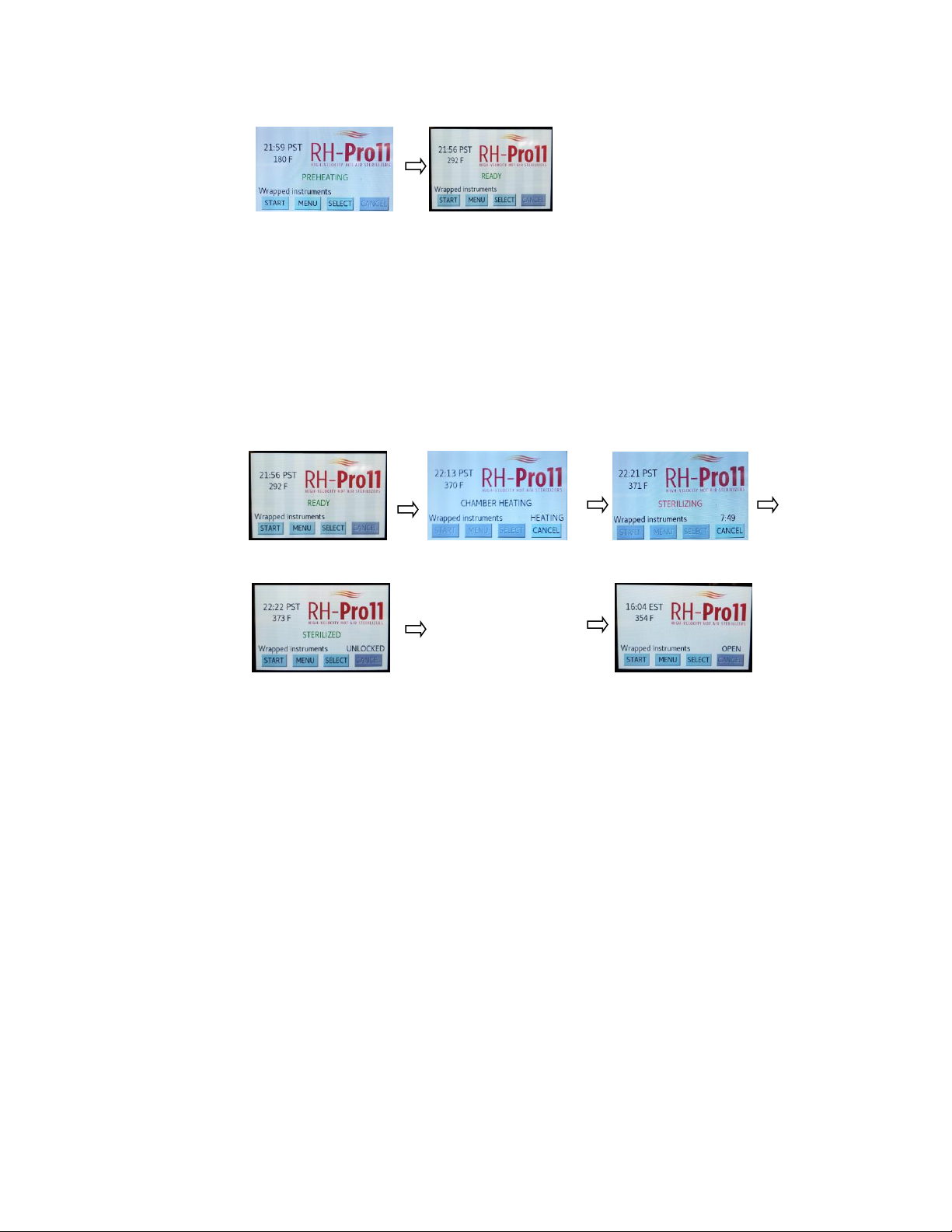

CPAC RapidCyde RapidHeat RH-Pro11 User manual

Table of contents

Other CPAC Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

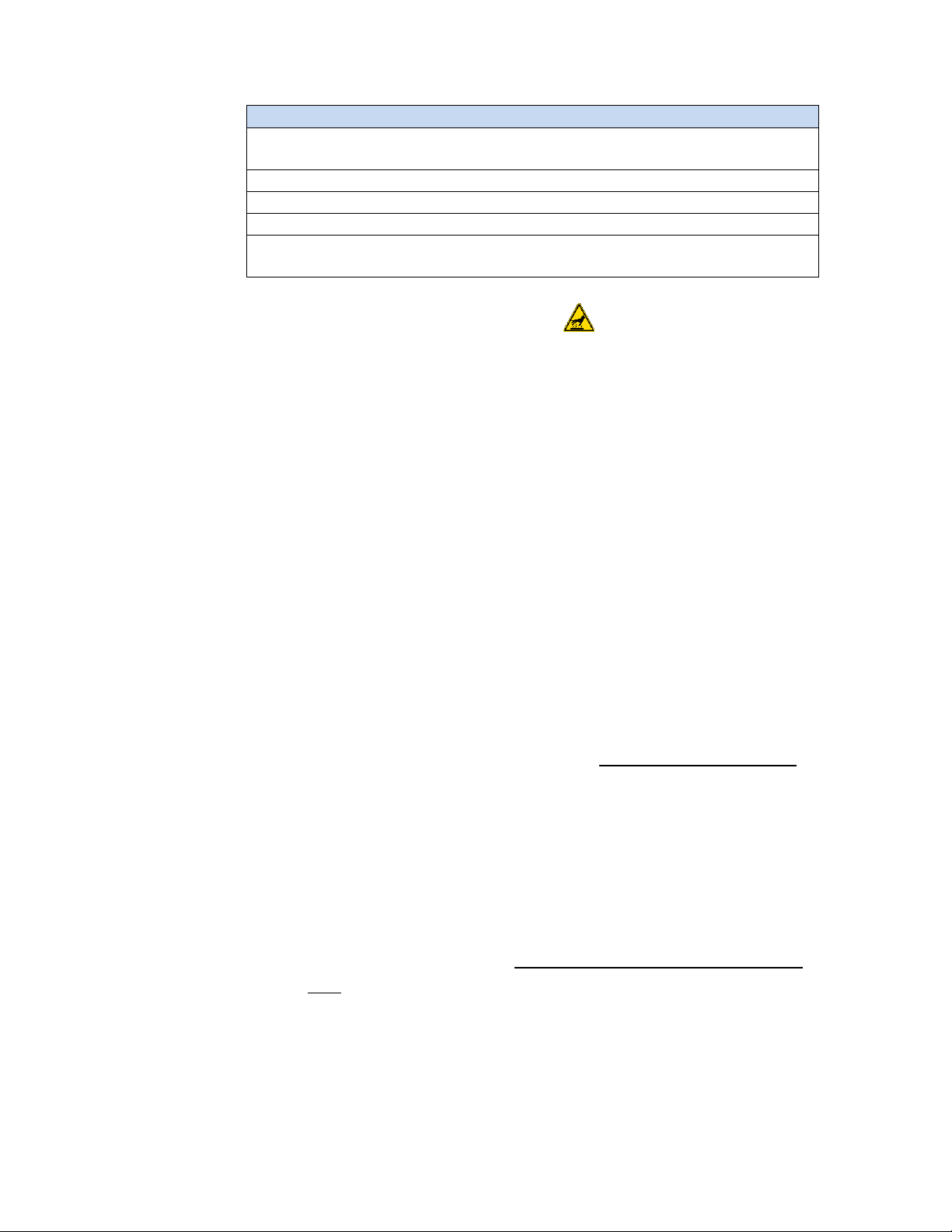

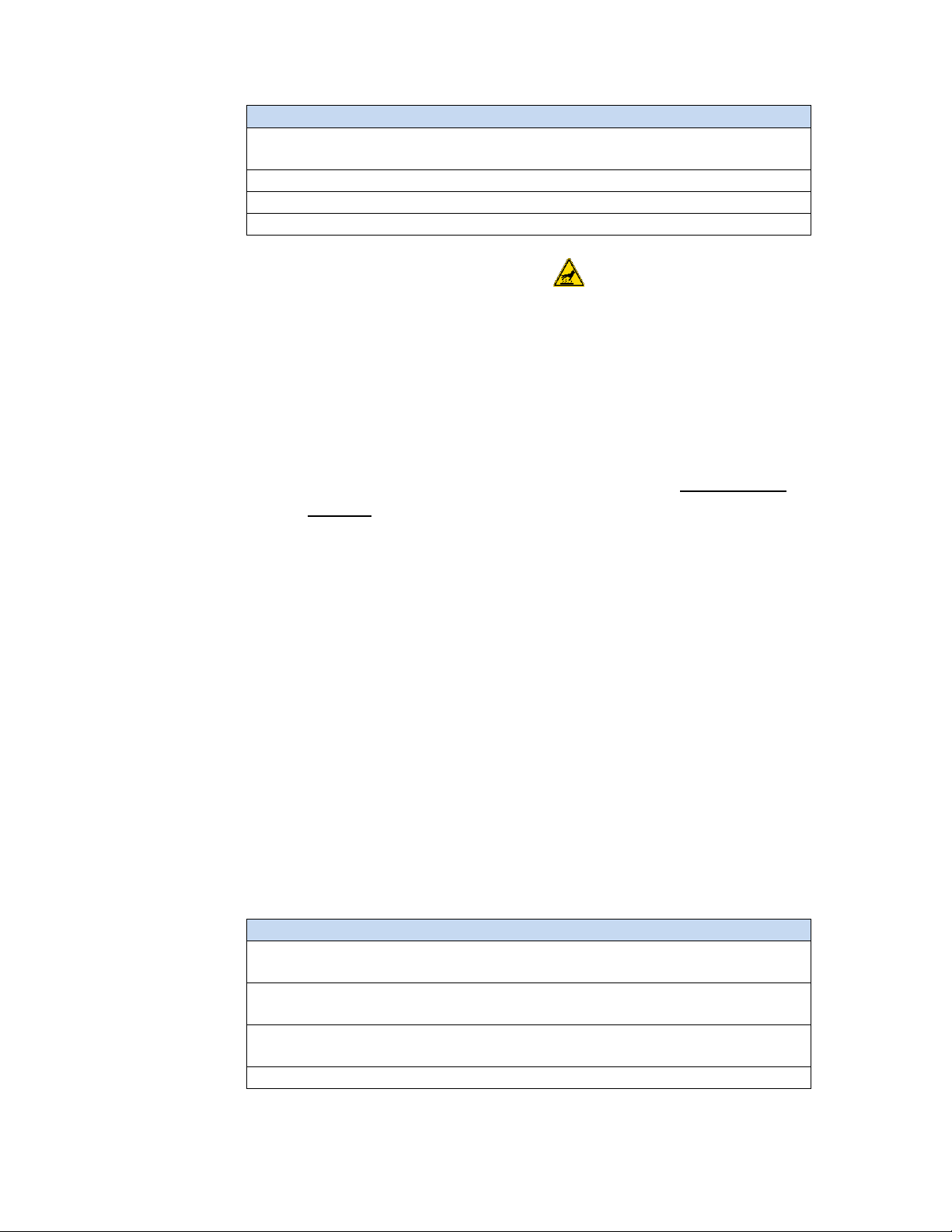

DNA

DNA DTlite Operation manual

PASCO

