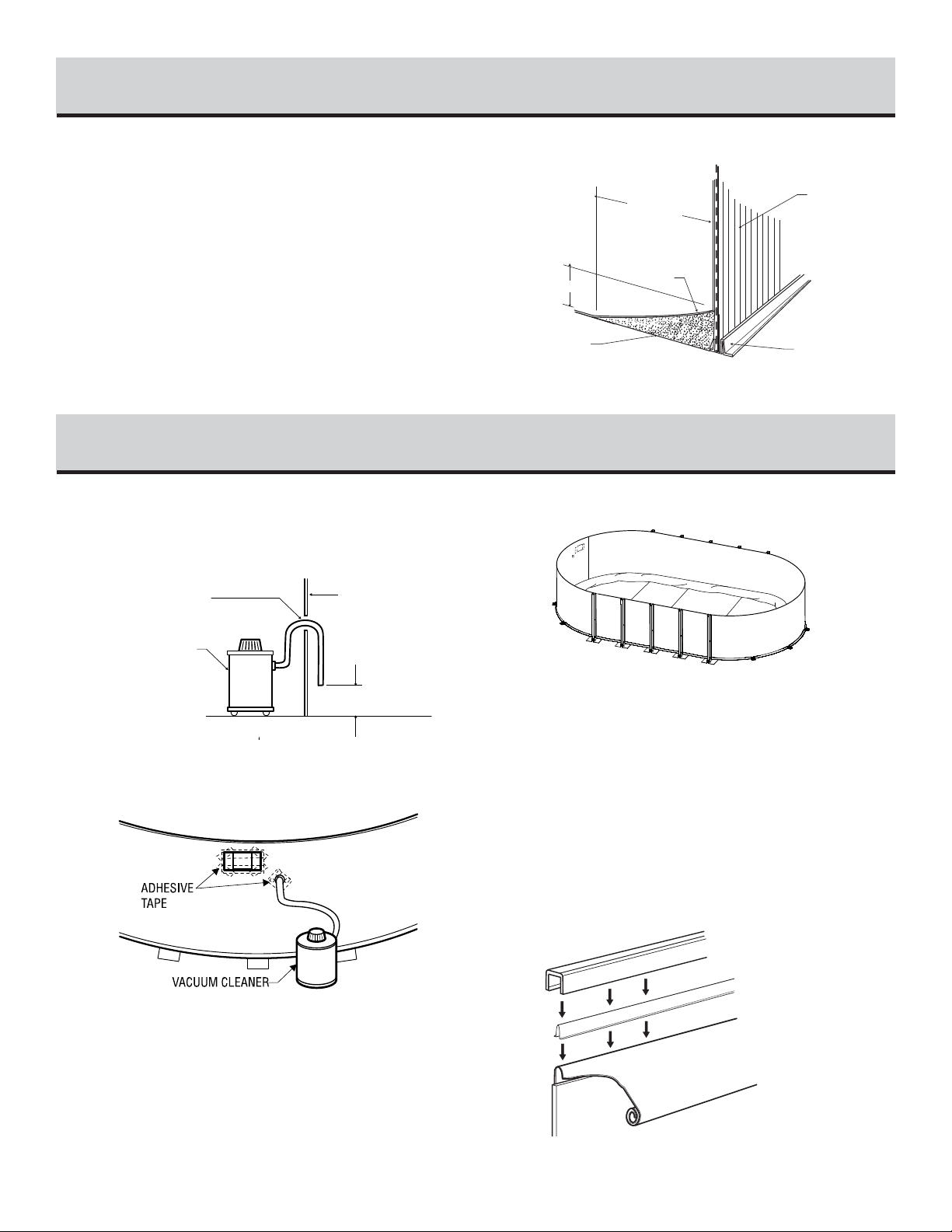

SITE PREPARATION

1

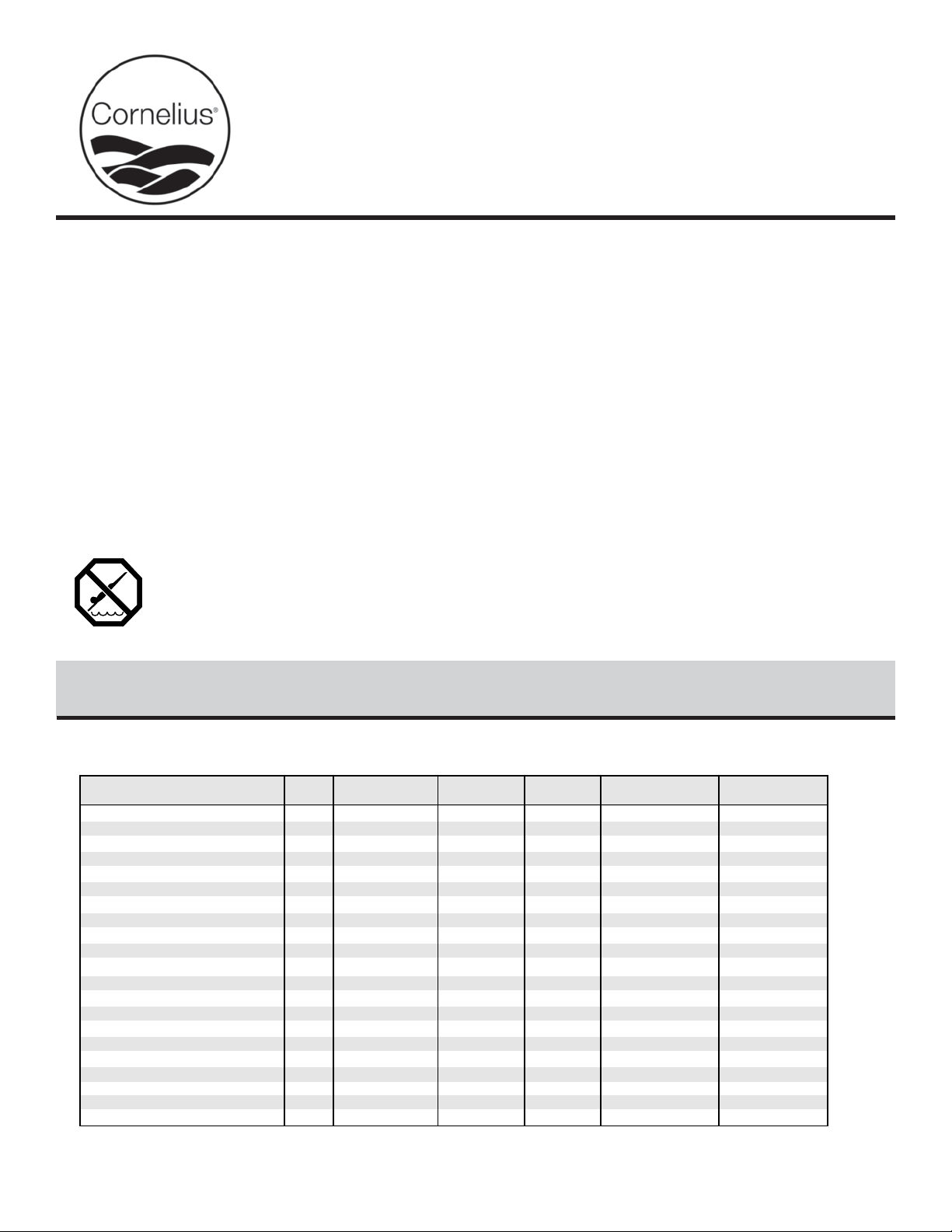

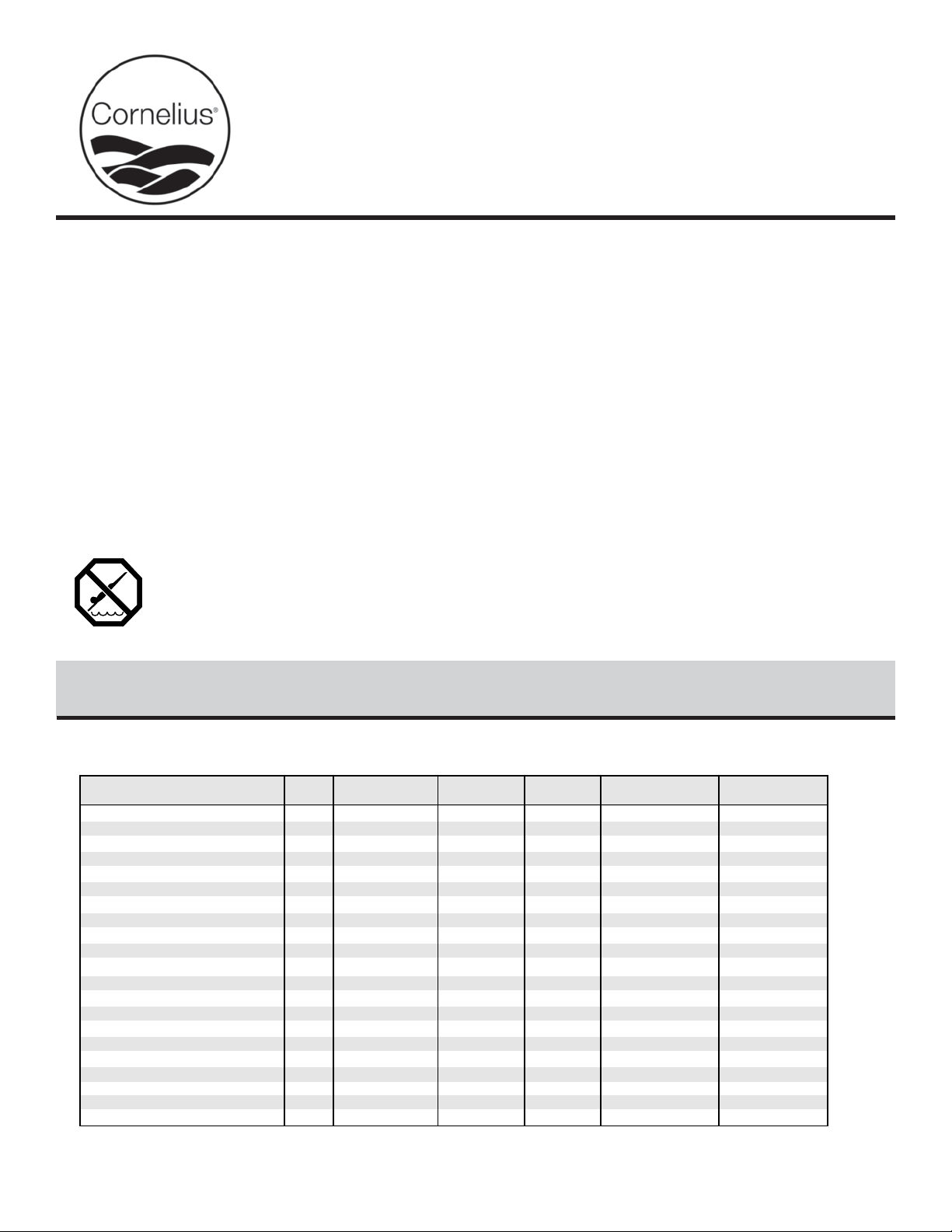

Chart 1.1 - Grass removal area (Figure 1.1)

1.70m (5'7")

1.70m (5'7")

2.13m (7')

2.13m (7')

2.44m (8')

2.44m (8')

2.44m (8')

2.90m (9'-6")

2.90m (9'-6")

2.90m (9'-6")

3.35m (11')

3.35m (11')

4.27m (14')

4.27m (14')

4.88m (16')

4.88m (16')

4.88m (16')

5.79m (19')

5.79m (19')

5.79m (19')

5.03m (16'-5 3/4")

6.69m (21-11")

5.48m (17'-11 3/4")

7.14m (23'-5")

6.30m (20'-8")

7.96m (26'-1 1/2")

9.64m (31'-7 1/4")

10.31m (33'-10")

11.98m (39'-4")

13.66m (44'-10")

1.90m (6'-3 1/2")

