Malvern Instruments Mastersizer X User manual

This manual suits for next models

9

Table of contents

Other Malvern Instruments Laboratory Equipment manuals

Malvern Instruments

Malvern Instruments Zetasizer uV User manual

Malvern Instruments

Malvern Instruments ZETASIZER User guide

Malvern Instruments

Malvern Instruments DEG0003 User manual

Malvern Instruments

Malvern Instruments Zetasizer Nano User manual

Malvern Instruments

Malvern Instruments Spraytec User manual

Malvern Instruments

Malvern Instruments Zetasizer Series User manual

Malvern Instruments

Malvern Instruments Zetasizer uV User manual

Popular Laboratory Equipment manuals by other brands

Cleaver Scientific

Cleaver Scientific omniDOC instruction manual

IKA

IKA T 65 D operating instructions

Thermo Scientific

Thermo Scientific Multidrop 384 user manual

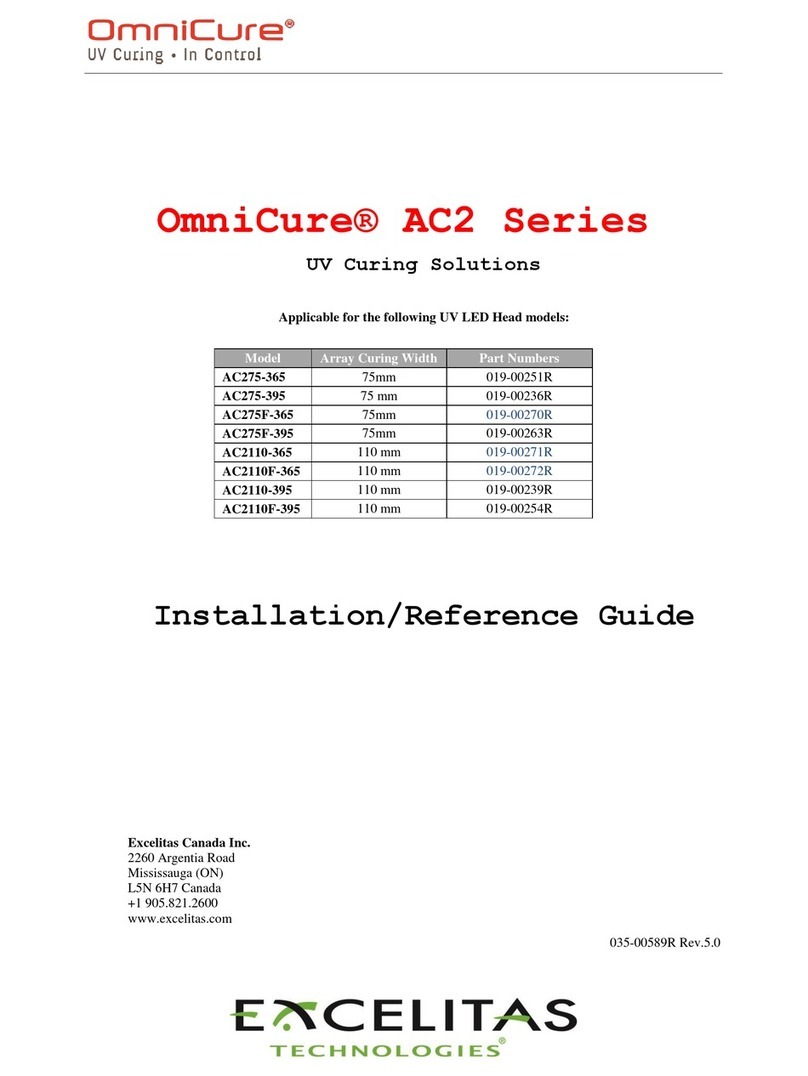

Excelitas Technologies

Excelitas Technologies OmniCure AC2 Series Installation reference guide

Ellab

Ellab TrackSense LyoPro user manual

Helmer

Helmer UltraCW II Operation manual

4titude

4titude TubeMarker 2 Operation manual

Miele

Miele PG 8593 operating instructions

INTEGRA Biosciences

INTEGRA Biosciences VIAFLO 96 quick start guide

VERDER

VERDER CARBOLITE GERO LGP 2/3370 Installation, operation and maintenance instructions

Oxford

Oxford Plasmalab 80 Plus operating manual

Metrohm

Metrohm 785 DMP Titrino Instructions for use