M220 User Manual Page 4

Warranty

When used in accordance with written instruction and under normal operating conditions, the Covaris

instruments are guaranteed to be free of defects in MATERIAL and WORKMANSHIP for one (1) year from the

date of original delivery by an authorized representative. Any component which proves defective during the

stated period will be repaired free of charge or replaced at the sole discretion of Covaris, F.O.B., Woburn,

Massachusetts, U.S.A. provided the defective component is returned properly packaged with all transportation

charges prepaid. The customer is expected to perform basic diagnostics and component replacement with

telephone support from Covaris personnel. If Covaris personnel are required to perform on-site repair, all travel

related costs are paid by the customer. A limited warranty as specified may apply to certain components of the

equipment.

Warranty Exceptions

This warranty is void if failure of the software or hardware has resulted from accidents, abuse, improper

maintenance, or repair, or misapplication by the customer. It is also void if damage is caused by any

unauthorized attachments or if modifications are made to the equipment. Removing or tampering with the

Safety Enclosure will void the warranty, and the customer will assume all liabilities.

This warranty is limited to the original purchaser and is not transferable.

The software will perform according to the accompanying written materials and the medium on which the

software is delivered is free of defects in materials under normal use and service. The warranty is void if

damage has resulted from third party software not intended for use with the system.

The high power focused transducer is designed to give maximal mechanical energy output in water. Permanent

damage to the transducer and electronic circuits could result if the transducer is operated without water.

Operation of the system without water in the water bath voids the warranty.

CONTACT COVARIS, INC. SHOULD YOU HAVE ANY QUESTIONS CONCERNING THE EQUIPMENT

Warranty Services

The purchased equipment is covered by a twelve (12) month warranty which includes all the service and

support necessary so that the customer can operate the equipment successfully. Extended warranties are

available at the end of the original 12 month warranty period.

Services included with the original purchase of the system are:

Technical Support – On-going assistance with the operation or application of the equipment and/or

troubleshooting is provided via:

•Telephone (+1 781 932 3959) during the hours of 9:00am to 5:00pm, Monday through Friday,

oUnited States, Eastern Standard Time (EST)

oGreenwich Mean Time (GMT-05:00)

•E-mail queries to techsupport@covarisinc.com or applicationsupport@covarisinc.com

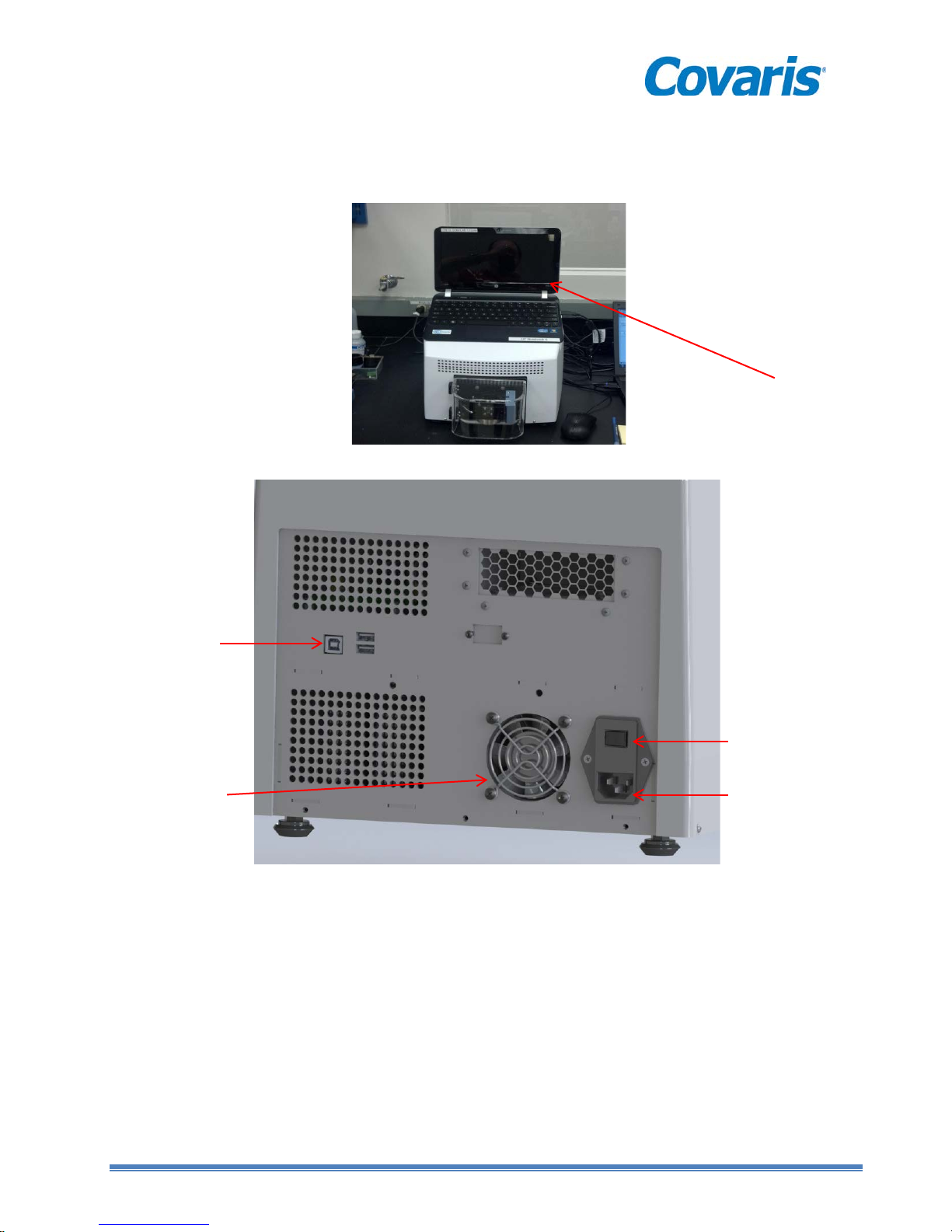

M220 Instrument Repair – Repair of all parts (including the laptop) from normal operation of equipment are

provided in our Service Depot. All labor charges are included. Instrument packaging and ground shipping will

be provided. Failure due to accident, abuse, or improper operation is not covered.

An Operator’s Manual is provided with the equipment. This manual includes sections on the operating

instructions, maintenance guidelines, and troubleshooting tips.