BCN3D BCN3DR User manual

R

2

RepRapBCN

User Manual

1. PRIOR INFORMATION

Specifications

FFF Technology

Compliance

Safety

Safety Warnings

2. SETTING UP YOUR BCN3DR

Tools and accessories

BCN3DR diagram

3. STARTUP PROCESS

Calibration

Loading filament

Working with your BCN3DR

4. LCD CONTROL

Home screen

Home menu

5. STL FILES

Obtaining STL files

Editing and repairing an STL file

Netfabb interfance

Repairment

Orientation and move home

G-CODE generation

Slic3r configuration

Slic3r first steps

Transfering our G-Code to the BCN3DR

6. PRINTING FROM USB AND SD CARDS

7. FILAMENTS

PLA

8. FIRMWARE

What is it and when to update it?

When it is necessary to update the firmware?

Downloading Arduino’s IDE

9. TROUBLESHOOTING

10. PRINT QUALITY DIAGNOSTICS

11. MAINTENANCE

12. TIPS AND TRICKS

13. TECHNICAL SUPPORT AND CUSTOMER SERVICE

14. GLOSARY

15. WARRANTY, REFUNDS AND REPLACEMENT POLICY

16. TERMS OF SERVICE

3

3

4

5

6

8

9

10

12

12

13

14

14

14

16

18

18

19

20

21

22

22

23

23

26

26

28

28

28

28

29

29

31

33

35

35

36

36

38

38

3

INDEX

32

RepRapBCN

User Manual

Extrusion Fused Filament Fabrication (FFF)

Ø370 mm x 560 mm

7 kg (without spool)

Diameter: 170mm

Height: 180mm

1

0,1-0,35mm (with standard 0,4mm nozzle)

0,2-0,5mm (with 0,6mm nozzle)

X Y and Z axis: 0,05mm

15-35ºC

260ºC

3mm

PLA

Arduino Mega 2560 + RAMPS 1.4

SD Card (autonomous operation)

USB Cable (controlled through Repetier Host)

Específico BCN3DR (basado en Marlin)

STL

Slic3r, Cura

AC 100–240 V, ~0.2-0.4 amps, 50–60 Hz

60W

3

1. PRIOR INFORMATION

Specifications

Print Technology:

Physical Dimensions:

Weight:

Printing Volume:

Number of extruders:

Layer height:

Positioning resolution:

Working temperature:

Max. extruder temperature:

Filament diameter:

Compatible materials:

Electronics:

Connectivity:

Firmware:

Compatible files:

Code converter software:

AC Input:

Power requirements:

4

RepRapBCN

User Manual

FFF Technology

BCN3DR is a 3D printer based on fused filament fabrication additive manufacturing technology, consisting in the

deposition of melted material layer by layer based on a previously divided digital model.

The head makes the necessary movements to deposit a layer of material, then a slight vertical movement to continue

with the next layer. The process is repeated until the full object is completed.

Through rotation, the extruder uses a

hobbed bolt to insert the right amount

of filament

4

The filament is lead to

the extruder through

the bowden

The heatblock fuses the filament

to a workable temperature

The printing surface

remains still

The material is distributed through

the model when necessary

The hot filament is extracted through

the extruder with a smaller diamater

54

RepRapBCN

User Manual

Compliance

Fundació Privada Centre Cim hereby states that BCN3DR complies with the essential requirements and other rele-

vant provisions of the following Directives:

Low Tension Directive 2006/95/CE

Directive on machinery 2006/42/CE

Directive RoHS2011/65/UE

5

6

RepRapBCN

User Manual

6

Safety

To avoid possible residual risks for the user , please read carefully the following safety measures.

REPRAPBCN IS EXEMPTED OF ANY LIABILITY IF THE USER DOES NOT FOLLOW THE FOLLOWING HANDLING

INSTRUCTIONS:

• Very important. Like with any other appliance, do not touch the terminals of the cables connected to

the main. The voltage is 230V and there is a risk of electrocution. Other cables from the machine working

at 12V and present no risk.

• This machine produces and emits radio frequencies during use. It is important to install and use

the equipment according to the instructions in this manual to avoid harmful interference to domestic

appliances such as television or radio. If the machine causes interference, increase the separation bet-

ween it and other appliances.

• Print materials are not innocous and may emit toxic fumes. Always print in open or vented spaces.

• Do not breathe closer to 25cm from the extruder head or heads when printing.

• Do not place any object or body part between the moving parts of the machine when

functioning.

• Do not touch its hot parts (hotbed and hotend) when the machine is turned on, or within 15

minutes of operation.

• Do not connect or disconnect any device and/or electrical connector when the machine is on.

• Oversee proper function of the machine during operation.

• In case of an emergency, stop the machine using the STOP button and unplug.

76

RepRapBCN

User Manual

Safety warnings

The following signs have been arranged on the printer to warn users about areas of potential risk arising from its use or

possible actions that are not recommended.

Hot Surface, allow it to cool down before handling.

Moving parts, danger of crushing, disconnect before handling

7

8

RepRapBCN

User Manual

2. SETTING UP YOUR BCN3DR

Unboxing

The BCN3DR kit is delivered inside a properly secured cardboard box.

