Creality 3D CR-10mini Series User manual

CR-10mini Series 3D Printer User

Manual

User Manual is for the CR-10 Series of 3D printers. It is also

applicable for the CR-10S/CR-10 S4/CR-10 S5.

But CR-10 mini without T-Bracket (Right) & Decoration Strip.

Due to the different types of devices ,Hardware and software upgrade. the

devices have little different, it is normal phenomenon. Subject to actual

device received.

Detailed instructions for using are available in the TF card.

V.6.0

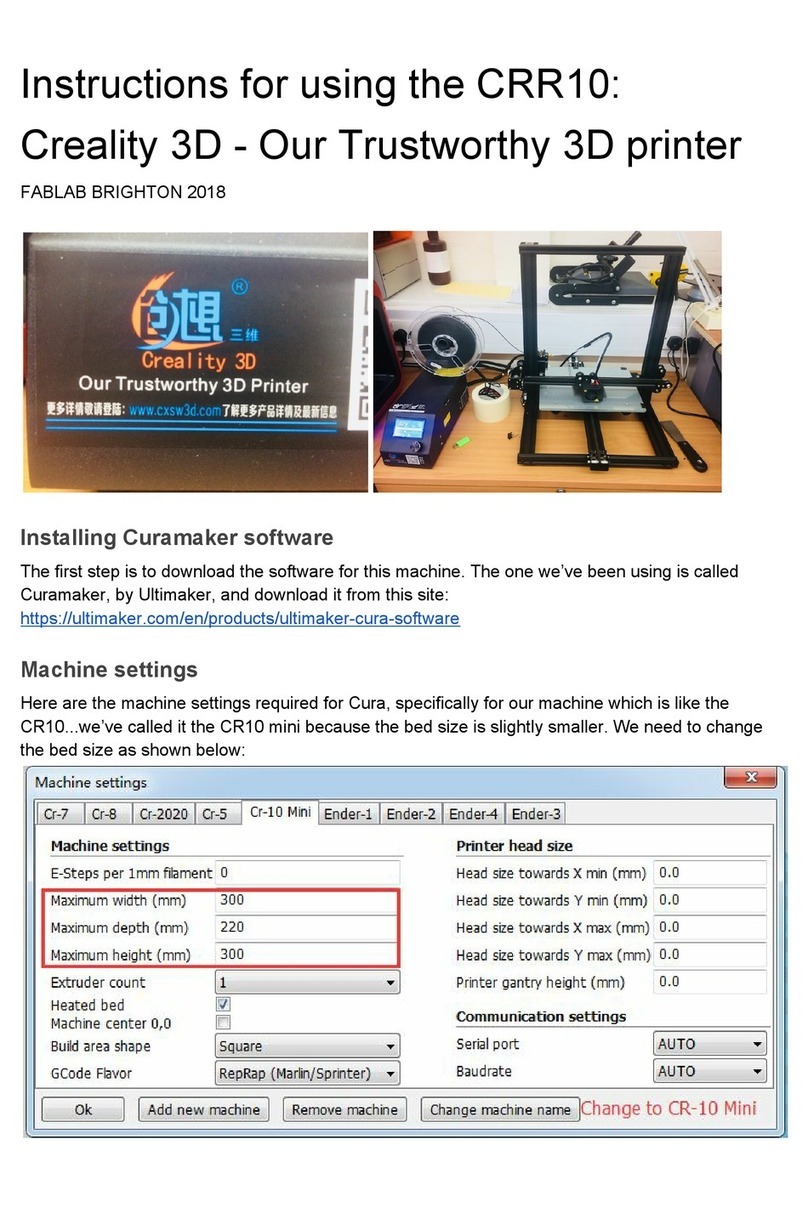

Parameters

Basic Parameters

Model

CR-10

CR-10S

CR-10 S4

CR-10 S5

CR-10mini

Printing Size

300*300*400mm

300*300*400mm

400*400*400mm

500*500*500mm

300*220*300mm

Molding Tech.

