3

www.cranecpe.com

NOZ-CHEK®Cryogenic Installation, Operation & Maintenance NOZ-CHEK®Cryogenic Installation, Operation & Maintenance

2.0 INITIAL COMMISSIONING

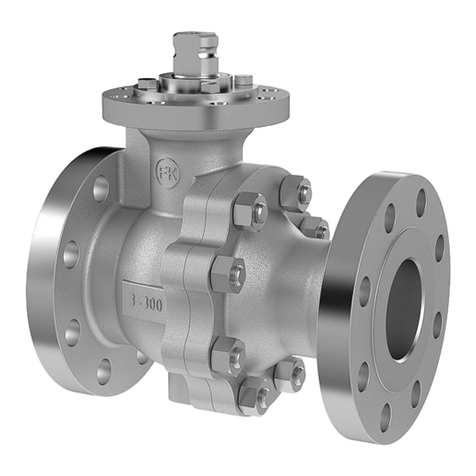

A Crane Stockham Valve Noz-Chek® check valve is a

precision built product, specifically designed for the

operating parameters of your system.

Please observe the following recommendations:

2.1 INITIAL / COMMISSIONING PROCEDURE

(a) Valves will be packed in accordance with our ESB 2155

APP20, Packing, preservation and site storage procedure

for cryo valve products.

(b) Care should be taken not to damage any paint work,

while lifting and moving valves.

(c) Care should be taken not to damage flange / mating

faces of valves.

(d) Care should be taken to avoid mechanical damage

to cable / junction box of the Position Switch during

installation of valve and throughout its working life, (if

applicable).

(e) Care should be taken to prevent contanmination of

the valve from dirt,dust or any other foreign bodies from

entering the valve internals.

(f) Remove any desiccants that have been placed in bore

of valve prior to installation.

2.2 STORAGE

The valve shall be stored within a sealed polyethylene bag

to prevent any contaminants from entering the valve.

