03

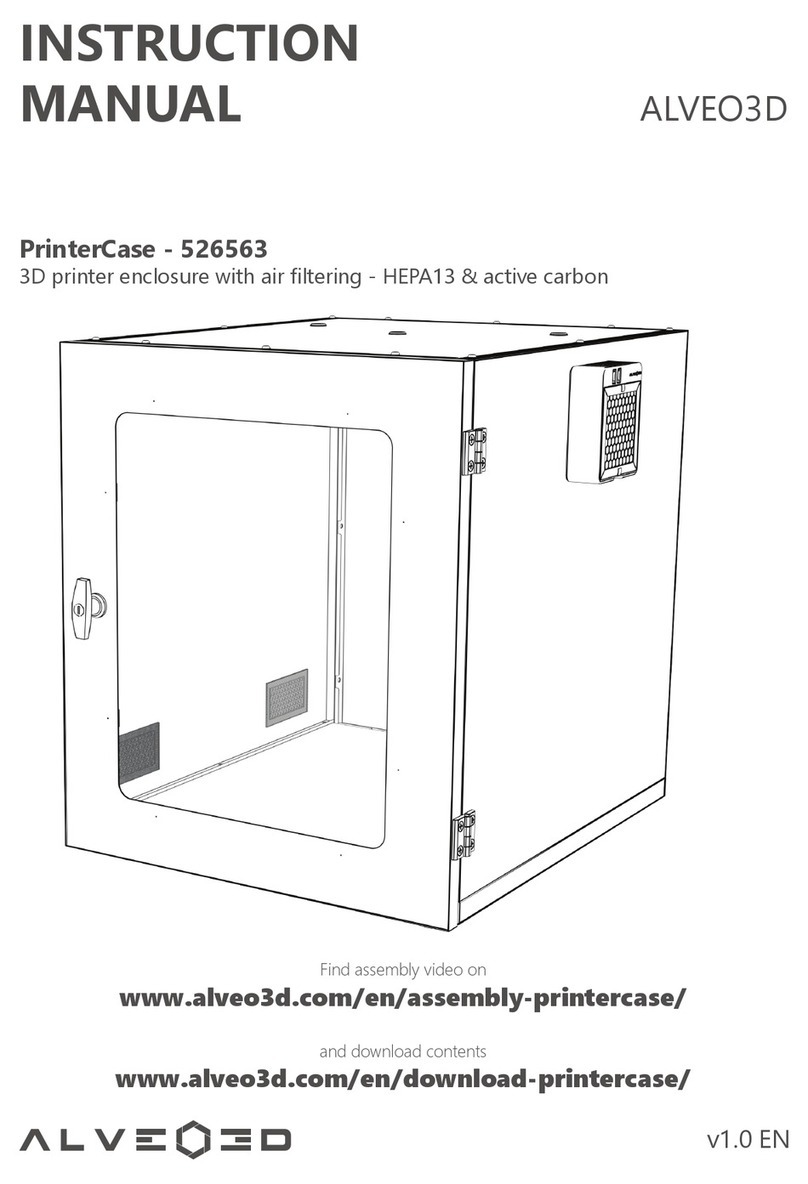

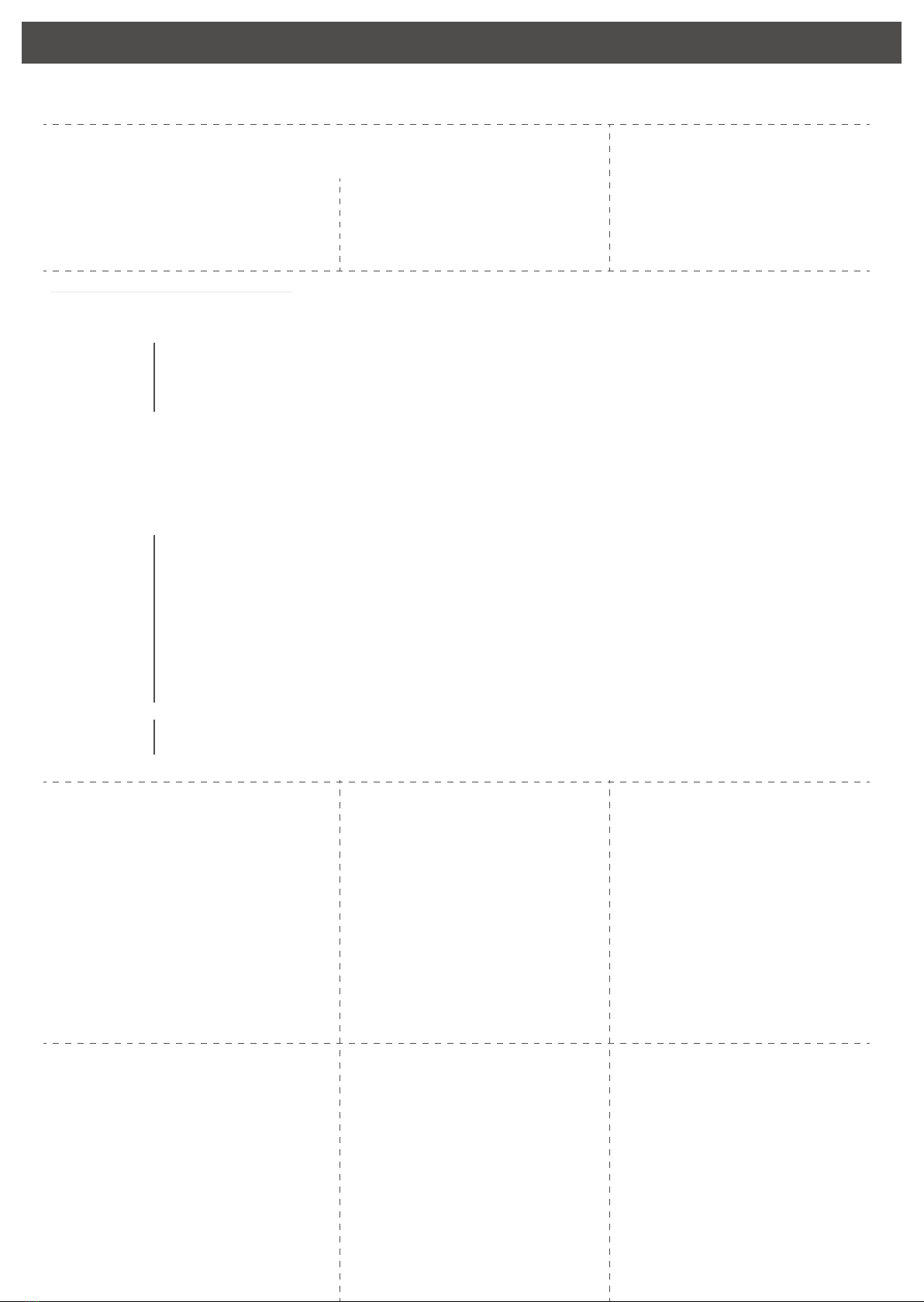

1x main box Model 900 / Model 800 / Model 600

ELEMENTS LIST

1x PMMA panel case

1x set of 5 panels 3mm thick

1x case Aluminium plates

1x bottom plate 4mm

1x top plate 2mm

1x carton tube

2x profiles with holes

2x profiles without holes

1x horizontal bar

Bag - Doors

