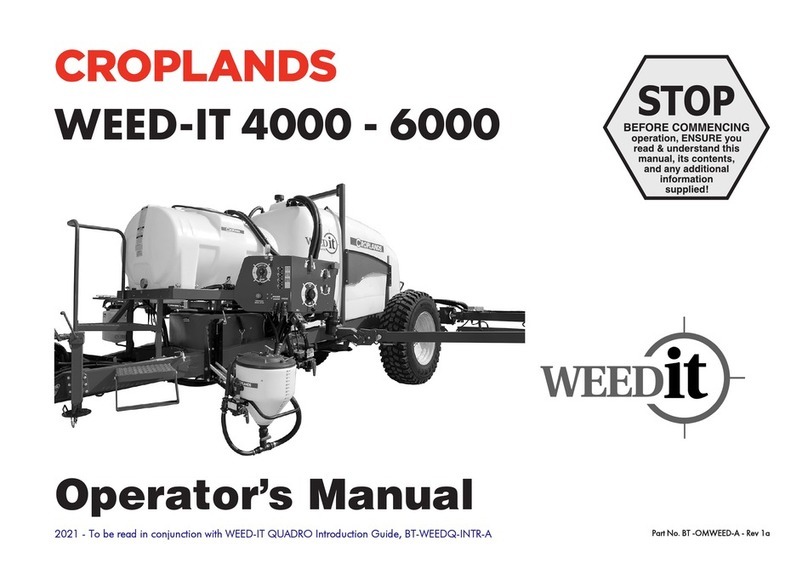

Croplands GEX Series User manual

WWW.CROPLANDS.COM.AU

CROPLANDS

SPRAY BOOMS

OPERATORS MANUAL

8/10/2020

GP-OMOBOOM-A

STOP

BEFORE COMMENCING

operation, ENSURE you read

& understand this manual, its

contents, and any additional

information supplied.

MODELS:

MB02 boom

MBX Series booms

MAX Series booms

GEX Series booms

MC6 firebreak boom

ATV Boomless Nozzle kit

MSO under-tree boom

MSC and MSCL-2

Covered booms

Vertiboom

Wheely Boom

2GP-OMOBOOM-A

WELCOME

Congratulations on the purchase

of your new Croplands spray

boom. Croplands are in the

business of building and selling

spraying equipment and have

been since 1972 (over 45 years).

We supply sprayers to farmers, contractors,

growers and others involved in growing crops &

controlling pests and diseases.

Use the contact details listed on the back page

to contact our staff during business hours. After

hours, e-mail us and expect a reply the following

morning. We trust you will get years of good use

from your Croplands spray boom.

Yours sincerely,

Sean Mulvaney

General Manager.

3

CONTENTS

1. Warranty policy 5

2. Foreword 5

3. Safety information 6

4. Product identification and specification 8

5. Boom assembly and installation 18

6. Precautions and instructions during 29

installation and use

7. Liquid plumbing and nozzles 39

8. Boom sprayer calibration 40

9. Maintenance 41

4GP-OMOBOOM-A

Terminology

These terms/symbols used throughout this manual:

About This Manual

This manual provides assembly, setting up,

operating and maintenance instructions for the

spray booms of the Croplands Optima boom

range. All types of the Croplands Optima range

of spray booms are in the Identification and/or in

the Specification Chapter. Some model types also

have different options available. Some features

explained in this manual may not be applicable to

your boom.

Please pass on this manual with the sprayer

or boom at the time of resale for use by the

new owner.

NOTE

To convey useful operating information.

CAUTION

To highlight potential injury or

machinery damage.

WARNING

To stress potential dangers and the

importance of personal safety.

DANGER

Probability of death or serious

injury if accident an occurs.

Croplands has taken steps to ensure this operator’s manual is as current and as accurate as possible. Due to the ever changing markets

of cropping and farming, Croplands is constantly striving to be at the forefront of innovation and technology. While the information

in this manual is considered accurate at the time of writing, Croplands reserves the right to change this information without notice.

