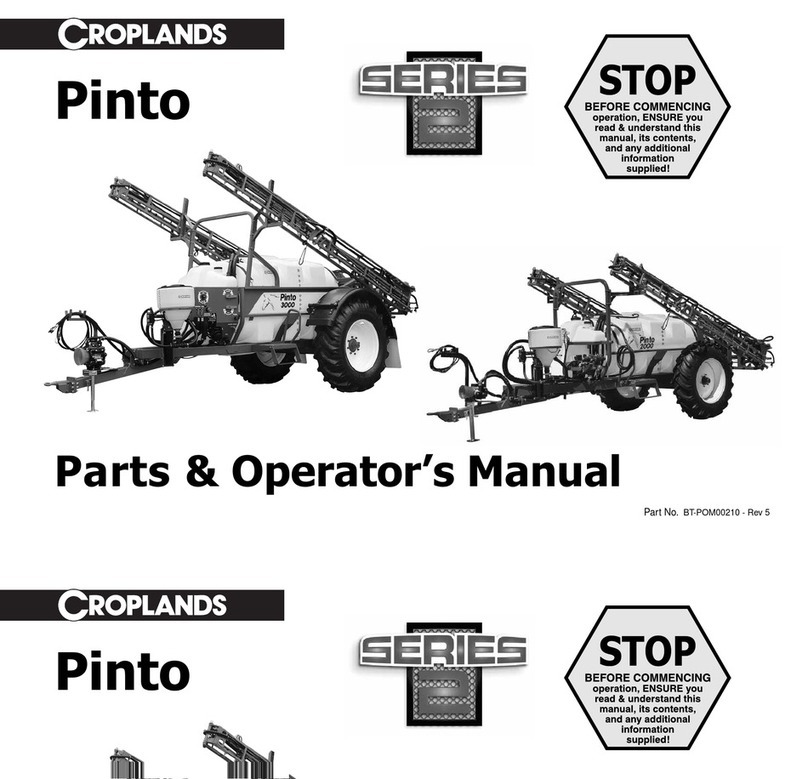

Croplands PEGASUS WEED-IT 4000 User manual

1

WEED-IT 4000 - 6000

Part No. BT -OMWEED-A - Rev 1a

Operator’s Manual

2021 - To be read in conjunction with WEED-IT QUADRO Introduction Guide, BT-WEEDQ-INTR-A

BT-OMWEED 012015- Rev 1

Contents

Foreword

Important Information Section 1

Pre-Operation Section 2

Operation Section 3

Calibration Section 4

Lubrication & Maintenance Section 5

Trouble Shooting Section 6

Assembly Drawings & Parts Listings Section 7

BT-OMWEED 012015- Rev 1

Foreword

About This Manual

This manual provides assembly, setting up,

operating and maintenance instructions for

the Croplands Pegasus sprayer.

Some features explained in this manual

may not be installed on your sprayer.

Please pass on this manual with the

sprayer at the time of resale for usage by

the new owner.

Before Operating

Your Sprayer

1 Before attempting to use your

sprayer, make sure you

read all Operator Manuals for this

sprayer:

• This Operator's Manual

• In Field use & Set up Training

- Croplands March 2013

• Boom Parking, Quick Start

Guide, Croplands Part no.

BT-OMWEED_QSG

• User Manual, Model 2013,

and properly understand:

• All Safety Issues.

• Assembly & Installation

instructions.

• Calibration of the sprayer.

• Sprayer Operation.

• Sprayer Maintenance.

Read and understand this Operators’ Manual before

operating the sprayer.

Terminology

These terms/symbols used throughout

this manual:

• NOTE - to convey useful

operating information.

• CAUTION -to highlight potential

injury or machinery

damage.

•WARNING - to stress potential

dangers and the

importance of

personal safety.

Indicates the strong possiblility of severe

personal injury or damage to machinery if

instructions are not followed.

WARNING

Highlights hazards, unsafe/unwise practices

which could cause injury, damage to property,

machinery or loss of crop yield if instructions

are not followed.

CAUTION

Refers to important and useful information which

should not be overlooked.

NOTE

2 Read and follow instructions on

chemical manufacturers' labels.

3 Always wear applicable protective

clothing.

Other manuals for this sprayer are:

• Parts List WEEDit Ag, October

2013

• Service Manual, Model 2013

BT-OMWEED 012015 - Rev 1 1.11.1

Section 1

Important Information

Introduction 1.2

General Specifications 1.3

Shipping Information & Product ID 1.5

1.2 BT-OMWEED 012015 - Rev 1

Important Information

Congratulations on the purchase of your

new Croplands sprayer.

Croplands have been in the business of

building and selling spraying equipment

since 1972. For over 40 years we have

been supplying sprayers to farmers,

contractors, growers and all our customers

involved in growing crops and in the control

of pests and diseases.

Croplands is a wholly owned subsidiary

of Nufarm Ltd, the largest supplier of crop

protection chemicals in Australasia, and

one of the fastest growing global suppliers

world-wide.

At Croplands, we pride ourselves on

our commitment to supplying machinery

that is at the forefront of the industry’s

needs. We believe we can back up our

products and through constant research

and development, bring to you the best

equipment you can find.

Introduction

We welcome any feedback from you about

our equipment.

On this page you will find our contact

details, and locations where our staff can

be reached during business hours.

After hours, you can e-mail us and expect

a reply the following morning.

Please read this manual in its entirety

before you operate your sprayer. This will

ensure you have a trouble-free start up.

We trust you will get years of good use

from your Croplands Sprayer.

Yours sincerely

Sean Mulvaney

General Manager

Contact details:

AUSTRALIA

Croplands Equipment Pty Ltd

ACN 006 450 184

PO Box 2441, Dry Creek

50 Cavan Road, Dry Creek

S.A. 5094

Australia

FreePhone: 1800 999 162

FreeFax: 1800 623 778

e-mail: [email protected]

website: www.croplands.com.au

NEW ZEALAND

Croplands Equipment Ltd

PO Box 2004,

Stotford Lodge, Hastings 4120

Location:

1422 Omahu Road,

Hastings 4120, New Zealand

FreePhone: 0800 106 898

FreeFax: 0800 117 711

e-mail: [email protected]

website: www.croplands.co.nz

Sean Mulvaney, General Manager of Croplands

1.3

BT-OMWEED 012015 - Rev 1

Section 1

General Description &

Specifications

Tank

4000, 5000 or 6000 litre polyethylene

tank with hinged lid, filling strainer, top/

bottom fill point, large sump with drain,

dual agitators, direct chemical induction

& tank rinsing jet. Calibrated sight gauge

fitted. UV and chemical resistant finish.

