Coxo C-SMART-1 Pro User manual

C-SMART-1

Pro

User Manual

&I

(

E:o197

Introduction

Congratulations

on your purchase of the endo

motor.

Read this operation Manual carefully before use for operating

instructions,

care

and

maintenance.Kee

p

this manual for future

reference.

11

Guarantee

C-SMART

-I

Pro

U11er

Manual

Contents

•

Product

and

technical

services

are in

charge

of our

company,the technical

department

will

provide technical

support

for you when there are

technical

problems.

·The

main unit is

guaranteed

for 24 months from the date of

purchase.

·The accessories (adaptor

and power

cord)are guaranteed

for 6

months.

•

The

guarantee

is valid for

normal

usage

conditions.Any modification

or

accidentaldamage

will render the

guarantee void.

1

General

information······························

·

·1

1.1

Symbols

used in these

operation

manual·······················

·1

1.2

Symbols

used on

Packaging,Device

and

Parts················

·1

2

Indications

for use

.................................

2

3

Contraindication&·······

·

......

··

......

··

......

··

..

2

12

Technical

services

Power

adaptor:

Input

100-240

Vac

50/60Hz

Battery:

DC 7.4V 2600

mAh

Rotation

speed:

150rpm-650rpm

Torque:

0.6-5.2N.cm

Temperatures: Operating

+10" +40"C

Output DC

1

OV/1.5A

Storage

-1

o·

-+55"C

4

Warnings···········································

·2

5

Precautions-

.

.......................................

4

6

Adverse

Reactions·································

,

4

7

Components, installation

and

charging

................

.

5

7.1

Standard

Component&··········································

·5

7.2

Structure

·

·

·

·

·

·

·

··

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

5

7.3

Howtoconnecteachpart

........................................

5

Humidity: Operating 20-80%RH

Storage 20-93%RH

Atmospheric pressure: Operating 80-106kPa

Storage

50-1

06kPa

Protection against electrical shock:

Type B

Protection against

shock type: Type

II

(Adaptor)

7.3.1

Connecting

and

Disconnecting

the Motor

Handpiece········

6

7.3.2

Connecting

and

Disconnecting

the Contra angle-

...........

-6

7.3.3

Inserting

and

Removing

the

lighting

device-·················

6

7.3.4

Inserting

and

Removing

the File-

................

·········

..·

"

7

7.3.5 M1 mode

connection

(only apex

locator

function

)

............

a

7.3.6 M2 mode

connection

(only motor

function}

..................

8

7.3.7 M3 mode

connection

(Dual mode Motor & Apex

locator)·····

8

7.4

Changing

the

Battery-

....................................

·······

·9

7.5

Charging

.....................................................

·

...

·10

8 Step by step

instructions-

.........................

·11

8.1

Language

,

LCD Panel and

Operation

Panel

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·11

8.1.1

8.1.2

8.1.3

8.1.4

Switch-on

and

Switch-off

the

Unit··········

..................

11

Language

Select

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·11

LCD

Pane

l

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·12

Operation

Panel···

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

··

·

·

·13

8.2 Sound Volume and Screen

Brightness

Adjustment-

............

-14

8.2.1 Sound Volume

Adjustment·

................

·········

..........

14

8.2.2 Screen

Brightnes

s

Adjustment·

..................

·········

....

14

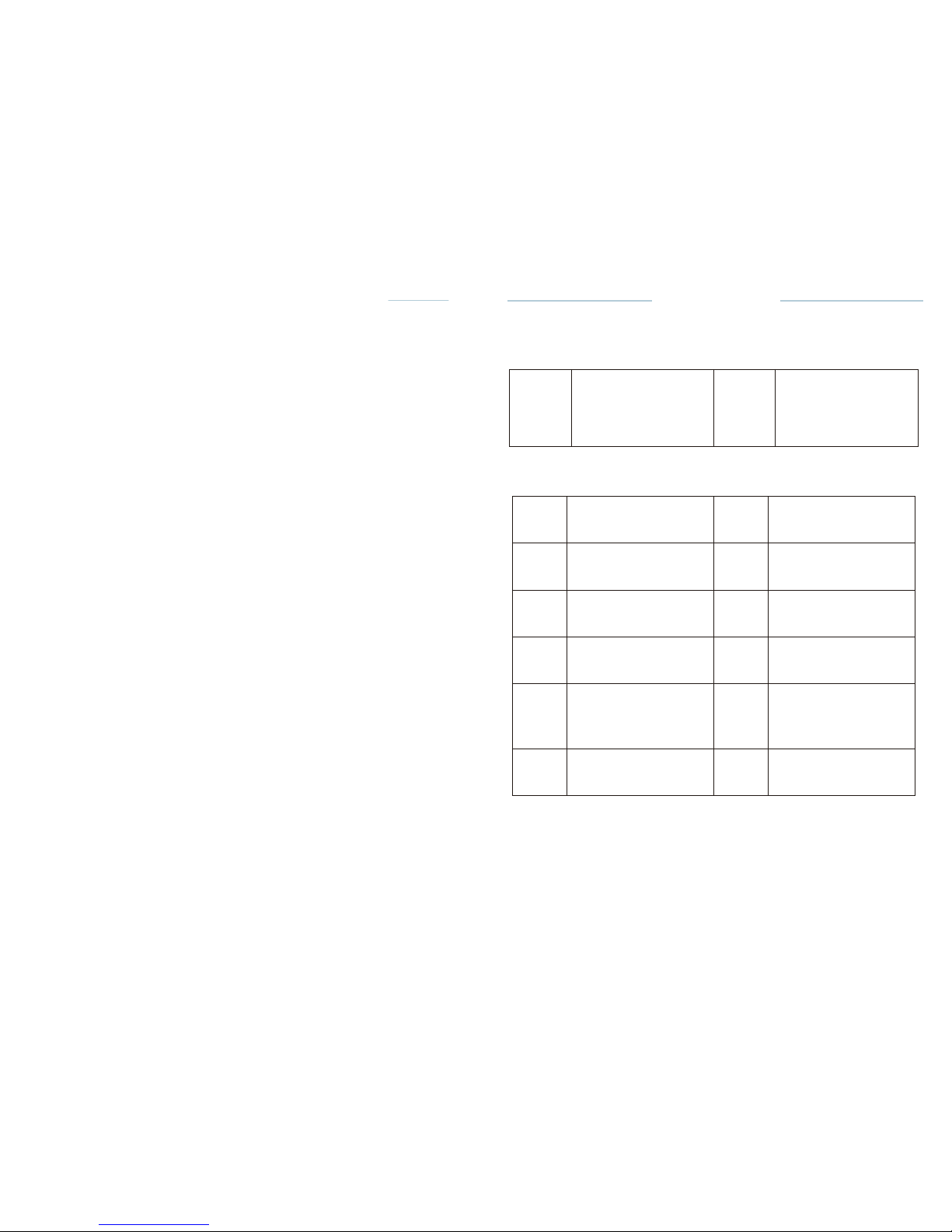

Problem

Cause

Solution

The power

is

not turned

on.

