• Never place your fingersor hands in path of cutting tools.

• Never reach in back of the workpiece with either hand to

support the piece, remove wood scraps, or for any other

reason.Avoid awkward operations and hand positions

where a sudden slipcould cause fingers or hand to move

intoa spinning workpiece.

• If the workplace splitsor is damaged in any way, turn lathe

OFF and removethe workplace from the holders. Discard

damaged workpiece and start with a new piece of wood.

•Use extra care when turning wood withtwisted grain or

wood that istwisted or bowed -- it may cut unevenlyor

wobbleexcessively.

KNOWYOUR CUTrlNG TOOLS

• Dull, gummy, improperly sharpened or set cutting tools can

cause vibration and chatterduring cutting operations.

Minimize potential injuryby proper care of tools and regu-

lar machine maintenance.

THINK SAFETY

Safety is a combinationof operator common sense and alert-

ness at all times when the lathe is being used.

•For your own safety, read all rules and precautions in the

operator's manual before using this tool.

For eye protection,wear safety glasses complyingwith

United States ANSI Z87.1.

Do not wear loose clothing, gloves, neckties, rings,

bracelets or other jewelry that could get caught in moving

parts ofmachine or workpiece.Wear protective haircover-

ing to contain long hair.

• Tighten all clamps, fixtures and tailstock before applying

power. Check to make sure that all tools and wrenches

have been removed.

With switchoff, rotate workplace by hand to make sure

that there is adequate clearance. Start the machine on

lowest speed settingto verify that the workplace issecure.

Do not mount any workpieces that have splits or knots.

Never attemptto remounta between-centersturningifthe

originalcenters on theturning have been altered or removed.

When remounting a between-centers turningthat has non-

altered original centers, make sure that the speed is at the

lowest settingfor start-up.

•Use extra caution when mountinga between-cantere turn-

ing to the faceplate, or a faceplate turning to between-cen-

ters, forsecondary operations. Make sure that the speed is

at the lowest setting for start-up.

•Never perform any operation with this toolwhere the work-

piece is hand-held. Do not mount a reamer, millingcutter,

drillbit, wire wheel or buffingwheel tothe headstockspin-

dle.

•Never runthe spindlein the wrong direction.The cutting

tool could be pulled from your hands.The workplace

should always turn towards the operator.

•For spindleturning, ALWAYS positionthe tool rest above the

centedine ofthe workpieceand spindle(approximately_k").

Refer to Figure 1.