• Printed parts

• Sheet metal panels

• Rods and bars

• NEMA 17 motors

• Arduino Mega , Ramps 1.4, LCD and Pololus drivers

• Wiring

• Fans

• Screws , bearings and belts

• Bowden tube and BCNozzle

• Glass printing surface

• SD card

• Power supply cable

• Power supplier

• 1Kg PLA spool

• Adhesive spray (3DLAC)

• Tools

8

98

RepRapBCN

User Manual

Tools and accessories

The BCN3DR comes with a kit with every tool necessary to build the printer from scratch included. It also includes a

fixing spray specially design for 3d printing.

Allen wrenches

set

Flat screwdriver Phillips screwdriver

9

Pliers

10

RepRapBCN

User Manual

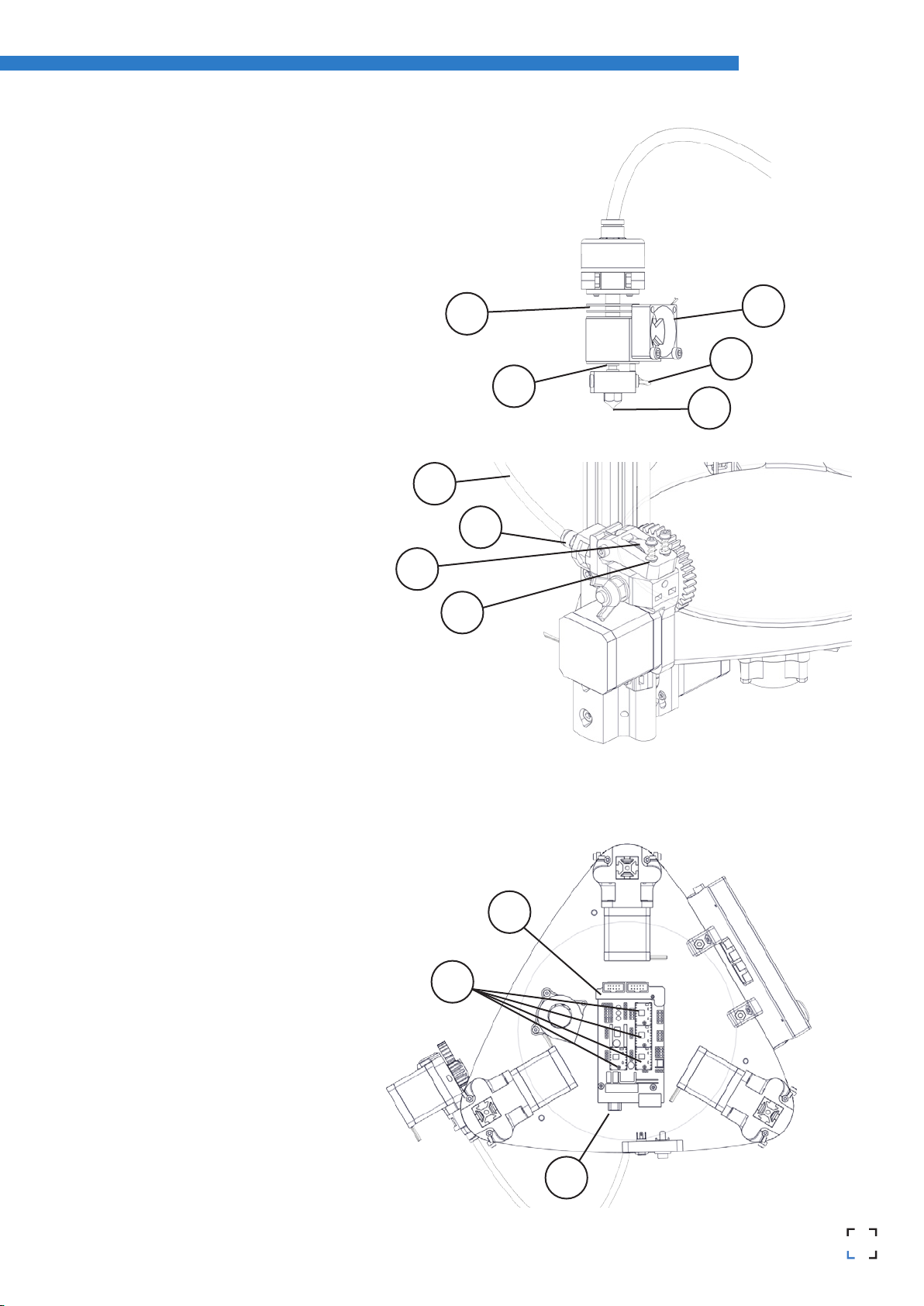

BCN3DR diagram

1. LCD Screen

2. SD Card Slot

3. Hot end

4. Extruder rod guides

5. Lineal guides

6.

7.

9.

3.

10.

2.

11.

1.

4.

8.

5.

