The fence lock handle is designed so that it may be

disengaged after use on the lock nut and will hang

in a neutral position as shown. The angle between

the fence and the table may be changed for beveling

operations by loosening the fence angle lock nut. The

angle selected for the bevel cut is indicated on the

protractor scale. After changing the fence position

as described above, check carefully that the fence

angle lock nut is secure before proceeding with a cut-

ting operation.

The handwheel when turned will raise or lower the

front table, thus regulating the depth of cut as in-

dicated by the depth of cut pointer and scale.

ADJUSTMENTS:

If at any time the cut obtained should vary from that

indicated on the depth of cut scale the following

adjustment may be made. Set the front and rear

tables at the same level and check with a straight-

edge. Loosen the screw X2951 holding the pointer

29719, and shift the pointer until it indicates zero

on the scale. Tighten the screw securely after making

the above adjustment°

If a 90 ° setting of the fence angle protractor does

not produce square cuts the fence may be reset square

with the table by using an accurate tri-square. After

the 90 ° relation between the fence and table has been

established, the screw X2951 holding the protractor

pointer may be loosened and the pointer reset at 0.

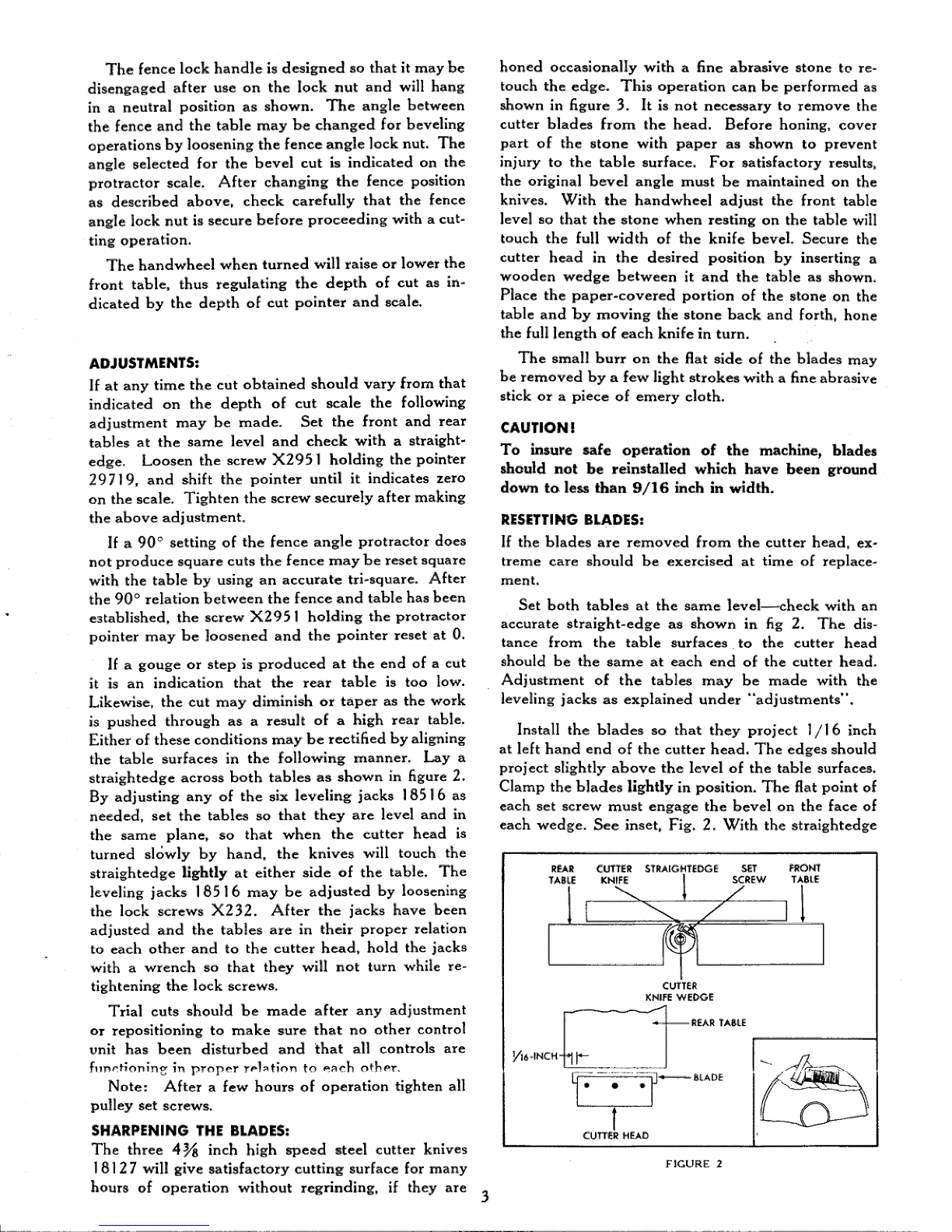

If a gouge or step is produced at the end of a cut

it is an indication that the rear table is too low.

Likewise. the cut may diminish or taper as the work

is pushed through as a result of a high rear table.

Either of these conditions may be rectified by aligning

the table surfaces in the following manner. Lay a

straightedge across both tables as shown in figure 2.

By adjusting any of the six leveling jacks 18516 as

needed, set the tables so that they are level and in

the same plane, so that when the cutter head is

turned slowly by hand, the knives -will touch the

straightedge lightly at either side of the table. The

leveling jacks 18516 may be adjusted by loosening

the lock screws X232. After the jacks have been

adjusted and the tables are in their proper relation

to each ether and to the cutter head, hold the jacks

with a wrench so that they will not turn while re-

tightening the lock screws.

