CPWR-AN26, Rev A, 08-2018

Copyright © 2018 Cree, Inc. All rights reserved.

The information in this document is subject to change without notice.

Cree and Zero Recovery are registered trademarks, and the Cree logo and C3M are trademarks, of Cree, Inc

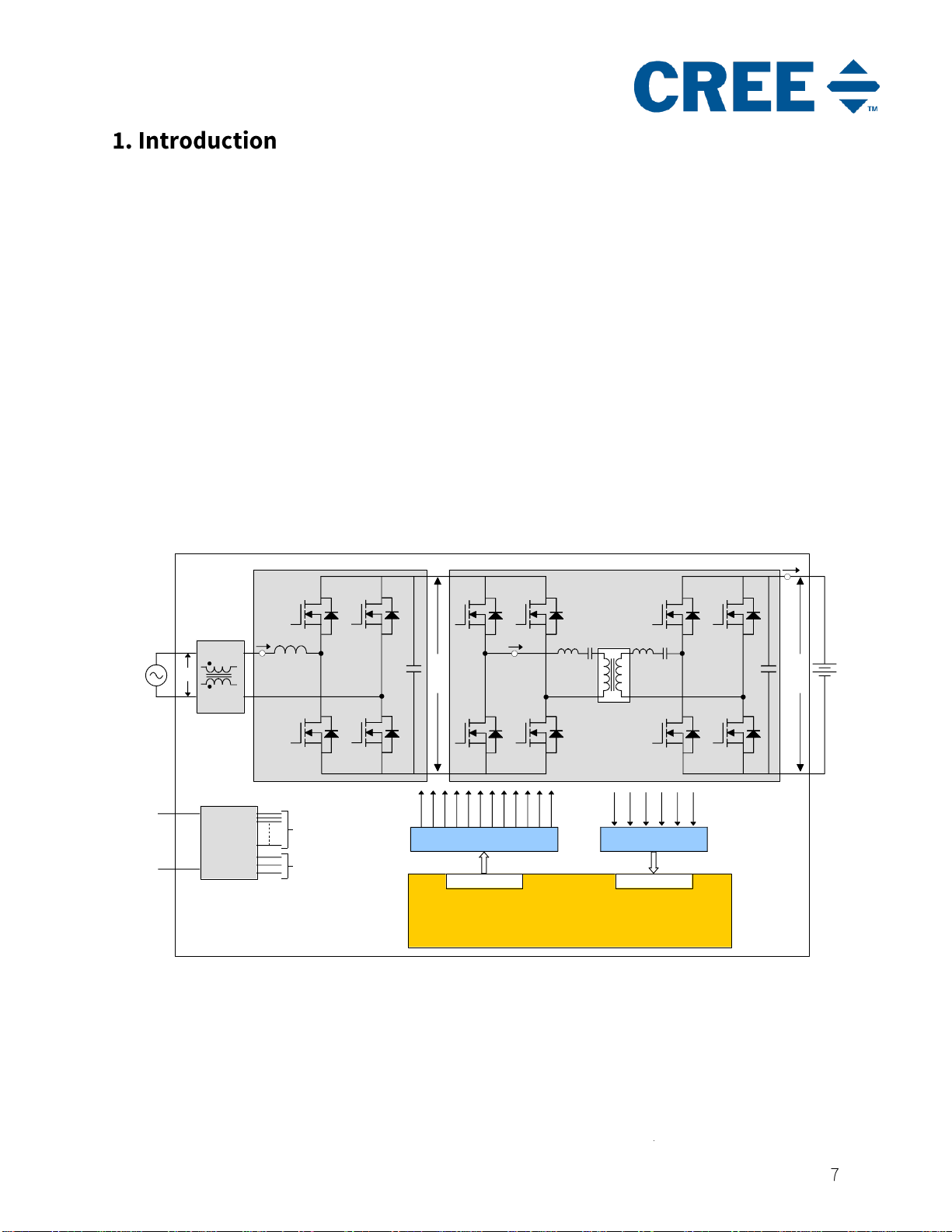

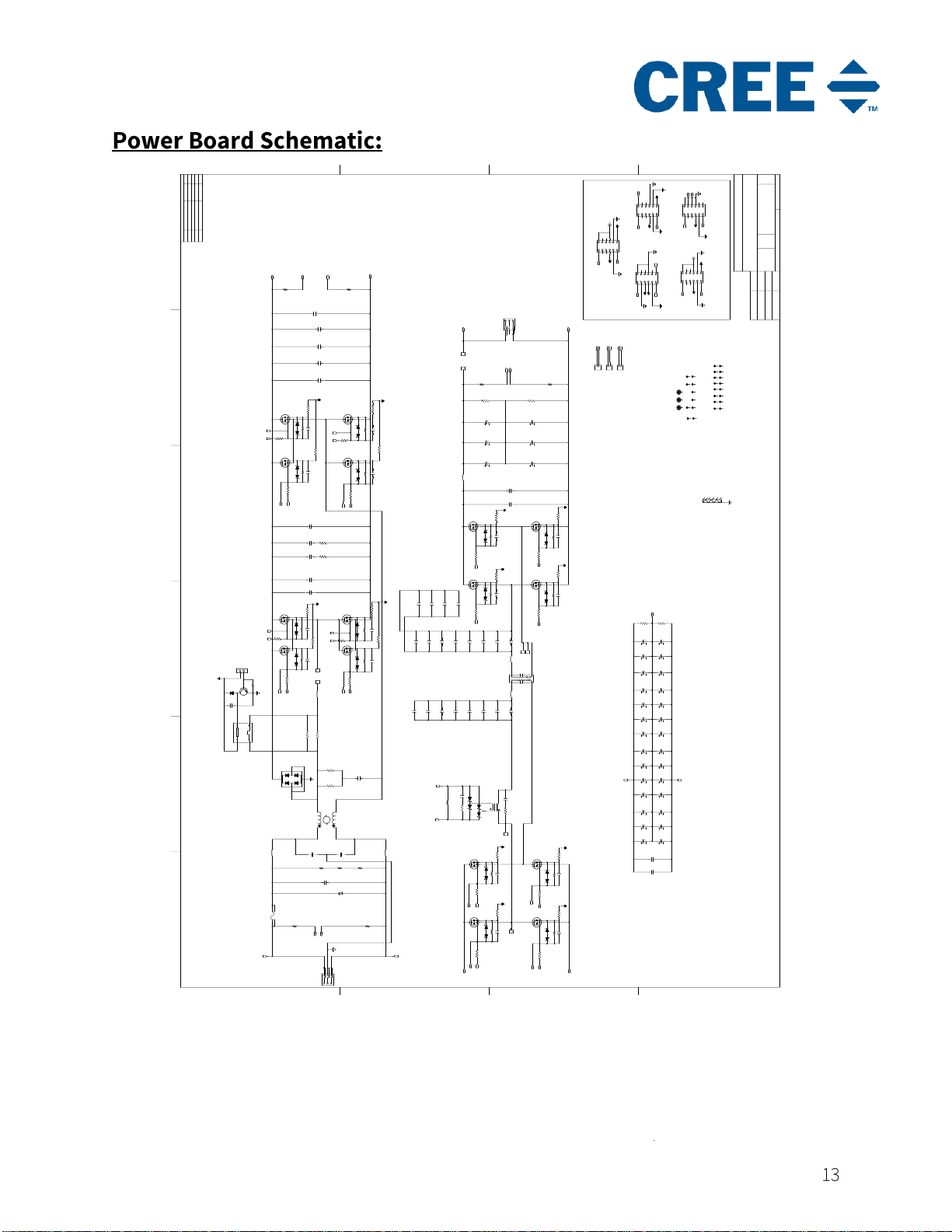

As shown in Figure 2, the Input AC voltage is connected to terminals 1 and 3 of CON5 followed

by the fuse F1 and MOV (Metal Oxide Varistor) RV1. Differential mode filters L1 and L2 and

common mode filter XL1 are then connected, and the filters are followed by a low frequency

rectifier BD1 which charges the output DC link capacitors through positive temperature

coefficient (PTC) resistors RV1 and RV2. RV1 and RV2 are shorted by relay, if the DC link voltage

crosses the peak value of the input grid voltage, then rectifier BD1 becomes reverse biased and

no current flows through the rectifier BD1. The main PFC inductor L3 is connected after the relay.

The other end of L3 is connected to the midpoint of the high frequency half bridge Totem-Pole

MOSFETs Q1, Q2, Q3, and Q4. After passing through the differential and common mode filters,

the neutral point of the grid is connected to the low frequency half bridge Q5, Q6, Q7, and Q8.