Left viewPerspective

10

6. Endstop

7. Stepper motors

8. Power supply

9. ON/OFF button

10. Spool holder

11. Extruder

1110

RepRapBCN

User Manual

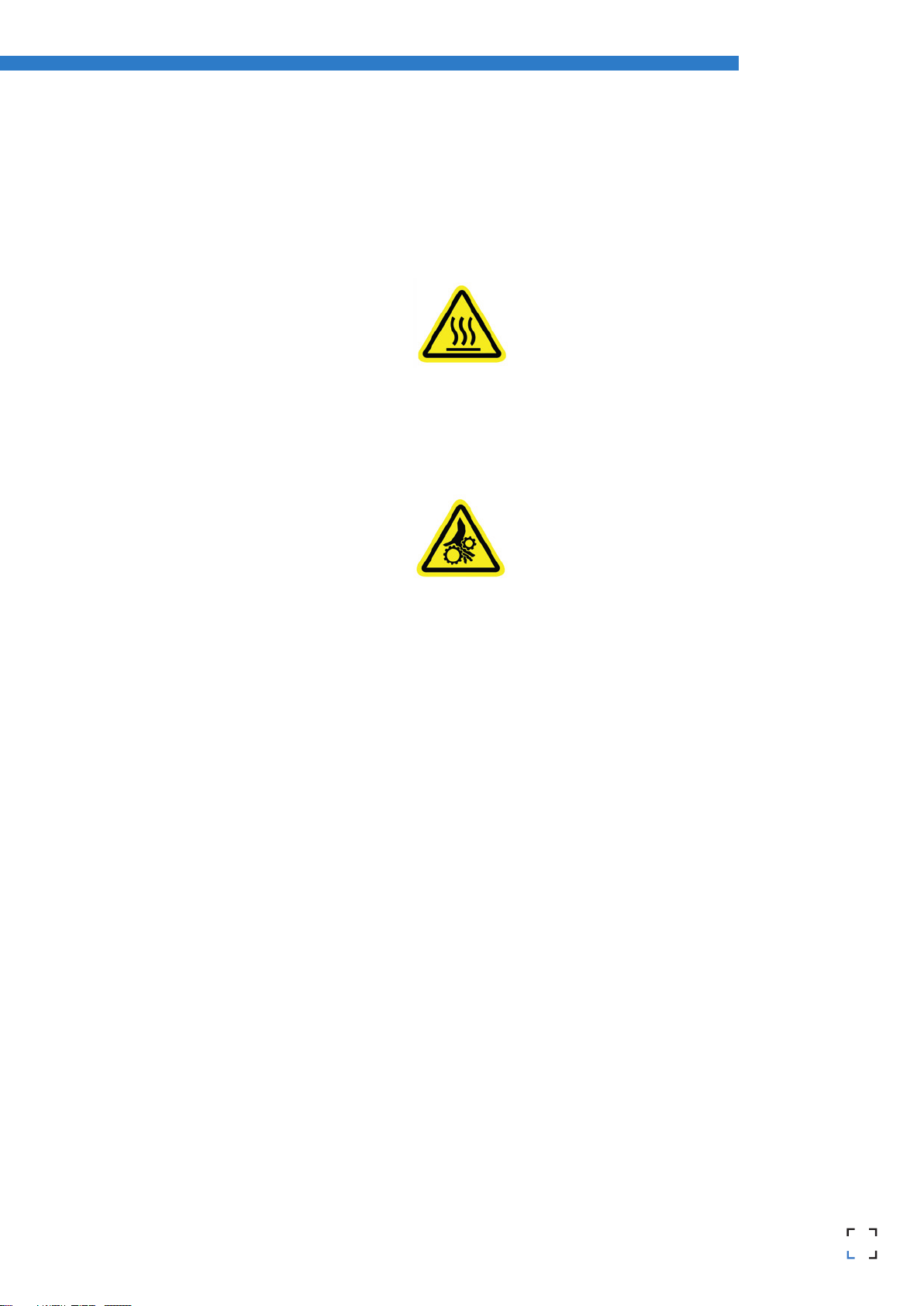

Hot end

1. Heatsink

2. Heat break

3. Heatblock

4. Nozzle

5. Hotend fan

Extruder

6. Idler

7. Tightening screws

8. Bowden tube

9. Pneufit

Electronics

10. Drivers (Pololus)

11. Arduino + RAMPS

12. USB connector

1.

8.

9.

6.

10.

11.

12.

2.

7.

4.

3.

5.

12

RepRapBCN

User Manual

3. STARTUP PROCESS

Hotbed height calibration

For a proper use, the nozzle movement must be parallel to the Hotbed Surface.

To achieve that, there are three screws available to calibrate its orientation.

There is a risk of the nozzle hitting the hotbed glass so the first layer not sticking on its surface when the base is decalibra-

ted. The following steps must be followed:

1. Click on Autohome (Prepare > Autohome) so the printer axes move to their initial position.

2. Tighten the three M5 screws located on the printing surface to compress the springs holding the base in order to

lower it.

3. Untighten the same screws five turns so the nozzle does not collide with the glass in preparation for the next step.

4. Click on Prepare > Move Axis > 1 mm > Move Z to move the extruder platform to Z:+000.00 mm.

5. Move the nozzle closer to the X tightening screw following the glass surface. To do that, click on Prepare > Move

Axis > 1 mm > Move X and set it to X: -085.0mm.

