Croplands Quantum Mist Smart Spray QM-420 User manual

1

WWW.CROPLANDS.COM.AU

HT-OMQM420-A

QUANTUM MIST

QM-420 SPRAYER

OPERATORS MANUAL

STOP

BEFORE COMMENCING

operation, ENSURE you read

& understand this manual, its

contents, and any additional

information supplied.

HT-OMQM420-A

2

INTRODUCTION | GENERAL MANAGER’S WELCOME

Dear Customer

Congratulations on the purchase of your new Croplands Sprayer.

Croplands have been in the business of building sprayer

equipment since 1972. For over 48 years we have been

supplying sprayers to farmers, contractors, growers and all

our customers involved in growing crops and in the control of

pests and diseases.

Croplands is a wholly owned subsidiary of Nufarm Ltd, the

largest supplier of crop protection chemicals for Australasia,

and one of the fastest growing global suppliers world-wide.

At Croplands, we pride ourselves on our commitment to

supplying machinery that is at the forefront of the industry’s

needs. We believe we can back up our products and through

constant research and development, bring to you the best

equipment you can find.

We welcome any feedback from you about our equipment.

On the back cover you will find our contact details, and locations

where our staff can be reached during business hours. After

hours, you can email us and expect a reply the following morning.

Please read this manual in its entirety before you operate your

sprayer. This will ensure you have a trouble free start up.

We trust you will get years of good use from your Croplands

Sprayer.

Yours Sincerely

Sean Mulvaney

General Manager

Sean Mulvaney

General Manager

Croplands has taken steps to ensure this operator’s manual is as current and as accurate as possible. Due to the ever-changing markets of cropping and farming, Croplands

is constantly striving to be at the forefront of innovation and technology. While the information in this manual is considered accurate at the time of writing, Croplands reserves

the right to change this information without notice. Croplands will not accept liability for any inaccuracy in this publication, or changes forthwith.