Chassis

Strong, fabricated wide-rail chassis, fully

welded for maximum strength. Standard

with solid fixed-width axle. Adjustable-

height drawbar hitch with cast swivel eye

and heavy duty jack-stand. Optional air

suspension axle and/or adjustable track

axle, 2.1 - 3 metres.

Wheels & tyres

?? on 4000 & 5000 litre models;

?? on 6000 litre models;

?? Mudguards optional (all models).

?? Mudflaps optional (all models).

General Specifications

Pump:

• Single Line Models -

Ace hydraulic motor driven

centrifugal pump standard.

• Dual Line Models -

Ace hydraulic motor driven

centrifugal pump standard, and

AR positive displacement oil-bath

four diaphragm pump, chemical

resistant, rated to 20 bar.

Normal operating range 1 to 8

bar. Standard 185 l/min output

(at zero pressure), optional 250 &

280 l/min pumps available. PTO

drive standard, hydraulic optional.

Booms

Trailing 24, 30 & 36 metre booms,

constructed of high quality steel. Finish is

in epoxy-coat paint for chemical resistance.

Outer boom wings feature hydraulically

adjusted steering wheels & castor wheels.

Boom liquid tubing is polythene tubing.

Each side boom section folds rearwards

behind the sprayer. Hydraulically adjusted

steering wheels facilitate steering & folding.

Each side is hydraulically locked/unlocked

in both transport & work positions.

Controller & Boom Systems:

• Single Line Models:

WEEDit Ag fully automatic

controller & weed detection sensors.

• Dual Line Models:

WEEDit Ag fully automatic

controller & weed detection sensors.

Blanket sprayline fitted with a fully

automatic controller.

Three electric (motorized) boom

section valves fitted standard

(4 or 5 optional), dump & servo

fitted, Polmac rapid-check flowmeter

with in-cab console with switches,

showing spray rate & other functions.

Optional ISO or Arag 400S.

Filtration

Filtration points: Basket (18 mesh), Filling

filter (32 mesh), Suction filter (50 mesh

[second line only]) and Pressure filter

(100 mesh).

Agitation

Dual supa-flow agitators are fitted. Pump

bypass also aids agitation & mixing.

Chemical handling

Integrated chemical mixer/induction unit

is fitted with a drop-leg device. Options

include a chemical suction probe, enviro-

transfer kit and a Dosmatic injection kit.

A 20 litre hand-wash tank is also fitted

for safety.

Flushing & controls

A 340 litre flushing tank is fitted, operated

from the easy-to use control panel, located

on the left hand side of the sprayer.

Options

Hydraulic pump drive, 280 l/min pump,

4/5/7 boom sections, single or dual lines,

axle width adjustment kit, air-ride axle

kit, mudguards and mudflaps, Arag 400S

controller, induction probe, enviro-transfer

kit, filling flowmeter, foam marker and/or

GPS Guidance system, electric fence-line

nozzles, larger wheels and tyres.

Machine specifications are subject to change without

prior notification.

??

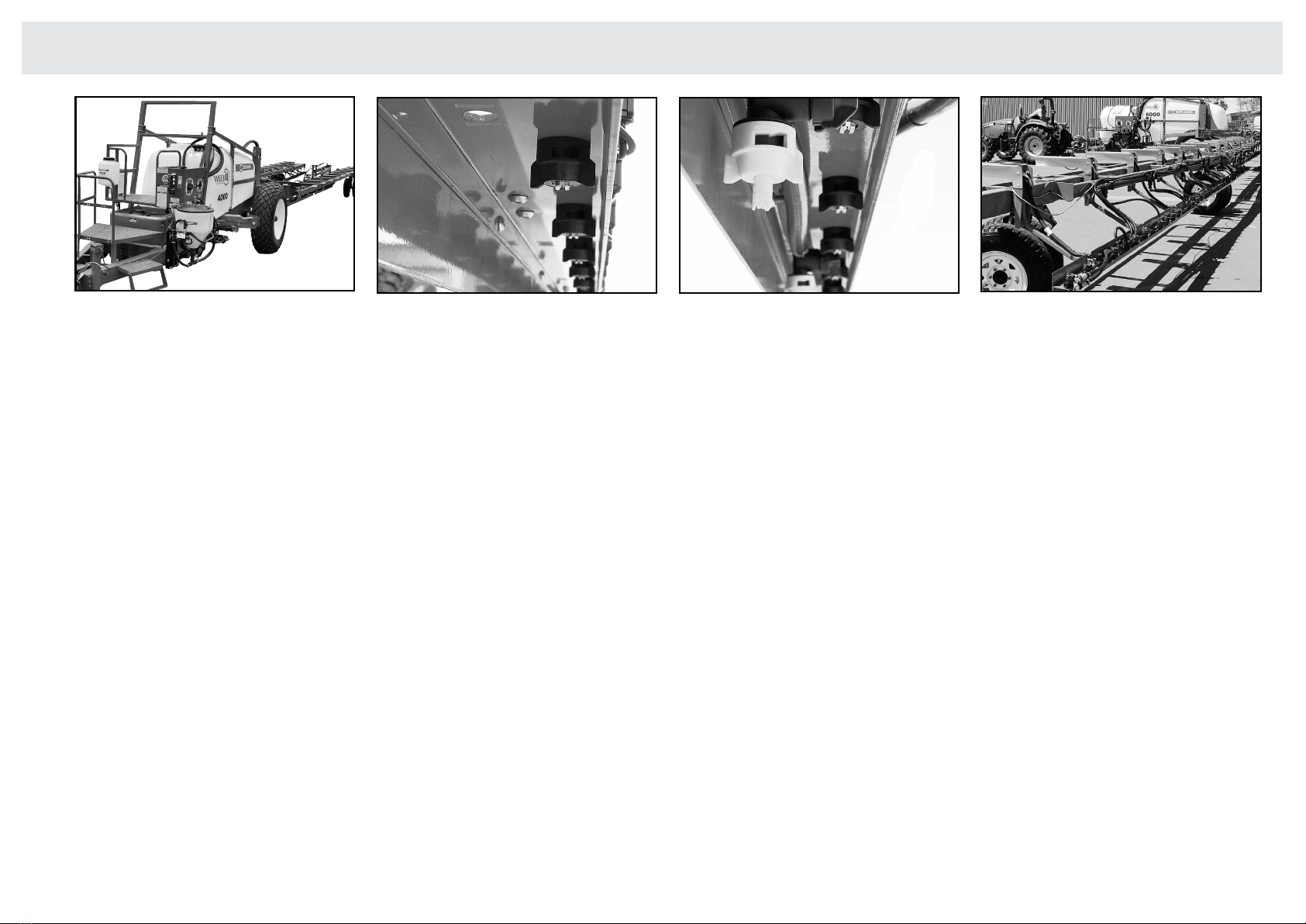

Dual line boom.Single line boom.4000 litre WEEDit Sprayer with 24m Single line boom.