6. Untighten once more the closest screw until the nozzle tip is 0.2mm from the glass. Use a folded paper to check

the distance, at 0.2mm it should slightly graze both the nozzle and the glass.

7. Move the nozzle close to the front tightening screw. To do that, click on Prepare > Move Axis > 1mm > Move X and set it

to X: +060.0mm and in menu Y set it to Y: -060.0mm.

8. Repeat the levelling process using a folded paper.

9. Move the nozzle close the rear tightening screw. Follow the same

procedure and use the values X: +045.0mm and Y: +060.0mm.

10. Repeat the levelling process using a folded paper.

11. To finish up, move the nozzle back to the first screw leveled using

the values X: -085.0mm and Y: +000.0mm.

12. Once again, level it using a folded paper.

x0

z

y

1312

RepRapBCN

User Manual

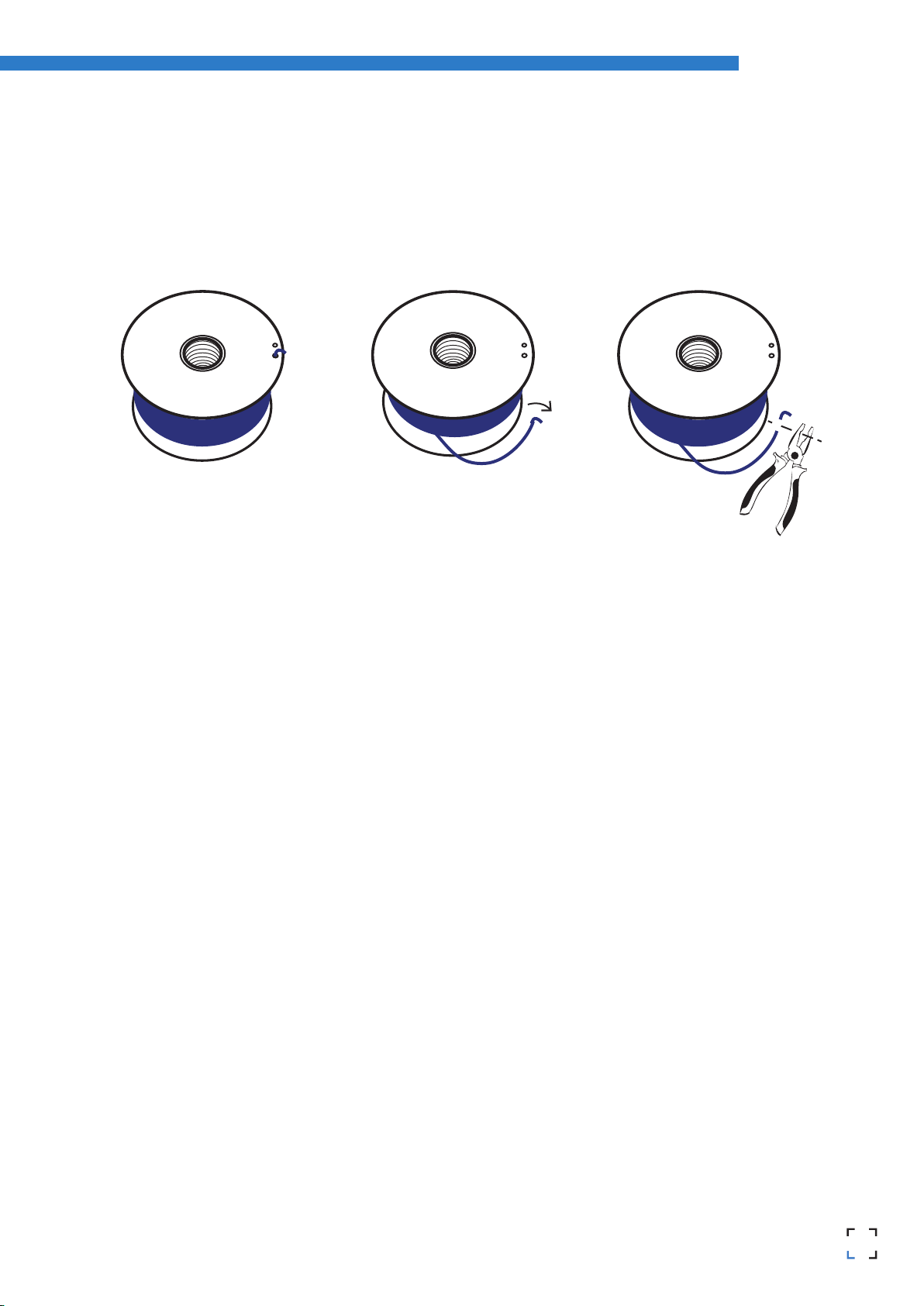

Loading filament

One of the more common operations in our BCN3DR will be, for several reasons, loading and unloading filament: a

change of color, a change of material, using a fresh spool, cleaning, maintenance...

• Unloading:

1. Heat the extruder selecting Preheat PLA in the menu.

2. Click on Prepare > Move Axis > 1 mm > Extruder and rotate the wheel slightly clockwise to extrude a few milli-

metres of material. This procedure will help prevent jams.