FDM

Nozzle Number

1

Slice Thickness

0.1mm-0.4mm

Nozzle Diameter

Standard 0.4mm

Precision

±0.1mm

Fliament

1.75mm PLA

File Format

STL/OBJ/AMF

Working Mode

Online or TF card offline

Slice Software

Creality Slicer/Cura/Repetier-Host/Simplify3D

Power Supply

Input:AC 115V/230V 50/60Hz

Output:DC 12V

Total Power

270W

270W

250W

270W

270W

Bed Temp.

≤100℃

≤100℃

≤60℃

≤60℃

≤100℃

Nozzle Temp.

≤250℃

Resume Print

NO

Yes

Yes

Yes

Yes

Filament Detector

NO

Yes

Yes

Yes

NO

Daul Z-Axis

NO

Yes

Yes

Yes

NO

language Selection

NO

EN/CN

Operating System

Windows XP/Vista//7/8/10 MAC/Linux

Printing Speed

≤180mm/s,Normal 30-60mm/s

CONTENTS

Dear consumers,

Thank you for choosing our products. For the best experience, please read the

instructions before operating the Printer. Our 3D team will always be ready to give

you the best service. Please contact us via the phone number or e-mail address

provided at the end when you encounter any problem with the Printer.

For a better experience in using our product, you may learn how to use the Printer in

the following ways:

View the accompanied instructions and videos in the TF card.

Visit our official website www.creality3d.cn You will find relevant software/hardware

information, contact details and operation and maintenance instructions on the

website.

Introduction................................1

General List................................2

Device Installion.........................3

Cable Connection......................4

Screen Information....................5

Loading Filament...…............…6

Platform Adjustment.................7

Software Installation.................8

For the First Printing................9

NOTES

1. Do not use the printer any way other than described herein in order to avoid

personal injury or property damage.

2. Do not place the printer near any heat source or flammable or explosive objects.

We suggest placing it in a well-ventilated, low-dust environment.

3. Do not expose the printer to violent vibration or any unstable environment, as

this may cause poor print quality.

4. Before using experimental or exotic filaments, we suggest using standard

filaments such as ABS or PLA to calibrate and test the machine.

5. Do not use any other power cable except the one supplied. Always use a

grounded three-prong power outlet.

6. Do not touch the nozzle or printing surface during operation as they may be hot.

Keep hands away from machine while in use to avoid burns or personal injury.

7. Do not wear gloves or loose clothing when operating the printer. Such cloths

may become tangled in the printers moving parts leading to burns, possible

bodily injury, or printer damage.

8. When cleaning debris from the printer hotend, always use the provided tools.

Do not touch the nozzle directly when heated. This can cause personal injury.

9. Clean the printer frequently. Always turn the power off when cleaning, and wipe

with a dry cloth to remove dust, adhered printing plastics or any other material

off the frame, guide rails, or wheels . Use glass cleaner or isopropyl alcohol to

clean the print surface before every print for consistent results.

10. Children under 10 years of age should not use the printer without supervision.

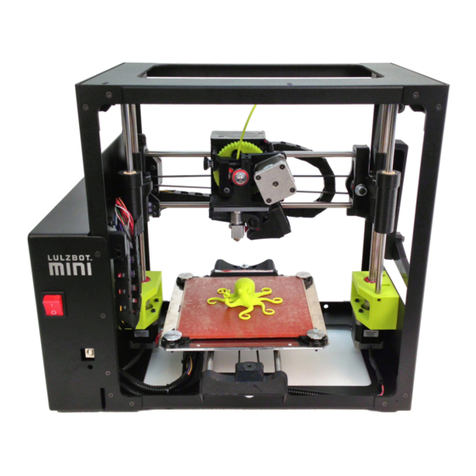

Filament Holder

Control Box

Nozzle Assembly Connection

Platform Connection

Power Cable Connection

Extruder (E) Stepper

X Limit Switch

X Stepper

Z Limit Switch

Z Stepper

Y Limit Switch

Y Stepper

Nozzle Kit

TF Slot and USB Port

Display Screen

Control Knob

Voltage Selection

Platform

Base Frame

Z Gantry Frame

A、 Introduction

1

uTool list

Tool Box Control Box

No.

