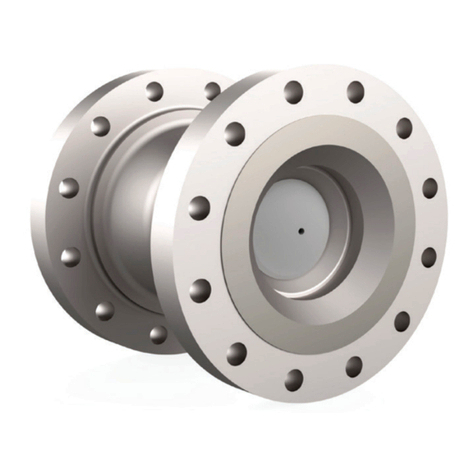

Tilting Disc Type Check Valves

Date:

prepared:

approved:

Page:

22.03.2005

C.Wied

H.Six

3 of 14

Operating instruction No.:

BUW-510/1-E

Danger

It must be ensured that the materials selected for the parts of the armature that

come into contact with the medium are suitable for the media used. KROMBACH

accepts no liability for damage which results from corrosion caused by aggressive

media.

Failure to observe this requirement can lead to danger to life and limb and

cause damage in the pipeline system.

⇒the pipeline system and the control system are correctly installed and regularly checked. The wall

thickness of the housing of the armature must be such that in such correctly installed pipeline

systems, an additional load Fzin the usual order of magnitude (Fz= ¶ /4 DN2PS) is taken into

account.

(PS = maximum permissible design pressure at room temperature)

⇒the armature and the drive (if ordered) are correctly connected to these systems.

⇒the activation time of the armature/drive unit is adapted to the parameters of the installation.

⇒the usual flow speeds analogously to EN593: 2002, Table 2 are not exceeded in continuous

operation in this pipeline system and that normal operating conditions such as vibrations, shocks,

erosion (e.g. due to wet steam), cavitations and more than an insignificant proportion of solid

material in the medium – particularly abrasive material – is clarified with KROMBACH.

⇒armatures which are operated at temperatures >50°C or <20°C, together with the pipeline

connections, must be protected against physical contact in order to protect the operator from

injury.

⇒installation, maintenance and operation are carried out only by properly qualified personnel (see:

DIN IEC 3/B/244/CDV).

3.3. Special hazards

Danger

to life

The valve has mounted a lever and weight. The pivoting range is necessarily

to be equipped with a protective grating.

Danger

to life

The valve shaft is sealed with a stuffing box. Before the nuts on the stuffing box

retainer are loosened or released, the pressure in the pipeline must be

completely normalised, so that no medium escapes from the stuffing box.

Danger

to life

Before releasing the bearing cover on the housing or before deinstalling the

armature from the pipeline, the pressure in the pipeline must be completely

normalised, so that the medium does not escape in an uncontrolled fashion from

the pipe. It must be ensured that the armature is open 5°-10° so that pressure

can be released on both sides of the armature. When it is necessary to deinstall

the drive, this may not be carried out until the armature has been opened for this

purpose and is left in the open position.

Danger

to life

When an armature must be deinstalled from a pipeline:

medium may escape from the pipe or from the armature. Where the medium is

hazardous to health or dangerous, the pipeline must be completely emptied

before the armature is deinstalled. Be careful with residues which subsequently

flow out of the dead spaces of the armature or out of the pipe or which

remain in the armature (under pressure).