3. Click on Prepare > Move Axis > 1 mm > Extruder and rotate the wheel anticlockwise a 100mm moving the gear a

few steps back until the filament is free.

4. Untighten the two idler screws on the extruder.

5. Manually extract all the filament from the Bowden tube.

• Loading:

Once the thread is out, disconnect the Bowden tube from the hotend connector. The easiest way to do that is by

following these steps:

1. Tighten the Bowden tube to the end from below.

2. Manually open the latch taking care not to crush the tube.

3. Pull the tube out of the connector

4. Untighten the two idler screws on the extruder.

5. Select Preheat PLA in the menu and insert the filament along the whole tube until 20mm stick out of it.

6. With the help of some pliers, insert the plastic thread into the hotend until filament is extruded through the

nozzle. If necessary, push the filament from the extruder deeper inside the tube.

7. Once the nozzle is full of filament, grab the end sticking out of the extruder and pull it out while, at the same

time, inserting the tube into the connector.

8. Once the Bowden tube is firmly held by the connector, slightly tighten the idler screws by hand.

9. Once this is done, the filament is loaded and the machine ready to print.

14

RepRapBCN

User Manual

E 26/0o

SD

BCN3DR ready.

___ __ __

%

FR

140% Z000.0

:

4. LCD CONTROL

The BCN3DR can be operated from its LCD menu, a single button combining two movements:

• Turn to move through the menu.

• Click to select desired option.

Adjacently to the control button there is an emergency red button to stop the machine in case of malfunction. It

stops the printer but keeps the screen and fans on. Once pressed, the printer resets itself to resume use.

Home Screen

The main screen reports on the status of the printer at the time of the printing currently in progress.

1. Printing speed (Fr)

2. Printing height indicator (Z)

3. Percentage of printing program read (SD)

4. Status bar and time elapsed

5. Notifications

6. Target/Current temperature

1.

6.

3

5.

2.

4.

1514

RepRapBCN

User Manual

Printing Speed (Fr)

The center left value indicates printing speed. By default a 100% value is shown, meaning it is printing at the specified

value in the executed printing program.

This value is modifiable at any time, even when not printing, by just turning the control button. Thus, with a 150%

value it will print 1,5 times faster than stipulated in the printing program.

NOTE: Varying the printing speed modifies the motors speed proportionally and directly to the printing velocity, affecting only

axes X, Y, Z and the extruder but no the temperature, therefore, printing problems can appear when increasing or decreasing

speed to a large degree. It is not recommended to modify this value by more than 50%..

Printing height indicator (Z)

The center right value indicates the printing head height.

NOTE: This value might be incorrect when mesured just after switching the printer on, Z=0 actually being the point at

which the printer stopped last time it was used.

Percentage of printing program read (SD)

In the lower part of the screen the percentage of program read is shown. Notice that this value states the percentage

of Gcode lines performed, not the percentage of the object being printed.

Status bar and time elapsed

In the lower right corner, a status bar shows the same information as before.

Above it, time elapsed since printing process started is shown.

Notifications

Last line shows different messages noticing the processes being carried out by the machine.

Actual and target temperature

In the upper left corner four different temperatue values can be visualised, indicating target temperature (up), actual

temperatures mesured by the thermistors (down), hotend temperature (left) and hotbed temperature (right).

16

RepRapBCN

User Manual

Home menu

To enter the menu, click the wheel from the Home Screen.

Three options are found: Prepare, Control, Print from SD/No SD (according to whether the SD has been inserted into

the slot or not).

http://www.reprap-electronics.de/

Prepare menu

Prepare allows you to operate the machine without being actually printing . The following options are found:

• DisableSteppers: Turns the motors off, easing the manual movement of the hotbed and printing head.

• Autohome: Positions the printing head in its home position.

NOTE: Before selecting this option, make sure nothing obstructs the movement of all the axes. Likewise, it is necessary to

perform the calibration process before selecting this option.

• Preheat: Unfolds a list of several materials. Selecting one of them makes the printer preheat to the proper wor-

king temperature for said material.

• Cooldown: Turns off the power of the heating parts.

NOTE: The machine cools down naturally, so the hot parts could be burning for a while.

• Move Axis: It controls axes movement. Select the distance and the axis. To move the axis, turn the control button.

Rotate clockwise to move in the positive direction, anticlockwise for the negative one.

NOTE: Before clicking on this option make sure nothing is blocking movement along all the axes. E axis will not move if the

extruder is cooler than a 150ºC.

Info screen

Prepare

Control

No SD Card

Main

Disable steppers

Auto home

Preheat PLA

1716

RepRapBCN

User Manual

Control menu

Allows you to modify the printer parameters before and during the printing process. They are much more specific

parameters, requiring a much deeper knowledge of the internal operations of the machine.

Print from SD /No SD

Allows you to access the SD card and select a stored file to print. If the SD card is not inserted, a No SD message is

shown. In that case, the BCN3DR can be connected to a PC through a USB cable (see printing section).