3

CONTENTS

SECTION 1

IMPORTANT INFORMATION 4

About this manual 4

Terminology 4

Before Operating Your Sprayer 4

Warranty Policy 5

SECTION 2

SAFETY 6

Safety first 6

Safety signs and decals 7

SECTION 3

PRODUCT IDENTIFICATION,

SHIPPING & SPECIFICATION 8

Product identification 8

Shipping information 8

Weights 8

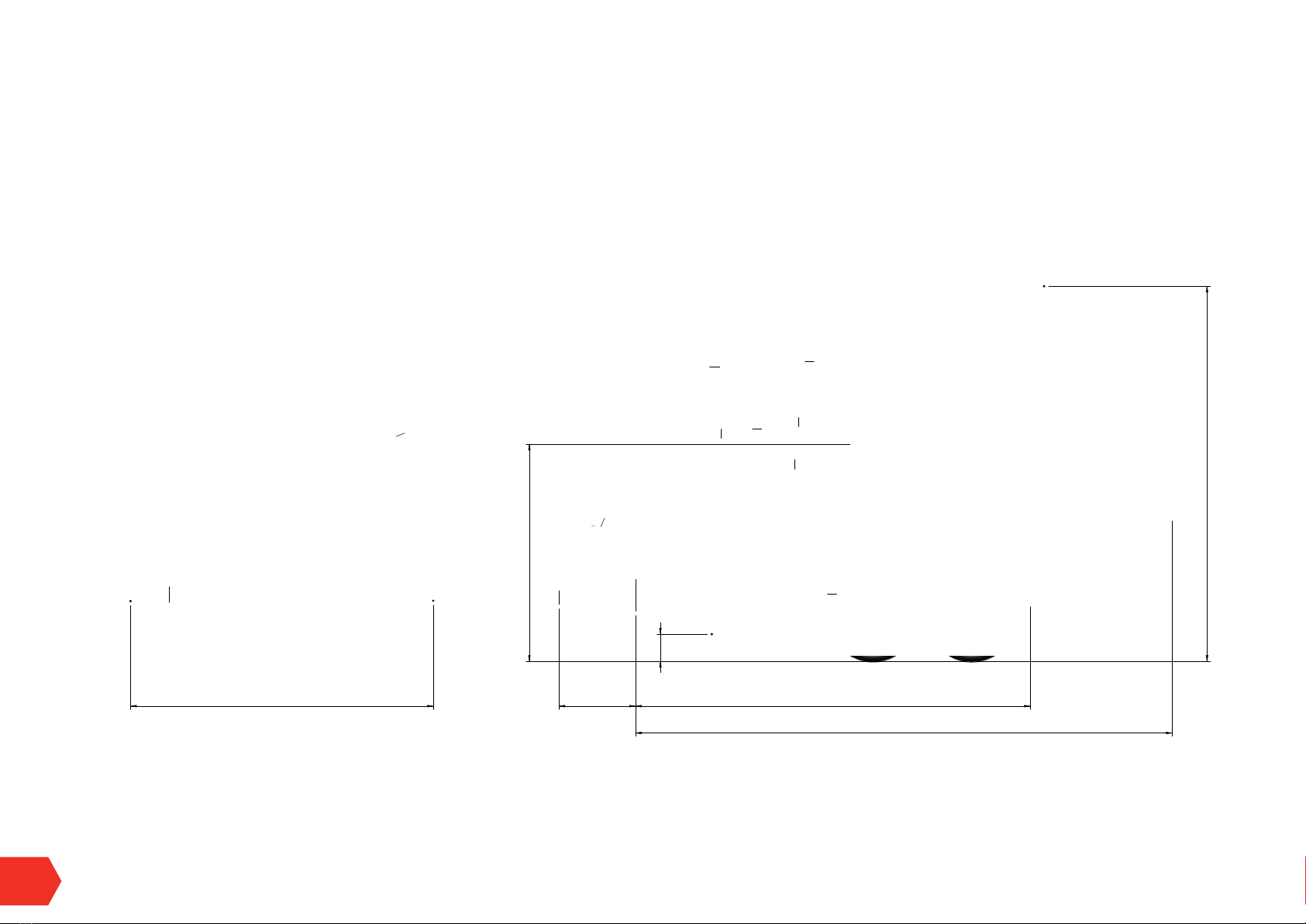

Dimensions 800LT Linkage 9

Dimensions 2000LT Single Row 9

Dimensions 3000/4000LT 3-Row Terracing 10

General Specification 11

SECTION 4

PRODUCT FEATURES /FAMILIARISATION14

Quantum Mist QM-420 Spray “fan”. 15

Fan frames, boom arms & tie rods 17

Boom controls 20

Fan Hydraulic System 20

Spray Pump & Self-Steer Linkage 22

Spray Controllers & Connection 23

Liquid system overview 26

Tanks & suction plumbing 26

Pump & pressure plumbing 29

Section controls 30

Tiered spraying 30

Chassis etc. 31

Linkage 33

SECTION 5

PREOPERATION 34

Safety first 35

Hook up 35

Hook-Up Hv4000 Auto Rate Controller 39

Hook-Up Windcomp 41

Hook-Up Bravo 180 42

Hook-Up Boom Switch Box 42

Hook-Up Micro Power Pack 43

Light kit 43

Confirming Boom Functionality 43

Confirming Fan Functionality 46

Set-Up Spray Pressure 48

Set-Up The Boom/Fan Positions 49

Pre-Operation Checklist 52

SECTION 6

SPRAY OPERATIONS 54

Safety first 55

Filters 55

Filling the sprayer 56

Setting sprayer pressure 57

Agitation 57

Mixing basket 57

Chemical probe 58

Calculate water & chemical quantities 59

Proceed to spray 60

Flushing 61

Tank and equipment cleaning 62

SECTION 7

SPRAYING INFORMATION 64

Spraywise 65

Calibration 65

Flowmeter calibration 66

Step 1 - ensure equipment is in good working order 66

Step 2 - determining the actual speed of travel 68

Step 3 - determine spraying volume required 68

Step 4 - determine sprayer configuration 68

Step 5 - determine the ideal spray pressure 69

Step 6 - determine & select correct nozzles 69

Step 7 - fit & test selected nozzles 70

Step 8 - calculate the actual application rate 70

Step 9 - if the tested rate is unsatisfactory 71

Step 10 - coverage assessment 72

Step 11 - add the correct amount of chemical to the tank 72

Step 12 - record all data for future reference 73

Calibration work sheet 74

SECTION 8

LUBRICATION & MAINTENANCE 78

Greasing & service procedures 79

Every 200 hours 79

Grease points 79

Diaphragm pumps 80

Filters 81

SECTION 9

TROUBLESHOOTING 83

SECTION 10

ASSEMBLY DRAWINGS,

PARTS & SCHEMATICS 92

HT-OMQM420-A

4

SECTION 1

IMPORTANT INFORMATION

ABOUT THIS MANUAL

This manual provides assembly, setting up, operating and

maintenance instructions for the Croplands (Quantum Mist)

QM-420 range of sprayers.

