9

SECTION 3

PRODUCT IDENTIFICATION, SHIPPING & SPECIFICATION

GENERAL SPECIFICATION

The SMART Sprayer is Croplands premium vineyard sprayer

that comes in double row and triple row configurations with

optional Recapture / Drift Reduction System.

The Quantum Mist™ system uses a combination of

individual hydraulically driven Spray fans with 5-blade

fans to give the maximum possible spray coverage in

grapes and dwarf tree crops.

All Smart Sprayers feature the Fusion Control system which

allows for full electric over hydraulic control for many of

the Smart Sprayer features.

For more detailed specification, see Section 4,

Product Features / Familiarisation

Controls

The Fusion controller with integrated joystick is used to

control all hydraulic (fan and boom) and spray functions.

Tank Sizes

2000, 3000 and 4000 litre tank options are available

and are constructed of impact resistant polyethylene and

UV stabilized. Each tank has an incorporated flushing tank

and a calibrated sight tube for filling level indication.

All main tanks drain completely via a large drain valve

and sump.

Chemical Handling

Quick fill (camlock) system and chemical suction probe

standard on all models.

Filtration

Lid-strainers & chemical mixing baskets are standard on all

models. Large suction filter, self-cleaning pressure

filter fitted.

Recapture system (when fitted) also incorporates inline filters.

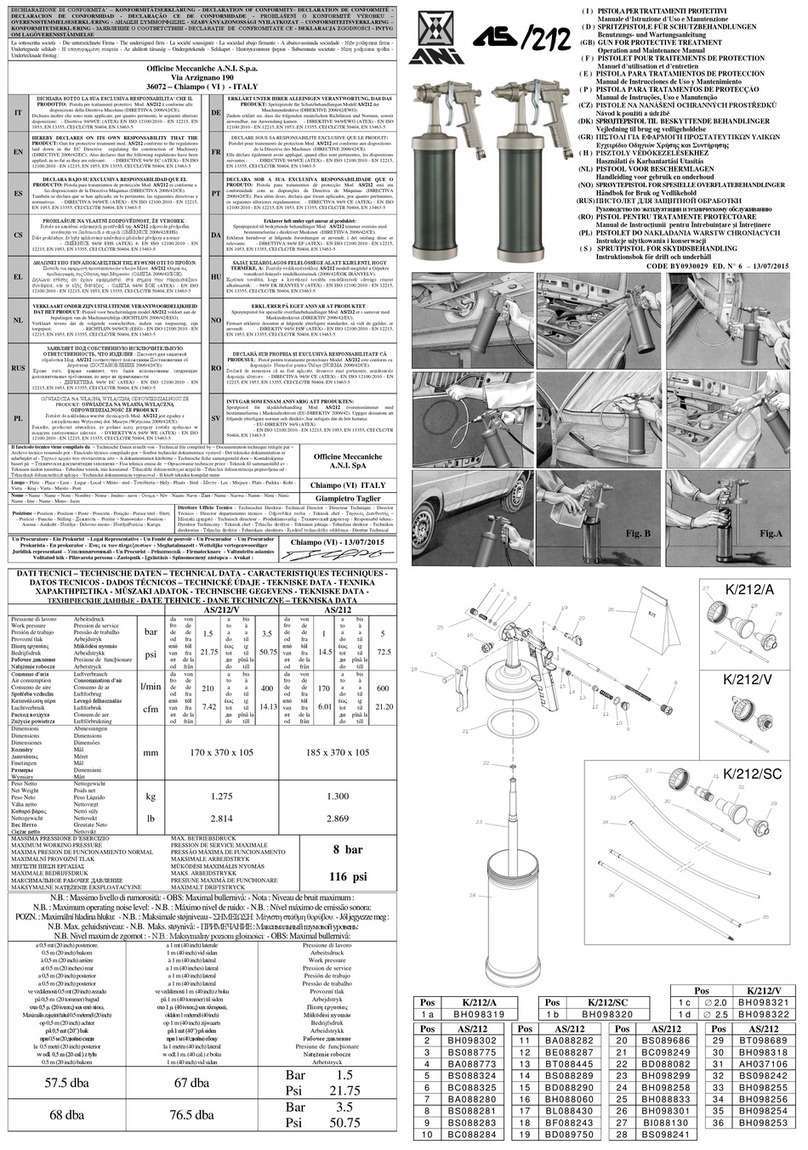

Pumps

All Smart Sprayers are fitted with an Annovi Reverberi

positive displacement diaphragm pumps with a capacity of

165 to 250 L/min - depending on the sprayer model.