Image

Name

Qty

No.

Image

Name

Qty

No.

Image

Name

Qty

1

Spool & Nuts

1set

7

Power Cable

1

13

Spade

1

2

Spool Holder

1

8

USB Cable

1

14

Cable Ties

1set

3

TF Card & Card

Reader

1set

9

PTFE Tubing

(spare part)

1

15

Hex keys, Wrench

& Screwdriver

1set

4

T-Bracket (Right)

1

10

Nozzle Cleaner

1

16

Spare Parts

1set

5

T-Bracket

& Z Limit Switch

(Left)

1

11

Filament(200g)

1

17

Decorative Strip

1

6

M5X25 Bolt & Lock

Washer

4 sets

12

Diagonal Pliers

1

18

Thumb Screw

3

Base Frame Gantry Frame

*CR-10 mini without T-Bracket (Right) & Decoration Strip.

B、General List

2

Note: Make sure that the nut for

profile ha s be en tur ned by 90°

before fastening the

T-shaped fixing block.

M5X25

4pcs *CR-10 mini without T-Bracket (right).

uInstall the Gantry Frame

uInstall the T-shaped fixing block.

C、Device Installtion

3

Install decoration belt into the

notch, starting from one end. Cut off the excess material with

the diagonal pliers

Attach the Decorative Trim to all

parts needing to be decorated.

Attach the Bracket

with two thumb screws.

Attach Spool Holder

with included Nuts

Finished

◆ Install the Rack

◆ Install decoration strip

*CR-10mini without Decoration Strip.

*The decoration Strip is available in various colors. The pictures above are for reference only.

4

Y Stepper and Limit Switch

Extruder (E) Stepper

X Stepper and Limit Switch

Z Stepper and Limit Switch

Connect the aviation connectors to the

ports with corresponding pins

Connect the Stepper Motors according to

the yellow labels on the 6pin (4-wire) side.

Connect the Limit Switches according to the

yellow labels on the 3pin (2-wire) side.

•Select the correct input voltage to match your local

mains (230V or 115V)

•Damage can occur if voltage is set incorrectly.

•Make sure the power cable is connected.

D、Introduction

5

Set Temperature of

the Nozzle

Current Temperature

of the Nozzle

Set Temperature of

the Hot Bed

Current Temperature

of the Hot Bed

Part Cooling Fan

Speed

Current Location of

the nozzle

Print Time

Print Progress

Prompt Message

Print Speed

Device Model

Push:OK/Enter Sub Menu

Turn:Change Option/Value

E、 Screen Information

6

1、Preheat

Method 1

Method 2

2、Feed Filament

Press and hold the extruder lever then insert the1.75mm filament through

the small hole of the extruder. Continue feeding until you see filament come out

the nozzle.

Tip:How to Replace the Filament?

1、Cutting filament near the Extruder and slowly feed new filament until they

are fed into the new filament.

2、Preheating the nozzle and withdraw the filament quickly and feed the new

filament.

7

F、Loading Filament

7

1. Prepare →Auto Home. Waiting for the nozzle to move to the left/front of the platform.→ Prepare→Disable Steppers(Close stepper drive,release

motor)

2. Move the nozzle the front/left leveling screw and adjust the

platform height by turning the knob underneath. Use a piece of

A4 paper (standard printer paper) to assist with the adjustment,

making sure that the nozzle lightly scratches the paper.

3. Complete the adjustment of the screw on all 4 corners.

4. Repeat above steps 1-2 times if necessary.

12

34

1111111

11111

The nozzle is too far away from the

platform, so the consumables can not

adhere to the platform.

Filament are extruded evenly, just

sticking on the platform.

The nozzle is too close to the platform,

and the filament are not extruded

enough, even scraping the platform.