Croplands will not accept liability for any inaccuracy in this publication, or changes forthwith.

5

NOTE

For full conditions of warranty and

warranty policy, please see the

Warranty & Pre-Delivery booklet

provided with this boom or sprayer

(if included as a part of the sprayer).

SECTION 1: WARRANTY POLICY

Refer to your Croplands Warranty and Pre-delivery Booklet supplied with your spray boom.

Always make contact with your Croplands Dealer first and foremost for warranty matters.

SECTION 2: FOREWORD

Croplands Equipment is a subsidiary of Nufarm

Australia Ltd and operates as Croplands Equipment

Pty Ltd in Australia and Croplands Equipment

Ltd in New Zealand. Croplands are a leading

manufacturer and supplier of spraying equipment.

This operator’s manual covers the Croplands’

Optima range of spraying booms from 2 metres

width to 12 metres width and includes the GEX

series Hydraulic folding booms. Croplands Optima

spray booms are commonly fitted to our Linkage

AgriPak sprayers, trailed 12-volt sprayers, Traymount

sprayers and larger Pony trailed sprayers.

The Hydralink MHL boom (sometimes referred to as

the BDX boom) is supplied with a separate manual

for the BDX boom. See page 28 for more details.

Manufactured to a high standard for use in

Agriculture and Horticulture, every effort has been

made to include all information needed for the

correct use of your spray boom.

As the owner of a Croplands product, please read

this manual thoroughly to fully familiarise yourself

with all aspects of the safe and correct operation

of your boom. Maintenance information and

useful tips have been included. We trust you will

use these tips to get the best from your boom.

WARNING

Read and understand this

operators’ manual before operating

the spray boom.

6GP-OMOBOOM-A

SECTION 3: SAFETY

INFORMATION

Please refer to the Croplands 20 page Safety

Manual, part number “GP-SAFE-A” which will

be supplied with this product. If for any reason

the Safety manual is not available, please see

your dealer, Croplands Customer service or the

Croplands Web Site to obtain a copy.

This product should not be operated before first

reading and understanding the full safety manual.

Be especially vigilant of the PTO shaft and high

pressure oil leaks.

WWW.CROPLANDS.COM.AU

SAFETY

MANUAL

OPERATORS

STOP

BEFORE COMMENCING

operation, ENSURE you read

& understand this manual, its

contents, and any additional

information supplied.

GP-SAFE-A | Update 1

7

SAFETY SIGNS AND DECALS

All signs and decals for sprayer safety and

operation must be maintained in good order and

replaced if damaged or missing. Most Croplands

labels have a part number printed on the decal to

aid identification and replacement.

Some examples are shown below.

Part No: XD -123

WARNING

!

1. Read your operators manual thoroughly before

operating the srayer.

2. Inspect hoses, connections and nozzles daily.

3. Clean filters regularly.

4. Always follow correct maintenance schedules

outlined in operator’s manuals.

5. Always read chemical manufacturers labels before use.

6. Always observe all warnings on chemical products.

7. Regularly check all nuts and bolts are tight.

8. Always wear rubber gloves and wash sprayer down

before doing any repair or maintenance work.

9. Do not ride on sprayer when moving.

10.Keep clear of moving parts when sprayer is operating.

11. Always keep guards in place when sprayer is operating.

12. Be sure tank lid is closed before operating basket

mixing facility.

13. Stand well clear of sprayer when operating.

14. Do not disconnect hoses, nozzles or filters while

sprayer is operating.

FAILURE TO FOLLOW THE ABOVE INSTRUCTIONS

MAY RESULT IN SERIOUS INJURY OR DEATH.

Croplands Equipment Pty Ltd XD-123MS

SAFETY INSTRUCTIONS

Part No: XD-181

Part No: XD-182

Part No: XD-190

8GP-OMOBOOM-A

SECTION 4: PRODUCT

IDENTIFICATION &

SPECIFICATIONS

Always use the serial number of the Optima

boom when requesting service information or

when ordering parts. Where a serial plate is not

provided, please use the part number from the

bar code affixed to this manual or the Warranty

& Pre-Delivery booklet. Early models or later

models may use different parts, or it may be

necessary to use a different procedure for specific

service operations.