The DC link capacitor bank consists of 18 pieces of 250 µf, 400 V capacitors connected in series

and parallel combination. There are some film capacitors and RC snubber circuits as well to

absorb the high frequency ripple and reduce EMI (Electromagnetic Interference).

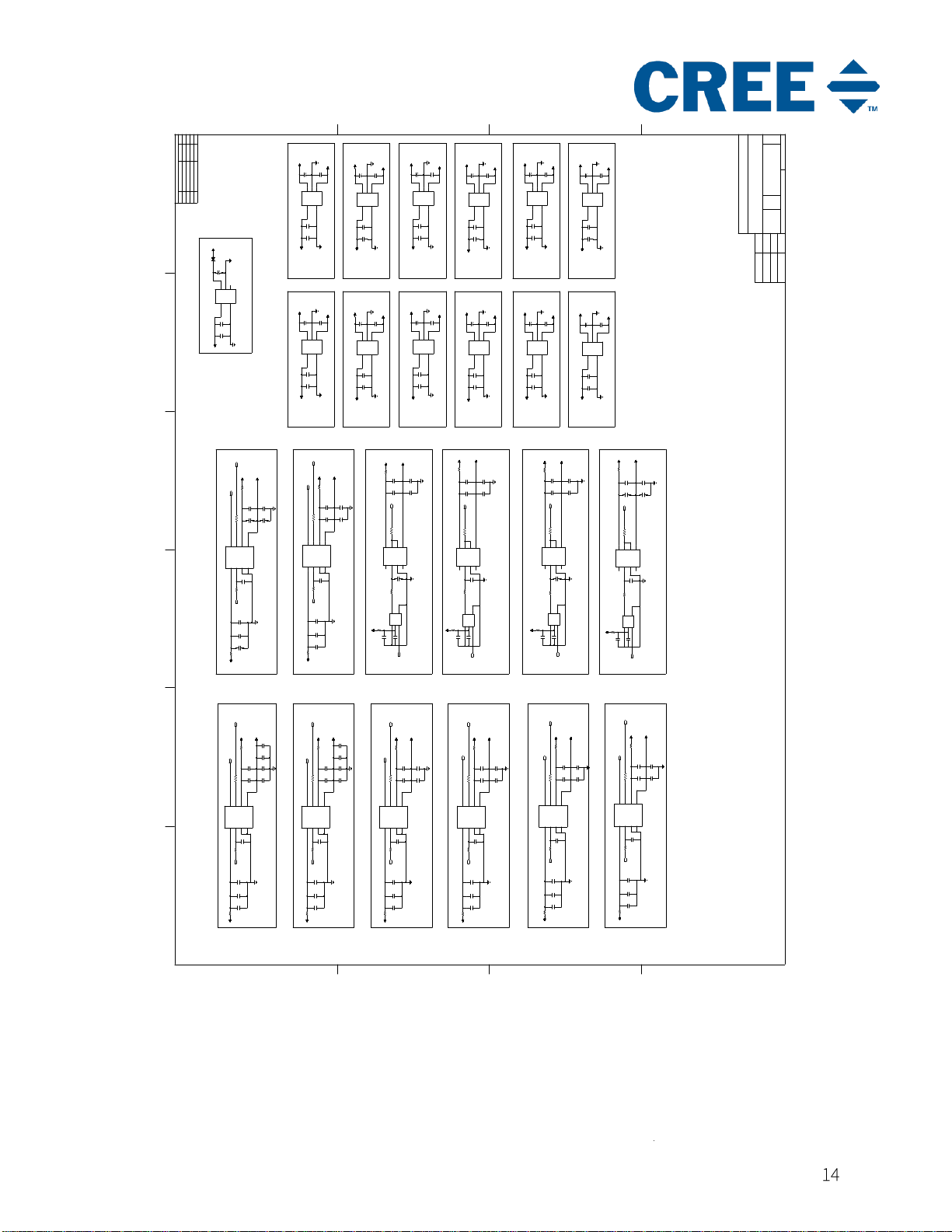

The DC link is connected to an H-bridge comprised of MOSFETs Q9, Q10, Q11, and Q12 which

forms the primary side of the bi-directional CLLC converter. The resonance tank is composed of

an inductor (L4) and a resonance capacitor bank of 12 pieces of 4.7nF film capacitor. The

inductance of main CLLC transformer is 100 µH with a PQ5050 core. The secondary side of

PQ5050 core is connected to the secondary side resonance inductor L5 and a bank of 18 pieces

of secondary side resonance capacitors. The secondary side H-bridge is composed of MOSFETs

Q13, Q14, Q15, and Q16 followed by film capacitors C58 and C59 and an electrolytic capacitor.