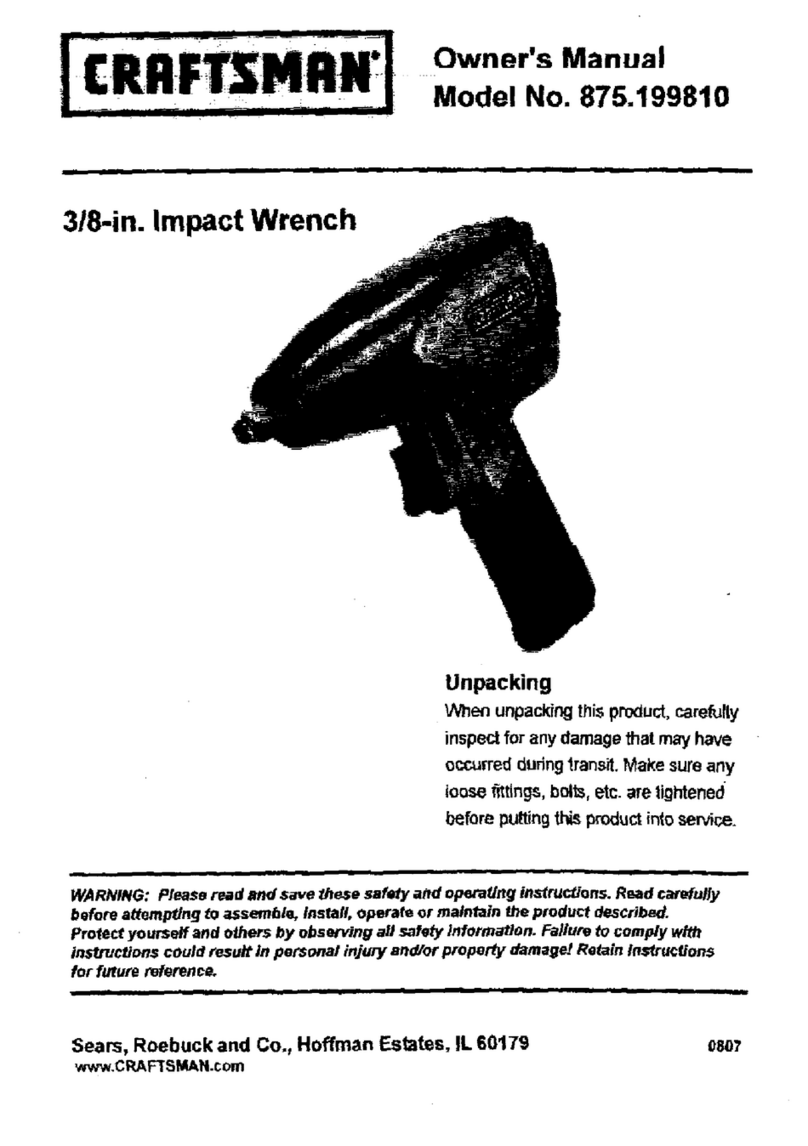

Check for shipping damage. If damage has occurred, a claim

must be filed with carrier.Check forcompleteness.

immediately report missing parts to dealer.

Your copycrafterisshippedcomplete inone carton.Separate all

partsfrom packingmaterialsand checkeach one withthe

unpackinglistto make certain all itemsare accountedforbefore

discardingany packingmaterial,

if any parts are missing,do not attempt to assemble copy

crafter untilthe missing parts are obtained and properly

installed.

ACarriage

B Bracket (2)

CSupport Bar with Rack

DSupport Bar

E Fine Adjustment Screw

F Cutting Tool

G Safety Shield

H Guide with Set Screw (Model 24951 only)

I Follower Assembly

J Locking Handle (model 24951, qty 1: Model 24952, qty. 2)

K Handle (4)

L Lever with Grip

M Pattern Support (2)

N Tool Rest Base Assembly (Model 24951 only)

O Carriage Support (Model 24951 only)

P Carriage Support (Model 24952 only)

Q Tool Rest Base Assembly (Model 24952 only)

A B D E

I

Figure1 - Unpacking

Model 24951 Hardware bag (Part No. 18987.00) includes

guide pin, two bracket nuts,four bushings,two pattern bolts,

six spacers, one 5-0.8 x 10mm socket head bolt,one 6-1.0 x

12mm pan head screw,two 8-1.25 x 60ram socket head bolts,

two 8-1.25 x 40mm socket head bolts, four 8-1.25 x 25ram

socket head bolts, four 8-1,25 x 20mm socket head bolts, one

8-1.25 x 10ram set screw,four 8mm fiat washers, one 10ram

fiat washer, two 8-1.25mm hex nuts, two 10-1.5mm hex nuts,

4 and 6ram hexwrenches and 13/14mm open end wrench.

Model 24952 Hardware bag (PN 19078.00) includes guide

pin, two bracket nuts, four bushings, two pattern bolts, six

spacers, one 5-0.8 x 12ram socket head bolt, one 6-1.0 x

12mm pan head screw,two 8-1.25 x 60mm socket head bolts,

two 8-1.25 x 40ram socket head bolts, one 8-1.25 x 30mm

socket head bolt, two 8-1.25 x 25mm socket head bolts, two

8-1.25 x 20mm socket head bolts, four narrow 8ram fiat

washers, two regular 8mm flat washers, two 8ram lock

washers, one 10mm fiat washer, two 8-1.25mm hex nuts, one

10-1.5mm hex nuts, spacer, four 8-1.25 x 8ram set screws,

one 8-1.25 x 10mm set screw, brass pin, 4 and 6ram hex

wrenches and 13/14mm open end wrench.