The battery is

bad

.

Change the

battery

.

The

motor

handpiece

does

not

rotate

The motor handpiece or

the

motor handpiece cord

Is

damaged.

Contact your

distributor.

The contra-angle is

clogged.

Clean or replace

the

contra-angle.

There is a short circuit

inside

the motor handpiece or

the

motor handpiece

cord.

Contact your

distributor.

Apex

measurement

is not

correct.

The file has no contact

with

the handpiece or file

holder

correctly.

Check the

connection

between the file and the

file

holder

,

clean it if

necessary.

Motor or test wire is

not

properly

connected.

Check the

connection.

File blocks

in

the root

canal.

Wrong file

setting.

Too much pressure on

the

instrument.

Change the

rotational

direction. Start the

motor

and pull out the file

carefully.

File not frequently

cleaned.

Clean the file

frequently.

8_3

Operation·

........................

·······

........................

··

·14

8.3.1 M2 Apex locator

only(without

motor.)·

..........................

14

0

Troubleshooting

C-SMART-1

Pro Uoer

Manual

8.3.2 M2 Motor only (without apex

locator

)··························

·22

8.3.3 M3 Motor and Apex locator (Dual

mode)······················

·28

8.4 Functional check of the apex

locator·······························

·

31

8.5

Calibration

....................

·········

........................

······

33

8.6 Factory Default Parameters-

......

·········

........................

·

36

If the device is not working

properly

,

please check the following table

before

calling our service

center.

9

Maintenance,

Cleaning

and

Disinfection············

·37

9.1

Genera

l

...................

········

.......................

········

.....

37

9.2

Cleaning,

Disinfection and

Sterilization···························

·

·38

(according to DIN EN ISO

17664)

9.2.1

Pre-treatment··················································

·

38

9.2.2

ManualCleaning

and

Disinfection·····························

·38

9.2.3

Inspection/Maintenance

.......................................

38

9.2.4

Packing·

......

·········

........................

·········

........

39

9.2.5

Sterilization·

..................

·········

......................

···

39

9.2.6 Storage

.........................................................

40

9.2.7 Material

Resistance············································

40

10

Troubleshooting

·········

..

·

..

···

......

··

......

··

..

·

..

41

11

Guarante

e

.

...........................................

42

12

Technical

services

..................................

·42

Ill

WARRING

CAUTION

If the instructions are

not

being followed

properly

,

operation may result

in

hazards for the

product

or the

user/patient.

c::r

NOTE

Additional

informatio

n

,

explanation on

operation

and

performance.

I

Lori

Lot

number

[]]

Refer

to the

operation

manual

Ill

Manufacturer

Fragile

===

Direct

current

Caution

[QJ

Class II

product

Keep

dry!

Type B applied

part

:a

-

Special disposal of

waste

electrical and

electronic

equipment

(

Directiv

e

2002/96/EEC)

IECIREPI

European Union

agent

(

E:ol

97

CE marked

product

C-SMART

-I

Pro

U11er Manual

C-SMART-1

Pro Uoer

Manual

•The rapid

Sterilization

method or the

Sterilization

method of

unpacked

accessories is not

permitted.

•

Also do not use any hot air

Sterilization,no

radiation

Sterilization,

no

formaldehyde or ethylene oxide

Sterilization

and no plasma

Sterilization.

9.2.6

Storage

After

Sterilization,

the instruments must be stored in the

Sterilization

package and kept dry and

dust-free.

1

Genera

l

Information

1.1Symbols

used in these

operation

manual

9.2.7

Material

Resistance

When selecting the cleaning and disinfecting agents, please ensure

that

they do not contain phenol, strong acids or strong aldehyde

disinfectants

or

anticorrosion

solutions. The material is resistant up to 137 °C/279

°F

(maximum exposure

temperature).

1.2

Symbols used

on

Packaging,Device

and Parts

'

*

II

2

Indications

for

use

C·SMART

·I

Pro

Usar

Manual

C-SMART-1

Pro User

Manual

o

Then

remove

the

accessories

from the

disinfection

bath and rinse

them

thoroughly

with water for at least five times for 1

min.and

press and

release

The

device

is the

supplementary root-cana

l

treatment

device which can

assist

the

dentists

to shape more

standard root-canal

in the

process

of

root-canal

treatment

based on the

micro-electronic

control

technology.

This

instrument

contributes

to

alleviate

the

dentist's working intensity.

This

device

must only be used in

hospital

environments,

clinics

or dental

offices

by

qualified

dental

personnel.

3

Contraindication&

o

In cases where a

patient

has been fitted with an

implanted

heart

pacemaker

(or other

electrical equipment)

and has been

cautione

d

against

the use of

small

electrical

appliances

(such as

electric shavers,

hair

dryers,

etc.)

it is

recommended

not to use the

device.

o The

device

should not be used for

severely curved

root canal

preparation.

o

Do not use the

device

for

implant

or any other

dentist procedure outside

endodontics.

f4

Warnings

The

device

must only be used in

suitable locations

and only by

specialized

physicians licensed

to

practice dentistry.

In this

chapter,

a

description

of

serious adverse reactions

and

potential safety

hazards

for the

product

or the

user/patient

is

included.

Read the

followin

g

warnings

before

use.

WARNINGS

o The device must only be used in

suitable locations

and only by

specialized

physicians licensed

to

practic

e

dentistry.

o Confirm that the

operating

voltage and the mains voltage are

compatible.

•

Use the specified battery for this

product.

Never use a battery other

than

those

specified

by

manufacturer.

o

Use the

manufacture

r

AC adapter for this

product.

Never use any other

AC

adapters.

o

If you do not use the device for a long period of

time,remove

the battery

to

avoid fluid

leak.

o

If you

should

notice battery fluid leak,

deformation

of the motor

handpiece

casing or partial

discoloring, immediately

stop use and contact your

distributor

II

the file clip five

times. Inspect,

dry and pack the

accessories

as

quickly as

possible

after

removal(see chapter INSPECTION,

and

PACKING).

Please

make sure that the

accessories

do not have direct

contact.

9.2.3

Inspection/Maintenance

Check all

accessories

after

cleaning

or

cleaning

I

disinfection.

Defective

accessories

should

be

immediately discarded.

These

defects include:

•Plastic

deformation

·Corrosion

Accessories

which are still

contaminated

must be

cleaned

and

disinfected

again.

Maintenance

is not

required.

Instruments

oil must not be

used.

9.2.4

Packing

Please

pack the

accessories

into

disposable Sterilization packages

(single

disposable packaging) meeting

the

following requirements:

•Compliant

with DIN EN

ISOIANSIAAMIISO 11607

·Suitable

for steam

Sterilization

9.2.5

Sterilization

Use only the

Sterilization methods

listed

below

;

other

Sterilization

methods

are

not

permitted.