Print from SD Print from USB

Main

Temperature

Motion

Restore failsafe

18

RepRapBCN

User Manual

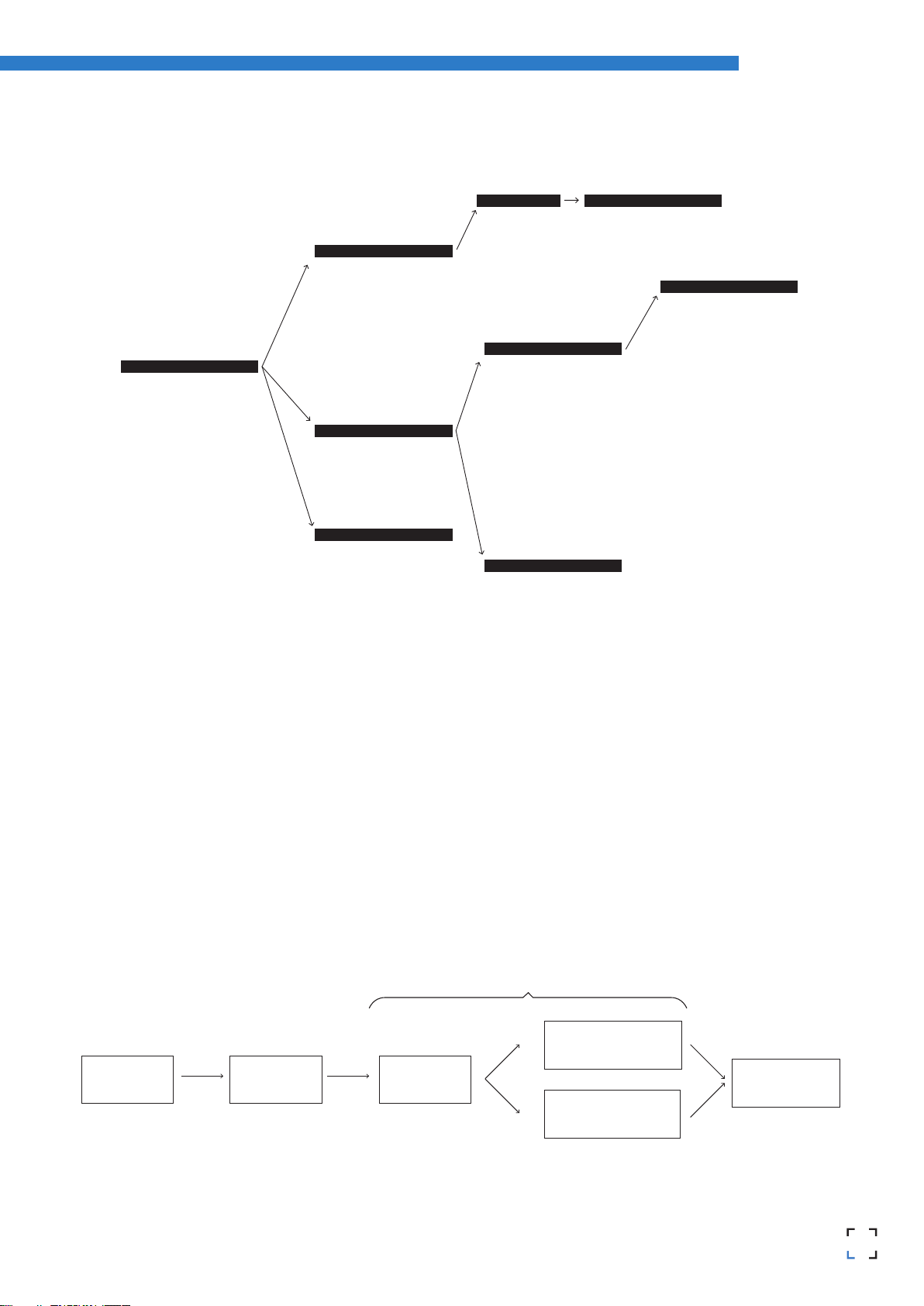

Just for reference, the full menu diagram is shown below:

Working with your BCN3DR

The BCN3DR operation diagram from beginning to end is show below. As shown, two alternatives operating

paths are possible:

Prepare

Control

No Card

Main menu

Main

Disable steppers

AutoHome

Preheat PLA

Cooldown

Move Axis

Prepare

Fan Speed

Nozzle

Control

Nozzle

Autotemp

Min

Max

Fact

Fan Speed

PID-P

PID-I

PID-D

PID-C

Preheat PLA Settings

Temperature

Control

Vmax-Y

Vmax-Z

Vmax-E

Vtrav-min

Vmin

Amax-X

Amax-X

Amax-X

Amax-X

Aretract

Xsteps/nn

Ysteps/nn

Zsteps/nn

Esteps/nn

Motion

Main

Temperature

Control

Main

Card Menu

VXY-Jerk

Vmax-X

Move Axis

Bed

Move

Move

Move

X:

Y:

Z:

Extrude

Move 1 mm

Move 0,1 mm

Move Axis

Temperature

Preheat PLA Settings

PLA

Load memory

Store memory

Restore failsafe

CAD model .STL file SLIC3R utility

(G-code generator)

SD card

Controller

firmware

CAM (Computer Aided Manufacturing) toolchain

SENDER

(USB connection)

1918

RepRapBCN

User Manual

5. ‘.STL’ FILES

The backbone of BCN3DR printing are the 3D model files.