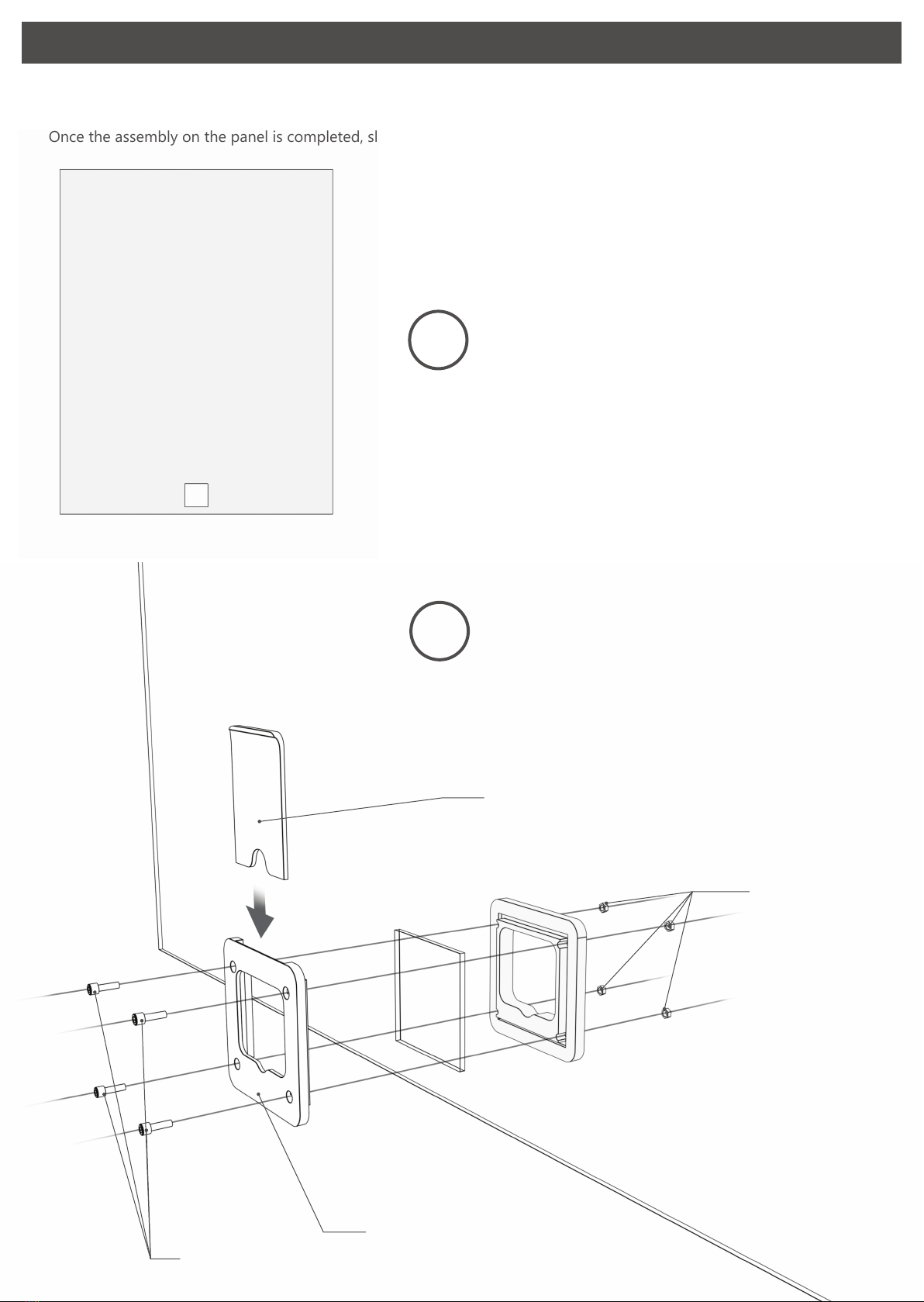

12x M4x12 screws black countersunk

12x M4x8 screws black countersunk

12x M4 hexa nylstop nuts

4x M4x16 stainless steel cylinder screws

4x M4 square nuts

4x M5x12mm black countersunk screw

4x M5 square nut

Bag - Back panel

4x M3 hex nuts

4x M3x10 black cylindrical screw

Bag - Side panel 1

6x M3 hex nuts