•Steam

Sterilization

•

Fractional

vacuum/pre-vacuum

(at

least

three

vacuum cycles)

method

or

gravity displacement

method

(product

must be

sufficiently

dry).

The less

effective gravitational

method should only be used if the

fractional

vacuum

method is not

available.

·Steam

sterilize

r

according

to DlN EN 13060 or DIN EN

285.

·The Sterilization validation

has been

performed

in

compliance

with DIN

EN

ISO 17665 (Valid

installatio

n

and

operation qualification

(IQ and OQ)

and

product-specific performance qualification (PQ).

•

Maximum Sterilization temperature

134

ac

(273

GF);

plus tolerance

according to

ISO DIN EN ISO

17665.

·Sterilization

time (exposure time

at

Sterilization

temperatura

)

at

least

18

min.at

134 •c (273

aF).

C-SMART

-I

Pro

U11er Manual

9.2

Cleaning,Disinfection

and

Sterilization

(according

to DIN EN ISO

17664)

The

procedure

for

cleaning

,

disinfection

and

Sterilization applies

only to

the

Lt.

WARNINGS

C-SMART·IPro Uoer

Manual

accessories

lip hook, file clip and

contra-angle.

9. 2.

1 Pre-treatment

Pulp and

dentin

residues

must be

removed immediately

from the

accessories

(within maximum

2 hrs). Do not let them

dry!After

the

accessories

have

been

used on

patients,

place the

accessories

for

cleaning,pre-disinfection

and

interim storage directly

into a bowl filled with an

appropriate cleaning

and

disinfecting solution

(for max. 2 hrs). Then clean the

accessories under

running

water or clean in a

disinfecting solution

to remove all

visible

contamination.

The

disinfectant should

be

aldehyde-free (aldehyde

fixes

blood stains),tested

for

effectiveness

(e.g. CE

mark),

suitable for

accessories disinfection

and

compatible

with the

accessories. Only

use

clean

,

soft

brushes

to

manually

remove

contamination

or a

clean,

soft cloth which you only use for this

purpose.

Do not use metal

brushes

or

steelwool.

For

better cleaning

of the inner parts, the file clip must be

pressed

and

released

five times during

cleaning process. Please

note

that

disinfectants

used for

pre-treatment

are only for

personal

protection

and

do

not

replace disinfection

when

cleaning

is

completed.

The

pre-treatment

process

should be

performed

in every

case.

.&.

CAUTION

Do not use an

automated

procedure

or

ultrasonic

bath to

clean

or

disinfect

the

accessories.

9.2.2 ManualCleaning

and

Disinfection

Cleaning

•

Place the

pre-cleaned

accessories

into the

cleaning

bath for the

prescribed

contact

time, the

accessories

must be

sufficiently covered

(if

necessary careful

brushing

with a soft

brush).

For better

cleaning

of the inner

parts,the

file

clip

must be

pressed

and

released

five times

during cleaning process.

·Then

remove the

instruments

from the

cleaning

bath and rinse them

thoroughly

with water for at least three times for 1 min. and press and

release

the file

clip

five

times.

Disinfection

·Place

the

cleaned

and

inspected accessories

into the

disinfection

bath

for

the

prescribed contact

time; the

accessories

must be

sufficiently covered.

For better

disinfection

of the inner

parts,

the file clip must be

pressed

and

released

five times

during disinfection process.

•Do not

disassemble

or alter the motor

handpiece.

•Do not

expose

the

unit,motor handpiece

or

battery charger

to any

liquid.

•Do not

expose

the device to

direct

or

indirect sources

of heat.

Operate and

store the device in a safe

environment.

•Do not drop the

device.

•In order to avoid

possible

risks due to

electromagnetic interference,

do

not

use any

electrical

medical

device

or

electrical

device of any other kind

in

close

proximity

to the

device.

•The

device

may

possibly malfunction if

used in the

presence

of

an

electromagnetic interference

wave. Do not

install

the

device

in the

vicinity

of any

device

that emits

magnetic waves.

•Do not use the device in the

presence

of free

oxygen

or

anesthetic

substances

or

flammable

products.

•None of the

device components

are

delivered disinfected

or

sterilized:

components

such as control

unit,motor

and motor cable need to

be

disinfected,the contra-angle

and Lip hook needs to be

sterilized

prior

to

first use and in

between

each

patient!

•The

plastic enclosure

is not

sealed

,

do not use any

liquid

or spray

directly

on the unit,

especially

on the

monitor

or near the

electrical

sockets

.

•

Follow

the file

manufacturer's instructions

for use of the

endodontic

files.

•The file

system

shown on the

display

must always match the file in use.

This

is of the utmost

importance

in order to

avoid misusing reciprocating

files

and

continuous

rotary

files.

II

C-SMART-1 Pro Uaer Menual C-SMAI[J-J Pro

u

..

r

M•nuel

5

Precautions

9 Maintenance, Cleaning and

Disinfection

•Read these safety precautions thoroughly prior to

use

.

Thes

e

precautions

allow

you to use the product safely, preventing harm to you and

others.

•Refer to the WARNINGS chapter to verify any special care to exercise

before

starting to use the complete

device.

•Before changing the

contra

-

angle

or file, turn off the power of the unit.

Changing

with the power kept on may cause unintended rotation by

accidentaltouc

h

of

the

ON/OFF

key

.

•Always clean the shank

ofthe

file to be

installed.Allowing

dirt to enter the

chuck

could cause loss of

concentricity

and

deterioration

of chucking

force.

•Pay attention to the direction of the battery connector when

installing.

Forcible

setting In the wrong direction may cause damage and fluid leakage due to

a

short

circuit.

•Fully-charged

rechargeable

batteries generally discharge gradually over

time

even though the device is not used. It is recommended to recharge the

battery

just before

use

.

•When disposing of the control unit, follow the

instructions

of your

local

government for disposal, as they contain materials which may become

industrial

waste.

•This product does not consider a patient's age,

gender

,

weight or

nationality.

The manufacturer declines any

responsibility

in the case

of:

•Use of the device for applications other than those specified In the

instructions

for use and

maintenance.

•Modifications or repairs performed by persons not authorized by

the

manufacture

r

.

·Use

of

non-original

components or components other than those specified in

the

Standard Components chapter_

•File breakage due to

missus

•Accessories or device breakages due to

sterilizatio

n

:

none of the

device

components are

sterilizable

(except for the

contra-angle).

6 Adverse

Reactions

There are no known adverse

reactions.

II

9.1

General

The device is maintenance free and does not contain user serviceable

parts.

CJ='NOTE

Service and repair should be provided by factory trained service

personnel

only

.

•The surface of the device

,

test wire ,lip hook wire, motor cable and

lighting

device should be cleaned using tissue or soft cloth soaked with aldehyde

free

disinfecting and detergent solution

(bactericidal

and

fungicidal

)

.