The most commonly file type found is the *.STL format. An STL file describes a raw unstructured triangulated surfa-

ce. The smaller the triangles are, the bigger the resolution and the detail of the 3D model.

Obtaining STL files

There are three different methods:

1) Own design: The users create their own objects with a Computer-aided design best suited for people with pre-

vious knowledge in modeling.

A wide range of available programs exist, some of them free (OpenSCAD, FreeCAD, Blender), while others requiere a

software license (SolidWorks, Rhinoceros, Inventor, etc.). In general terms, all of them allow the user to import/ex-

port STL files.

2) Download: Nowadays there are lots of online repositories where people share their own models with the rest of

the community. As an example, the following ones are mentioned:

• www.grabcad.com – Repository specialized in engineering, design and architecture models. Not always in STL

format but in the original format used by the creator.

• www.thingiverse.com – Repository marketed by MakerBot, contains a great deal of STL models and customiza-

tion tools.

20

RepRapBCN

User Manual

3) Digitalization: Paralel to the development of 3d printing, home scanning technology is evolving at high speed. In

this regard, it’s worth visting Autodesk’s own www.123dapp/catch. In there, free tools to obtain digital models from

pictures taken with a photographic camera are provided.

Other existing methods are: specialized softwares that combine the use of projectors and cameras or 3D scanners.

Editing and repairing a .STL file

As it has been mentioned before, a file in STL format is not always in the best condition. Some of the most common

errors are:

• Holes. The model must be unclosed, with no holes present.

• Faces orientation: An STL model is composed of flat faces. Their orientation must be the same and outwards. In other words,

it cannot be that some sides point in one direction and some in other, they all must be facing outwards. This usually happens

by accident when working with modeling software.

Existen varios software para editar y reparar archivos STL corruptos. RepRapBCN recomienda Netfabb que, en su versión

gratuita BASIC permite realizar las operaciones básicas de edición (escalar, rotar, cortar, combinar, etc.), reparación y medición.

http://www.netfabb.com/downloadcenter.php?basic=1

The essential information for editing STL files is detailed below. For more detailed information, it is advisable to visit

the official site.