3.33m (10'-11")

1.66m (5'-5 1/2")

3.33m (10'-11")

1.66m (5'-5 1/2")

3.33m (10'-11")

4.99m (16'-4 1/2")

5.24m (16'-4 1/2")

6.90m (22'-8")

8.56m (28'-1 1/2")

MODELTRUE POOL SIZE

DISTANCE (A-B)

RADIUS (R) WIDTH (D) TOTAL LENGTH (E) TRENCH (F)

10'x16' 1.68m (5'-6")

10'x21' 3.35m (11'-0")

13'x17' 1.18m (3'-10 1/2")

13'x23' 2.84m (9'-3 3/4")

15'x20' 1.42m (4'-7 3/4")

15'x26' 3.07m (10'-1")

15'x31' 4.75m (15'-7")

18'x33' 4.57m (15'-0")

18'x38' 6.25m (20'-6")

18'x44' 7.92m (26'-0")

3.05 x 4.72 m (10' x 15' 5-3/4")

3.05 x 6.38 m (10' x 20' 11-1/8")

3.96 x 5.17 m (13' x 16' 11-3/4")

3.96 x 6.83 m (13' x 22' 5")

4.57 x 5.99 m (15' x 19' 8")

4.57 x 7.65 m (15' x 25' 1-3/8")

4.57 x 9.33 m (15' x 30' 7-1/4")

5.44 x 10.00 m (17' 10" x 32' 10")

5.44 x 11.61 m (17' 10" x 38' 4")

5.44 x 13.36 m (17' 10" x 43' 10")

1.40m (4'7 1/2")

1.40m (4'7 1/2")

1.40m (4'7 1/2")

2.75m (9')

2.75m (9')

2.75m (9')

4.45m (14'-7")

5.03m (16'-6")

6.12m (20'-1")

1.90m (6'-3 1/2")

3.33m (10'-11")

3.58m (11'-9")

8'x14' 1.68m (5'-6")

8'x16' 2.45m (7'-5")

8'x19' 3.35m (11'-0")

2.46 x 4.14 m (8' 1"x 13' 7")

2.46 x 4.72 m (8' 1"x 15' 6")

2.46 x 5.82 m (8' 1"x 19' 1")

1.70m (5'7") 3.35m (11') 5.85m (19-2 1/2") 3.33m (10'-11")

10'x18' 2.45m (8'-3")3.05 x 5.53 m (10' x 18' 2-1/2")

1.98m (6'6 3/4")

1.98m (6'6 3/4")

1.98m (6'6 3/4")

3.96m (13')

3.96m (13')

3.96m (13')

5.94m (19'-6")

7.59m (24'-11 1/2")

8.43m (27'-8 1/4")

1.90m (6'-3 1/2")

3.58m (11'-9")

5.23m (17'-2 1/2")

12'x18' 1.98m (6'-6 1/2")

12'x24' 3.65m (12'-0")

12'x27' 4.47m (14'-8")

3.65 x 5.63 m (11' 11-1/2"x 18' 6")

3.65 x 7.30 m (11' 11-1/2"x 23' 11-1/2")

3.65 x 8.12 m (11' 11-1/2"x 26' 8-1/4")

2.31m (7'7 1/2")

2.31m (7'7 1/2")

4.57m (15')

4.57m (15')

6.27m (20'-7")

7.95m (26'-1")

1.90m (6'-3 1/2")

3.58m (11'-9")

14'x20' 1.68m (5'-6")

14'x25' 3.35m (11'-0")

4.29 x 5.97 m (14' 1"x 19' 7")

4.29 x 7.65 m (14' 1"x 25' 1")

2.59m (8'6 1/2")

2.59m (8'6 1/2")

5.18m (17')

5.18m (17')

8.38m (27'-6")

10.05m (33')

3.58m (11'-9")

5.23m (17'-2 1/2")

16'x26' 3.23m (10'-7 1/2")

16'x32' 4.90m (16'-1")

4.85 x 8.08 m (15' 11"x 26' 6")

4.85 x 9.75 m (15' 11"x 32' )