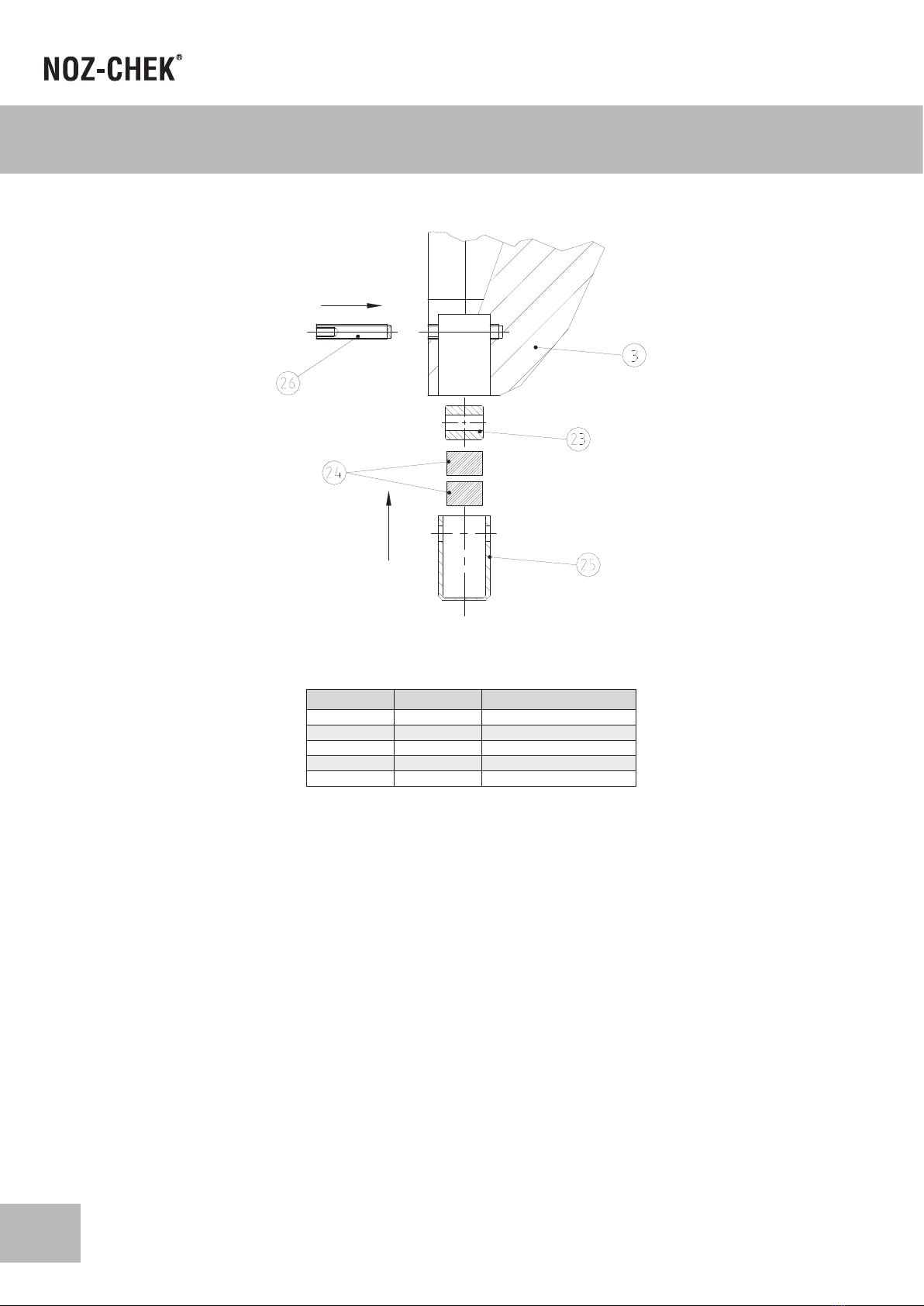

3.0 INSTALLATION

(a) Direction of Flow

The direction of flow should coincide with the flow

direction indicated by the cast‘arrow’ on the body of the

Noz-Chek®.

(b) Operating Orientation

Ensure that the mounting position is in the operating

orientation as advised on the Service specification for

each valve when ordered i.e. horizontal, vertical upwards

or downwards flow.

(c) Line positioning

Ideally the check valve should have 5 diameters of

straight pipe before and 6 diameters after the valve. For

practical reasons this is often not possible. The valve

should have as a minimum, 2 diameters of straight

pipe before and after its location. The valve will under

normal circumstances still function as a non-slam check

valve if fitted closer to other equipment than the stated

guidelines; however this will normally result in increased

pressure loss and wear of components. This phenomenon

is not exclusive to Crane equipment, and should be

applied to any pipe layout as good practice.

The pressure loss of any piece of piping equipment

in a system will be affected by the presence of other

equipment. Pressure loss is an unrecoverable energy loss

and is the measured decrease in pressure. Measuring

the pressure drop immediately before and after piping

equipment will give a higher reading than measuring a

sufficient distance before and after the piping equipment.

This is due to pressure recovery after the equipment as

the flow returns to the full flow area of the pipe. Standard

flow loop testing requires two diameters of straight pipe

before the equipment and six after. Most of the pressure

recovery will occur in the first three diameters after a

nozzle check valve and a significant amount after two

diameters.

Two diameters before the piping equipment will allow

for the pressure recovery of the upstream equipment.

The flow will also lose the increase in turbulence caused

by the disruption of the flow by the equipment. Placing

equipment too close together will amplify any disruption

to the flow and make the overall pressure loss to the

system more than the sum of the individual pressure loss

of the equipment.

Insufficient straight pipe before the piping equipment

can also cause a significant increase in the wear of the

components and reduce the life of the equipment.

Research has shown that typically five diameters are

required to stop the effects of accelerated wear with

the affects increasing in an exponential curve. With the

geometry of the nozzle check valve it has been shown

that two diameters is sufficient to make the affects of the

accelerated wear minimal.

(d) Lifting and Flange Assembly

Always lift the valve by the lifting eyes provided, or

alternatively a well padded sling.

Ensure that no external pipeline stresses are imposed on

the valve prior to tightening bolts and pipework mating

flanges are parallel.

Ensure bolts are tightened correctly. Always tighten in

a diagonally opposing bolt sequence, to ensure that all

bolts apply a uniform load, with the gaskets properly

installed.