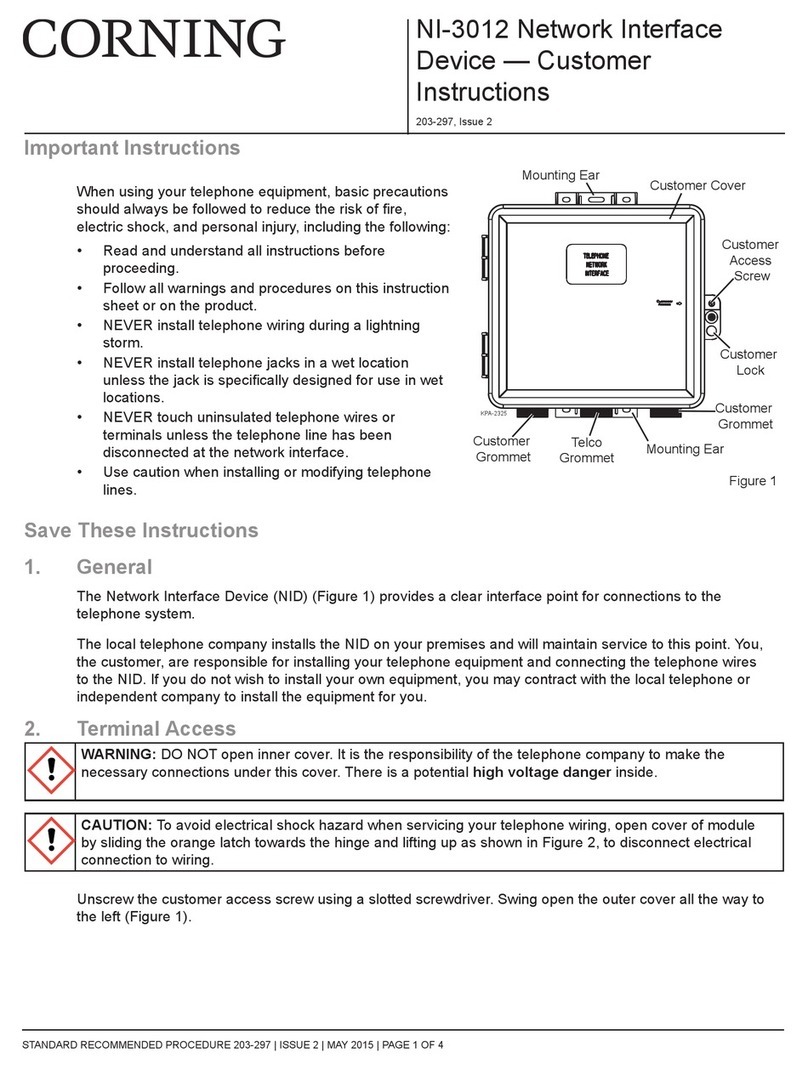

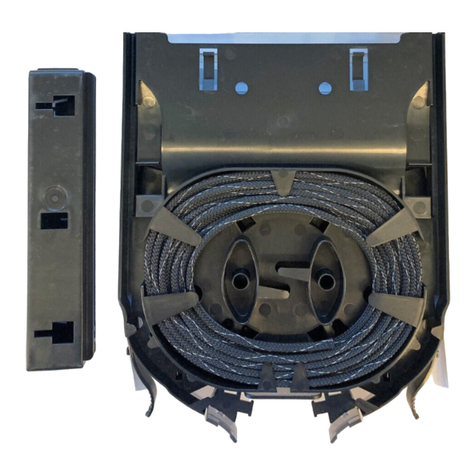

4.12 Place the fiber in the cleaver to give the desired cleave

length as shown in Figure 7. Hold the fiber in place with

your left thumb or forefinger- position the fiber so that its

bow is placed downward to force the fiber to lay straight

across the blade.

The bare fiber should extend across the base to the right fiber

guide. Make sure that no aramid yarn is on the clamping pads

during cleaving (Figure 7).

Figure 7

4.13 Gently swing the cleaver arm down so that the upper

fiber clamps are resting on the fiber.

4.14 Push down on the cleaver with a slow and gentle motion

until you hear a click – the fiber is now cleaved (see Figure

4).

4.15 Remove the cut end of the fiber with tweezers and

put it on the loop of tape (see Figure 5).

4.16 After completing use of the cutter, properly dispose of

the tape loop holding the cut fiber ends.

5. Maintenance

Cutter Cleaning

5.1 After each day’s use, clean the guides, clamping pads,

blade, and anvil of the FBC-006 as follows:

a) Clean the clamping pads by inserting a cleaning

strip soaked in alcohol between the pads and

pressing down on the cleaver to close them. Pull

the strip from between the pads (Figure 8). Repeat

this step several times.

b) To clean the diamond cutting blade:

Insert a cleaning strip soaked in alcohol between the

anvil and the cutting blade. Gently press down on

the cleaver bar to bring the anvil into contact with the

strip. Pull the strip from the cleaver.

