E220 evolution User Manual Page 5

TABLE OF CONTENTS

1.0 INTRODUCTION................................................................................................................................6

1.1 Overview of the User Manual.........................................................................................................6

1.2 The E220 evolution and the Covaris Process................................................................................6

2.0 INSTALLATION AND SETUP............................................................................................................7

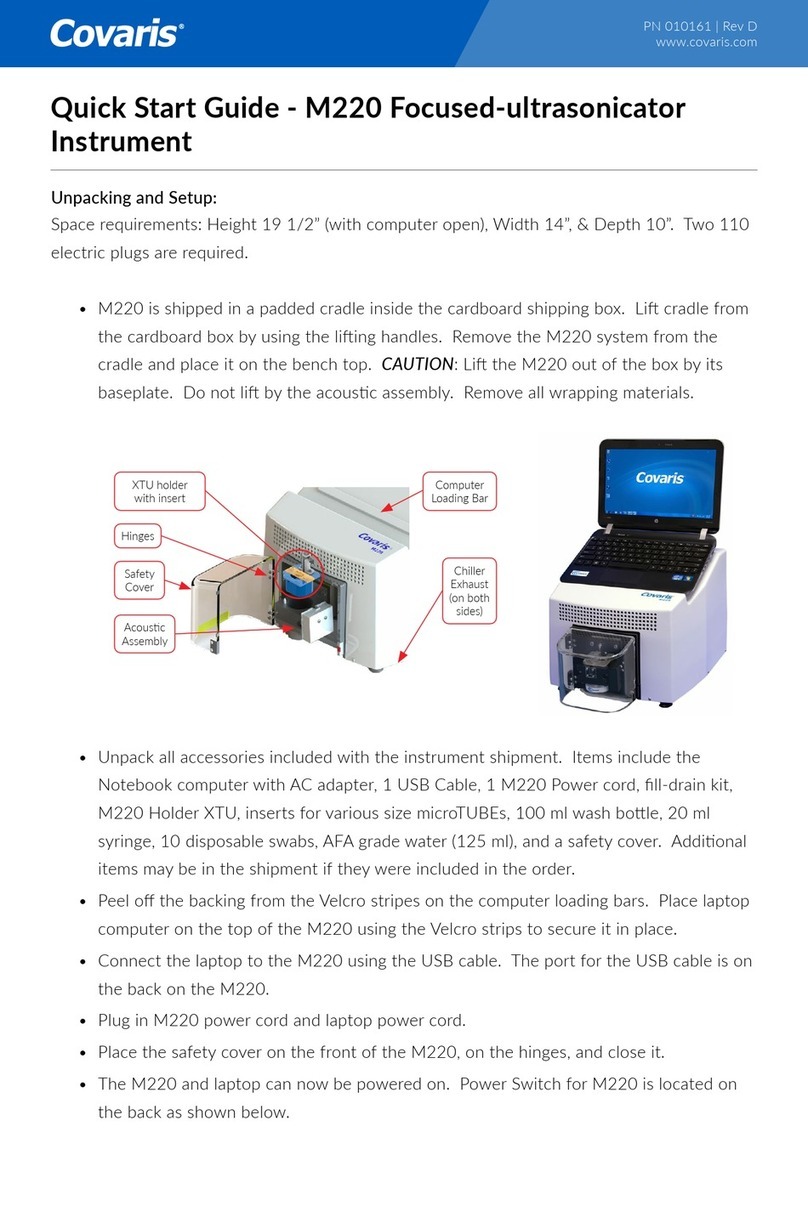

2.1 Assembly........................................................................................................................................7

2.2 Installation......................................................................................................................................8

3.0 GETTING STARTED .......................................................................................................................11

3.1 Fill the Water Bath........................................................................................................................11

3.2 Start the System...........................................................................................................................11

3.3 The SonoLab Run Screen - Running a Method...........................................................................13

3.4 System Shutdown ........................................................................................................................17

3.5 Temperature Control....................................................................................................................18

3.6 Degas System..............................................................................................................................19

4.0 SonoLab™ APPLICATION SOFTWARE.........................................................................................19

4.1 Create and Edit Methods .............................................................................................................20