1.4 BT-OMWEED 012015 - Rev 1

Important Information

Shipping Information & Product ID

Product

Identification

Always use the serial number of the WEEDit

when requesting service information or

when ordering parts.

Early or later models (identification made

by serial number) may use different parts,

or it may be necessary to use a different

procedure for specific service operations.

WEEDit Unit Serial

Numbers

Each WEEDit unit has a Serial Number

located on the back of the unit (A).

Shipping Information

The following shipping information is

provided but variations can occur without

prior notification.

Approx Weight

Model Approx Dry Weight

4000 litre 3900 kg (24m boom)

5000 litre 4300 kg (30m boom)

6000 litre 5000 kg (36m boom)

Maximum Towing Speed

Do not exceed 30 kph when towing on

roads.

Dimensions (Approx)

Model W x L x H

4000 litre 2.6m x 7.9m x ??m (24m boom)

5000 litre 2.6m x 7.7m x ??m (30m boom)

6000 litre 3.5m x 7.7m x ??m (36m boom)

(with boom folded)

Sprayer Serial Number

AR Pump Serial Number

(C)

(B)

Use the tie-down points provided when transporting.

Sprayer Serial Number

Plate

The Sprayer Serial Number Plate is

located on the chassis above the hitch

adjustment (B).

This plate shows name of manufacturer,

serial number, product code and date of

manufacture.

AR Pump Serial Number

The AR Pump Serial Number Plate is

located on the pump (C).

This plate shows name of manufacturer,

serial number, type of pump, year of

manufacture, maximum flow rate and

maximum working pressure of the pump.

Controller Serial

Number(s)

The WEEDit Controller Serial Number is

located on the side of the console (D).

If using a dual spray model, a second

Spray Controller Serial Number is located

on the second console.

6000 litre WEEDit with 36m dual line boom.

WEEDit Unit Serial Number

WEEDit Controller Serial Number.

(D)

(A)

BT-OMWEED 012015 - Rev 1 2.1

Section 2

Pre-Operation

Safety 2.2

Boom Assembly 2.10

Hook-up 2.12

Un-hook 2.25

Main Controls & Functions 2.26

Pre-Operation Check 2.27

2.2 BT-OMWEED 012015 - Rev 1

Pre-Operation

Safety is the

Operator’s

Responsibility

The WEEDit is designed to meet the

most demanding farming conditions,

where large areas, uneven terrain, and

weather-controlled deadlines set the

toughest challenges.

The WEEDit is capable of spraying a

wide range of pesticides and fungicides

and the operator must be aware of the

hazards associated with the WEEDit

operation.

The dealer explains the capabilities,

application and restrictions of the

WEEDit.

The dealer demonstrates the safe

operation of the WEEDit according to

Croplands instruction material, which

are also available to operator.

The dealer can also identify unsafe

modifications or use of unapproved

attachments.

The following publications provide

information on the safe use and

maintenance of the WEEDit and

attachments:

• The Operator’s Manual delivered

with the WEEDit gives operating

information, as well as routine

maintenance and service

procedures. It is a part of the

WEEDit and must stay with the

machine when it is sold.

• Replacement Operator’s Manuals

can be ordered from your

Croplands dealer, WEEDit Part

No. BT-OMWEED.

