5 | P a g e

handwheel. In severe temperature applications (300 degrees F and above , insulation may be

required on the valves to protect operators from the heat.

•Certain processes utilize flammable, caustic and/or otherwise unstable media. Care should be taken

in these circumstances to ensure the operator is aware of the specific health and safety risks

associated with that medium.

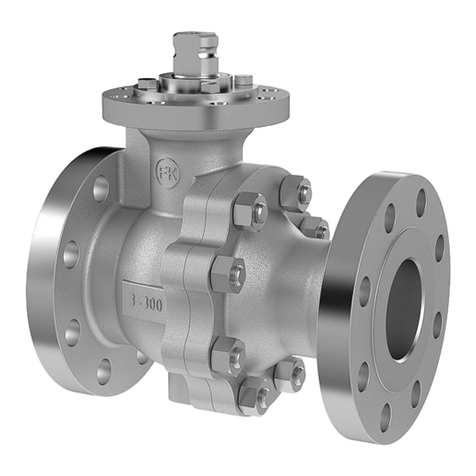

•All Pacific valves should be operated within the pressure and temperature ranges listed in Table 2 of

ANSI B16.34. Under no circumstances should the valves be operated at conditions outside these

tables.

•All piping systems should contain independent support mechanisms and should not utilize the valve

as a sole means of support.

•The estimated total lifespan of a Pacific valve when installed within ideal boundary conditions is 20

years.

•All valve actuators shall be sized by referring to the specific relevant valve torque and thrust data

published by Pacific Valves. Generic or standard valve information shall not be used.

•It is the ultimate responsibility of the piping designer to ensure that each valve is sized appropriately

for the given system parameters of pressure, temperature, flow rate, velocity, pressure drop, etc.

Additionally it is the responsibility of the piping designer to ensure that the corresponding actuator

sizing data is correct for the given application.

•Valves other than globes should not be used for throttling applications. Severe damage may occur to

other valve styles. When using globe valves for throttling, do not operate the valve continuously at

less than 10% open.

•All valves shall only be used within their defined boundary conditions. All standard materials of

construction, including bolting are suitable for operation within the boundary conditions listed in

section 8.0 of this document. Care should be taken to ensure that all valves are not operated at

conditions that exceed or deviate from the defined boundary conditions. The boundary conditions

must be adhered to regardless of the piping system status, including but not limited to: Start-up,

hydro-testing, chemical cleaning, system flushing, etc.

•Valves are not suitable to serve as block valves during system hydrostatic pressure tests that

exceed 1.1 times the cold working pressure.

•Care should be taken around all valves as injury or damage may occur from the leakage of hot, high

pressure and/or caustic materials from a gasket and/or packing joint. Additionally, packing and/or

gasket leaks may cause external corrosion damage to the valve.

•When possible, gate valves should be relieved of maximum seating force when left in the closed

position. By relieving this force, it may help prevent damage caused by excessive thermal stem

expansion. Care should be taken however to ensure that the valve is not opened, only that the

torque/thrust has been removed from the stem.

•It is the responsibility of the user/owner of a plant to ensure that all valve operators are ordered to

meet all applicable requirements and specifications.

•Only valves that have been certified as fire safe shall be used in piping systems that may be

exposed to fire.

•Standard graphitic packing is suitable for 500ppm VOC emissions. Consult the factory if lower

emissions are required. Crane Pacific meets API-622 / Method 21 emissions standards.

•When operating manual valves, gloves should be worn to minimize the risk of injury to the hands.

•In situations where manual valves are difficult to operate due to substantial torque requirements, it is

recommended that the valve be supplied with a gear or motor operator.

•All valves should be mounted with the stem vertical and the pipeline horizontal. Check valves may

be installed in vertical pipelines only when the normal flow is in the upward direction. For any other

orientation, please contact the factory.

•Depending upon the specific application, normal lubricants may not be sufficient for higher

temperature applications. In this case, higher temperature lubricants should be used in place of the

standard type.