A heavy duty PTO shaft is supplied to drive the pump. This

will be supplied to suit the drawbar fitted.

Hydraulic driven pumps (in lieu of PTO) are also an option

when a Micro Power Pack is fitted to the sprayer.

Agitation

The agitation system is driven by the pump via twin supa-

flow venturi tank agitators & bypass agitation.

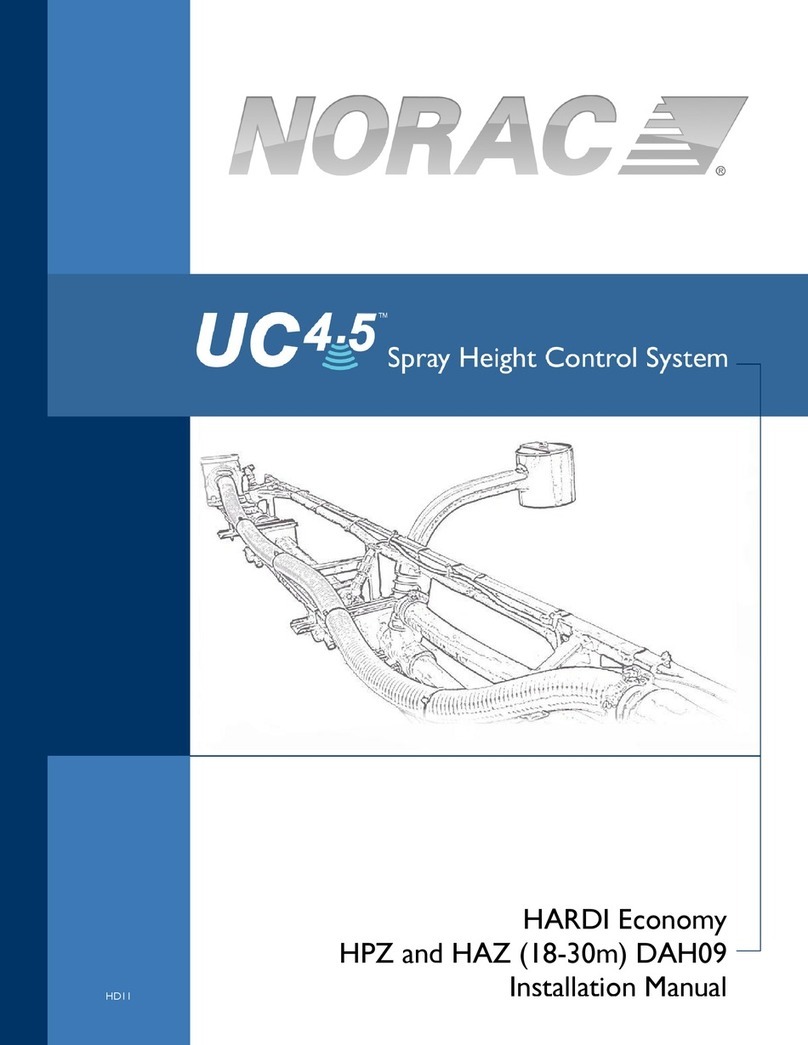

Hydraulic System

Hydraulic oil supply is from the tractor or Micro Power Pack.

The oil supply feeds to the main hydraulic control block

from which the oil is distributed to the hydraulically driven

fans and boom functions. The block also includes the main

pressure relief valve, anti-cavitation valve, soft-start and

test ports (pressure and return).

All models are fitted with a hydraulic oil radiator with

thermostat switching of an electric fan cooler.