Open the cleaver and use the strip to clean the end

faces of the blade (Figure 9).

Figure 9

c) Carefully inspect the cutter for any fiber remnants,

bits of dirt, etc. Repeat steps a and b if necessary.

Changing Guides

5.2 The following optional guides and guide sets are

available for the FBC-006 cleaver:

• FBC-006-04 -standard universal fiber guide (for 250 mm

and 900 mm fiber

• FBC-006-05 - 3 mm fiber guide, permits cleaving 3 mm

cable for FuseLite™ termination.

• FBC-006-07 - Fanout and OptiStrip Kit, two fiber guides

and instructions, permits cleaving 3 mm

OptiStrip cable or fanned-out fibers in a

buffer tube fan-out kit.

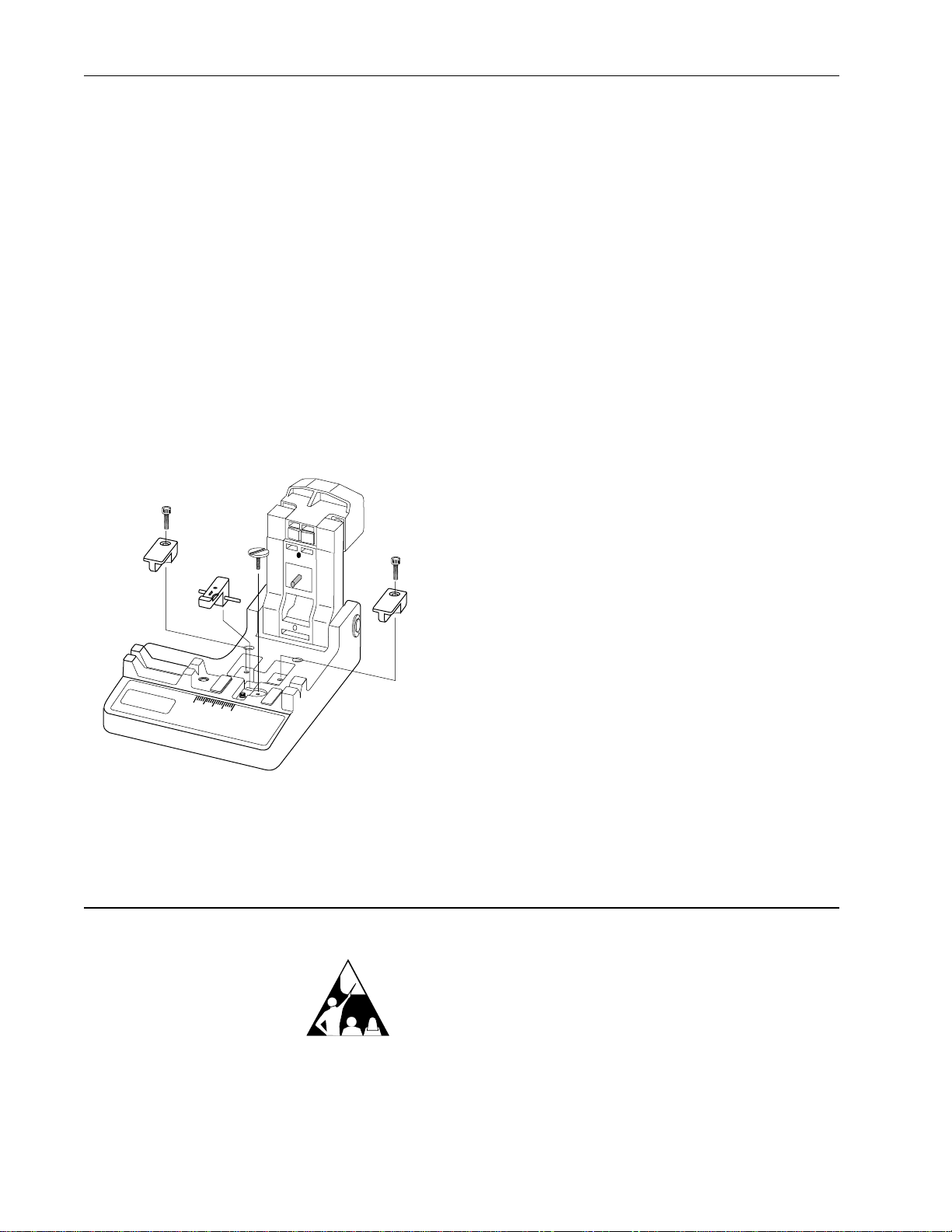

5.3 To change a guide :

a) Use a 2.5 mm hex key to remove the hex-head

cap screw which secures the guide to the cleaver

base (Figure 0).

b) Place the new guide in the base and secure it with

the cap screw. Optionally, the guide may be held in

place by the magnetic base without the securing

screw.

Issue 7 SRP-001-062 Page 3

CAUTION: Never substitute sand paper or other

abrasive papers for the cleaning strips. Doing so will destroy the

polished surface of the anvil and clamps.