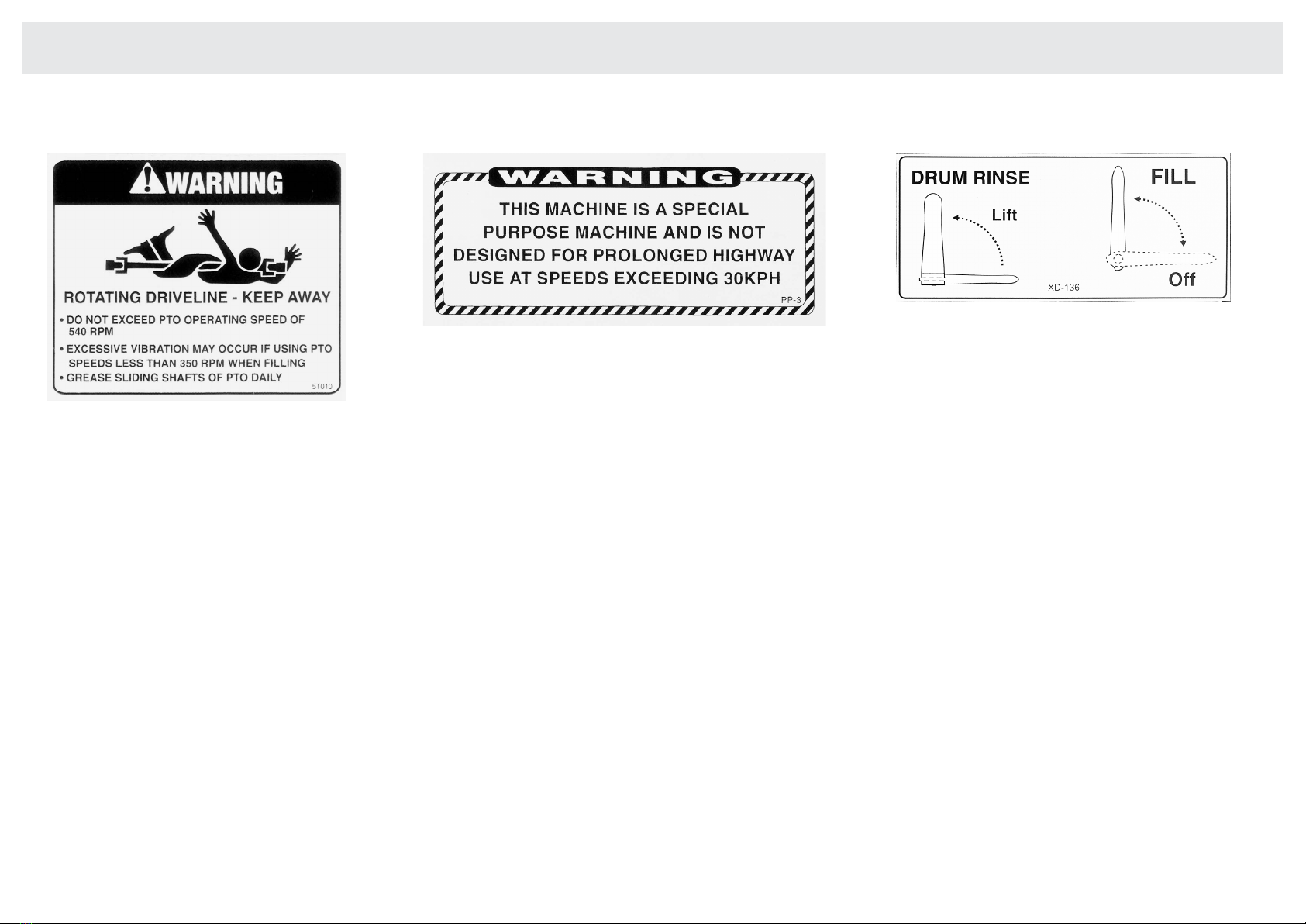

• The WEEDit has machine signs

(decals) which instruct on the

safe operation and care. The

signs and their locations are

shown in the Operator’s Manual.

Replacement signs are available

from your Croplands dealer (as

shown on pages 2.4, 2.5, 2.6).

Safe Operation

Needs a Qualified

Operator

A Qualified Operator Must

Do the Following:

1 Understand the

Written Instructions, Rules

& Regulations

• The written instructions from

Croplands are included in the

WEEDit Operation Manual and on

the machine's decals.

• Check the rules and regulations

at your location. The rules may

include any Federal and State

safety requirements for the

chemical applicator.

2 Have Training with Actual

Operation

• Operator training must consist of

a demonstration & verbal

instruction. This training is given

by your dealer before the

WEEDit is delivered.

• The new operator must start in an

area without bystanders and use

all the controls until they can

operate the WEEDit safely all

conditions of the work area.

3 Know The Work Conditions

• The operator must know any

prohibited uses or work areas.

They need to know about

excessive slopes and rough

terrain.

• Wear protective clothing as

recommended by the chemical

manufacturer. Always wear safety

goggles when maintaining or

servicing WEEDit.

• For an operator to be qualified,

they must not use drugs or

alcoholic drinks which impair

alertness or coordination while

working.

An operator who is taking

prescription drugs must get

medical advice to determine if

they can safely operate a

machine.

Farm Owner

Operations Manager

Machinery

Dealer/Manufacturer

Spray Parts Retailer

Agronomist

Chemical Supplier

Chemical Company

Accredited Trainer

Spray Operator

Spray Contractor

Safety

There are accredited training programmes for

spray application in each state. We recommend

all operators have accredited training.

NOTE

2.3

BT-OMWEED 012015 - Rev 1

Section 2 Safety

Rules for Safe

WEEDit Operation

• Always read your sprayer operator’s

manual thoroughly before operating.

Accidents occur every year because

of careless use of farm chemicals

and farm machinery. You can avoid

these hazards by observing these

safety instructions.

• Dispose of all chemical containers as

per instructions on label. Failure to

do so could result in contaminating

the environment with chemicals.

• Inspect hose and hose connections

daily. Always wear rubber gloves

when tightening connections.

Damaged, loose or worn hoses could

result in operator being

exposed to toxic chemicals which

could result in serious illness or faulty

sprayer operation.

• Always use the proper application

rate. To assure proper application

rate calibrate sprayer correctly.

The wrong application rate of a

pesticide concentration that is too

high may expose the operator and

the environment to danger.

• Be sure to disconnect the battery

before attempting welding repairs.

• Always wear relatively tight and

belted clothing to avoid entanglement

in moving parts. Failure to do so

could result in serious injury.

• Always stay out from under the

sprayer unless it is resting on the

ground or supported on solid blocks.

Hydraulics or jacks could fail letting

the sprayer fall. This could result in

pinning or crushing of personnel.

• Check the entire sprayer, prior

to each use, for any loose bolts

or mechanical connections. These

precautions can prevent injury to

personnel and damage to equipment.

• Only inflate tyres to rated pressures.

Over inflating causes tyres to burst

resulting in serious injury.

• Use only genuine Croplands parts

for any necessary replacement.

Special alloy steels are used in

many parts which are important to

the equipment design. Home made

parts may look the same but might be

dangerous in operation.

• Follow the chemical manufacturer’s

precautions before cleaning the

sprayer. Exposure to chemicals could

result in serious illness or death.

• Always wear gloves and wash the

machine before doing any

disassembly repair work. Chemical

residues on the machine parts could

contaminate operator or service

personnel causing serious illness.

• Always relieve system pressure

before doing any work on the

machine. Failure to do so could cause

operator to be exposed to high

pressure spray of chemical resulting

in serious injury or machine damage.

• Always be sure all safety guards are

properly installed on machine before

operating. Failure to do so could

result in entanglement in moving

parts resulting in serious injury to

operator.

• Always keep PTO guard in place

when sprayer is operating. Failure

to do this may result in

entanglement.

• Do not ride on machine when in

motion. This is an unsafe practice

and can lead to serious injury should

the rider fall from the machine.

• Always replace warning decals when

damaged and make certain operator

understands proper safety practices.

• Always stand well clear of the sprayer

when operating. The sprayer is

capable of spraying chemicals 20-30

metres from the boom which may be

hazardous to humans.

• Do not disconnect any hoses, nozzles

or filters while sprayer is operating.

Disconnecting components while

under pressure will result in

uncontrolled spray discharge which

may be hazardous to humans.

• Always clean the WEEDit and

disconnect the battery before doing

any welding repairs. Cover rubber

hoses, and all other flammable parts.

Keep a fire extinguisher near the

WEEDit when welding. Have good

ventilation when grinding or welding

painted parts. Wear dust mask when

grinding painted parts. Toxic dust

or gas can be produced.

2.4 BT-OMWEED 012015 - Rev 1

Pre-Operation

Rules for Safe Use of

Chemicals

• Always read the label before

using chemicals. Follow instructions

from chemical manufacturer on how

to select, use and handle each

chemical. Note protection information

each time before opening the

container.

• Always observe all warnings on

chemical products. Failure to do so

could result in operator or

others being exposed to toxic

chemicals which could result in

serious illness. Remember chemical

manufacturers go to much research

and expense to develop labels for

your protection.

• Be sure you recognise the categories

of toxicity and their key words.

• Verbal warnings must be given if

written warnings cannot be

understood by workers.

• If symptoms of illness occurs during

or shortly after spraying, call a

physician or go to a hospital

immediately.