Where the boom is supplied as a part of a

complete sprayer including boom, please use

the serial number attached to the sprayer when

requesting service information.

Boom Models

(i) MB02, MBX03, MBX04 & MBX06

(ii) MAX08, MAX10, MAX12L

and Leveling device

(iii) GEX6H, GEX8H, GEX10H

(iv) Boomless nozzle kits

(v) Specialty booms - Under-Tree,

Firebreak, Shrouded boom, Vertiboom &

Wheely boom

(vi) MHL12 & MHL15 Hydralink booms

(vii) Optional Extras

(nozzles, suspension kits etc)

AirMix low drift air-induction nozzles fitted

standard to Croplands booms

NOTE

For further information on Croplands

sprayers & booms,

see www. croplands.com.au

WARNING

Ensure your vehicle is rated for the

weight of the sprayer and/or boom

when full of of liquid. Failure to do this

may cause instability and serious injury.

9

MB02 boom

» Single stainless steel tube with end cap one end,

inlet with hosetail on opposite end

» Non-drip nozzle bodies fitted to boom tube at

500mm spacing

» AirMix® low-drift nozzles and caps fitted to

nozzle bodies with nozzle filters under each cap

» Clamps with u-bolts supplied

» Typically fitted to ATV bikes and small trailed

sprayers for small areas

MBX Series Manual Cross-fold Booms

» Galvanised steel construction with stainless steel

boom tubes

» Nozzles are protected being placed above the

boom rail

» Non-drip nozzles bodies with AirMix® low-drift

nozzles fitted

» Adjustable tension spring breakaway for each

boom arm to ensure the arm returns to position

» Folds neatly behind the sprayer or vehicle

– typically used on small 3-point linkage

sprayers, Traymount units, RTV & utility vehicles

& small trailed sprayers

Product update, all MBX and MAX booms now

use forked hose fittings.

MBX03

» 3 metre galvanised boom; 6 non-drip nozzles

at 500mm spacings. 1.25 metres folded width;

0.85 metres folded height. Dry Weight - 25kg.

MBX04

» 4 metre galvanised boom; 8 non-drip nozzles

at 500mm spacings. 1.25 metres folded width;

0.85 metres folded height. Dry Weight - 28 kg.

MBX06

» 6 metre galvanised boom; 12 non-drip nozzles

at 500mm spacing. 1.95 metres folded width;

1.15 metres folded height. Dry Weight - 36 kg.

10 GP-OMOBOOM-A

MAX Series Manual Cross-fold Booms

» Rugged galvanised steel construction with stainless

steel boom tubes

» Nozzles are protected being placed above the

boom rail

» Non-drip nozzles bodies with AirMix® low-drift

nozzles fitted

» Adjustable tension spring breakaway for each

boom arm to ensure the arm returns to position

» Folds neatly behind the sprayer or vehicle

– typically used on larger linkage sprayers,

Traymount sprayers, utility vehicles & larger trailed

sprayers to 2000 litres

Product update, all MBX and MAX booms now use

forked hose fittings.

Models:

MAX08

» 8 metre galvanised boom; 16 non-drip nozzles

at 500mm spacings. 2.07 metres folded width;

1.8 metres folded height. Dry Weight - 82kg.

MAX10

» 10 metre galvanised boom; 20 non-drip nozzles

at 500mm spacings. 2.07 metres folded width; 1.8

metres folded height. Dry Weight - 90 kg.

MAX12L

» 12 metre galvanised boom plus leveler; 24 non-

drip nozzles at 500mm spacings. 2.07 metres

folded width; 2.1 metres folded height. Dry

Weight - 130 kg.

SELF-LEVELER

» Optional Leveling device (standard on 12 metre

boom) - allows boom to self-level on undulating

ground. An ideal option for rougher country or

where ground is undulating and uneven. Weight

- 28 kg.