In addition to this manual, the sprayer will be delivered

with the General Safety Manual (GP-SAFE-A) and where

applicable the Controller Manual and Micro Power Pack

Manual (HT-OMMICRO-A). For details not covered

by the manuals, please contact Technical Support on

1300 650 724.

Some features and options explained in this manual may

not be installed on your sprayer.

Please pass on this manual with the sprayer at the time of

resale for usage by the new owner.

This manual, HT-OMQM420-A, was first published in

January 2021.

Check online as there may be more recent revisions of

this manual. www.croplands.com.au

TERMINOLOGY

These terms/symbols used throughout

this manual:

NOTE

This Note sign is in place to convey useful

information and will help you to identify

the best possible way to operate the

machine.

CAUTION

This Caution sign shows the potential for

incident. An incident may include damage

to the machine itself, or possible injury to

the operator.

WARNING

This warning sign shows the potential for

risk or injury and highlights the need for

steps to be taken to protect ones safety.

DANGER

This Danger sign will be used in areas where

the highest risk is present. Always read the

information on these signs and ensure you

are taking steps to prevent risk or injury.

BEFORE OPERATING YOUR SPRAYER

Before attempting to use your sprayer, make sure you

read all Operator Manuals for this sprayer including but

not limited to:

This Operator’s Manual, and all other supplied

manuals for items such as Micro Power Pack, Pumps,

PTO etc.

And properly understand:

• All Safety Issues.

• Assembly & Installation instructions.

• Calibration of the sprayer.

• Sprayer Operation.

• Sprayer Maintenance.

DANGER

!

Probability of death or serious

injury if an accident occurs

WARNING

!

To stress potential dangers and the

importance of personal safety.

CAUTION

!

To highlight potential injury or

machinery damage.

NOTE

To convey useful operating information.

5

SECTION 1

IMPORTANT INFORMATION

WARRANTY POLICY

Each sprayer will be delivered with a

Warranty & Pre-Delivery Booklet which

includes:

• the Sprayer’s unique serial number,

• the Sprayer’s specification sheet,

• a pre-delivery checklist and

• outlines the Croplands Warranty policy.

Always contact your Croplands Dealer first

and foremost for warranty matters.

NOTE

For full conditions of warranty and warranty

policy, please see the Warranty & Pre-Delivery

booklet provided with this sprayer.

1

WWW.CROPLANDS.COM.AU

GP-WARH-A | updated Jan 2021

HORTICULTURE

SPRAYER SPECIFICATIONS

WARRANTY & PRE-DELIVERY

STOP

BEFORE COMMENCING

operation, ENSURE you read

& understand this manual, its

contents, and any additional

information supplied.

HT-OMQM420-A

6

SECTION 2

SAFETY

SAFETY FIRST

Please read and understand all supplied manuals,

guides and safety decals before operating this

sprayer. This includes the Croplands Operators

Safety Manual – as pictured here.

This manual is available on the Croplands Web site,

or for printed versions contact Croplands customer

support and ask for part number GP-SAFE-A (or later

version if available). WWW.CROPLANDS.COM.AU

SAFETY

MANUAL

OPERATORS

STOP

BEFORE COMMENCING

operation, ENSURE you read

& understand this manual, its

contents, and any additional

information supplied.

GP-SAFE-A | Update 2

CLD5701_Croplands safety manual_update 2_2021.indd 1CLD5701_Croplands safety manual_update 2_2021.indd 1 19/1/21 3:00 pm19/1/21 3:00 pm

STOP

BEFORE COMMENCING

operation, ENSURE you read

& understand this manual, its

contents, and any additional

information supplied.

7

SECTION 2

SAFETY

SAFETY SIGNS AND DECALS

All signs and decals for sprayer safety and operation must be maintained in good order and replaced if damaged or missing.

Most Croplands labels have a part number printed on the decal to aid identification and replacement.

Some examples are shown below.

Part No: XD-122V

Part No: XD-194

Part No: XD -195

Part No: XD -125V

Part No: XD -126V

Part No: XD -127V

Part No: XD -123

WARNING

!

1. Read your operators manual thoroughly before

operating the srayer.

2. Inspect hoses, connections and nozzles daily.

3. Clean filters regularly.

4. Always follow correct maintenance schedules

outlined in operator’s manuals.

5. Always read chemical manufacturers labels before use.

6. Always observe all warnings on chemical products.

7. Regularly check all nuts and bolts are tight.

8. Always wear rubber gloves and wash sprayer down

before doing any repair or maintenance work.