• Follow label directions and advice

to keep residues on edible portions of

plants within the limits permitted by

law.

• Keep chemicals out of the reach

of children, pets and unauthorised

personnel. Store them outside of the

home, away from food and feed and

lock them in a secure area.

• Keep bystanders away from spray

drift.

• Always store chemicals in original

containers and keep them tightly

closed. Never keep them in anything

but the original containers.

Read labels for hazards about

chemical reaction with certain types

of metals.

• Do not spill chemicals on skin

or clothing. If chemicals are spilled,

remove contaminated clothing

immediately and wash skin (and

clothing) thoroughly with soap and

water.

Wash hands and face with soap

and water and change clothing after

spraying. Wash clothing each day

before reuse.

• The spray tank and system should be

emptied of chemical mixture and

flushed with clean water before

servicing the spray system

or spraying components. Clean the

WEEDit of all chemical residue

before servicing.

• Avoid inhaling chemicals. When

directed on the label, wear protective

clothing, face shield or goggles.

• Never smoke while spraying or

handling chemicals.

• Cover food and water containers

when spraying around livestock or pet

areas.

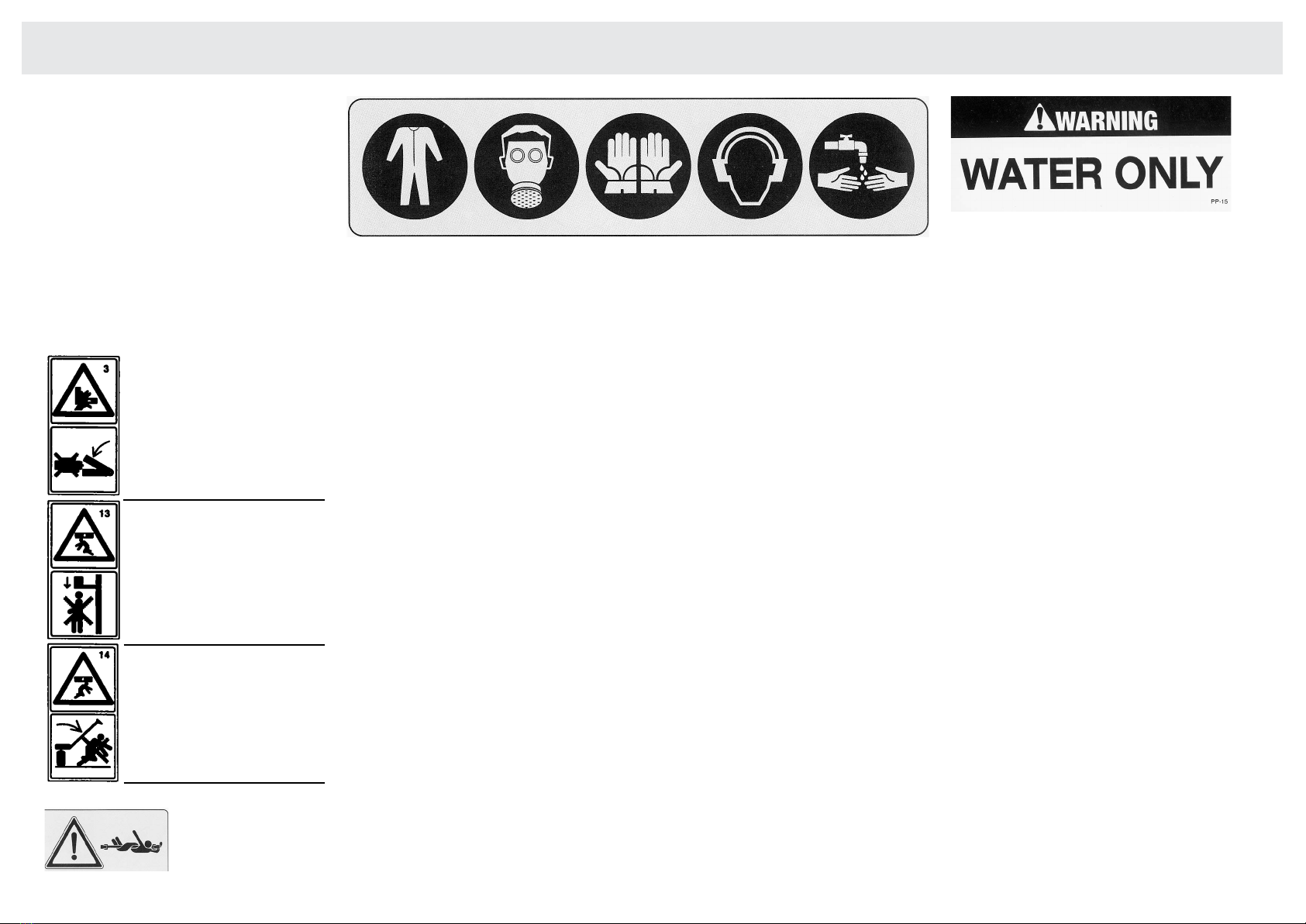

Make sure all boom safety decals are

clear and in place. Replace them if

damaged

Danger of arms crushing.

This area must be kept clear

during equipment operation.

Danger of body crushing.

This area must be kept clear

during equipment operation.

Danger of body crushing.

This area must be kept clear

during equipment operation.

do not stand within range of

boom arms

Danger of PTO

entanglement.

This is a common injury in

farming. Ensure PTO cov-

ers are always in place.

Safety

2.5

BT-OMWEED 012015 - Rev 1

Section 2 Safety

Please order replacements if required

Decals -

2.6 BT-OMWEED 012015 - Rev 1

Pre-Operation

Safety

Please order replacements if required

Decals -

2.7

BT-OMWEED 012015 - Rev 1

Section 2 Safety

Safety must be an Integral Part of

Chemical Farming Operations

• Not Just an After Thought!

The Hazard

All agricultural chemicals or pesticides, as

they are commonly called, are biologically

active. When handled incorrectly or

carelessly, they can be dangerous to all

living organisms such as humans, birds,

fish, bees, domestic animals and plants.

Method of Pesticide Entry

Oral - Direct by drinking,

splashing into mouth,eating

and smoking with contaminated

hands, eating sprayed produce,

cleaning nozzles with mouth.

Inhalation - Nose, mouth, but

predominately the lungs.

Dermal - Absorption through the

skin. Increased when skin is

broken or perspiring.