Self Leveller

11

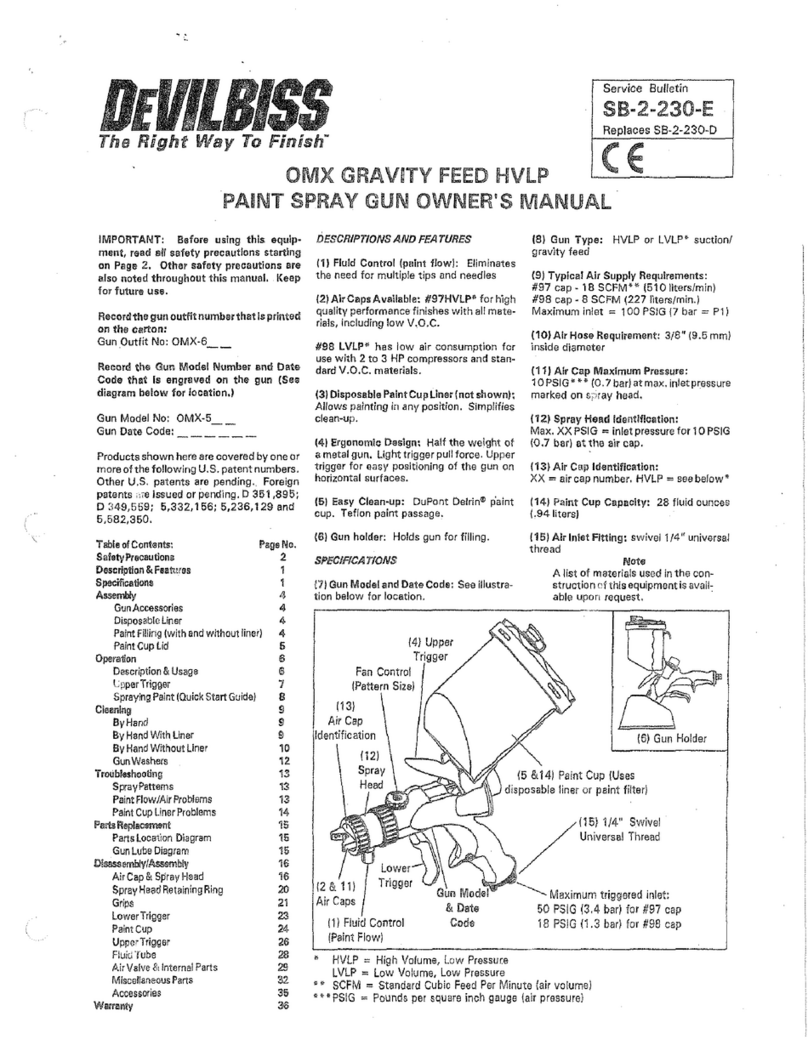

Hydraulic Folding GEX Boom models

NOTE

The 8 and 10 metre models have a manual

flip-over outer section which needs to be

manually secured in the folded position

prior to folding the boom for transport.

GEX6H

» 6 metre galvanised hydraulic folding boom;

12 non-drip nozzle bodies, 2 rams for folding,

hydraulically plumbed to fold together.

» 2.06 metres folded width; 1.55 metre folded

height. Dry Weight - 87kg.

GEX8H

» 8 metre galvanised hydraulic folding boom;

16 non-drip nozzle bodies, 2 rams for folding,

hydraulically plumbed to fold together. 1 metre

of each end is manually unfolded to make the

boom 8 metres.

»

2.06 metres folded width; 1.55 metres folded

height. Dry Weight - 93kg.

GEX10H

»

10 metre galvanised hydraulic folding

boom; 20 non-drip nozzle bodies, 2 rams

for folding, hydraulically plumbed to fold

together. 2 metres of each end is manually

unfolded to make the boom 10 metres.

» 2.06 metres folded width; 1.55 metres folded

height. Dry Weight - 96kg.

MHL12-2-KIT

» Second set of hydraulic hoses to allow left/

right individual fold of GEX boom

General Information

» Boom folds hydraulically in a cross-fold style.

