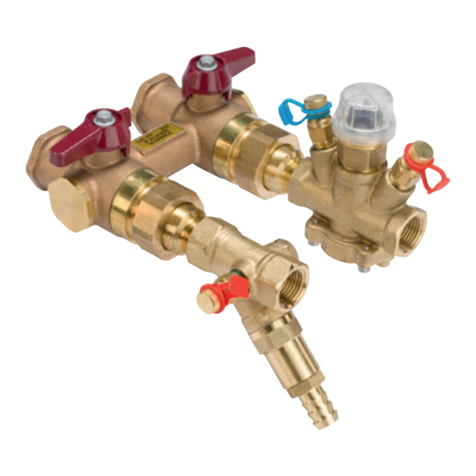

INSTALLATION

All valves: Valves must not be lifted by the

hand wheel

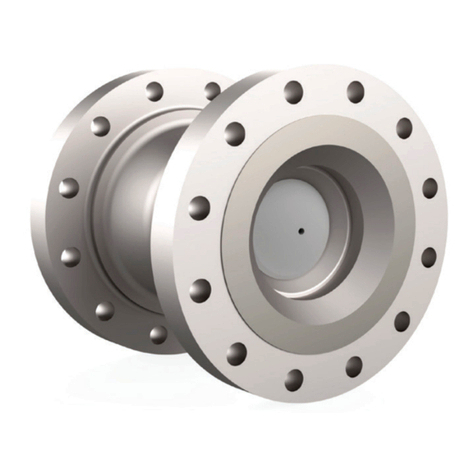

The valves should be installed in a straight run

of pipe of the same nominal size with

the arrow pointing in the direction of flow. They

may be orientated at any angle.The gaskets

must be assembled so that they are concentric

with the pipe bore and do not intrude into it, or

the measurement accuracy may be reduced.

When used for end of line service, a blanking

flange should be fitted.

A blanking flange is not required for temporary

installation or servicing. Crane recommends

that the valve is not left unattended in this con-

dition if the system has been filled.

Type 941:To ensure maximum flow measure-

ment accuracy, it is essential that the piping

is straight for a minimum length equivalent to 5

diameters on the inlet and 2 diameters on the

outlet. If it is located on the outlet side of a

pump, the equivalent straight length of pipe

leading up to the valve must be a minimum of

10 diameters.

The valves are calibrated to give the correct

readings when used with BS1387 medium

grade pipe for sizes up to DN150 (6”). Larger

sizes are calibrated for use with BS3600 or BS

EN 10220 pipe, having a wall thickness of

6.3mm (1/4”). Schedule 20 pipe is also

satisfactory. Pipes with a significantly different

bore will give an altered reading. If in doubt

consult Crane Fluid Systems Sales Dept.