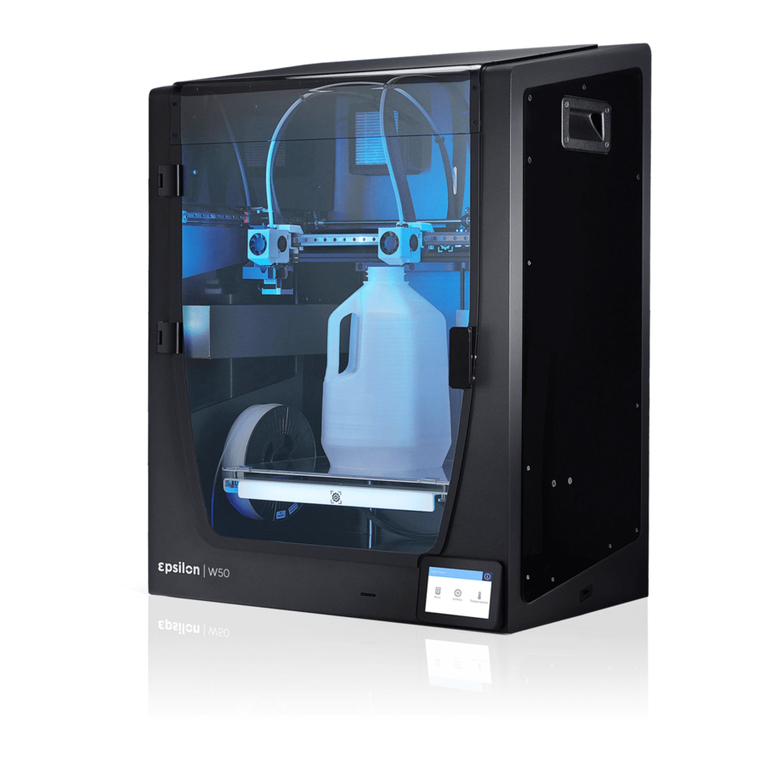

Table of contents

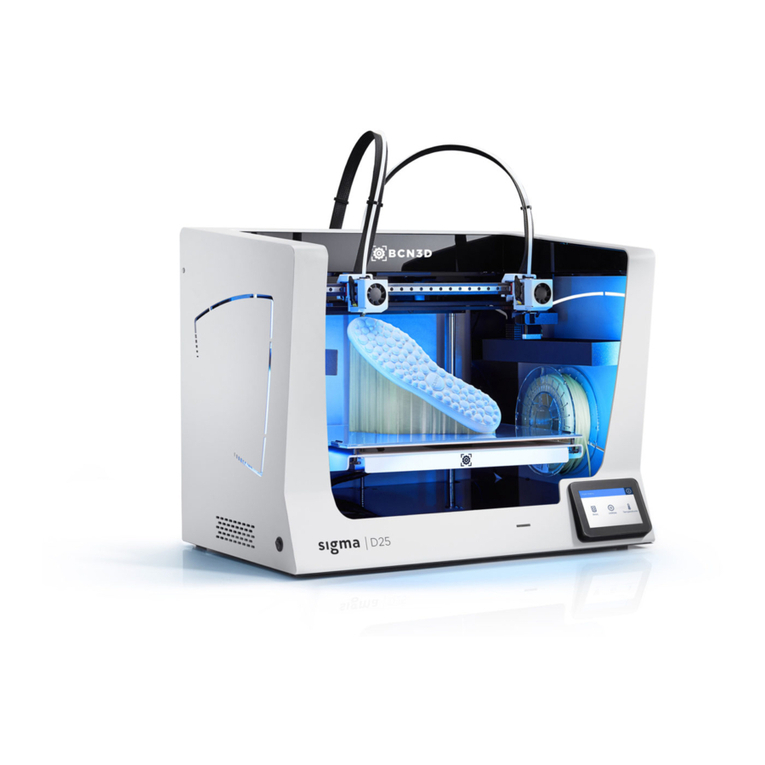

Other BCN3D 3D Printer manuals

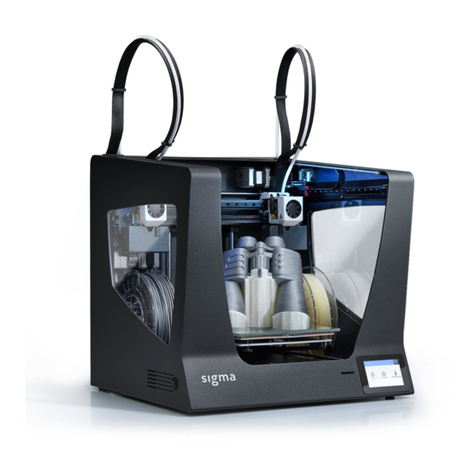

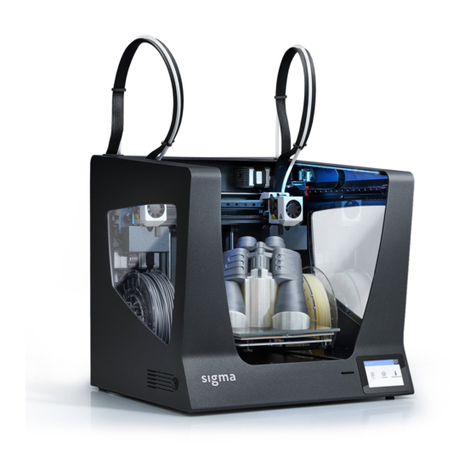

BCN3D

BCN3D sigma R19 User manual

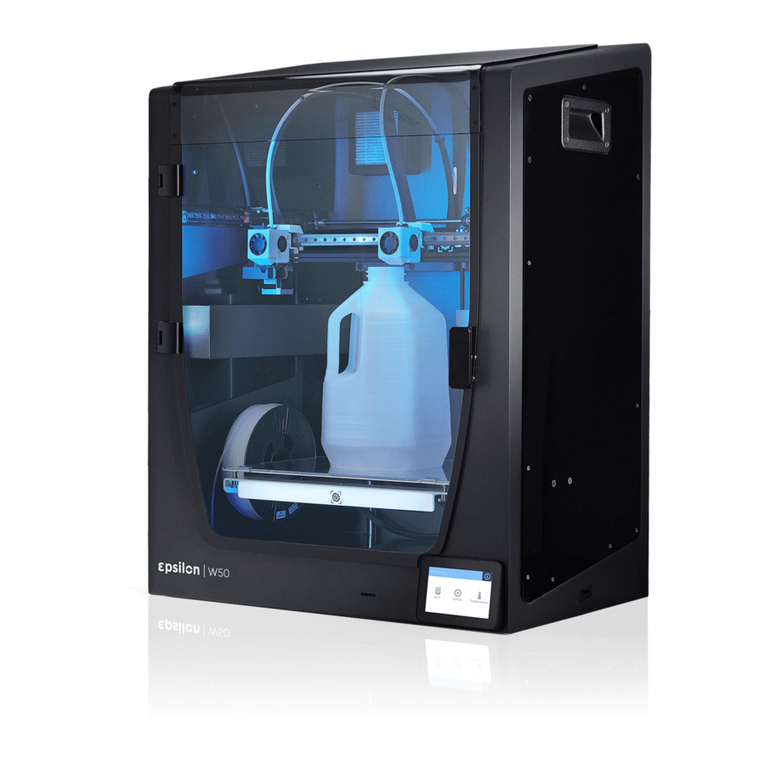

BCN3D

BCN3D Epsilon Series User manual

BCN3D

BCN3D Sigmax User manual

BCN3D

BCN3D Sigma Series User manual

BCN3D

BCN3D Sigma R16 Parts list manual

BCN3D

BCN3D Sigma Series User manual

BCN3D

BCN3D Epsilon User manual

BCN3D

BCN3D Sigma User manual

BCN3D

BCN3D Epsilon Series User manual

BCN3D

BCN3D Epsilon Series User manual