&cAUTION

•Wipe The surface

ofthe

device

,

test wire ,lip hook

wire,motor

cable

and

lighting device with a clean

cloth,lightly

moistened with a

non-aggress

i

ve

disinfectant

.

•Do not apply any liquid or spray directly on the

device,especially on

the

display

.

•Do not use high-proof alcohol for

d

i

sinfection

.

•The accessories lip

hook,

file clip and contra-angle must be cleaned,

disinfected

and sterilized prior to each

use_

Thorough cleaning and disinfection are

essential

prerequisites

for effective

Sterilization.The

specific Instructions for

cleaning/

Sterilization

must be applied according to the

Instructions

in chapter 9.2

·cleaning,

Disinfection

and

Sterilization

•

.

In

addition,the

operating

instructions

of

the

devices used in your practice must be followed.As part of your

responsib

ili

t

y

for

accessories

sterility

,

always ensure that only

val

i

date

d

methods for

cleani

n

g

/

dis

i

nfect

i

on

and

Sterilization

are used, that devices

(dis

i

nfector,sterilize

r

)

are

regularly maintained and inspected and that the validated parameters

are

maintained with each

cycle.

•In

addition

,

always observe the validated legal regulations and

regula

t

ions

on

hygiene relating to your practice or the hospitaL This applies in particular to

the

guidelines regarding effective prion

inactivatio

n

.

•For your own safety, always wear protective gloves, glasses, mask

when

handling contaminated

accessories.

=

b

.....

-

C-SMART

-I

Pro

Usar

Manual

8.6

Factory Default Parameters

To return to the

original

default

parameters,

follow the

general

reset

instructions:

@

SETUP

C-SMART-1

Pro Uoar

Manual

Components,

installation

and

charging

7.1

Standard Components

A

E

I

.

Intlllhnml•r gu•l•

A

: :!

'!!

IIAute-n•IIKMM

F

!!!

n

.ht

!

:c

dlll)

'·-

8

:=

-

.....

....

B

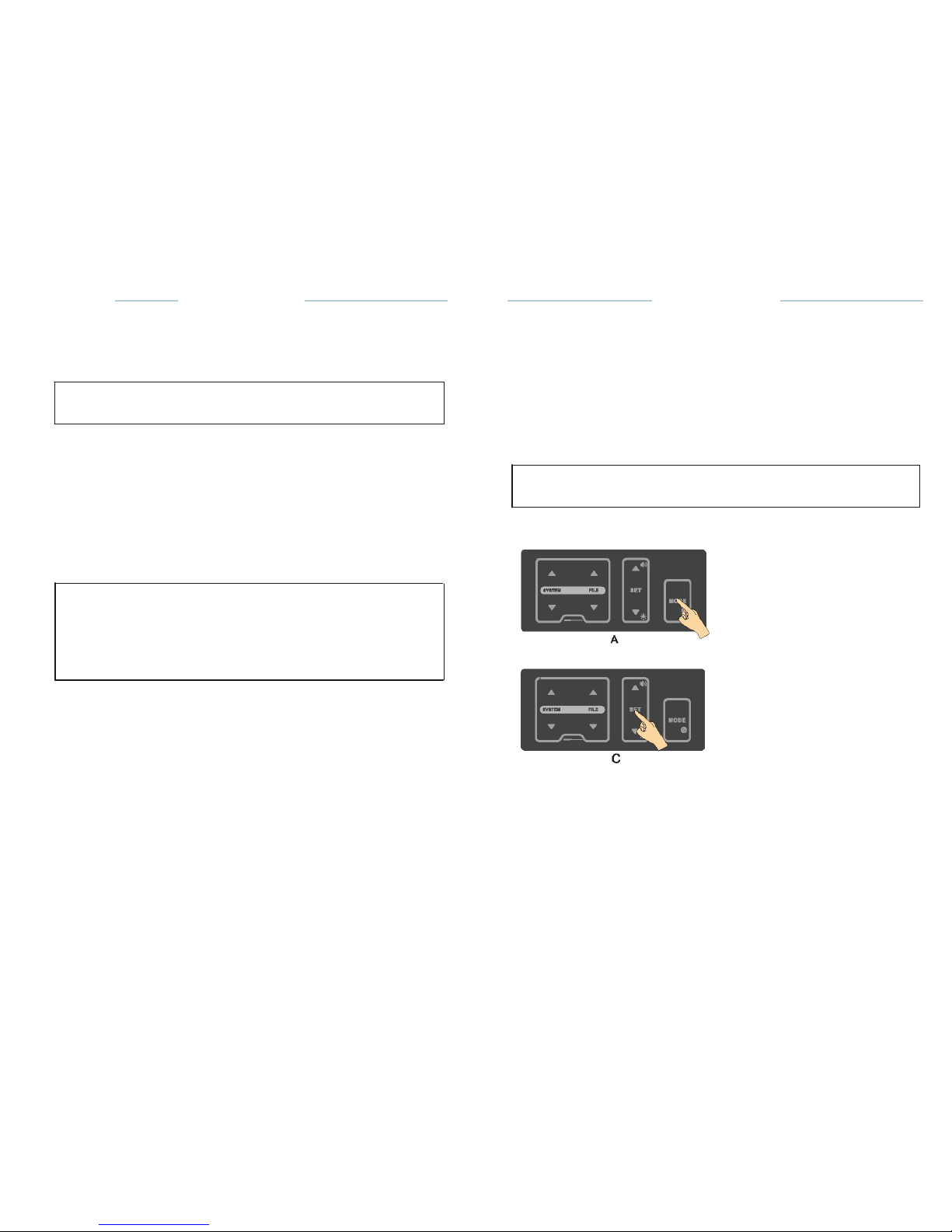

•Press the SET key to enter the RESET

state;

Engliah

•

ON

•

ON

•

Contro

l

unit Motor

handpiece

#I

Contra

angle

(

External

)

File

clip

•Press the MODE key for 2

seconds

(A) to enter setting

interface;

•Press Up or Down key to select RESET

(B);

•When the

factory

reset is

complete,

the

display returns

to the M1

interface.

.&.

CAUTION

Please

note: when the

factory settings

are

restored,

all

personal

settings

Lip hook Test

wire

Lip hook

wire

Lighting

device

D

will be

lost.

'

Handpiece

stand

Operation

Manual

Tester AC

adapter

7.2

Structure

CD

Charging

socket

I

test wire

socket

® Lip hook wire

socket

@ Motor

handpiece socket

@ Power

button

Fig.

1

II

C-SMART

-I

Pro

Usar Manual

C-SMART-1

Pro Uoar

Manual

7.3 How

to connect

each

part

CAUTIONS

Do not pull on the wire when removing the part with the

wire.

L

.