PASCO ME-9892 Instruction Manual with Experiment Guide and Teacher's Notes

Henry Schein

Henry Schein Maxima Turbo Instructions for use

Sakura

Sakura Tissue-Tek Prisma Plus Quick reference guide

iET

iET SRL Series Operation manual

3M

3M Attest Auto-reader 390 Operator's manual

Bibby Sterilin

Bibby Sterilin Techne TC-512 Operator's manual

IKA

IKA ULTRA-TURRAX Tube Drive P control manual

Curiox

Curiox Laminar Wash HT2000 user manual

Parr Instrument

Parr Instrument 4540 Operating instructions manual

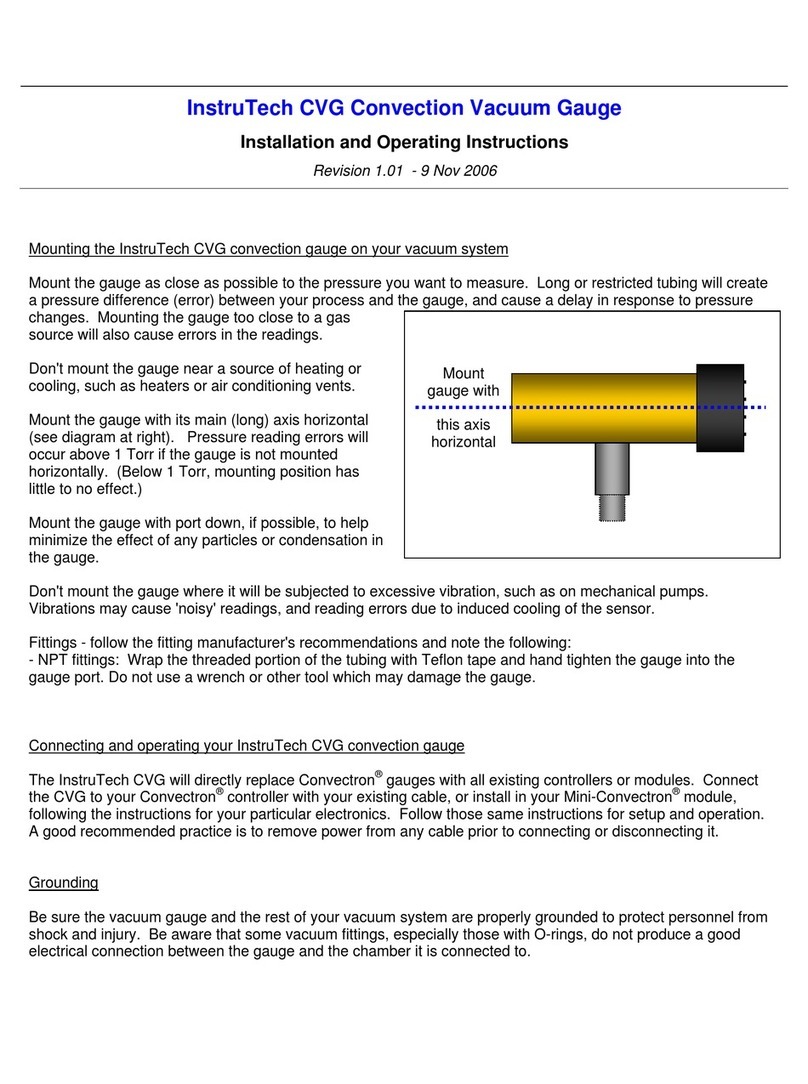

Instrutech

Instrutech CVG Installation and operating instructions

Velp Scientifica

Velp Scientifica AREC.T instruction manual

Malvern Instruments

Malvern Instruments Mastersizer X manual

Hettich

Hettich ROTOFIX 32 Repair instructions

IKA

IKA C 7010 operating instructions

BIO RAD

BIO RAD PowerPac Universal Power Supply instruction manual

Beckman Coulter

Beckman Coulter Optima L-XP Instructions for use

VWR

VWR avantor Star-Blender 400 Silent instruction manual