What protective clothing and

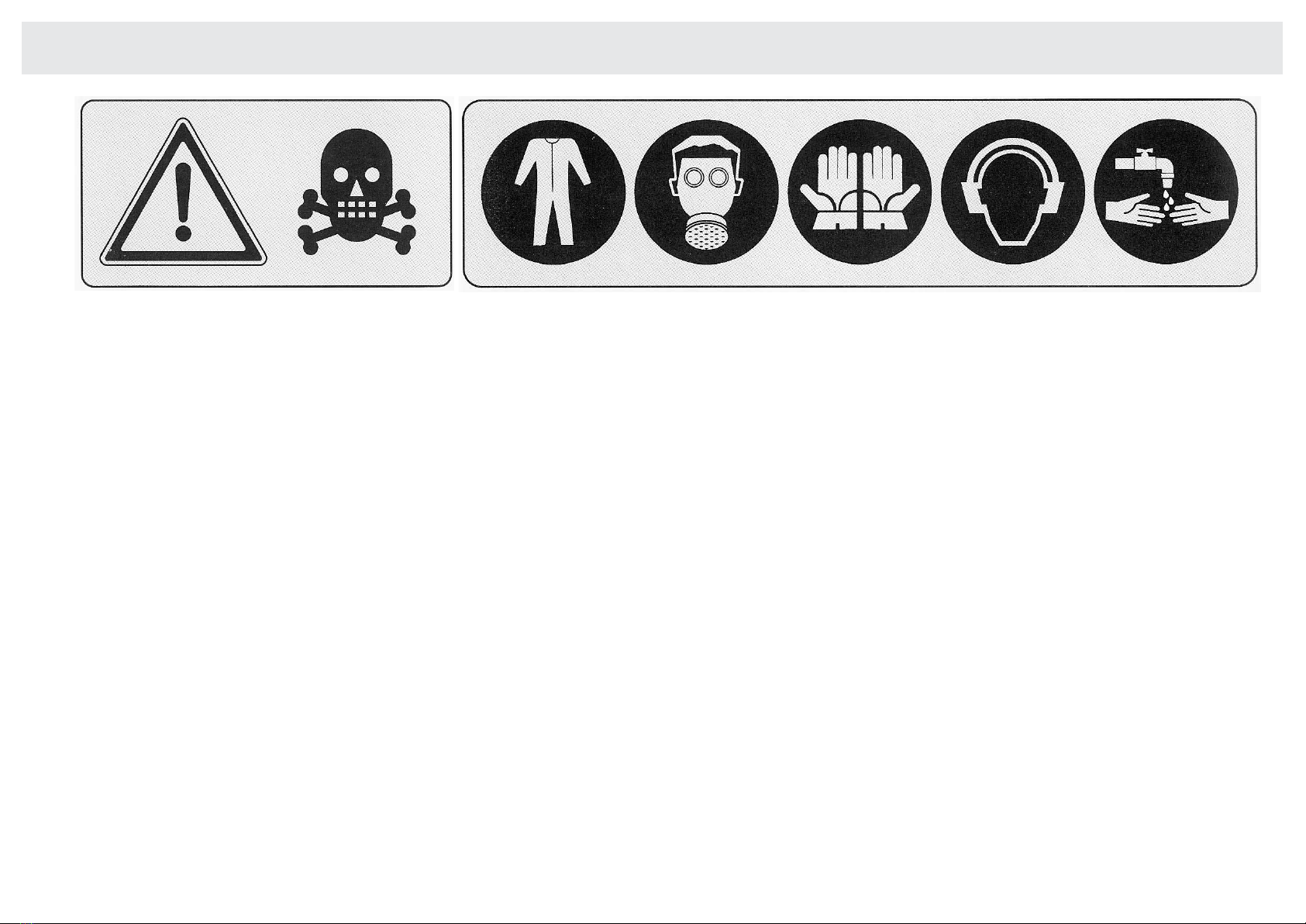

equipment is needed?

Know the correct first aid/safety in

case of poisoning.

Seek medical advice if health is

affected by chemicals.

Mixing the Product

Reduce or eliminate operator

contact by using closed loading

systems, auto fillers, wettable

powder mixtures or wettable

dispersable granules.

Use the right protective clothing

when handling the concentrate.

The user is at greatest risk when

handling chemical in concentrate

form.

Open bags carefully. Cut to open,

do not tear.

Do not stir chemicals with hands

or arms.

Choose the mixing site carefully &

the fate of the probable residues.

Do not mix more spray solution

than is needed and avoid

needless disposal of unwanted

chemicals.

Rate of Absorption

While pesticides are absorbed more

completely orally and by inhalation,

greater exposure and more poisonings

occur through skin (dermal) contact.

Hazard and Chance of

Poisoning

The hazard and chance of poisoning is

much higher when handling pesticides in

concentrate form than in the dilute form.

Safe Handling

Know your Pesticides:

STOP!! Read the label

Is it the right pesticide?

What is its poisons schedule or

toxicity?

What safety precautions are

required?

What is its persistence and

withholding period?

What is its mode of action?

Will it be a hazard to neighbouring

crops and people?

Plan your Spray Route

Observe weather conditions,

especially wind direction & speed.

Try to travel across wind and into

untreated crop.

Prevent double or over spraying.

Prevent or minimise drift onto

other crops, workers, etc.

Disposal of Unwanted

Pesticides and Containers

Calibrate correctly to ensure you

do not have a large quantity of

unwanted spray left over.

Rinse empty containers and pour

residue into the spray tank.

Dispose of containers in the

correct manner and where

provided, use pesticide drum

disposal schemes.

2.8 BT-OMWEED 012015 - Rev 1

Pre-Operation

Safety

Decontamination

Change out of protective clothing

and shower as soon as possible

after spraying.

Wash before eating, drinking or

smoking.

Provide clean water at filling site

and on sprayer in case of field

contamination.

Wash and clean respirators

regularly.

Keep Sprayers and Safety Equipment

in Good Working Condition

Replace hoses and fittings when

they leak.

Clean sprayer regularly.

Replace respirator filters regularly.

Do not use worn, faulty or

contaminated safety equipment.

Storage

Store pesticides in a locked, well

ventilated store.

Do not pour pesticides into other

containers, especially not drink

containers.

Pesticide Free Tractor

Cabs

Ensure the cab filter is adequate

for the pesticide used.

Be careful not to contaminate the

cabin environment.

Cabin filters alone are not

adequate when the operator is

required to leave the cab to refill

the sprayer. Safety equipment

used outside the cab should not

be stored in the cab.

Protective Safety

Equipment

The amount and type of protective clothing

and equipment is determined by the

type of chemicals, degree and duration

of exposure, weather conditions and

application equipment used.

Read and follow the direction on the

label.

Over protection can be uncomfortable and

unnecessary.