_

i

error

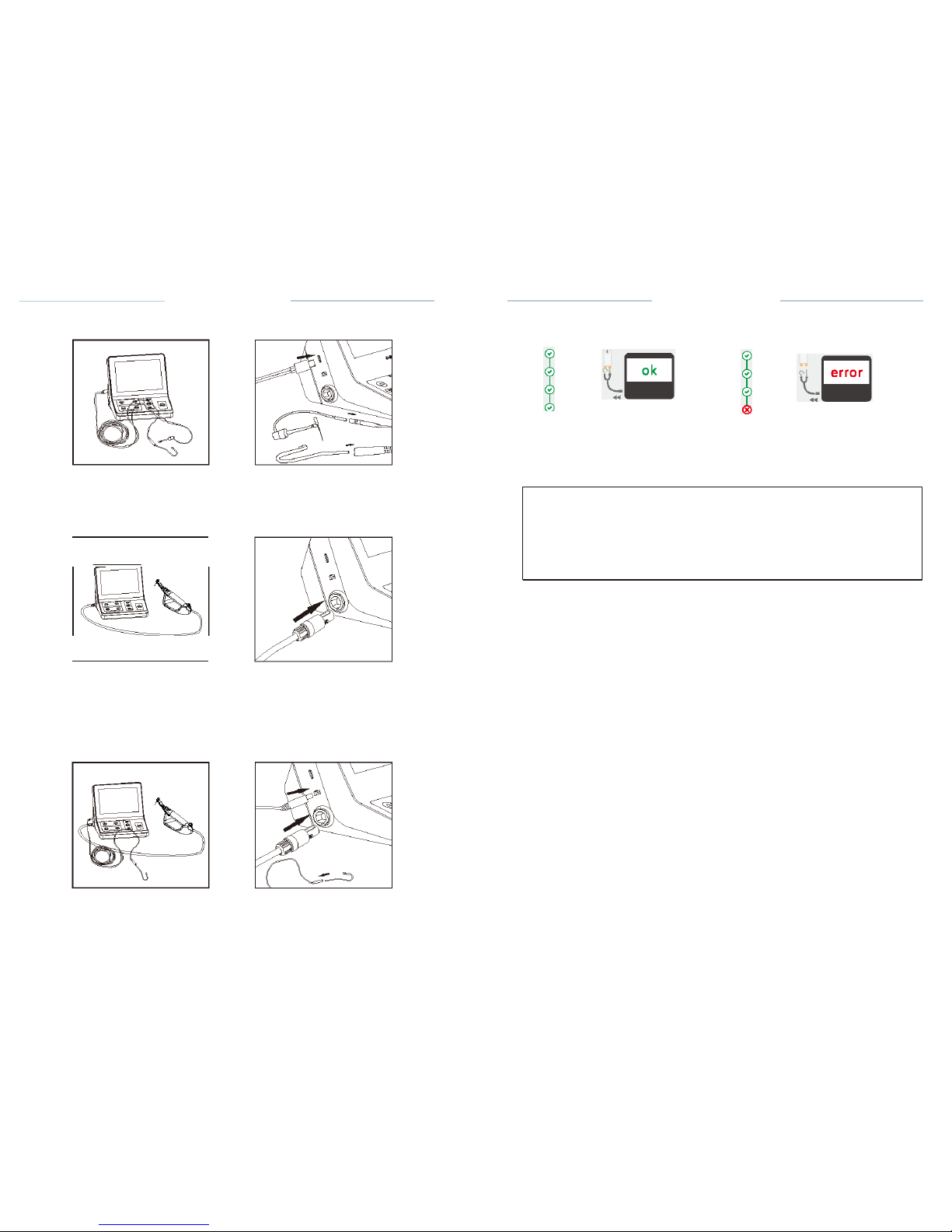

7.3.1Connecting

and

Disconnecting

the

Motor Handpiece

a.

Connecting

Align

the--

mark of the cord plug with the notch of the motor handpiece

socket

(see

Fig.)()()()

at the left

side

of the

device

and

insert

the

plug unti

l

it locks.

b.

Disconnecting

Hold the plug ring and pull it out. Do not twist in any

direction.

7.3.2

Connecting and Disconnecting

the

Contra angle

a

.

Connecting

The contra angle can be connected at 6 adjustable head

positions.Align

the

positioning

pins of the contra angle with the

positioning

slots of

the

motor handpiece and insert the head until it

clicks.

b.

Disconnecting

When removing the contra angle, pull it straight

out.

CAUTIONS

•When connecting and disconnecting the contra angle, turn the power

off

beforehand.

•Check that the contra angle is securely assembled to the motor

handpiece.

Fig.39

Contra-angle

is OK Fig. 40

Contra-angle

is ERROR

!Lt.

CAUTION

ERROR message indicates that the contra-angle is not operating

properly

Please contact your local dealer or contact the factory directly for

assistance

r::.7'

NOTE

Should you at any time wish to stop the calibration process, turn the power

oft.

Calibrate every time the contra angle is lubricated or replaced after sterilizing

,

or at least once a week

(Lubricating

the Contra angle

,

Cleaning

,Disinfection

and

Sterilization

see the operation manual of contra

angle).

Do not touch or apply a load to the contra angle chuck during

calibration.

7.3.3

Inserting and Removing

the

lighting device

a.

Inserting

Insert the lighting device into the motor

handpiece(Fig.2),

clamp the

contra

angle and

file

(

Fig.3

)

.

Fig.2

Fig.3

0

e

8.5

Calibration

C-SMART·

l Pro Uaar

Manual

b.

Removing

C-SMART·IPro Uoar

Manual

This

function

is to

decrease fluctuation

in the

rotation

speed of the

motor

handpiece

and the

difference

in

torque

by the contra

angle.

Calibration

is

recommended

when using a

new/other

contra

angle or

after

an

extended

period of

operation,

as the

running properties

can change

with

usage,

cleaning

and

sterilization.

Sliding

it in the

direction

of the socket and then

removed

with

contra-angle,

Otherwise

it will be

damaged.

The

calibration

steps as

follows:

·Turn

the power

on.

0

SETUP

.&.

Fig.4

Fig.5

A

ld

.

.

,.MII"'

·

A

.,

...

-

. ·

;

.tit

,.

'i

tt

:

l

L

E

EDdiiiJt!Mt.

: T torvw

Engllah

•

ON

•

ON

•

CAUTIONS

When

inserting

and

removing, please

do not

shake,

so as not to

damage

the

plug.

8

=

torNWI,.fMIGIIJMtlll'll

B

•Press the MODE key for 2

seconds

(A) to enter

setting interface;

•Press Up or Down key to select

calibration (B);

·Press

the SET key to enter the

calibration

state:

•The

screen

will be

prompted

to insert the motor

handpice

(

Fig.37

)

;

•

During

the

calibration process

the

display

will read

(Fig.38):

7.3.4

Inserting

and

Removing

the

Fila

a. File

insertion

•Insert the file into the chuck until it

stops.

•

Lightly

turn the file until

it engages

with the

latch mechanism. Push

inwards

to

click.

b. File

removal

Press the

push-key

and pull out the

file

.

_,

r:::-1

0

0

.

-

.&.