» Ideal boom for small row-cropping situations

or vegetables.

Models:

12 GP-OMOBOOM-A

XP Boomkit

» XP BOOMKIT Kit to mount 2 XP BoomJets* for

a sprayed width of approximately 6 metres.

Clamps supplied for fitting to rear carrier of

most quad bikes.

* Minimum pump flow required 6.4 L/min at 2

bar pressure.

Firebreak Boom – model MC6

» Ideal for the back of utes, RTV vehicles or small

trailing sprayers for spraying firebreaks, farm

tracks, contours, ditches and fencelines.

» 1.5 metre wide with offset nozzles on adjustable

swivel nozzle bodies on each end for additional

1.5 metre spray each side

Under-Tree Boom – Model MSO

» MSO Treeliner boom with breakaway and 2

nozzles with manual-tap shut-off

» MSO boom is galvanised with extendable outer

section which can be lifted up for transport &

secured with the chain system

» Perfect for spraying under trees or hedgerows

» An electric shut of system can be installed – talk

to your Croplands Sprayshop or Dealer as this

is not a factory installed option

NOTE

XP BoomJets must be purchased separately

& output matched to your pump flow. See

page 27 for further details.

XP Boom Kit shown with XP BoomJets fitted

and in use. Ensure you talk to your Croplands

Dealer to select the right XP BoomJet for your

XP Boom kit to suit your application For more

information, see section 5, point number 6.

13

Covered Booms – models MSC (single sided)

and MSCL (double sided)

» For spraying under sensitive crops such as

grapes and other tree crops

» Weight - 18kg (double sided)

Wheely Boom – Model MW02

» 2 metre width boom with frame and wheels,

shut-off trigger and gauge

» Suitable for greens, golf courses and turf

applications

» Handle includes a shut-off trigger and gauge

for the operator to control the application as

required

» Ideal to hook up to an existing spray pump for

spraying greens.

Vertiboom – Models MVB4-4 and MVB5-5;

4 and 5 nozzles per side

» Vertiboom can be fitted using a motorised pump

(AR30-5H) for supplying adequate pressure &

flow to the nozzles.

» Typically used for Horticultural applications

to spray trellis crops and row crops such as

grapes, tomatoes and berries

» Usually mounted on a 3-point linkage or small

trailed sprayer

MCSL

»

Single sided light covered boom with

breakaway and 2 nozzles under spray shield

MSCL-2

»