A respirator left hanging around your neck

is useless.

Measuring

Croplands’ calibrated, easypour

1, 3 and 5 litre measuring jugs

and 25 litre chemical mixing

bucket are practical, easy to

clean, U.V. resistant and chemical

resistant.

Clothing

Cover as much of the body as

possible, especially the neck,

chest and forearms. Use

washable fabric overalls,

disposable overalls or preferably

waterproof clothing especially

when coming in contact with

large quantities of pesticides.

Wear the trouser legs outside the

boots.

Gloves and Boots

Never use leather or cloth

materials because they absorb

pesticides and provide a constant

source of contamination. Gloves

should be un-lined for this reason.

Croplands Nitrile Chemical Handling

Gloves are recommended.

1, 3, 5 litre measuring jugs & 25 litre mixing bucket. Kasco helmet, Breathable spray suit & gloves. Respirator, Breathable spray suit & gloves.

Croplands Breathable

Spray Suits are

especially designed

and ideally suited to our

climatic conditions. They

provide greater protection

than ordinary fabric and

disposable overalls.

Fresh water on the sprayer for personal safety.

2.9

BT-OMWEED 012015 - Rev 1

Section 2

SELECTIVE HERBICIDE

CAUTION

KEEP OUT OF REACH OF CHILDREN

READ SAFETY DIRECTIONS BEFORE OPENING OR USING

ACTIVE CONSTITUENT: 480 g/L TRIFLURALIN

SOLVENT: 557 g/L LIQUID HYDROCARBON

A pre-emergence herbicide for the control of annual grasses and certain broadleaf weeds

in certain horticultural and agricultural crops as listed in the Directions for Use table.

IMPORTANT: READ THE ATTACHED LEAFLET BEFORE USING THIS PRODUCT.

Contents: 200 Litres

Nufarm

GROUP HERBICIDE

D

Nufarm Australia Limited

ACN 004 377 780

103-105 Pipe Road

Laverton North Victoria 3026

Tel: (03) 9282 1000

Fax: (03) 9282 1001

™ Trademark pending

™

10692 Triflur X 200L 11/9/03 12:48 PM Page 1

Safety

Head & Face

Hard hats, washable hats,

goggles, spray helmets and face

shields are important when

handling concentrates.

Croplands Spray Goggles feature sealed,

anti-fog, double lens goggles for practical,

comfortable eye protection. Croplands

Kasco Spray Hood is fully approved by

D.I.R.

Respirators

Choose the correct type and have

the correct cartridge fitted.

Replace cartridges regularly and

write the date on each cartridge.

Ensure there is an adequate fit to

the face.

Croplands' respirators are recommended

for most spraying applications.

Operator Safety

When handling pesticides, always use

elbow-length gloves, long clothes and

above all, a respirator.

If you and your clothing become

contaminated with spray, DO NOT

WORK ON.

Stop work, remove clothing and wash

affected areas thoroughly with soap and

water. Put fresh clothing on before starting

again.

Ensure that contaminated clothing is

washed thoroughly before being used

again.

Don’t guess when choosing protective

equipment. Feel free to call Croplands

and make use of our safety database

for comprehensive information on safety,

handling and storage exposure levels,

symptoms, health effects, first aid and

personal protection.

Spraying Precautions

Agricultural chemicals applied under

unfavourable weather conditions or from

poorly adjusted and operated equipment

can cause damage due to run-off and/or

drift problems.

Crops and pastures are more susceptible

to spray drift of herbicides while people,

stock and water supplies are generally

more susceptible to insecticide drift.

Pollution, crop damage and the potential

health hazards are something agriculture

can ill afford. It is simply not acceptable ,

socially or environmentally.

Additionally, pesticide which drifts or runs

Off the target reduces the efficiency of the

pesticide on the target. Spray failures are

a waste of money and effort.

Be SURE the equipment is

functioning correctly. Check that

nozzles are in good condition.

Check all other aspects of

machine operation are correct.

Be SURE pesticides are mixed

thoroughly and according to the

label.

Be SURE the recommended

registered pesticide is used for

the job at hand.

Be SURE pesticides are applied

at recommended rates.

Be SURE only target plants are

sprayed.

Be SURE to follow the safety

precautions on the label.

Respirator.Safety goggles for eye protection.

A full agri-chemical manual is available in

Australia and New Zealand. Talk to your local

Agronomist for more information.

NOTE

Sample of Agrichemical Manual. Read the Chemical Label

2.10 BT-OMWEED 012015 - Rev 1

Pre-Operation

Boom Assembly

Boom Assembly

The WEEDit has been asembled & tested

at the factory, but for transport the:

• Outer boom sections are removed

and attached on top of the inner

boom sections using:

- 2 end pivot mounts

- 6 mount brackets

- 2 pivot braces.

• Outer castor wheels are removed

and shipped on a pallet

• Two truck tray supports are also

used.

6000 litre 36m dual line WEED, loaded for transport.

Outer Boom Assembly

The outer booms (removed for transport)

require a suitable crane or forklift to lift and

re-assemble each boom.

To reassemble each outer boom:

1 Ensure the WEEDit is on level ground,

then, position a crane or forklift to

support & lift one of the outer booms.

2 Remove the bolts (8) from the base of

the end pivot mount & holding plates

at the base of the inner boom beam.

3 Remove the lower bolts & bottom

clamp plate from each of the

mount brackets (2).

5 Lift the outer boom from the inner

boom, then, remove the:

• End pivot mount - requires

the removal of 8 bolts.

• Mount brackets (2) - each requires

the removal of 4 bolts & a top plate.

Outer booms on top of inner booms for transport.

Remove the bolts at the base of the end pivot mount & the

holding plates at the bottom the inner boom beam.

Remove the bolts, then, the end pivot mount.

Remove the lower bolts & clamp plates from each

mount bracket. Remove the bolts (4 each), then, attachment jigs (2).

6 Remove the outer nuts and washers

(8) from the end of the matching inner

boom.

7 Relocate, align the joining brackets of

the inner & outer booms, then, refit

the washers & nuts.

8 Adjust the nuts either side of the

joining plates to:

• Maintain 1m camera spacing

• Align the boom horizontally, and

• Align the boom longitudinally.

Once aligned, fully tighten the nuts to

lock the boom in position - use a 3/4"

socket & tighten to approx 450 ft/lb.

Recheck alignment after tightening.

Remove the outer nuts & washers (8) from the end of the

inner boom.

Align each boom horizontally & longitudinally.

2.11

BT-OMWEED 012015 - Rev 1

Section 2 Boom Assembly

10 Repeat steps 1 - 9 for the other

outer boom.

