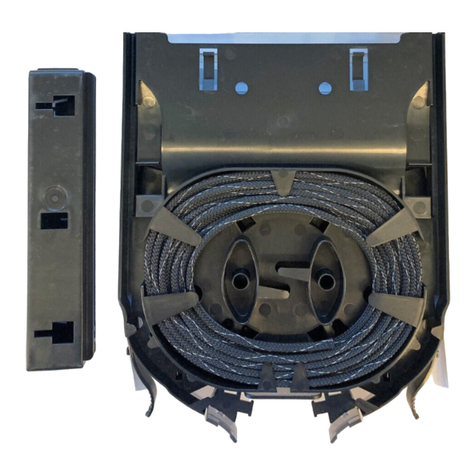

CORNING PCH-96F-01U User manual

Other CORNING Network Hardware manuals

CORNING

CORNING FBC-006 User manual

CORNING

CORNING ONE SD-LAN User manual

CORNING

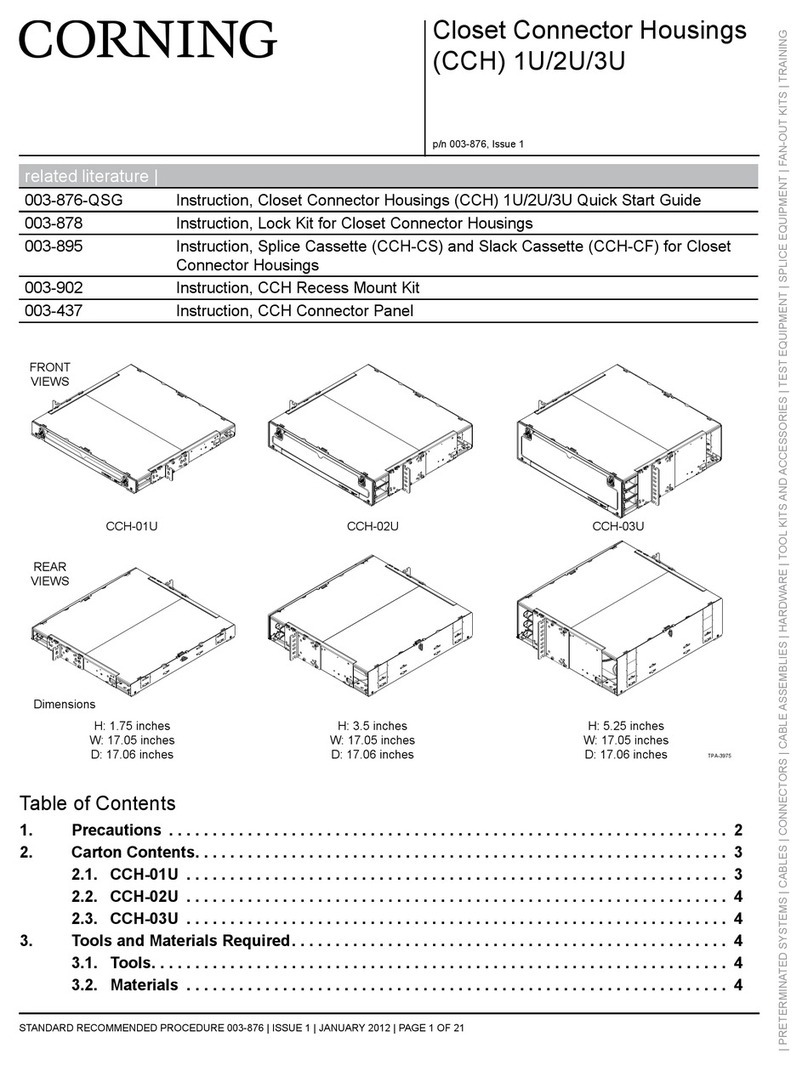

CORNING CCH 1U User manual

CORNING

CORNING Everon 6000 G2 User manual

CORNING

CORNING CCH-CS User manual

CORNING

CORNING ONE User manual

CORNING

CORNING EDGE User manual

CORNING

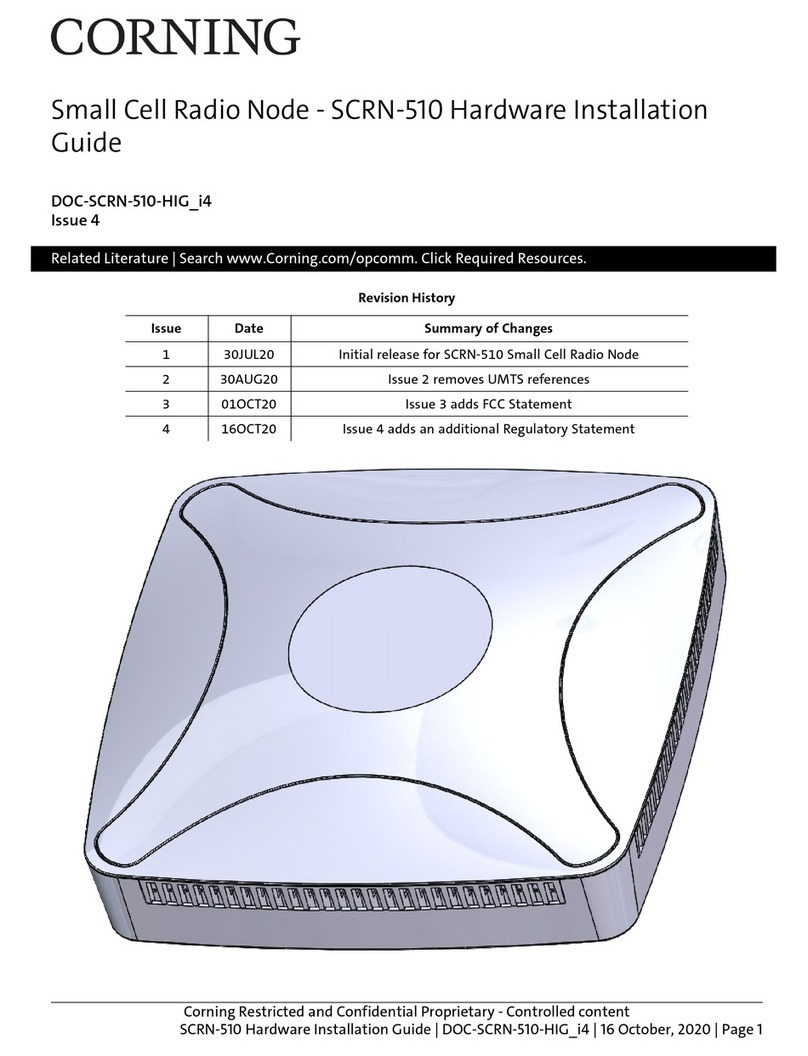

CORNING SCRN-510 Manual

CORNING

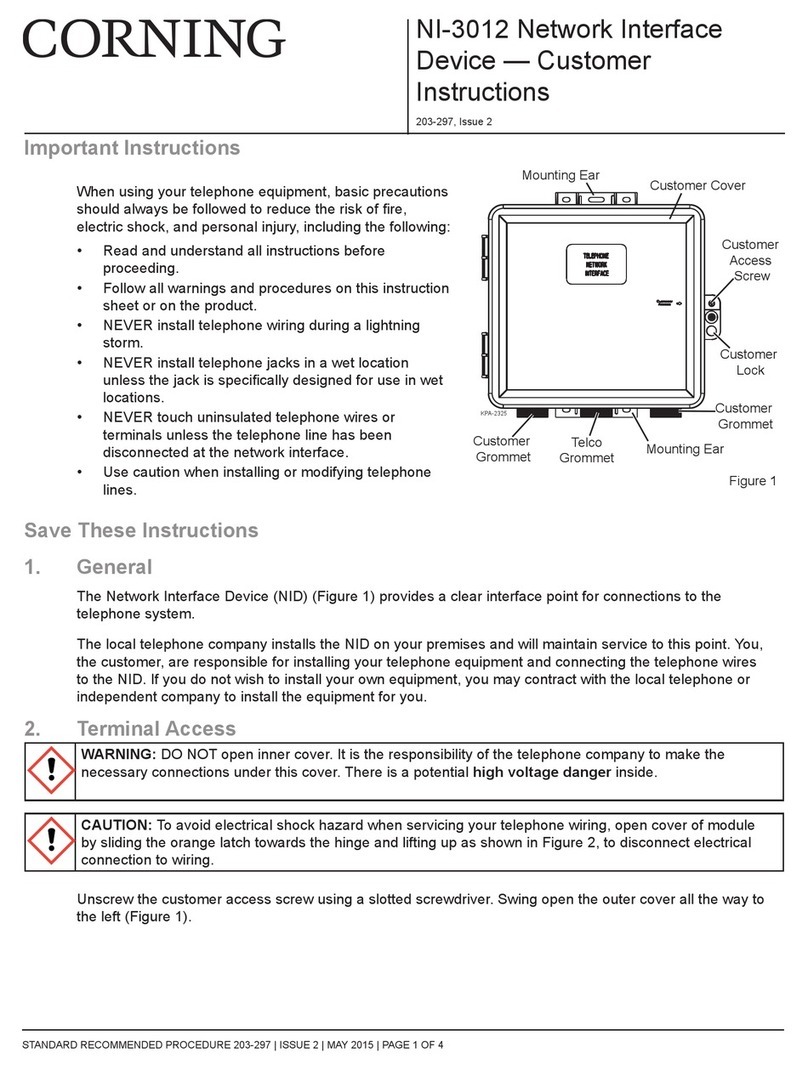

CORNING NI-3012 Reference guide

CORNING

CORNING EDGE8 Series User manual

CORNING

CORNING Everon 6000 v1.0 User manual

CORNING

CORNING EDGE 1U User manual

CORNING

CORNING Eclipse 01U User manual

CORNING

CORNING CCH-01U User manual

CORNING

CORNING Centrix User manual

CORNING

CORNING Pretium EDGE 01U-RDH User manual

CORNING

CORNING Centrix User manual

CORNING

CORNING ONE User manual

CORNING

CORNING PS-MP Owner's manual

Popular Network Hardware manuals by other brands

Matrix Switch Corporation

Matrix Switch Corporation MSC-HD161DEL product manual

B&B Electronics

B&B Electronics ZXT9-IO-222R2 product manual

Yudor

Yudor YDS-16 user manual

D-Link

D-Link ShareCenter DNS-320L datasheet

Samsung

Samsung ES1642dc Hardware user manual

Honeywell Home

Honeywell Home LTEM-PV Installation and setup guide