4.2 Temperature Tab..........................................................................................................................25

4.3 Saving Methods in Folders...........................................................................................................26

4.4History Tab...................................................................................................................................27

4.5 Setup Screen................................................................................................................................27

4.6 Maintenance Screen ....................................................................................................................32

4.7 About Tab.....................................................................................................................................33

4.8 Motion Tab ...................................................................................................................................33

5.0 SYSTEM SPECIFICATIONS ...........................................................................................................35

6.0 MAINTENANCE...............................................................................................................................36

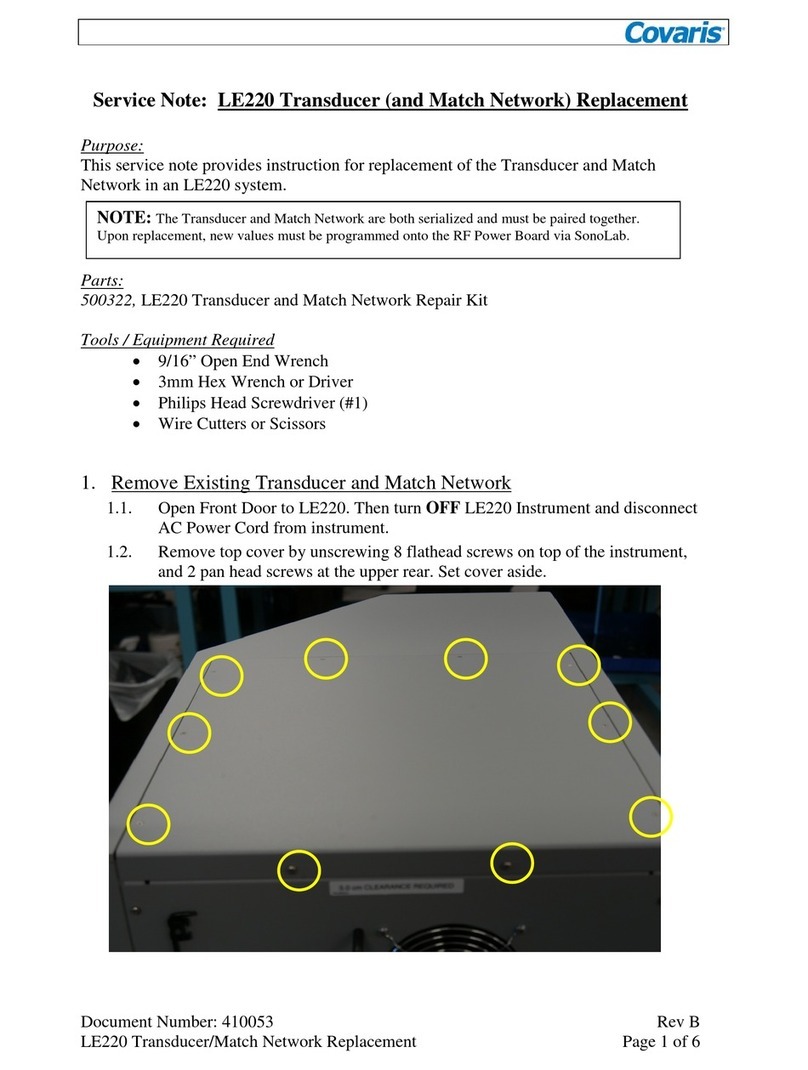

6.1 Cooling Air Intake.........................................................................................................................36

6.2 Water Bath ...................................................................................................................................36

6.3 Transducer...................................................................................................................................36

6.4 Safety System..............................................................................................................................36

6.5 Degassing System .......................................................................................................................36

6.6 Cleaning the System....................................................................................................................37

7.0 TROUBLESHOOTING.....................................................................................................................38

Appendix A: Suggested E220 evolution IQ / OQ / PQ ................................................................................40

Appendix B: E Series Site or Transport Preparation...................................................................................46

Appendix C: Installing SonoLab Software, Firmware and Instrument Drivers............................................48

Appendix D: Recirculating Chiller................................................................................................................53

Appendix E: Humidity and Water Management in Covaris E and LE Systems ……………………………..55