11 Once the assembly of the second

outer boom is completed, remove

the bolts (8), base plates, then, the

body of the pivot brace from each

each of the inner boom sections.

12 Reconnect all plumbing lines for each

outer boom.

Remove the bolts (8), then, U-shaped clamp from each

inner boom.

Reconnect all plumbing lines for each outer boom.

13 Reconnect all electrical cables for

outer each boom.

Ensure the "Power Return" cable is

connected to the last camera on

both ends of the boom.

14 Pack and return all transport

components to Croplands:

• End pivot mounts (2)

• Mount brackets (4)

• Truck tray supports (2)

• Pivot braces (2).

15 Install the parking bumpers (supplied

on a seperate pallet) - see drawing

for positioning (page ?).

Reconnect all electrical cables for each outer boom.

Once WEEDit boom is fully assembled,

it is necessary to:

• Inflate the air suspension of the

boom steering and castor wheels.

Minimum required air pressure is

110 psi. Any less than this will

cause undue wear of the shock

absorbers - refer to step 6 - Inflate

Shock Absorbers & Adjust Boom

Height - page 2.23.

• Level the boom so that the base

of the cameras are 1100mm above

the ground surface.

To inflate the shock absorbers & check

the boom hieght, it is recommended to

connect the WEEDit sprayer to the tractor.

Reconnect all boom electrical cables.

Pack & return all transport components to Croplands.

8 Unpack & fit the outer castor wheel

assembly (supplied on a pallet).

Position the castor wheel between

the second & third camera from the

outer end of the boom (approx 2.5m

from the boom end).

Ensure the bolt heads are located

on the clamp plate side (not the

wheel side).

9 Once all clamp bolts are fitted, fully

tighten them.

Unpack & fit the outer castor wheel assembly.

Repeat steps 1 - 9 for the other outer boom.

DO NOT attempt to inflate the shock absorbers

without lifting the wheels off the ground.

Damage to shock absorbers will occur if inflation

is attempted without taking all weight off the

wheels.

CAUTION

2.12 BT-OMWEED 012015 - Rev 1

Pre-Operation

Connect the WEEDit

Sprayer to the Tractor

Single line WEEDit sprayers utilise

hydraulic-drive for the centrifugal pump.

Dual line sprayers may use hydraulic-drive

and PTO drive.

Please read the set-up procedure

instructions for the drives carefully.

1 Connect the WEEDit

Hitch to the Tractor

To connect the WEEDit hitch to a suitable

tractor:

1 Check the WEEDit is level fore & aft,

and the base of cameras closest to

the chassis are 1100mm above ground.

If not, adjust the hitch up or down

using the hitch jack until the base

cameras are 1100mm above ground.

2 Connect the WEEDit hitch to the

tractor drawbar.

If the WEEDit hitch is higher or

lower than the tractor drawbar, adjust

the height of the WEEDit hitch to

match the tractor drawbar height.

To adjust the Hitch Height:

1 Use the front and/or rear pins, holding

the hitch in place, to adjust the height

of the hitch tongue to match your

tractor drawbar.

Ensure the pins are correctly re-

installed after adjustment is complete.

2 Insert the drawbar pin & lock the

retaining pin in position to ensure the

pin cannot come out while

transporting or operating.

Remove the pin to adjust the hitch height as required.Adjust the hitch jack until the work platform is level.

Ensure the drawbar pin is locked-in.

The WEEDit hitch must be correctly adjusted so

that the camera closest to the chassis is 1100mm

above the ground (ground to base of camera)

when connected to the tractor.

If the hitch hieght is adjusted too low or too high,

the camera height will not be correct, which will

adversely affect accuracy of boom camera &

spray operation.

NOTE

Six steps are required to hook up the

WEEDit sprayer to your tractor.

1 Connect the WEEDit hitch to the

tractor drawbar.

2 Connect hydraulic hoses to the

tractor for the:

• Trailed boom fold & operation, and

• Hydraulic pump drive.

• Set the Hydaulic Pump Drive.

3 Fit the Controllers:

• WEEDit Controller

• Trailing Boom Controller

• Other optional controller(s).

4 Fit the PTO shaft (If supplied - for

Dual Line Sprayers only).

5 Connect all power leads direct to the

battery.

6 Inflate shock absorbers and adjust

boom height.

Hook-up

2.13

BT-OMWEED 012015 - Rev 1

Section 2 Hook-up

3 Lower the sprayer hitch onto the tractor

drawbar and fold up the hitch jack:

a) Rotate the jack handle until the

sprayer fully rests on the tractor

drawbar and the hitch jack base

plate is off the ground.

b) Rotate the jack pin to align the

lock-pin with the slot, then remove

the jack pin to lift-up the jack foot-

plate.

Rotate & pull-out the jack pin to lift-up the jack base. The jack base fully-lifted & jack pin locked into position.

The transport safety chain must be fitted.

Rotate and align the pin & slot to remove the jack pin.

Rotate the jack handle lowering hitch onto the drawbar.

c) When fully lifted-up, refit the jack

pin and turn it clockwise, to lock

the pin in position.

4 Fasten the safety chain securely to

both the WEEDit hitch and the tractor

for transporting the sprayer.

5 Recheck the distance from the ground

to the base of cameras (closest

to the WEEDit chassis) still measures

1100mm.

If not, re-adjust the hitch height until

the distance measures 1100mm

when the WEEDit is hitched to the

tractor.

2 Connect Hydraulic

Hoses to the Tractor

The WEEDit Sprayer uses:

• Hydraulic drive for the Centrifugal

pump.

• Hydraulic folding and locking of

the Trailed Boom for operation

and transport.

Connect to the tractor the:

1 Pump drive hydraulic hoses, and

2 Trailing boom hydraulic hoses.

Please read the following page to ensure you

know if your tractor has open or closed centre

hydraulics.

This is VERY IMPORTANT to ensure your pump

drive works correctly.

NOTE

The Centrifugal Pump is hydraulically driven.

This manual suits for next models

2

Table of contents

Other Croplands Paint Sprayer manuals

Croplands

Croplands AgriPak LA300 User manual

Croplands

Croplands GEX Series User manual

Croplands

Croplands RSRL3-100RC REEL User manual

Croplands

Croplands Pinto 2000 User manual

Croplands

Croplands CROPPAK US200F User manual

Croplands

Croplands Quantum Mist Smart Spray QM-420 User manual

Croplands

Croplands WEED-IT User manual

Croplands

Croplands MHL12 User manual

Croplands

Croplands Quantum Mist Smart Spray QM-420 User manual