6x M3x10 black cylindrical screw

Bag - Side panel 2

8x M5x16 self-drilling screw

4x M3x14 cylindrical screw

Bag - Top panel

8x M5x20mm screw black domed

4x M5x12 screw black domed

2x M5x10 screw black domed

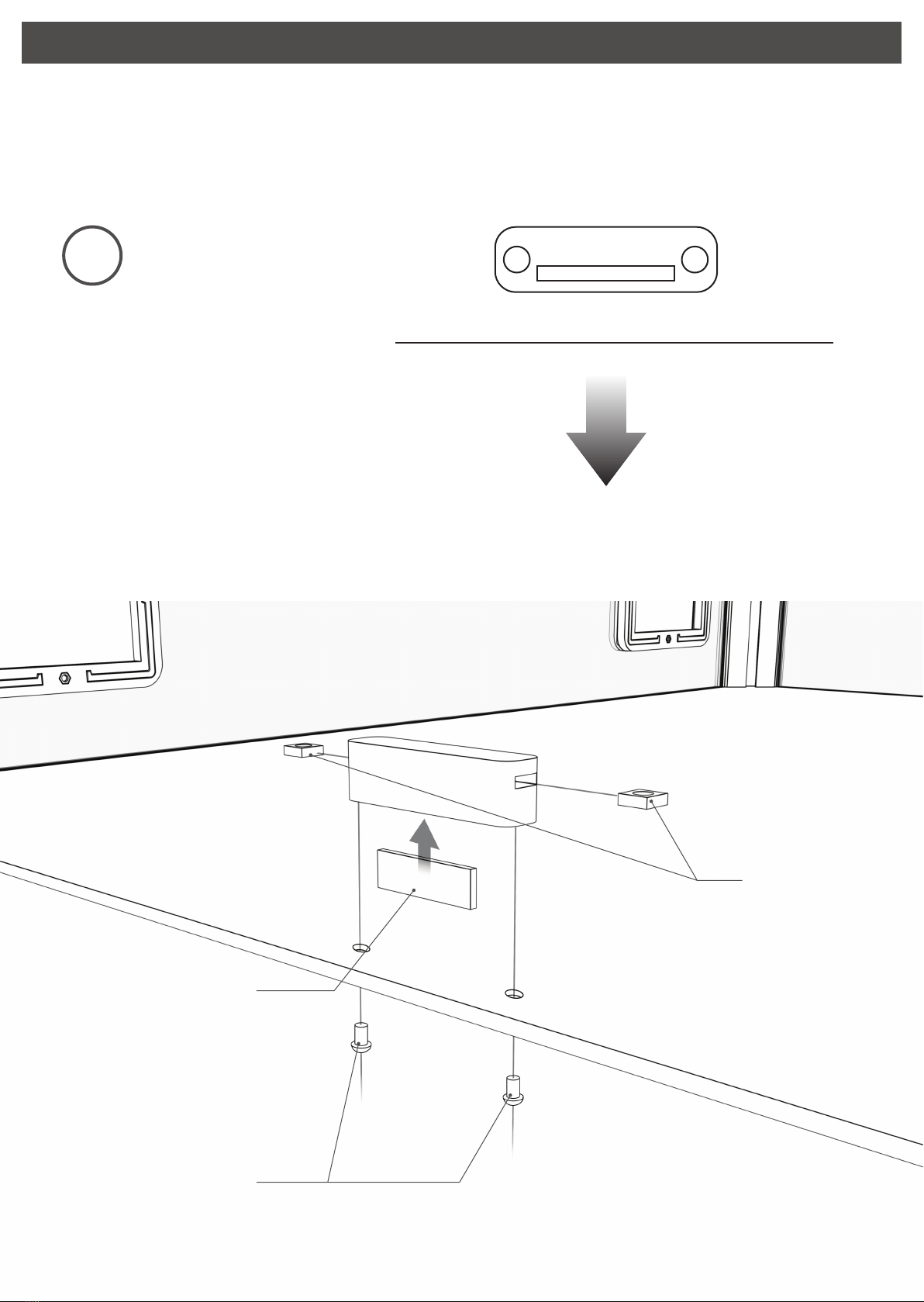

1x base plate

1x cable clamp

Bag - Bottom panel

8x M5x20mm screws

2x screw M4x16 black oval

2x M4 square nuts

2x M5x10 screw black domed

2x M5 hex nuts

4x anti-skid adhesive pads

The elements supplied with the PRINTERCASE SERIES 900 - 800 - 600 Aluminum enclosure

2x accessory boxes 30x30x100

1x manual

1x power supply 24v angled

1x zip bag :

1x v2 card - 1x short temperature probe - 1x cable clamp + self-adhesive base - 1x 4 wires 19cm