CAUTIONS

•

When

attaching

and

detaching

the file, turn the power off

beforehand.

•

After the file is

locked

in

place, lightly

pull out the file to make sure the

file

is

locked.

•

Always

clean

the shank of the file to be

installed.Allowing

dirt to enter

the

chuck could cause

deterioration

of

chucking

force.

Fig. 37 Insert the motor

handpice

Fig. 38

Cerebration state

·The

motor

handpiece

begins to

rotate: leave

it as

it

is until

it stops.

·When

the

calibration process

is

completed,the rotation

stops and

the

display reads:

·Then,

the

display returns

to its

originalstate.

II

C-SMART

-I

Pro

Uaer

Manual

7.3.5 M1 mode

connection (only

apex

locator function)

C-SMART-1

Pro Uoer

Manual

Fig. 35 Accessories are OK Fig.36 Accessories are ERROR

Fig.6

Fig.7

Connect the test wire with lip hook and the File clip to the Control unit,

test

wire's plug must be fully inserted into the test wire

socket.

Lt.

CAUTION

7.3.6 M2mode

connection (only motor function

)

Fig.B

Fig.9

•Connect the motor cable to the

Controlunit's

motor handpiece

socket.

•Connect the contra angle to motor

handpiece.

•Install

the lighting

device.

•Insert

the

file.

7.3.7 M3 mode

connection(Dual

mode

Motor&Apex

locator)

Fig.10

Fig.11

ERROR message indicates that the accessories are not functioning

properly

(wire breakage) or the contact area is

dirty.

Please contact your local dealer or contact the factory directly for

assistance

CHECK mode will exit automatically after 3s

.

C-SMART

-I

Pro

U11er Manual

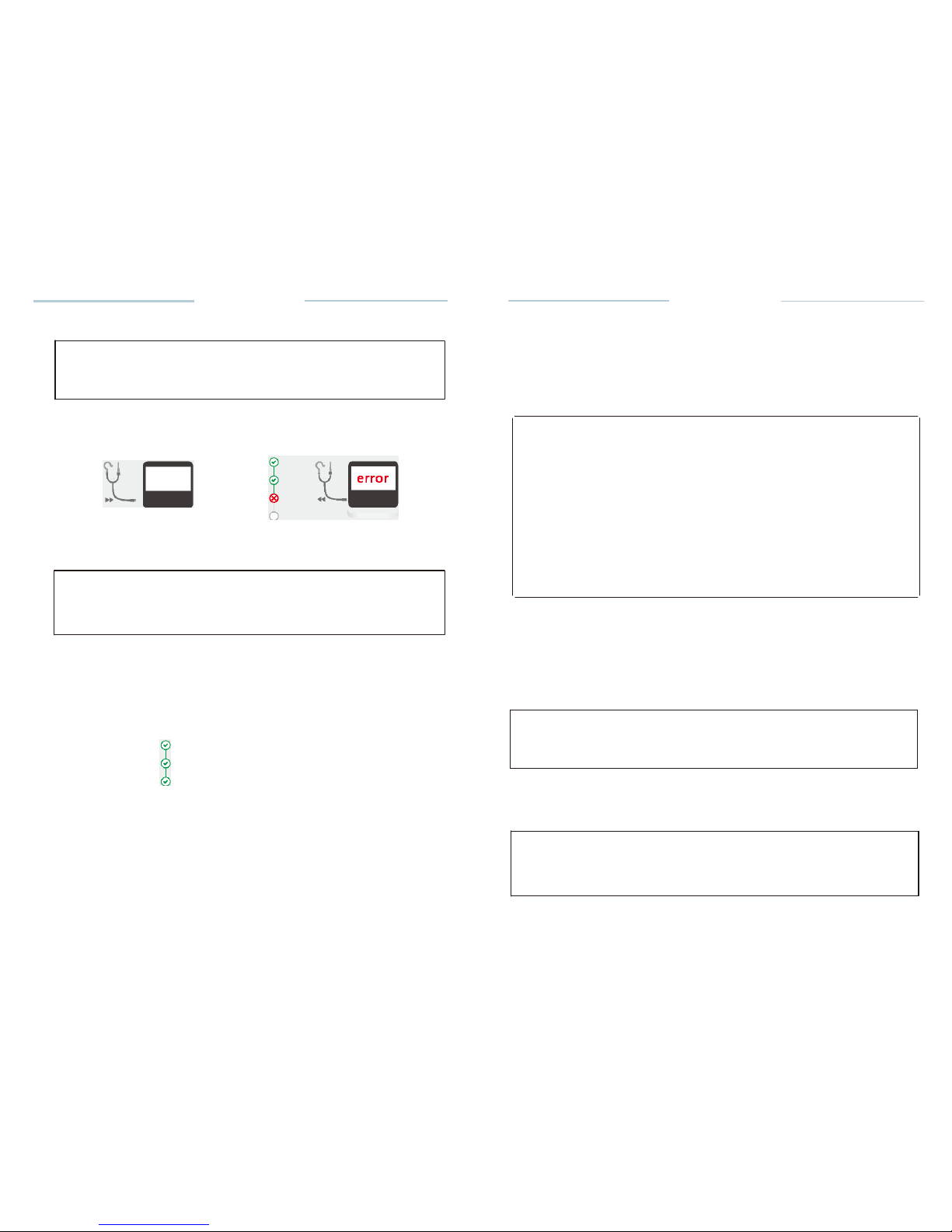

Test Wire Functional CHECK

NOTE

If the device functional CHECK is OK, then you have to proceed to

the

cables

functional

CHECK.

Connect the test wire to the device

(Fig.32).

0

0

Fig. 32 Connect the test wire Fig.33 Test wire is ERROR

.&.

CAUTION

ERROR message indicates that the test wire is not operating properly.

Please contact your local dealer or contact the factory directly for assistance.

•Insert the File clip and lip hook (or replace the lip hook with another File

clip)

in the test

wire.

•Connect File clip and lip clip (or a second File clip) to the contact strips

on

the tester as shown on the screen(Fig.

34).

't.

0

Fig.34 Connect

tester

•Cables CHECK will start

automatically

and the

results

-

either OK (Fig.

35)

or ERROR (Fig.

36)-

will be shown on the

screen.

C-SMART

·I

Pro

User

Manual

•Connect the motor cable to the Control unit's motor

socket.

•Connect the contra angle to the motor handpiece and insert the

file.

•Install the lighting device and catch the

file.

•Connect the lip hook wire to the Control unit and connect the lip

hook.

7.4

Changing

the

Battery

.&.

CAUTIONS

PRECAUTIONS ON CHANGING BATTERY:

•Do not open any part other than the battery

cover

•Be sure to purchase and use only the recommended

battery.Otherwis

e

,

battery may cause

damage,fluid

leakage or

explode.

•Ensure that the AC adapter is disconnected and turn off before

changing

the

battery.

•Do not change the battery with wet hands as this may cause

short-circuiting

of the battery and moisture infiltrating the

device.