G、Bed Leveling

8

1. Double click to

install the software.

3. Select language→Next→Select your machine→Next→Finish.

2、Double click to

open the software.

H、Software Installation

9

1.Slicing

2.Printing

Insert the TF card→ Print → Select the file to be printed.

Open the software→Load→Select the file→Wait for slicing to finish ,and save the gcode file to TF card.

I、First Printing

10

After- Sales Service

Service

1, The printer can be returned within seven days, 15 days replacement,

one year warranty, lifetime maintenance.

Replacement requirement

1. The appearance of the product is intact, without damage, scratches,

smudges, cracks, deformation, etc.;

2. Machine parts, tools and others are complete;

3. Provide a complete and valid purchase invoice and warranty, product

number should be the same.

Warranty coverage

1. The following accessories are not included in the warranty coverage

if they are not damaged by transportation: platform sticker; platform

forming plate; acrylic cover; card reader and TF card; platform glass;

USB cable; filament; rack and tools,etc.

2. Profile: Before we deliver the goods, we will do the machine test, so

maybe there will be light scratch, or due to long-distance

transportation, which scratch the profile a little bit. in the premise of

not affecting the normal use, in principle, not within the scope of

warranty;

3. Nozzle assembly (nozzle, heating block, throat pipe,heat sink, Teflon

tube, etc.) warranty period is 3 months, if it is damage after the

warranty expires, you need to purchase another one;

4. Motherboard, LCD display, power supply, hot bed,warranty period is

12 months, if there are quality problems, you can get free

maintenance; over the warranty period, can be sent back to the

original factory maintenance, the users need to bear the return

shipping and maintenance costs;

5. Not included in warranty coverage:

(1) It is not possible to provide an effective after-sales service card or

serial number;

(2) The whole machine and components exceed the warranty period;

(3) Equipment failure or damage caused by unauthorized modification

of the equipment (private modification includes: 1. modification of

the nozzle assembly; 2. modification of the machine structure; 3. use

of third-party components; 4. use of third-party firmware procedures

or change the original Factory firmware program, etc.);

(4) Equipment failure or damage due to incorrect installation and use;

(5) Equipment failure or damage caused by the use of the equipment

in a working environment not specified by the product;

(6) Equipment failure or damage due improper use (beyond workload,

etc.) or maintenance (moisture, etc.);

(7) Equipment failure or damage due to the use of other branded

components or low quality consumables.

Statement:

For better highlighting the function and effectiveness of 3d printer and

promoting the development of global market economic, strengthening

the user self-discipline of 3d industry and establishing a good image

of 3d printing, since Creality 3d printer have passed all kinds of

authorized product certificates and quality management system.hereby

we declare that it is strictly forbidden to use our printer to print any

products or equipment that are in violation of the specific country and

regions legislation.

SHENZHEN CREALITY 3D TECHNOLOGY CO.,LTD.

11F&Room1201,Block3,JinChengYuan,TongshengCommunity,Dal

ang,LonghuaDistrict,Shenzhen,China,518109

Official Website: www.creality3d.cn

Tel: +86 755-2105 9455

E-mail: info@creality3d.cn cs@creality3d.cn

The revision date: April 24,2019

This manual suits for next models

5

Table of contents

Other Creality 3D 3D Printer manuals

Creality 3D

Creality 3D CRR10 Installation and operation manual

Creality 3D

Creality 3D CR20 Series Manual

Creality 3D

Creality 3D LD-001 Series Manual

Creality 3D

Creality 3D Ender-3 Pro Assembly instructions

Creality 3D

Creality 3D HALOT-ONE User manual

Creality 3D

Creality 3D Ender-3 Pro Assembly instructions

Creality 3D

Creality 3D Ender-3 Pro Assembly instructions

Creality 3D

Creality 3D CR-2020 Operating and maintenance instructions

Creality 3D

Creality 3D Ender-3 Pro Manual

Creality 3D

Creality 3D Ender-5 Plus User manual