Double sided light covered boom with left/

right shielded booms with breakaways,

adjustable width, and a 600mm wide

uncovered centre section with 2 nozzles

NOTE

For boom drawings and parts

information refer to

www.croplands.com.au

14 GP-OMOBOOM-A

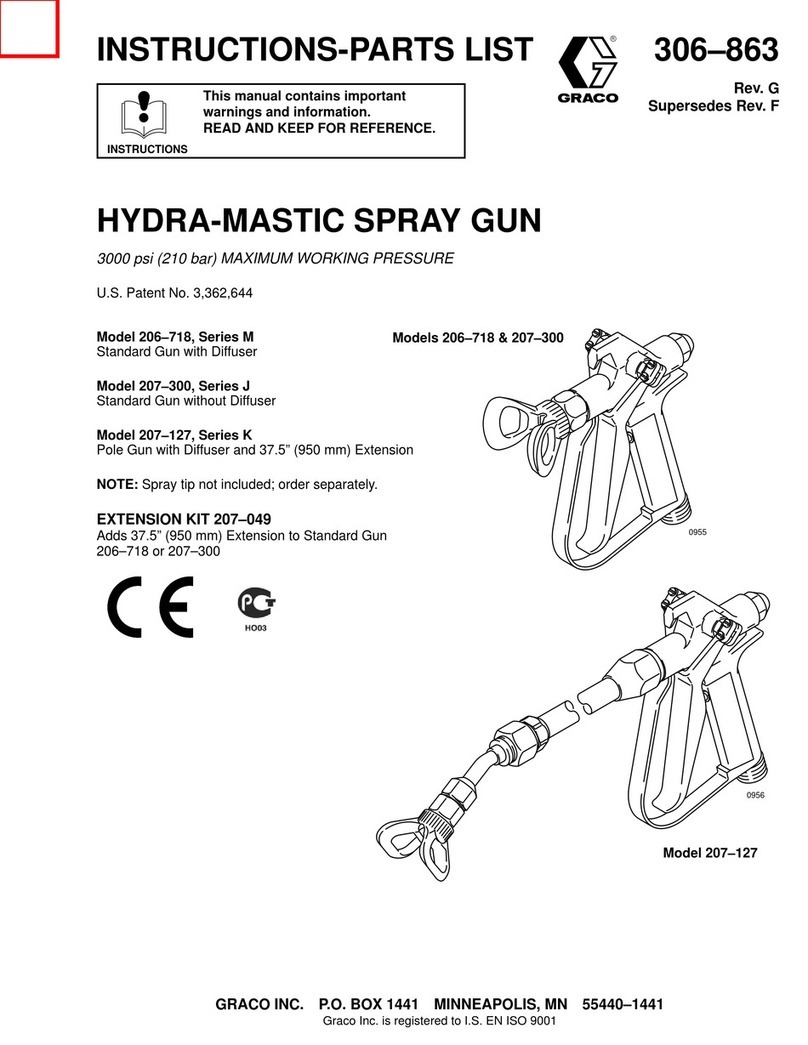

Hydraulic MHL Hydralink Booms – 12 & 15

metre models

» Heavy duty galvanised steel construction with

stainless steel boom tubes with nondrip nozzles

bodies and AirMix® lowdrift nozzles fitted

» Nozzle protection fitted to protect nozzles and

nozzle bodies from damage

» Adjustable tension breakaway on outer sections

» Self-leveling centre section standard

» Boom folds sequentially in a cross-fold style

for transport - using the left/right hydraulic kit

option, each side can be lifted independently

which also automatically locks the self-leveling

system. Ideal for lifting over fences at the

headland or irrigation sprinklers

» Ideal boom for row-cropping, pasture spraying,

vegetables or undulating farm country.

The MHL boom will is supplied with a separate

manual covering the Bargam / BDX Book.

MHL12

»

Heavy duty galvanised 12 metre hydraulic

folding boom with 24 nozzles, twin ram with

auto folding tips, hydraulically plumbed to

fold both sides together. Central self-locking

self-leveller standard. Dry weight - 240 kg.

MHL15

»

Heavy duty galvanised 15 metre hydraulic

folding boom with 30 nozzles, twin ram with

auto folding tips, hydraulically plumbed to

fold both sides together. Central self-locking

self-leveller standard. Dry weight - 265 kg.

MHL12-2-KIT

» Second set of hydraulic hoses to allow left/right

individual fold of MHL boom.

15

Optional extras

Airbag suspension

Available as

an option, the

parallelogram airbag

suspension device

is very useful for

protecting the spray

boom in rougher

conditions. This is

normally sold only

as a fitted option to

Croplands’s range

of 3-point Linkage

sprayers and is seldom

sold separately.

It is recommended this be fitted by your

Authorised Croplands Dealer to ensure correct

fitting & operation.

Suitable for use with MAX series, GEX series

and MHL series booms only.

For more information, please visit

www.croplands.com.au for instructions

and more details.

If fitted to your sprayer, a separate parts list

will be supplied.

Hydraulic Accumulator suspension device

Available as an option,

the hydraulic accumulator

suspension kit is very

useful for protecting the

spray boom in rougher

conditions.

It is recommended this be

fitted by your Authorised

Croplands Dealer to

ensure correct fitting &

operation.

Suitable for MHL and MAX booms only on certain

models of Croplands Linkage sprayers.

For more information, please visit

www.croplands.com.au for instructions and

more details.

If fitted to your sprayer, a separate parts list will be

supplied.