Trial cuts should be made after any adjustment

or repositioning to make sure that no other control

unit has been disturbed and that all controls are

f,,ncHonin_ it) proper r_lztion to each other.

Note: After a few hours of operation tighten all

pulley set screws.

SHARPENING THE BLADES:

The three 4_ inch high speed steel cutter knives

1812 7will give satisfactory cutting surface for many

hours of operation without reg_nding, if they are

honed occasionally with a fine abrasive stone to re-

touch the edge. This operation can be performed as

shown in figure 3. It is not necessary to remove the

cutter blades from the head. Before honing, cover

part of the stone with paper as shown to prevent

injury to the table surface. For satisfactory results,

the original bevel angle must be maintained on the

knives. With the handwheel adjust the front table

level so that the stone when resting on the table will

touch the full width of the knife bevel. Secure the

cutter head in the desired position by inserting a

wooden wedge between it and the table as shown.

Place the paper-covered portion of the stone on the

table and by moving the stone back and forth, hone

the full length of each knife in turn.

The small burr on the flat side of the blades may

be removed by a few light strokes with a fine abrasive

stick or a piece of emery cloth.

CAUTION !

To insure safe operation of the machine, blades

should not be reinstalled which have been ground

down to less than 9/16 inch in width.

RESETTING BLADES:

if the blades are removed from the cutter head, ex-

treme care should be exercised at time of replace-

ment.

Set both tables at the same level---check with an

accurate straight-edge as shown in fig 2. The dis-

tance from the table surfaces to the cutter head

should be the same at each end of the cutter head.

Adjustment of the tables may be made with the

leveling jacks as explained under "'adjustments".

Install the blades so that they project 1/16 inch

at left hand end of the cutter head. The edges should

project slightly above the level of the table surfaces.

Clamp the blades lightly in position. The flat point of

each set screw must engage the bevel on the face of

each wedge. See inset, Fig. 2. With the straightedge

REAR CUTTER STRAIGHTEDGE SET FRONT

SCREW TAB|E

FIGURE 2

LDownloaded from www.Manualslib.com manuals search engine