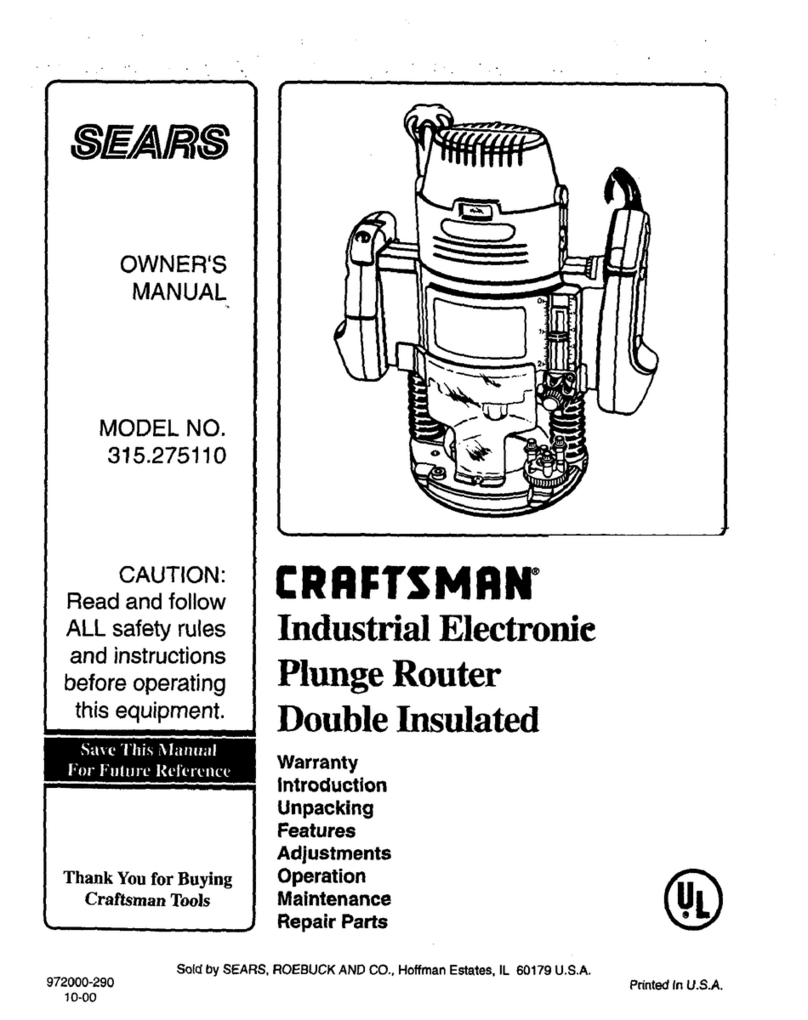

UNPACKING

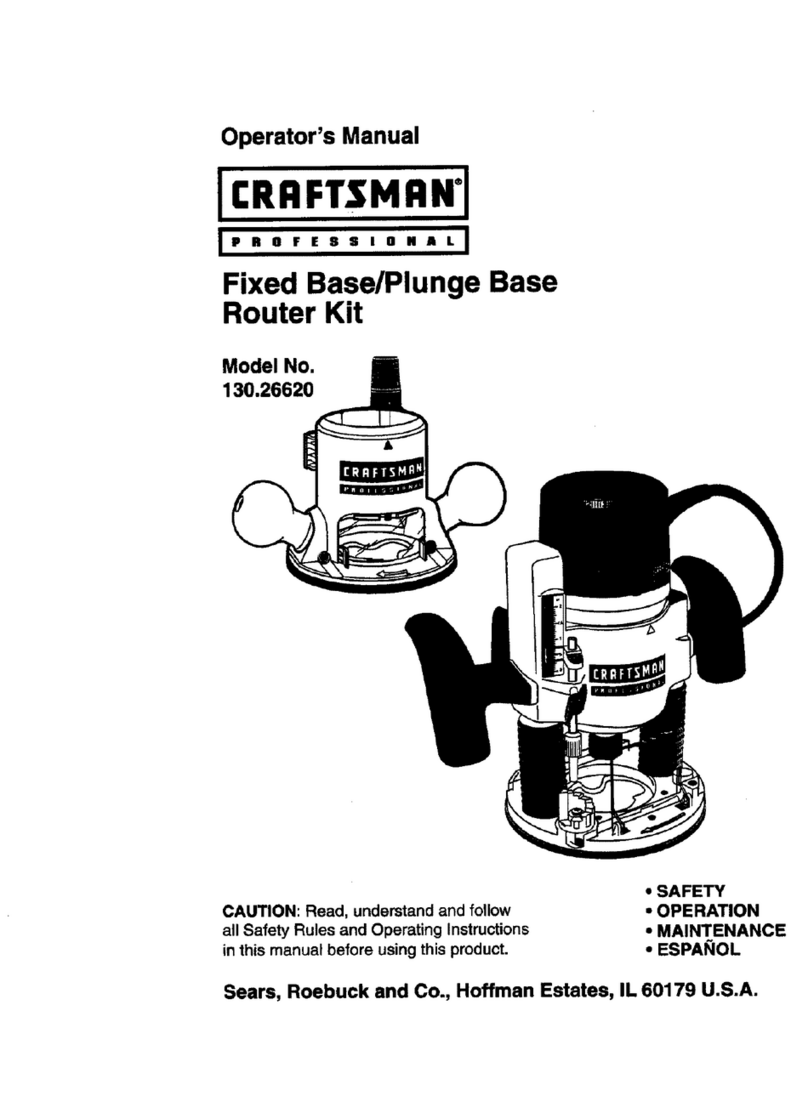

Your new plunge router comes fully assembled. After removing it from the box, inspect itcarefully to make sure that it isnot

damaged and that no parts are missing. See Figure 1. The following accessories should also be included in the box:

1_ Combination Wrench (3/8"- 7/8") 4, Roller(Contour) Guide

2. 1/4"Adapter 5. Guide Bushing

3. Edge Guide

FEATURES

Your electronic router isa versatile woodworking toot which will give you years of trouble-free performance. It is engineered

with the professional in mind, but its ease of operation allows the amateur to produce work which is beautiful and precise.

3.5 HORSEPOWER MOTOR

Your router has a powerful 3.5 horsepower motor with suffi-

cient power to handle the toughest routing jobs. The motor

also has externally accessible brushes for ease of servicing.

SOFT START

The soft start feature builds motor RPM gradually tominimize

start-up torque. Pressing or releasing the "on-oft" trigger will

turn your router on or off.

DEPTH CONTROL KNOB

Alargedepth control knob makes precise depth ofcut changes

possible. It also is very helpful when making depth of cut

changes with your router mounted upside down on a router

table.

DEPTH STOP SYSTEM

The depth stop block located on the base of your router

provides three adjustable stops and three fixed stops for

quick depth of cut changes. A depth adjustment scale makes

quick adjustments to depth of cut changes possible. The

spring loaded adjustment knob quick releases stop bar by

depressing center of knob.

1/4" AND 1/2" SHANK CAPACITY

Your router has a 1/2" diameter collet that accepts cutters

with 1/2" shanks. An adapter has been provided so that

cutters with 1/4" shank bits can also be used,

CHIP SHIELD

A clear plastic see-through chip shield has been provided on

the base of your router for protection against flying dust and

chips. It is designed to fit the front opening of the router base,

POSiLOCK SPINDLE LOCK

Aposilock spindle lock secures the spindle so that only one

wrench is needed to loosen collet nut and change cutters. A

spindle lockindicator light alerts you that spindle is locked if

you connect router to power supply before unlocking spindle.

