-Save these instructions-

CTJTJ1KA 3 03/23/20

INSPECTION

Visual inspection should be made before each use of the jack, checking for leaking hydraulic fluid and damaged, loose or missing parts. Each

jack must be inspected by a manufacturer’s repair facility immediately, if subjected to an abnormal load or shock. Any jack which appears to be

damaged in any way, is found to be badly worn, or operates abnormally MUST BE REMOVED FROM SERVICE until necessary repairs are made by

a manufacturer’s authorized repair facility. It is recommended that an annual inspection of the jack be made by a manufacturer’s authorized repair

facility and that any defective parts, decals or warning labels be replaced with manufacturer’s specified parts. A list of authorized repair facilities is

available from the manufacturer.

SETUP

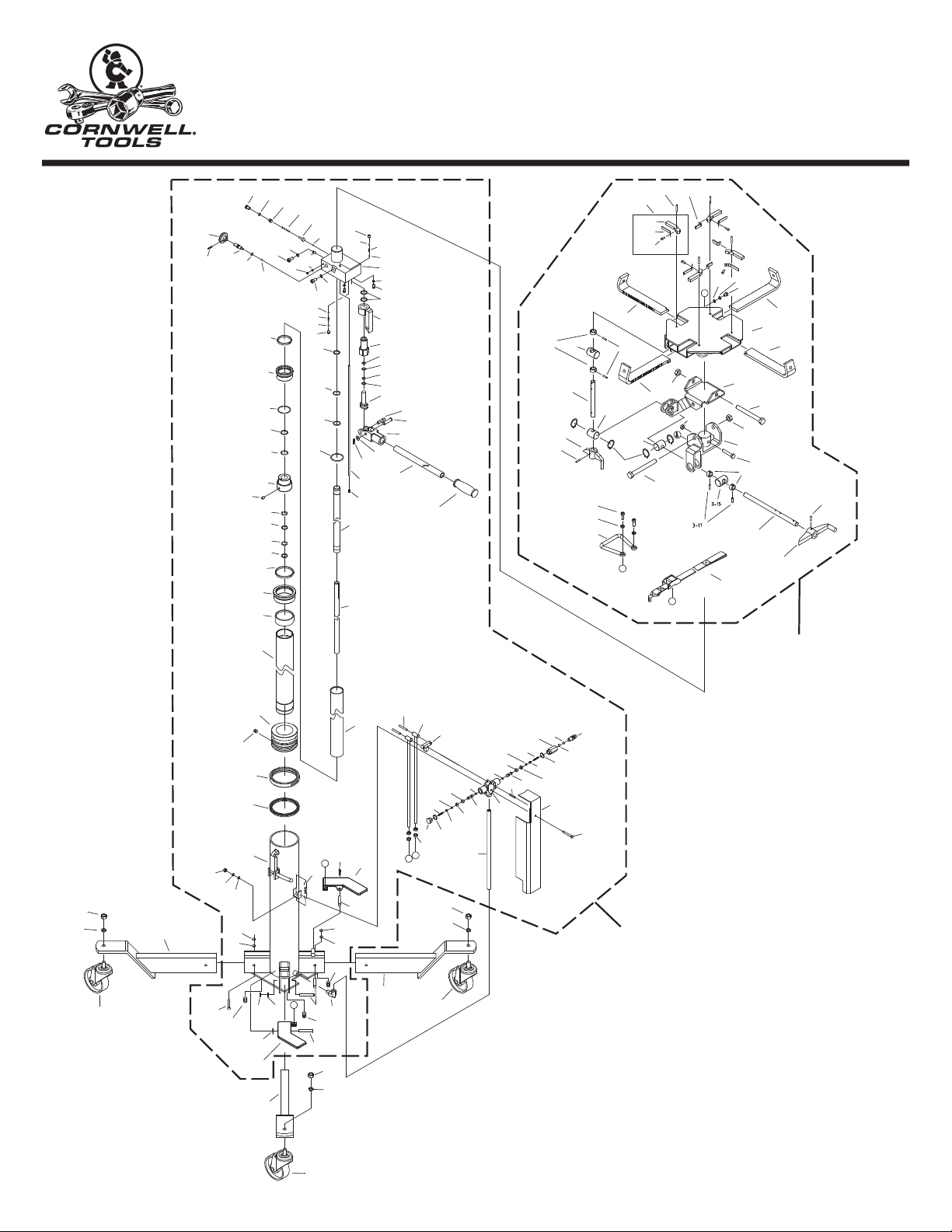

Please refer to the exploded view drawing on page 5 in this manual in order to identify parts:

1. Place the hydraulic power unit horizontally on a bench. Secure the legs (#2-4) in the receivers in the bottom of the cylinder (#1-1A)

with the bolts (#2-5), washers (#2-6) and nuts (#1-29). Do not tighten.