Micro Power Pack

Supplied as standard on all 18 x fan models,, optional for

12 and 8 fan models, the Micro Power Pack is a compact,

independent oil supply system incorporated into a 3

point linkage, self-steering drawbar. Driven by the tractor

PTO shaft, the Micro Power Pack is available in single or

dual pump configuration depending on Sprayer model

specifications.

See separate manual for this option.

QM-420 Spray fans

The new QM-420 Spray fans “Fans”, comprised of

a Polyethylene Rotomoulded cowling which includes

mounting points on either side, into which there are

installed dual spray rings, front and rear safety guards and

drive body & fan.

The 5-blade 420mm diameter fan has been designed for

maximum air efficiency in the agricultural environment with

excellent characteristics for canopy spraying.

The fans are hydraulically driven by a case drained 6.5cc

or 9.8cc motor, driving via a double bearing “drive body”

and shaft with well proven rubber coupling to smoothly

drive the fan.

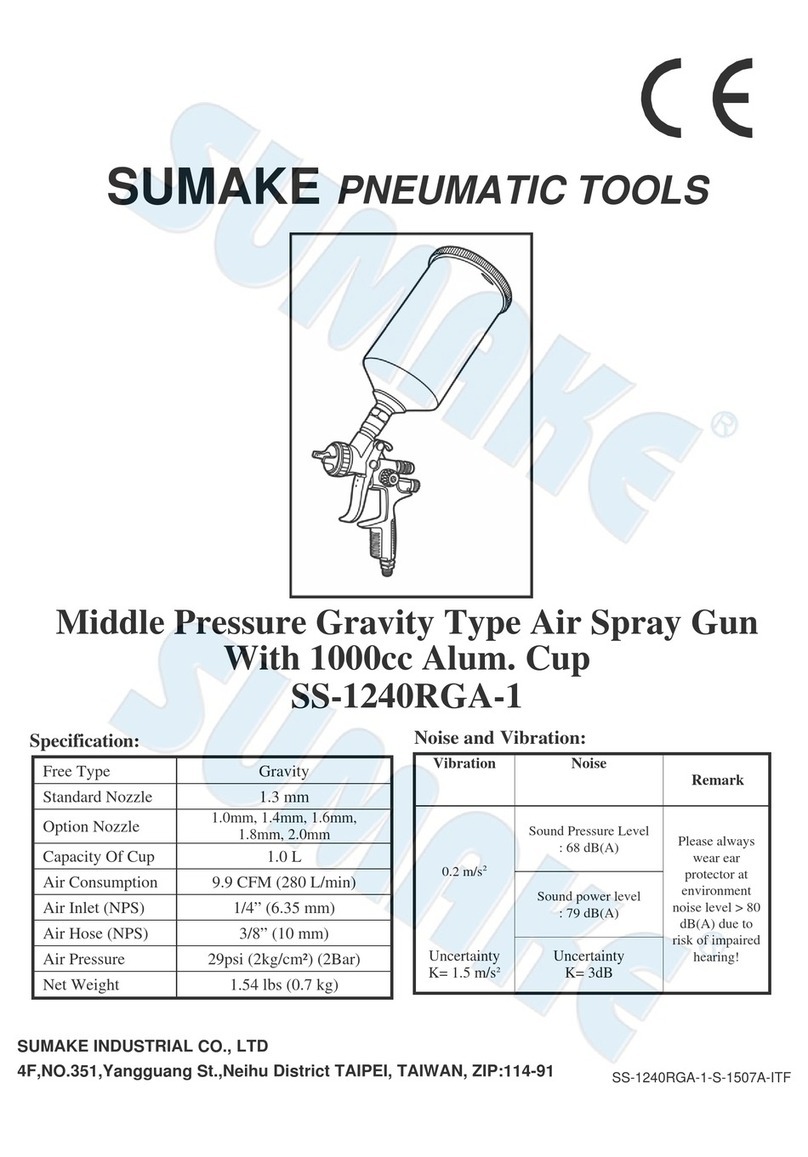

Nozzles

Each Spray fan comes with 2 spray rings with 5 nozzles

per ring, for a total of 10 nozzles per fan. The nozzles

are used in a 3 tier system, with low, medium and high

volumes available.

QM-420

P

A

N

T

P

E

G