NOTE: Your router wilt not run if spindle is locked.

"LOCK-ON" FEATURE"

Your router is equipped with a "lock-on" feature that is conve-

nient when continous operation for extended periods of time

is required.

LARGE HANDLES

Your router has large oversized handles for easy handling and

maintaining proper control when routing. The left handle

allows you to set cutter depth of cut when making plunge

cuts, while the right handle provides easy access to the "on-

off" trigger, "lock-on" button, and variable speed control se-

lector. The handles have also been designed so that they

are comfortable and easy to grasp when operating in differ-

ent positions or at different angles.

VARIABLE SPEED SWITCH WITH ELEC-

TRONIC SPEED CONTROL (Feedback Switch)

Your router has advanced electronic features, designed to

assist you ingetting the maximum use from your router. By

making proper speed selections, your router+can be ad-

justed to specfic routing needs. This eliminates much of the

guess work previously needed to perform a given job. Both

the experienced and inexperienced router users benefit,

obtaining professional like results with fewer job errors.

The variable speed control allows the router speed to be

adjusted from 10,000 to 25,000 rpm+ The variable speed

control selelctor is conveniently located inside the right handle

near the operator's thumb or hand.

The electronic feature of your router introduces the flexibility

of adjusting the motor speed to required job conditions. An

electronic speed control module senses the load applied to

the motor, and increases or decreases motor voltage to

compensate forand maintain desired RPM.

Speed can be set according to the approximate cutter diam-

eter you will be using and to the hardness of the material

being cut. The best cuts are made when the cutter is fed

through material at the proper rate of feed.

ROUTER ACCESSORIES

Your router comes equipped with several accessories. The

edge guide keeps the cutter parallel with an eclge of the

workpiece when cutting grooves and rabbets. The roller

(contour) guide allows the router to be used totrim laminates

and make cuts parallel with an irregularly shaped edge. The

template guide bushing enables the router to follow a tem-

plate for making duplicate shapes.

Page 4