16 GP-OMOBOOM-A

Hydraulic lift devices

Available as an option,

the hydraulic boom lift

device allows lifting of the

boom hydraulically. This

is normally sold only as a

fitted option to Croplands’s

range of 3-point Linkage

sprayers and is seldom

sold separately. However,

if purchased separately at

a later date for fitting to an

existing Croplands sprayer,

a basic instruction sheet and

parts list will be supplied.

It is recommended this be fitted by your Authorised

Croplands Dealer to ensure correct fitting &

operation.

For more information, please visit www.croplands.

com.au for instructions and more details.

If fitted to your sprayer, a separate parts list will

be supplied.

Hydraulic fold hose kits

Available as an option, individual hose kits for

hydraulic fold of GEX and MHL Hydralink boom are

usually supplied with the boom when purchased, or

as a fitted option to a Croplands sprayer.

It is recommended this be fitted by your Authorised

Croplands Dealer to ensure correct fitting &

operation.

If purchased with your spray boom, an instruction

sheet and basic parts list will be provided.

For more information, please visit www.croplands.

com.au for instructions and more details.

17

Nozzles

For specific

applications, there are

a number of specialty

nozzles available in

Croplands range.

It is highly

recommended you use

your local Agronomist

or Authorised Croplands

Dealer for advice on

what nozzles to use for

specific applications.

Alternatively, you

can purchase a copy of the Nufarm Spraywise

Application Handbook, available from Croplands

and their dealers throughout New Zealand and

Australia.

Albuz Ceramic CVI nozzle example

Off-centre AirMix

nozzle option for

boom-end

TurboDrop nozzle sample for ultra low drift

situations

NOTE

For boom drawings and parts

information refer to

www.croplands.com.au

18 GP-OMOBOOM-A

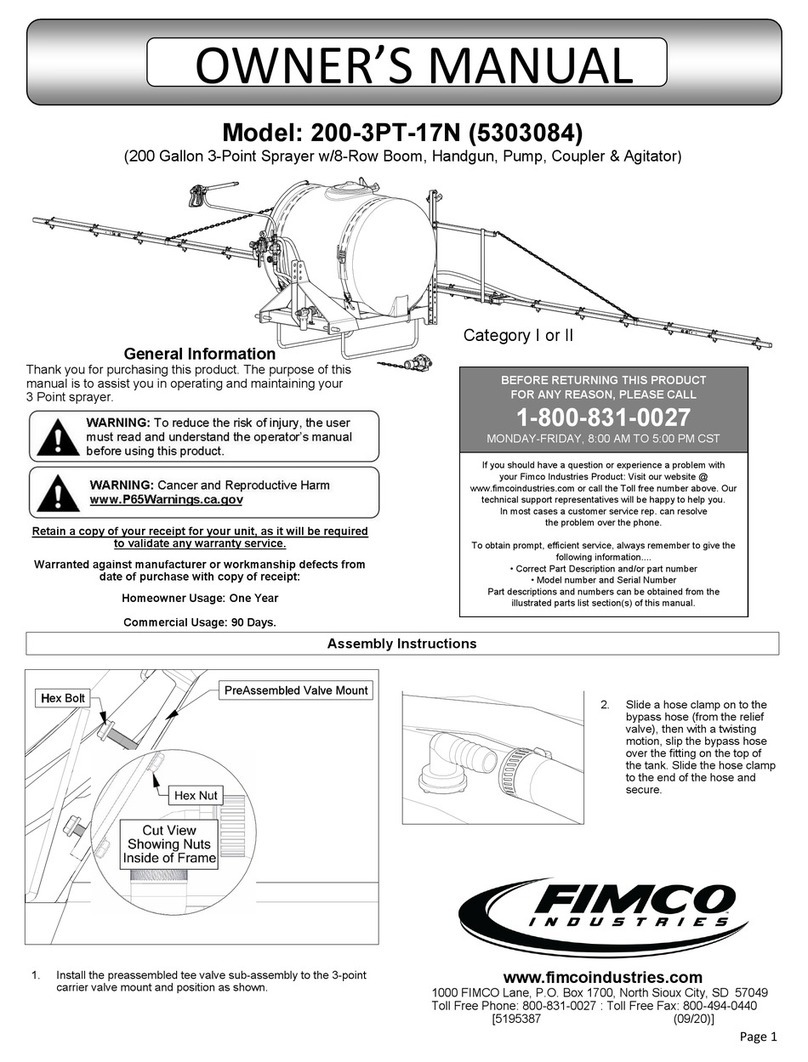

SECTION 5: BOOM ASSEMBLY

& INSTALLATION

MBX boom series assembly instructions

To assemble the boom (more information

on next page):