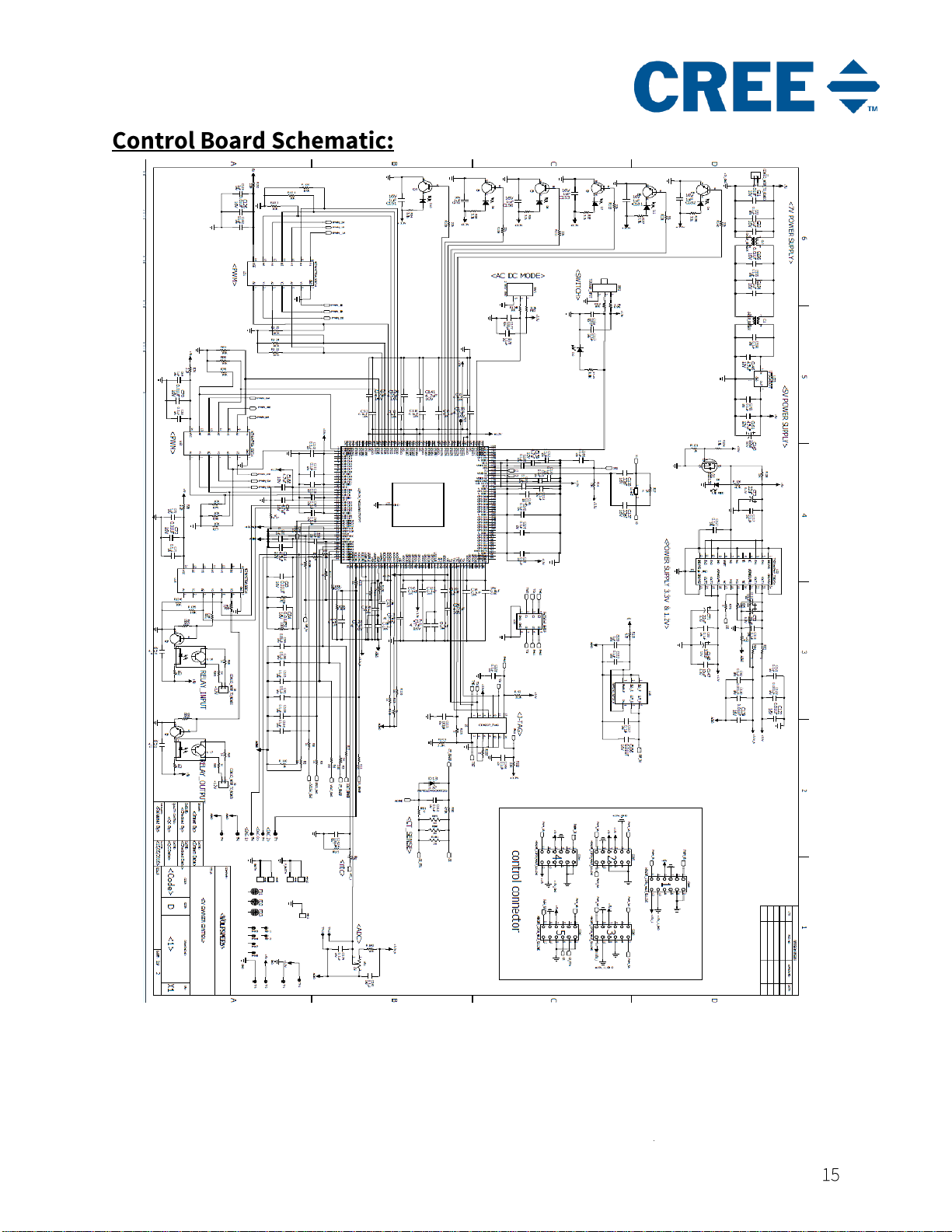

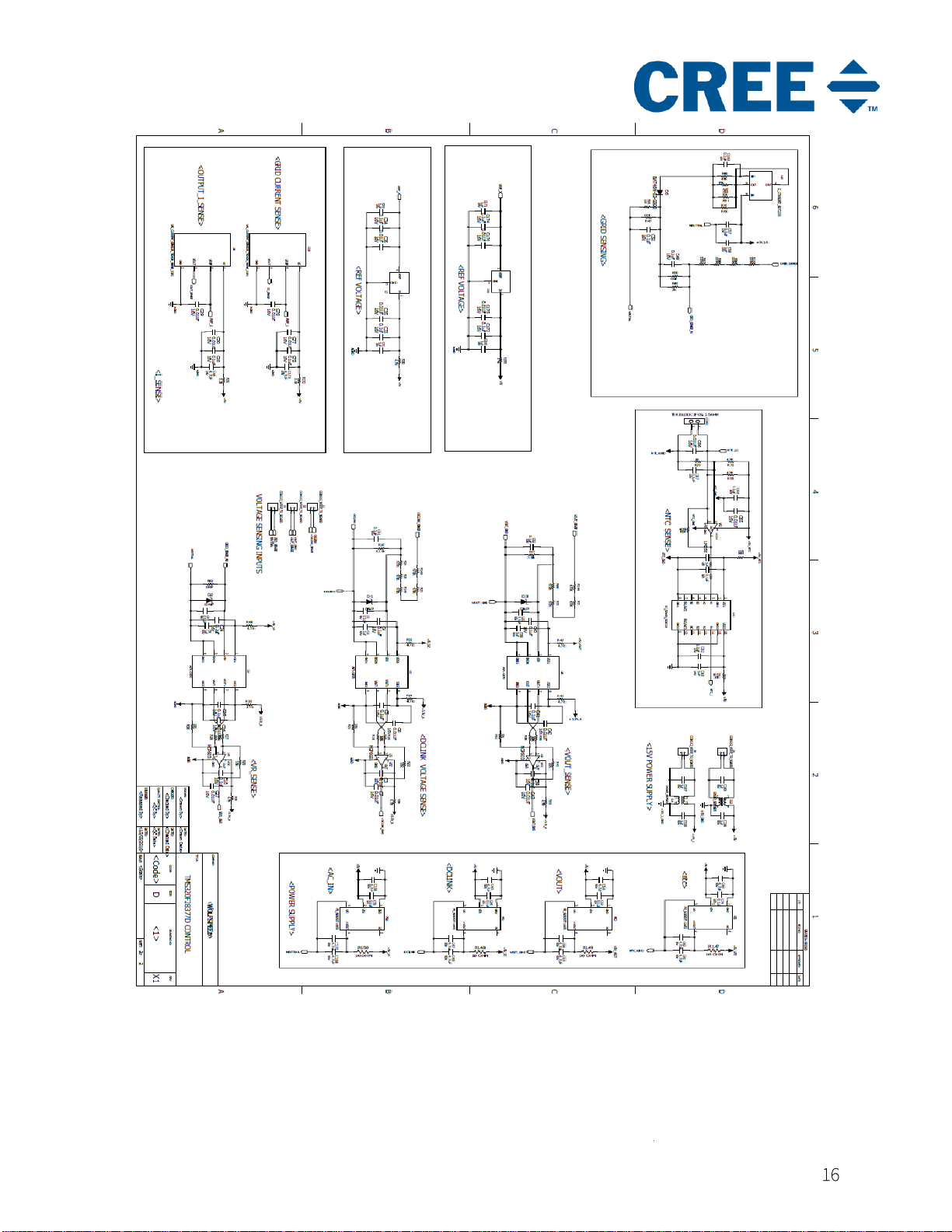

As shown in Figure 3, the gate drive signals for the MOSFETs of the PFC stage and the resonance

stage are generated by the DSP (Digital Signal Processing) controller and each MOSFET is further

isolated by their respective gate drivers. There are separate isolated DC/DC (VIN = +15, VOUT =

+15V, -3V) supplies for all gate drivers. The input currents and output load currents are sensed

by a current sensor for processing in the DSP controller. All voltage sensing (grid as well as the

output voltage) signals are isolated with an analog optocoupler before being fed into the DSP

controller for further processing.