•The used battery must be disposed of in accordance with the

local

regulations.

•Turn the power

off

•

Disconnect the AC

adapter.

•

Remove the screw from the cover with a screw driver, and remove

the

battery

cover.

•Insert the battery cord connector into the device connector in

accordance

with the polarity indication inside the battery compartment and place

the

battery into the compartment with care so as not to catch the

cord.

NOTE

In case of difficulty in inserting the

connector,the

polarity may be

incorrect.

Do not insert it by

force.

•Close the battery cover and lock the

screws.

•If

you need to replace the battery,remove the battery and unplug

the

battery

connector.

.&.

CAUTIONS

When removing the battery cord, make sure to hold it at the

connector.

Failure to do so may damage the

cord.

II

7.5

Charging

C-SMART

-I

Pro

U11er

Manual

C-SMART-1

Pro User

Manual

8.4 Functional check of the apex

locator

Charge the

battery according

to the

following steps:

•Connect

the

charger's connector

to the

Control unit's charging socket

G)

(Fig.

12).

•Connect

the plug of the

charger

to a power

outlet

•

It

takes about 4 hours to fully

charge

and about 5 hours for fully

discharged

batteries

(

E.g.,

the

device

is not used for a long

time).

•

When

charging,

the

charging

status will be

displayed

on the

screen.

(Fig.13)

7

-

0%

Fig.12

Fig.13

r:::T

NOTE

In case of

difficulty

in

inserting

the

connector,

the

polarity

may be

incorrect

Do not insert

it

by

force.

It is

recommended

to check the

performance

of the Apex

Locator

once a

week.

With the

built-in inspection

function,

the

special

test plug can

automatically

check the basic

functions

of the

instrument

in the first step, and then

inspect the

accessories

in the second step (Fig.

29).

e

0

0

0

Fig.29

Device

inspection

The

specific

steps to use the check

function

,

as

follows:

•Disconnect

the test wire,

adapto

r

and motor

handpiece

from the

device.

·Device

CHECK will start

automatically if

the tester

inserted

in the

device and

the

results

will be shown on the

screen.

•Display

shows OK (Fig. 30)

,Indicates

that the device

function

is

normal

.

·Display

shows ERROR (Fig_

31),Indicates

that there is a

fault

0

0

0

0

Fig.30 Device

is OK

Fig.31 Device

is

ERROR

.&.

CAUTION

ERROR

message indicates

that the

device

is not

operating properly.

Please

contact

your local

dealer

or

contact

the

factory directly

for assistance_

•

Disconnect

the tester from the

device

and

prepare

the test of the wire

with

accessories.

Ill

Torque

bar

C-SMART

-I

Pro

U11er Manual C-SMART·IPro Uoer

Manual

8 Step by step

instructions

When the motor handpiece starts and its load reaches approximately half

of

the preset torque limit value, the torque bar display••••• ,when the

load

approaches the torque limit value, the torque bar displaY•••••

II

.

r:::.7'

NOTE

This function is only available in continuous rotary file

system.

Working length

determination

o

In M3 mode,As soon as the file makes contact with the root

canal,the length

measurement is started. During the apex area, with further progression

of

the file in the root canal, the numerical value on the graphical scale

changes.

The unit emits

audible.

o When the file tip reaches the DR'S CHOICE apex

position,it

indicates

that

the apex is reached. The motor

automatically

reverses or stops

depending

on the selected auto reverse

mode.

8.1

Language,LCD Paneland Operation Panel

8.1.1

Switch-on

and

Switch-off

the

Unit

o Hold down the POWER

button@

(Fig. 1)for more than 2

seconds.

A welcome screen is

displayed.Then,

the display will return to the

last

mode before switching the device

off.

o Press the POWER button again to turn off the

power.

r:::.7'

NOTE

If 5 minutes pass without operation, the power turns off

automatically.

8.1.2

Language Select

@I

SETUP

&cAUTION

Do not forget to connect the lip clip to the patient prior to

measurement.

Occasionally, the graphical scale will make a sudden drop as soon as

the

file is inserted into the root canal, but it will return to normal state as the file

is advanced down towards the

apex.

8.3.3.9 Functional check of the apex

locator

It is recommended to check the performance

ofth

e

Apex Locator once

a

week. the detailed check methods, see Chapter 8.4

.

A

..

o:t

d

'"-"

1

'"'

'

''

"

'"

IR

!

AIIIO-

ruMtMi

e

;;

:

fg

:

ht

:

d

E

..

.,-ttrn&

RKJ .....

u•

El

!!

E

iD

...... IMfi"l

B

English

•

ON

•

ON

•

o Press the MODE key for 2 seconds (A) to enter setting interface

(

B

)

;

o Press the SET key to select the desired language

(C);

o

The change will be saved automatically. Press any key other than SET and

up or down key to exit the setting, or exit the setting

automatically

after

3

seconds.

m

A

Working

area

Displays

operating parameters

in

different modes.

B

Mode

area

The device can be

operated

in three

different modes:

M1: Apex

locator only,

M2: Motor

only,

M3:

(Dualmode)

Motor with apex

location

function.

c

Motor

option

area

Display

motor

rotation direction,

auto

reverse,

lighting

and LED delay

time.

*M2 and M3 are

available

D

Status

area

BATTERYdisplays

the

present remaining

amount

of

the

battery

:

CJJ Full

charge

[

-

!!]

Less than 30%

remains.

E:!]

Approximately

30-80%

remains.

The

remaining amount

of

batter

y

mark

indicates

a

voltage

. When a load is

applied

to the

motor

handpiece,

there

remaining amount

of

battery

mark

appear

to be come

lower.

SOUND

VOLUME displays

the

current

sound

volume

(see

chapter

6.5.7. Sound Volume

Adjustment).

4 marks can be

displayed:

OJ

High

volume

rm

Low

volume

Minimum

volume

1:1

Limited

off

I

C-SMART-

l Pro Uaar Manual C-SMART-lPro Uoar

Manual

8.1.3 LCD

Panel

,---------------- ---------------

-

1

SYSTEM:

CI!Mwo

SPEED:

I

Wave

0

150

..

m

l

FlU: TORQUE

liJ

ID

IDCKJ 0.6 N<m

I

@J@J

: •••••

II

Fig.14

LCD

Panel

8.3.3.5 Changing

Speed,

Torque and set

Changing

Speed and

Torque

•See

8.3.2.5 Changing

Speed and

Torque

Set the DR'S CHOICE apex

position

Follow

these steps to set the DR'S CHOICE apex

position:

•

Press the SET key, the apex

setting

icon

becomes

adjustable

state,(Fig.28)

·Press

the Up or Down key to

adjust

the apex

position.

Path File

·-

0

•pm

SYSTE

M

:

l:loaru-

SPEED!

15

Fn.E

:

0.6

••m

·Cill

mm

mCill

•••••

I

l

-

8.3.3.6

Auto

Reverse

Fig.28

Set Apex

Position

Battery

is

drained

or very low

battery voltage.

