Safety and Assembly Instructions

CRRFTSMRN®

FLEX SHAFT for

ALL-IN-ONE

CUTTING TOOL

ASSEMBLYINSTRUCTIONS

.

2,

Turn cutting tool motor switch OFF and remove

plug from the power source.

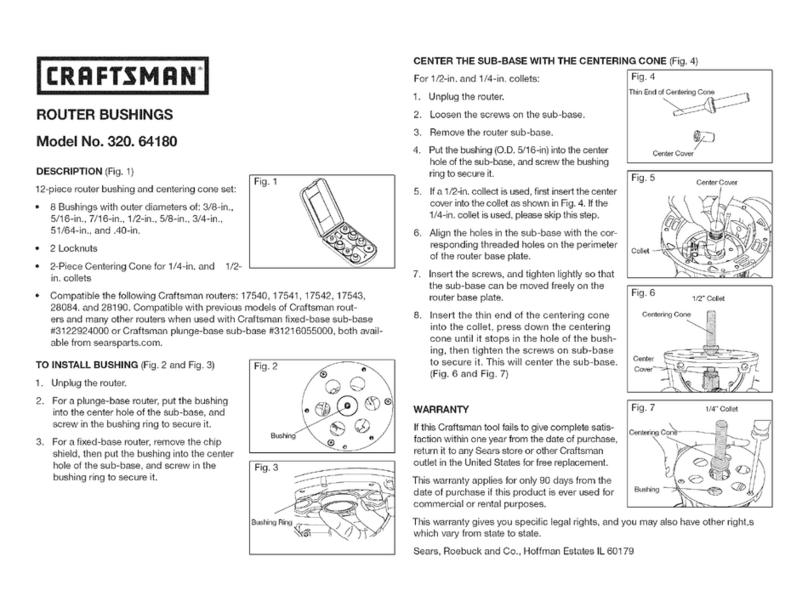

Lock main shaft (3) by rotating the collet nut (1)

while pressing on the spindle lock button (4)

until the spindle lock prevents shaft from

rotating (see Fig. 1).

Model No.

183.287660

.Use cutting tool fiatwrench (5) to loosen the

collet nut by turning itcounter clockwise.

Remove collet (2) from inside main shaft of

cutting tool.

AWARNING ]

ALWAYS WEAR EYE PROTECTION. Any power

tool can throw foreign

objects into your eyes

which could cause

permanent aye damage.

ALWAYS wear safety

goggles (not glasses) that

comply with ANSI safety

standard Z87.1. Everyday glasses have only

impact resistant lenses. They ARE NOT safety

glasses. Safety goggles are available at most

hardware stores.

Glasses or goggles not in compliance with ANSI

Z87.1 could cause serious injury when they

break.

USE FACE OR DUST MASK along with safety

goggles if cutting or routing operation is dusty.

Make sure work area is well ventilated.

NEVER PLACE HANDS IN THE PATH OF THE

CUTTER or under the workpiece.

USE HEARING PROTECTION, particularly

during extended periods of operation,

ALWAYS RE-TIGHTEN COLLET before starting

the tool after a cutting bit or accessory has

been changed. Loose bits and accessories can

cause unexpected shifting of the tool, resulting

in loss of control and injury from the bit or

cutting tool being thrown.

NEVER TOUCH THE CUTTING BIT

IMMEDIATELY AFTER USE. The bit will be too

hot to be handled with bare hands and will burn

your fingers.

2

Fig. 1

4.

.

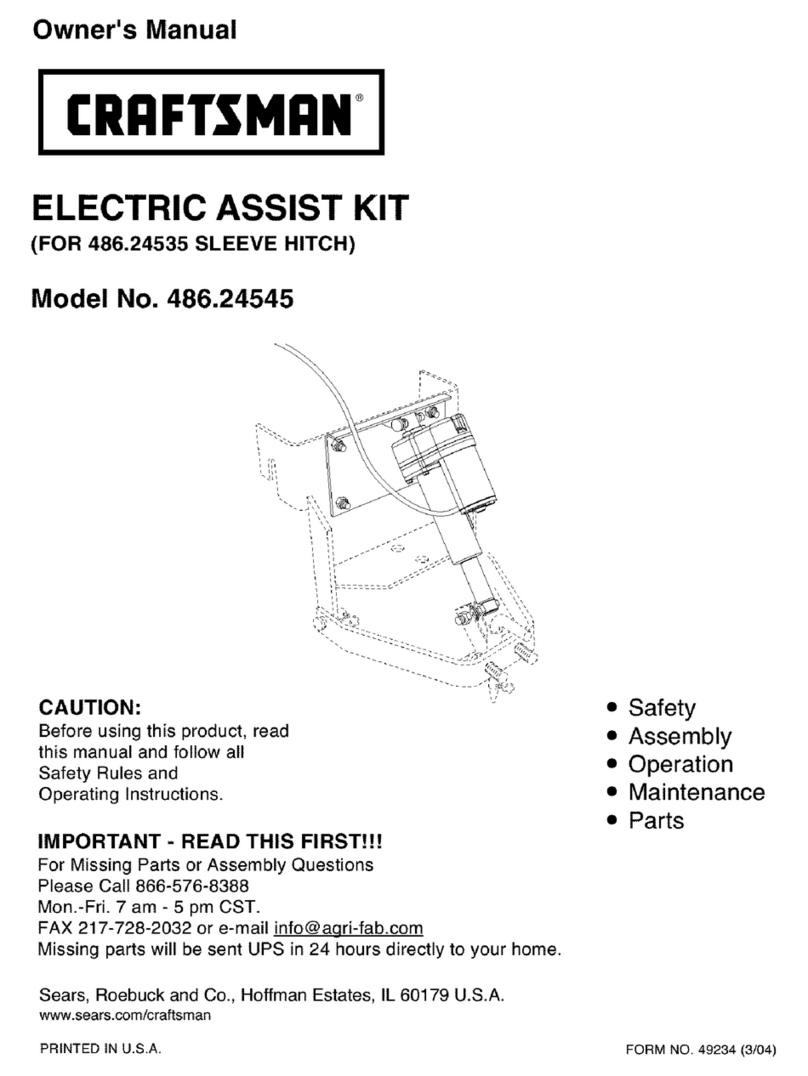

Insert collet with square hole (6) into main shaft

(3) and re-install the collet nut (1) onto the main

shaft (see Fig. 2).

NOTE: Collet with square hole is packed with

the flex shaft package.

Use cutting tool fiat wrench (5) to tighten the

collet nut firmlyonto the main shaft while

spindle lock isengaged into the main shaft.

Turn nut clockwise to tighten.

5

Fig. 2

Sears, Roebuck and Co., Hoffman Estates, IL 60179 USA

Part. No. 183287660001 07103102