2. Install the set screw (#1-85) at the bottom of each leg receiver so the legs are firmly seated in the receivers.

3. Secure swivel casters (#2-1 and #2-7) to leg caster brackets as shown in the exploded view drawing on page 5 and place the jack upright

on the floor.

4. Tighten the hardware that secures the legs (#2-4) to the cylinder (#1-1A).

5. Place the saddle assembly on the stud protruding from the top of the hydraulic unit assembly, (CTJTJ1KAPUNIT). Align the hole in the

saddle with the hole in the stud and secure with the bolt (#3-26) and nut (#3-27).

6. Sometimes air gets trapped in the second stage hydraulic system during shipping and/or handling. Evidence of an air bound system is a

spongy feeling during the pump operation, or the ram will not rise to maximum extension, or the ram will not rise proportionate to a full

incremental pump stroke.

PURGING AIR FROM THE SECONDARY STAGE HYDRAULIC SYSTEM:

a. Turn the release valve knob in a clockwise rotation until it stops. Now turn the knob in a

counterclockwise direction two full rotations.

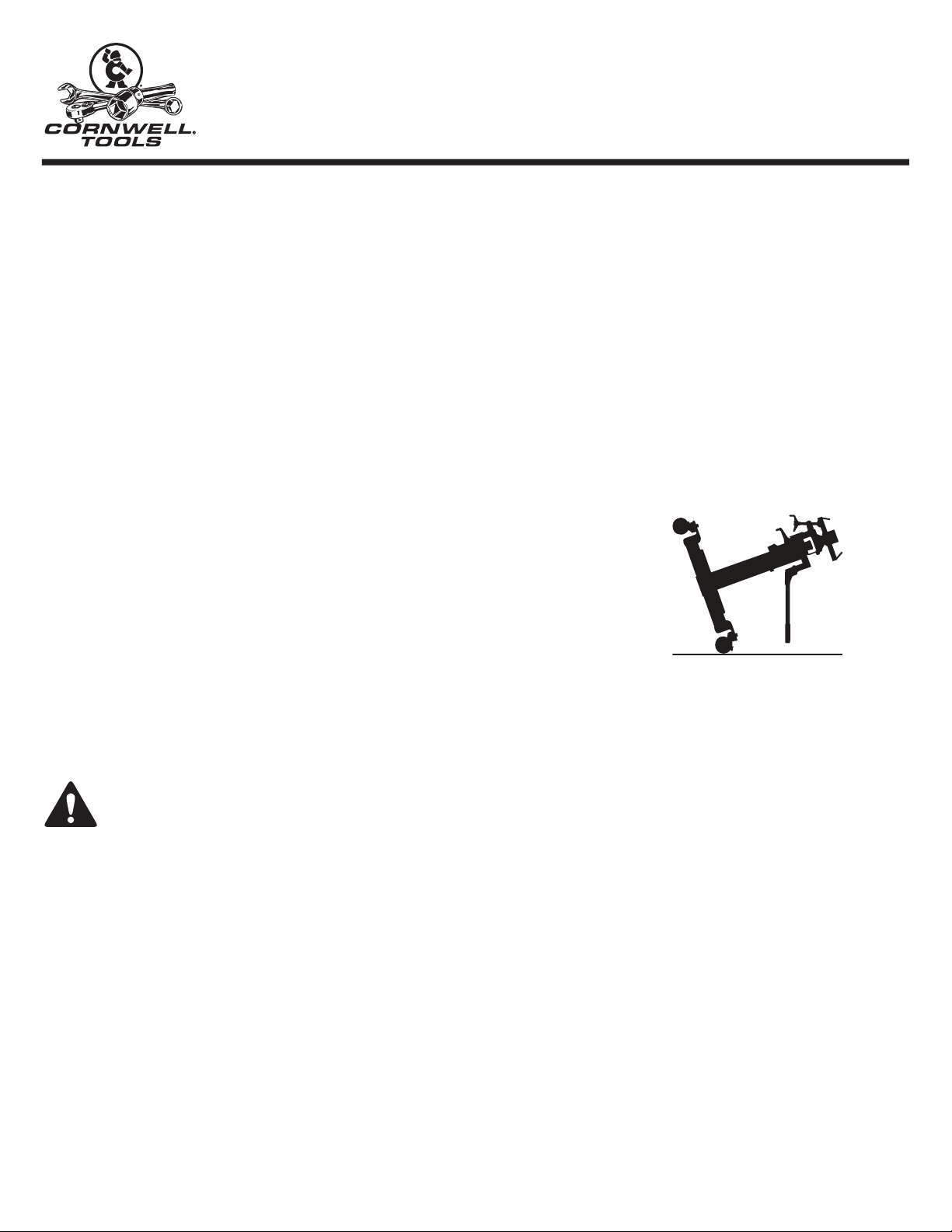

b. Tilt the entire jack on two caster wheels with the pump handle pointing down as shown in

the accompanying silhouette. At the same time, operate the pump handle until the loose feel

of the pump is met with some resistance.

c. Turn the release valve knob in a clockwise rotation until it stops and at the same time continue

pumping the handle while lifting the jack to its upright position.

d. Pump the jack to maximum extension. Repeat steps "a" through "c" until all air is purged

from the system.

7. The primary stage of the power unit is air activated. The air activated portion will also give the user many years of trouble free operation

if the shop air system is properly maintained. The shop air system must have an air regulator adjusted to the proper pressure. The system

must be free from dirt and moisture. Do not drop disconnected air lines on dirty shop floor or dirty environment and then reconnect to the

jack. Contaminants in the air system can cause the air valve to malfunction and the air cylinder to score. Contaminants and/or water

found in the air cylinder voids the warranty.

OPERATION

This is the safety alert symbol used for the OPERATING INSTRUCTIONS section of this manual to alert you to potential personal

injury hazards. Obey all instructions to avoid possible injury or death. IMPORTANT: Before attempting to raise any vehicle, check

vehicle service manual for recommended lifting surfaces.