1. Unpack the unit and check that nothing is

missing or has been damaged in transit.

2. Assemble the boom arms to the centre section

3. Connect the hoses from each section to the

boom tubes

4. Mount the boom to your sprayer. Note –

standard clamps and brackets are supplied,

however if being mounted to a sprayer

other than a Croplands model, you or your

Croplands dealer may need to fabricate

brackets to suit. The cost of any fabrication, or

modification of the brackets supplied, will be

the responsibility of the purchaser

5. Connect the hoses to the boom tubes for the

number of sections required

6. Check all worm-drive clips for tightness (if

applicable)

7. Grease the boom arm breakaway knuckles

and pins.

8. When ready, start the spray pump and check

all nozzle bodies and hose connections for

leaks & make necessary adjustments and/or

tighten fittings. Take care not to over tighten &

break fittings or nozzle bodies.

NOTE

Whilst all precautions are taken in

assembly and testing, it is possible that

debris will remain in boom lines. This

debris will collect in the nozzle filters (see

picture below) and should be cleaned

after your first testing of the boom using

water.

WARNING

Only use water when testing the boom

for leaks.

W

E

A

R

G

L

O

V

E

S

19

Attach hoses to the boom tubes

Mount the centre section to your sprayer using the bolts & brackets supplied.

Bolt the left & right outer wings to the centre section.

The MBX boom will look like this fully assembled Product update, all MBX and MAX

booms now use forked hose fittings.

20 GP-OMOBOOM-A

MAX boom series assembly instructions

1. Unpack the unit and check that nothing is

missing or has been damaged in transit.

2. The Max Series booms will be supplied fully

assembled from the factory. Note – standard

clamps and brackets are supplied, however

if being mounted to a sprayer other than a

Croplands model, you or your Croplands

dealer may need to fabricate brackets to suit.

The cost of any fabrication, or modification of

the brackets supplied, will be the responsibility

of the purchaser.

3. When mounting the boom, ensure a suitable

crane or block & tackle lifting device is used to

support the boom.

4. Once mounted, ensure all boom hose

connections are fully sealed and then tested

using water to check for any leaks. Also check

the nozzle bodies and caps for leaks before

using the boom for spraying.

5. Ensure all hinge points and leveller slides

(if applicable) are greased (also see boom

maintenance in section 9)

NOTE

Whilst all precautions are taken in

assembly and testing, it is possible that

debris will remain in boom lines. This

debris will collect in the nozzle filters

(see picture on page 18) and should be

cleaned after your first testing of the

boom using water.

WARNING

Only use water when testing the boom

for leaks.

WARNING

Do not attempt to mount the

boom without the use of approved

lifting equipment. Injury may result

if the boom is lifted without the correct

method being used.

Ensure a suitable lifting device is used to

support the MAX Boom when fitting

This manual suits for next models

16

Table of contents

Other Croplands Paint Sprayer manuals

Croplands

Croplands RSRL3-100RC REEL User manual

Croplands

Croplands PEGASUS WEED-IT 4000 User manual

Croplands

Croplands Quantum Mist Smart Spray QM-420 User manual

Croplands

Croplands Quantum Mist Smart Spray QM-420 User manual

Croplands

Croplands AgriPak LA300 User manual

Croplands

Croplands CROPPAK US200F User manual

Croplands

Croplands Pinto 2000 User manual

Croplands

Croplands WEED-IT User manual

Croplands

Croplands MHL12 User manual