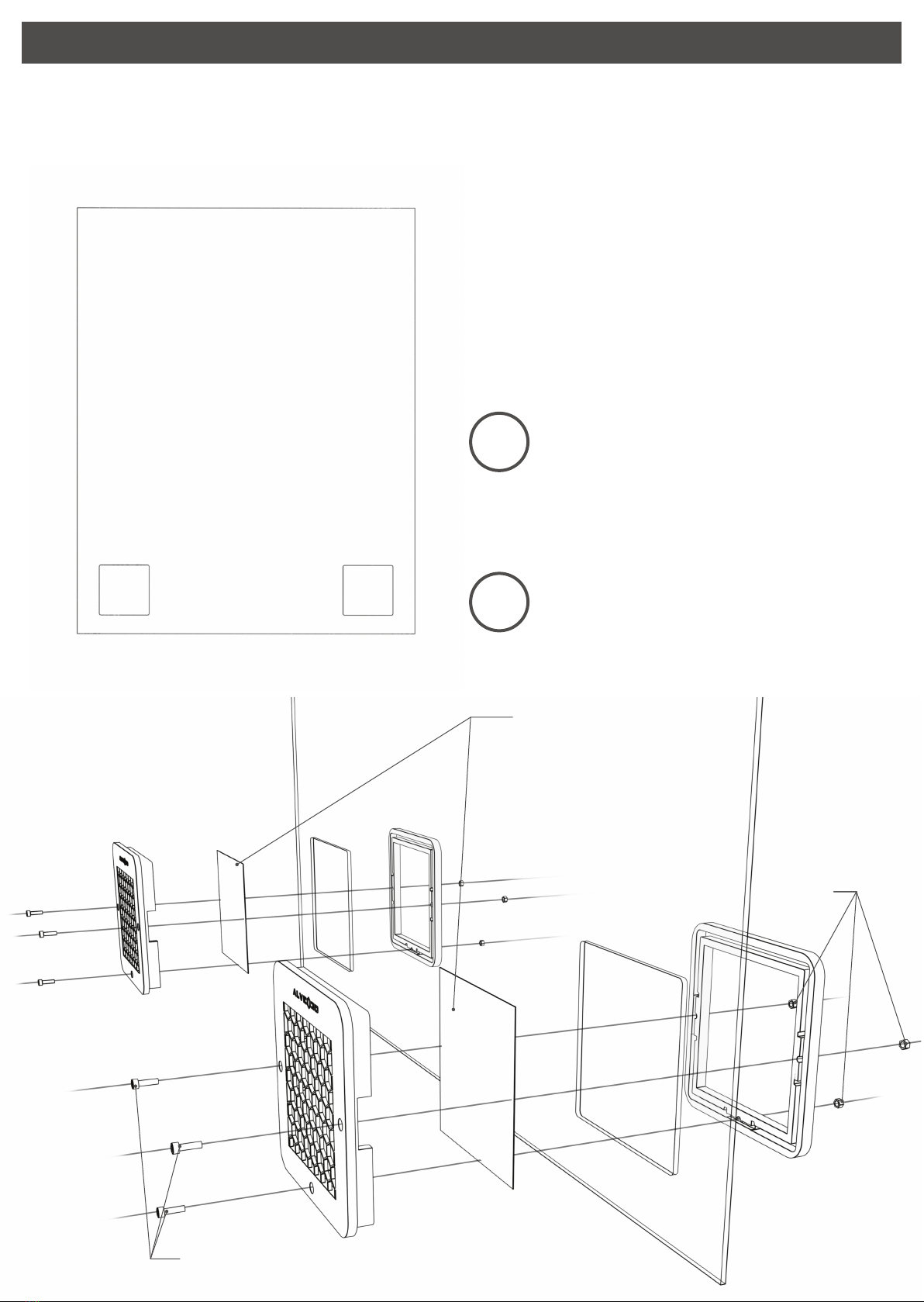

1x alveoZERO = shell fan / filter / grid + 1x gasket 120mm - 1x card V0 double switch + 1x fan H8

1x filtre P3D

1x LED 230cm Model 600 / 270cm Model 800 / 320cm Model 900)

1x LED installation template

1x bag :

Accessories

1x bag :