Charge the

battery.

r::::7'

NOTE:

See

2.3.2.6

Auto

Reverse

8.3.3.7

LED

lighting function

See

2.3.2.7

LED

lighting function

8.3.3.8 Working

Start and stop the Motor

handpiece

The motor is

started

and

stopped

with the ON/OFF key on the

handpiece.

fyou

press the

ON/OFF

key briefly, the motor

handpiece

starts.

If you

re-press

the key,

it stops.

Reverse

Press the on I off

button

for more than 2

seconds

to change the

direction

of

file

rotation (whether

the motor is

stopped

or

running).

The

current direction

of file

rotation

is

displayed

in the motor option

area.

Means

forward

rotation

Means

reverse rotation

r::::7'

NOTE

Only

continuous rotary

file

systems

can

change

the

direction;

reciprocating

file

systems

can not change the

direction.

....

....

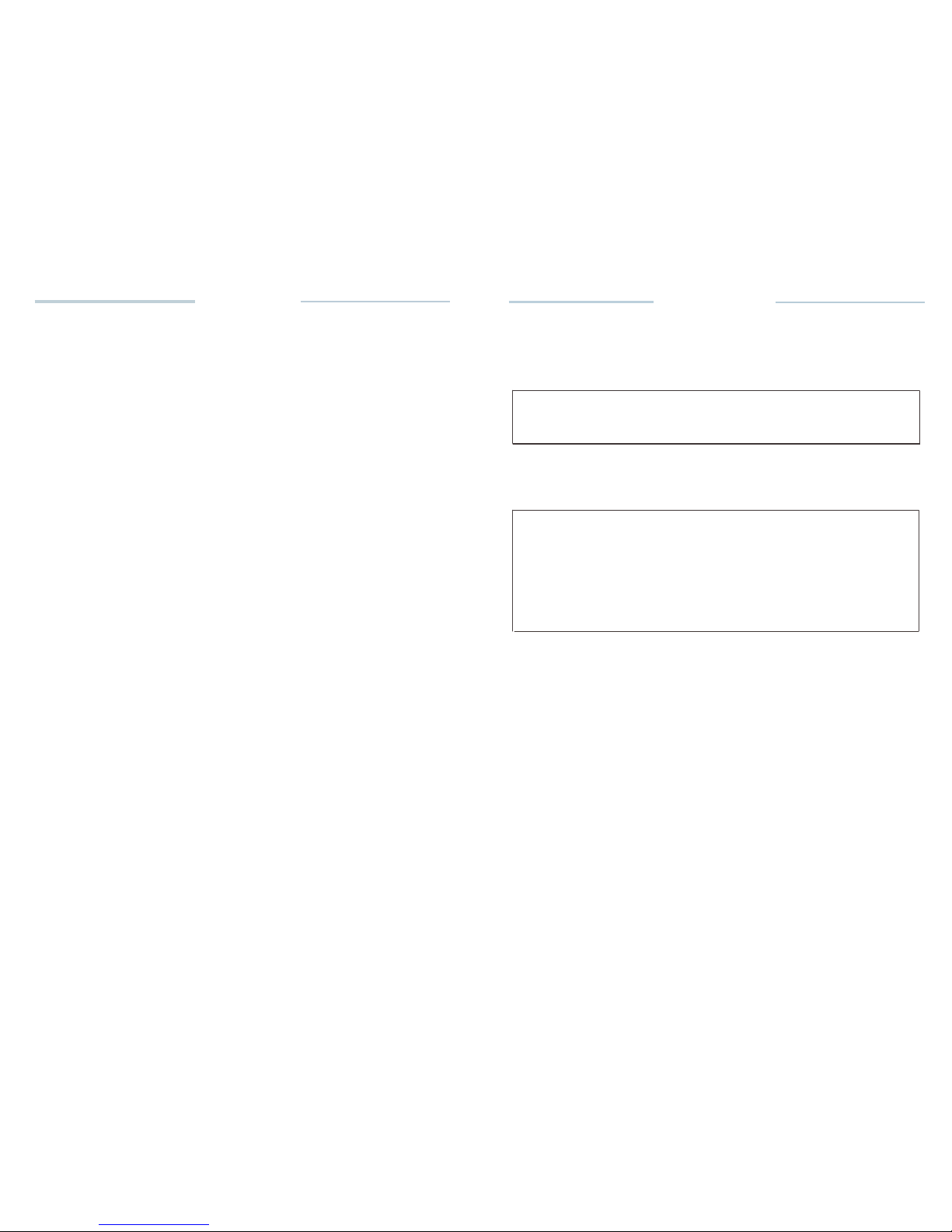

D

....

T

1

SYSTEM

See2.3.2.3

2

FILE

See2.3.2.3

3

SPEED

See2.3.2.3

4

TORQUE

See2.3.2.3

5

TORQUE

BAR

See2.3.2.3

6

ROTATIONAL

DIRECTION

See2.3.2.3

7

AUTO

REVERSE

See2.3.2.3

8

Motor

and

LED

lighting

See2.3.2.3

9

Root

apex

Area

Specially

shows

the Root apex area

and

indicates where

the file

was

reached.

1

SYSTEM

.lit./,.

Change the file

system.

2

FILE

Change the file within a

system.

3

SET

Press this key to

adjust

the

different parameters.

4

[

...

>

>

]

a.Up

key

b.Adjust

the sound

volume(idle

state)

5

..

a. Down

key

b. Adjust the

screen brightness(idle

state)

6

[

•oo

]

;

a. Short press to switch

between

3

operating

modes: Apex

Locator,

Motor

,

Dual

mode

b. Long press to enter setting

interface.

m

•

C-SMART

-I

Pro

U11er Manual

8.3.3 M3

Motor

and

Apex

locator

{Dua

l

mode)

Press mode key to enter M3 mode. In this mode, as a

combined unit

(Dual mode) when the apex

location function

drives the

endo-motor.

8.3.3.1 Connection

The

connection

method in this mode is shown in

chapter

7.3.7

Fig.1O,Fig. 11.

8.3.3.2 Calibration

Calibration

is

recommended

when using a new

contra angle,

the

detailed

calibration methods,

see

Chapter

8.5.

8.3.3.3 Working area

SYSTEM: S EEO:

150

,.m

C-SMART-1

Pro User

Manual

Screen

Brightness display

the

Brightness

of

the

screen (see

chapter 8.2.2.Screen Brightness

Adjustment

)

.

4 marks can be

displayed

D

Status

area

n

brightest

bright

darker

dark

8.1.4

Operation Panel

Path

File

TORQUE

8

FD.E: 0.6

Ncm

Cill

mm

-

.....

l

l

Fig.27 M3

interface

Fig.15

Operation

Panel

[

:;:

[

8.3.3.4 System

and File

Select

See

8.3.2.4 System

and File

Select

Table of contents

Other Coxo Medical Equipment manuals