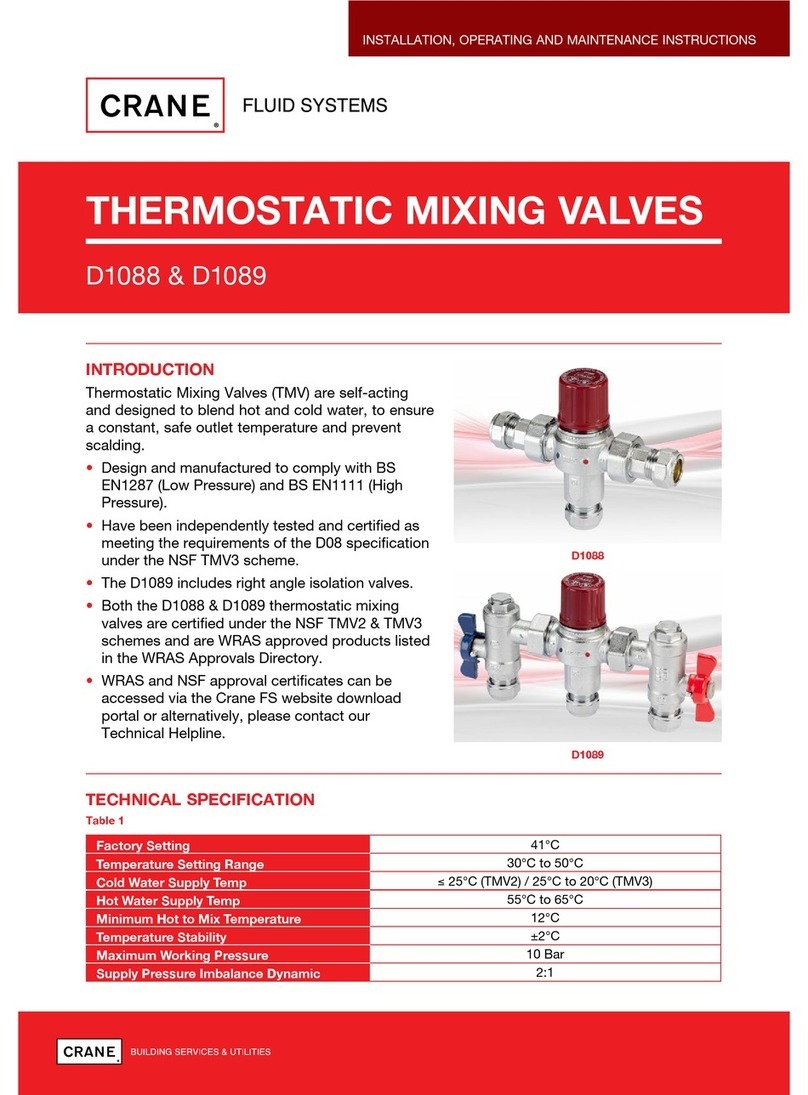

VALVE SETTING INDICATOR

The micrometer style hand wheel uses two

scales:

1) A grey plastic sleeve within the hand wheel

which has 8, 12 or 18 numbered rings

depending on the size of the valve.

2) A collar snapped into a groove on the

outside of the hand wheel boss which is

numbered 0 to 9 around the circumference.

As the valve is opened from the fully closed

position, each turn of the hand wheel reveals

one extra ring on the plastic sleeve. When

closed, the zero on the collar lines up with a

groove in the sleeve and each number

represents 1/10 of a turn.

The fully open position is reached when all

rings on the sleeve are visible and the zero

again lines up with the groove. A total of 10

settings are available therefore for each turn of

the hand wheel.

REGULATION

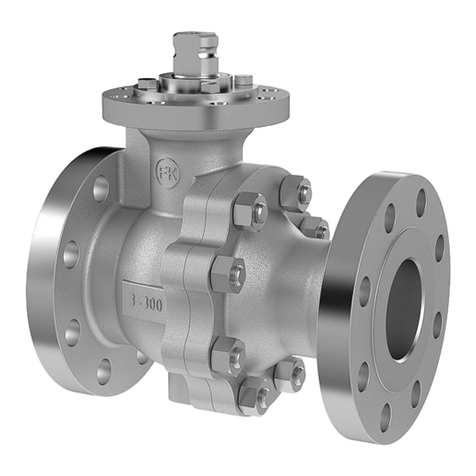

Type 921: Flow regulation is achieved by

adjusting the hand wheel setting until the

desired flow rate is obtained. The micrometer

type hand wheel will indicate the final setting.

Type 931: Flow regulation is achieved in the

same way as the Type 921. The flow rate may

be derived from the pressure drop signal

easured across the pressure test valves. Flow

charts are available on request for all valve

sizes. They show the flow rate which results for

the pressure drop measured, depending on the

hand wheel position.

Type 941: Flow regulation and measurement is

obtained in the same way as with the Type 931.

With this valve, a different chart is required and

the relationship between pressure drop and

flow is not altered by the hand wheel setting.