1x Allen key 2,5mm

1x Allen key 3mm

1x pipe wrench 7mm

1x screwdriver

1x passageway cable

1x pair of grids

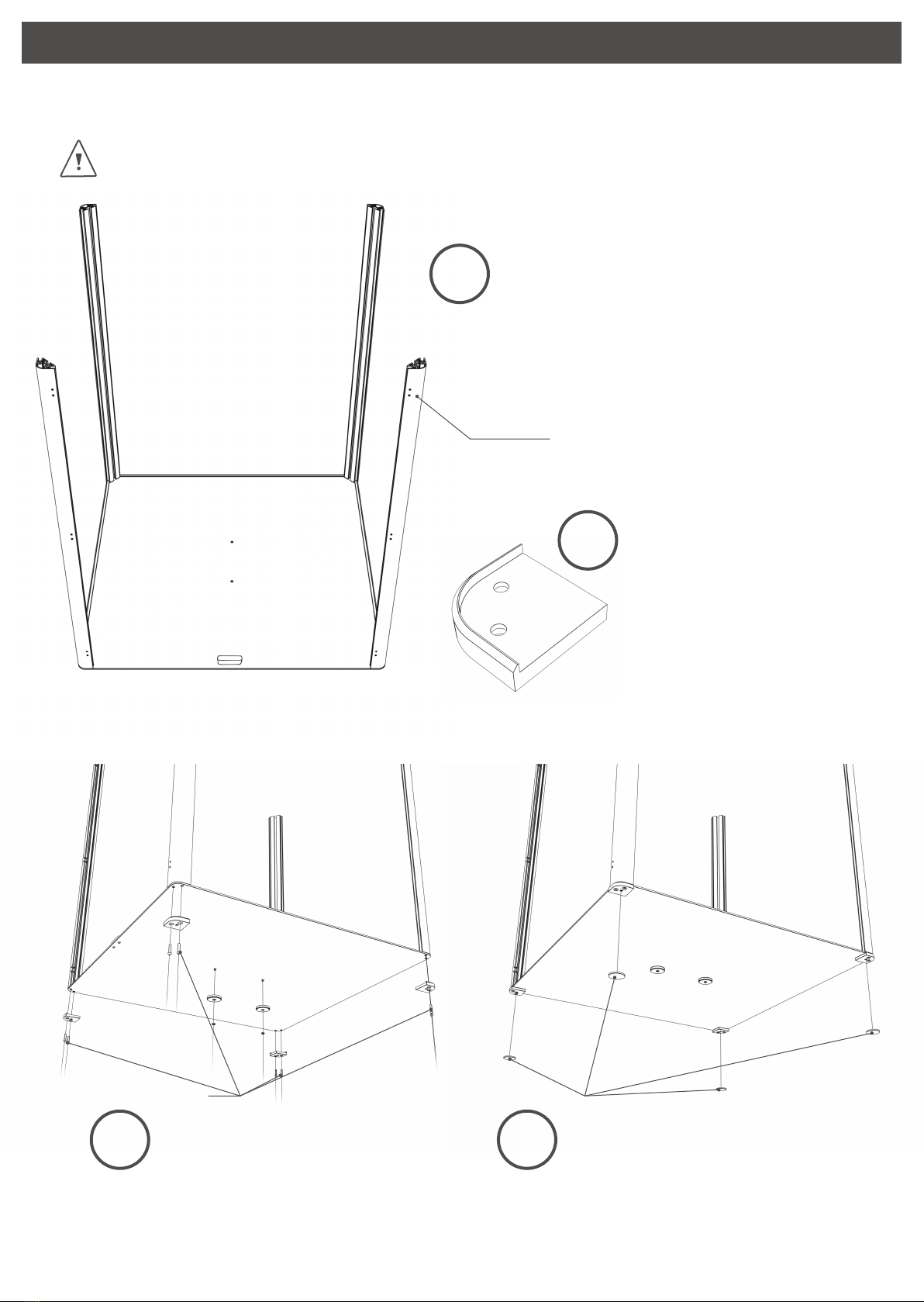

4x corner feet

2x central skids

1x magnet block (bottom) 4x cover caps square nuts M5

1x magnet block (top) 4x cover caps screws handles

2x wide magnets