1. Lift the vehicle to the desired work height and support the vehicle in accordance with the lift manufacturer's recommended support

procedure and all the instructions and warnings in this manual.

2. Use an under hoist stand rated greater than the weight of the engine to support the engine before unbolting the transmission from the

engine or bolting the transmission to the engine.

3. Position the transmission jack directly under the transmission. Depress the foot pedal marked "UP" to raise the jack to maximum first

stage height. Pump the handle on the hydraulic second stage in order to raise the saddle to a height very close to the center of balance

point of the transmission oil pan but do not touch the transmission. IMPORTANT: When applying a load to the jack's saddle, the jack's

air stage ram should be either lowered all the way down or extended all the way up and in its pressurized locked position. If a load is

applied to the jack's saddle when the first stage air ram is only partially raised, the jack's ram may drop suddenly.

4. Adjust the ratchet arms on the saddle so that the bent up section of the arms will fit in the mounting flange around the perimeter of the

transmission oil pan. Slowly and gently pump the jack so the connection is made and then secure the transmission to the jack's saddle

with the tie down strap provided. Sometimes it is necessary to turn the fore and aft and also the side to side tilt knobs so the saddle is

in the proper alignment with the transmission pan before securing the load to the saddle.

5. Make sure the tie down strap is very tight when securing the transmission to the saddle and before raising or lowering the transmission.

6. Remove the transmission from the engine according to instructions in the vehicle service manual.

7. Once the transmission has been disconnected from the engine, very slowly turn the release valve knob on the second stage hydraulic

block in a counter clockwise direction. Make sure the jack's saddle and transmission do not hang up on any under car components,

wiring, fuel lines, etc.

IMPORTANT: Continue to lower the load until the second stage bottoms out and then depress the first stage "UP" pedal for a second to increase

air pressure before depressing the "DOWN" pedal to lower the transmission all the way down.

8. When installing a transmission, follow the above instructions but in the applicable order and according to the vehicle manufacturer's

installation procedure.

CTJTJ1KA

1,000 Lb. Telescoping Transmission

Jack with Air