INSTALLATION

02 CRANE FLUID SYSTEMS DOUBLE REGULATING AND COMMISSIONING VALVES 03

CRANE FLUID SYSTEMS DOUBLE REGULATING AND COMMISSIONING VALVES

INSTALLATION AND OPERATING INSTRUCTIONS

TEMPERATURE / PRESSURE RATING

DP931/DP933/DP934 - when used with compression fittings

These instructions are issued as guidelines only and do not cover all installed conditions – if

unsure please contact our Technical Helpline before installation.

• Crane products are designed for installation and use within suitably designed systems

reflecting CIBSE, BSRIA and HVAC guidelines. Particular care should be taking

with regards to;

- accessibility to valve for setting/adjustment

- tube cutting

- jointing

- bracketing/supports

• where possible the D921/D923 should be installed in a run of pipework of the same

nominal diameter and with the flow in the correct direction. There is no requirement for

straight lengths of pipework for DRVs

• the D931/D933/D934 and the DP931/DP933/DP934 mu t be installed in a run of

pipework of the same nominal diameter and with the flow direction as indicated

on the body.

- to ensure flow measurement accuracy, it is essential that the pipework on the inlet

and outlet is straight, is of the same diameter as the valve and has a minimum length

equivalent to 5 diameters on the inlet and 2 diameters on the outlet

- Note: the requirement for 5 and 2 clear diameters are minimum requirements. Where

possible longer lengths should be achieved

- if installed near to pump outlet, it is essential that the straight lengths of pipework

between pump and valve inlet is a minimum of 10 diameters, greater if possible

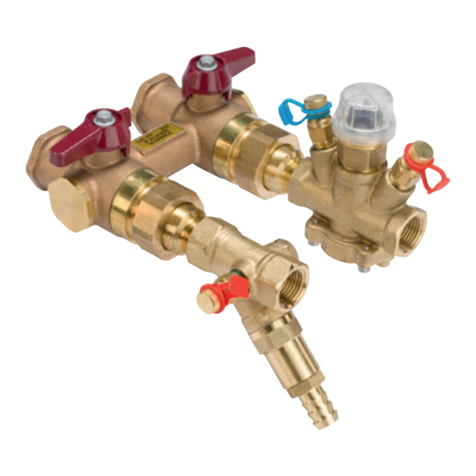

• the DP931/DP933/DP934 Companion Valves should be installed in the opposite pipework

to the DPCV, ie. DPCV installed in return pipework – Companion Valve installed in flow

pipework. The Companion Valve should be connected to the DPCV via the impulse tube

(supplied with the DPCV). If required an isolation valve can be installed in the

impulse tube

• for the DP931/DP933/DP934 because the impulse tube is connected with a compression

fitting, the temperature and pressure ratings are limited to PN16 rating as follows. If the

valve is used separately, ie impulse tube connection blanked off, the full pressure rating

applies, ie PN25.

• end connections are as follows;

- for sizes ½” to 2”, D921/D923/D931/D933/D934 have female ISO 228-1 parallel threads

suitable for connection to threaded steel pipework. ½” and ¾”, when used with the

compression adaptor, are suitable for connection to BSEN1057- half hard copper.

- the DP931/DP933/DP934 have male threaded ends to ISO228-1 parallel, therefore

require a flat face sealing gasket suitable for the service.

TEMPERATURE ˚C -10 to 30 65 120

PRESSURE (BAR) 16 10 5

D921/D923/D931/D933/D934 - when not used with compression fittings

TEMPERATURE ˚C -10 to 100 110 120

PRESSURE (BAR) 25 23.4 21.8

D921/D922/D931/D933/D934 when used with compression fittings

TEMPERATURE ˚C -10 to 30 65 120

PRESSURE (BAR) 16 10 5