2x handles

4x magnet screw covers

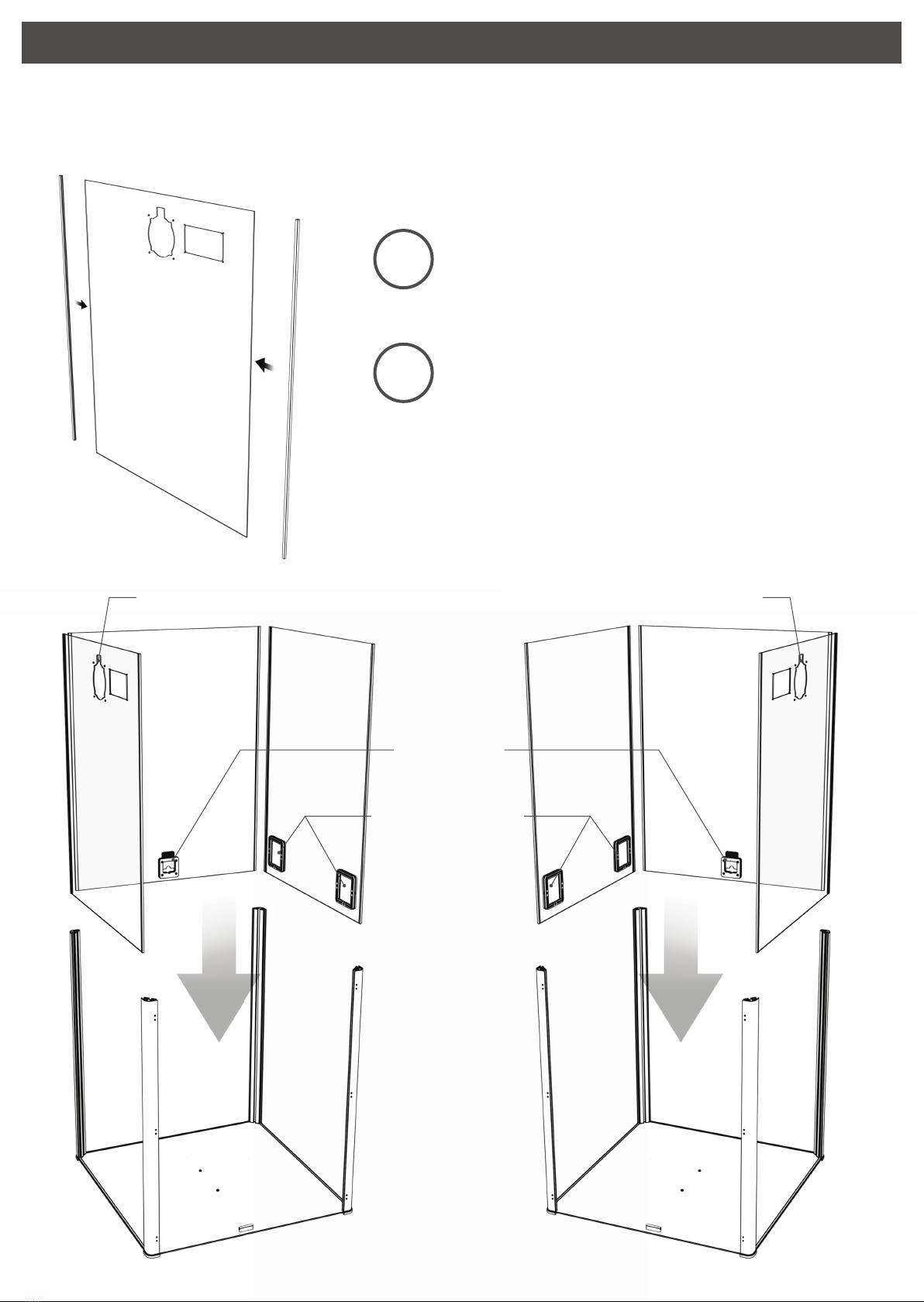

6x hinges Model 900 / Model 800 4x hinges Model 600

6x top panel block Model 900 / Model 800 3x top panel blocks Model 600

4x top cap

6x silicone gaskets Model 900 / Model 800 / Model 600

3x EPDM gaskets Model 900 / Model 800 / Model 600