9. Do not ride on sprayer when moving.

10.Keep clear of moving parts when sprayer is operating.

11. Always keep guards in place when sprayer is operating.

12. Be sure tank lid is closed before operating basket

mixing facility.

13. Stand well clear of sprayer when operating.

14. Do not disconnect hoses, nozzles or filters while

sprayer is operating.

FAILURE TO FOLLOW THE ABOVE INSTRUCTIONS

MAY RESULT IN SERIOUS INJURY OR DEATH.

Croplands Equipment Pty Ltd XD-123MS

SAFETY INSTRUCTIONS

HT-OMQM420-A

8

SECTION 3

PRODUCT IDENTIFICATION, SHIPPING & SPECIFICATION

PRODUCT IDENTIFICATION

Always use the serial number of the Sprayer when

requesting service information or when ordering parts.

Early or later models (identification made by serial number)

may use different parts, or it may be necessary to use a

different procedure for specific service operations.

The serial numbers of all controllers, pumps etc should also

be recorded for future reference.

SHIPPING INFORMATION

All provided tie down points (and more) should be used to

help secure the sprayer for transporting.

Note serial number plate in the attached image.

WEIGHTS

The below is a general guide to standard model empty

weights. For more detailed information consult the

Croplands Customer Service team.

600 Lt Linkage, 4 fans = tba

800 Lt Linkage, 4 fans = tba

1000 Lt Linkage, 4 fans = tba

1000 Lt Trailed, 4 fans = tba

1500 Lt Single row, 4 fans = tba

1500 Lt Single row, 6 fans = tba

2000 Lt Single row, 6 fans = tba

2000 Lt 2-Row, 8 fans = tba

2000 Lt 2-Row, 12 fans = tba

2000 Lt 3-Row, 12 fans = tba

3000 Lt Single row, 6 fans = tba

3000 Lt 2-Row, 8 fans = tba

3000 Lt 2-Row, 12 fans = tba

3000 Lt 3-Row, 12 fans = tba

3000 Lt 3-Row, 18 Fans + MPP = tba

4000 Lt 2-Row, 8 fans = tba

4000 Lt 2-Row, 12 fans = tba

4000 Lt 3-Row, 12 fans = tba

4000 Lt 3-Row, 18 Fans + MPP = tba

add 190kg +/-10kg for the standard Micro Power Pack (MPP)

add for Terracing tower option = tba

Photo 1

Photo 2

9

SECTION 3

PRODUCT IDENTIFICATION, SHIPPING & SPECIFICATION

DIMENSIONS 800 LT LINKAGE DIMENSIONS 2000 LT SINGLE ROW

1375

1492.50

2050

2350

1665 800LT

1420 600LT

1860

D

E

F

C

1

2

3

4

B

A

3

2

1

5

C

D

4

6

7

8

A

B

ASSEMBLY

HL800QM-Q4 DIM

WEIGHT:

N/A

N/A

A3

SHEET 1 OF 1

SCALE: 1:25

DWG NO.

TITLE:

ISSUE

DO NOT SCALE DRAWING

MATERIAL:

DATE

SIGNATURE

NAME

DEBUR AND

BREAK SHARP

EDGES

FINISH:

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

0.2

TOLERANCES:

LINEAR:

0.5

ANGULAR:

0.5

Q.A

MFG

APPV'D

CHK'D

DRAWN

COPYRIGHT PROPRIETOR

THIS DRAWING IS THE PROPERTY OF CROPLANDS PTY. LTD.

AND MUST BE TREATED AS CONFIDENTIAL.

REPRODUCTION OF THIS DRAWING (OR PART THEREOF) OR COMMUNICATION OF

ITS CONTENTS IS PROHIBITIED WITHOUT THE CONSENT OF CROPLANDS PTY. LTD.

CROPLANDS

A NUFARM LIMITED COMPANY

QUANTUM LINKAGE

A

RPJUCO

151220

REVISION

E

1375

1492.50

2050

2350

1665 800LT

1420 600LT

1860

D

E

F

C

1

2

3

4

B

A

3

2

1

5

C

D

4

6

7

8

A

B

ASSEMBLY

HL800QM-Q4 DIM

WEIGHT:

N/A

N/A

A3

SHEET 1 OF 1

SCALE: 1:25

DWG NO.

TITLE:

ISSUE

DO NOT SCALE DRAWING

MATERIAL:

DATE

SIGNATURE

NAME

DEBUR AND

BREAK SHARP

EDGES

FINISH:

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

0.2

TOLERANCES:

LINEAR:

0.5

ANGULAR:

0.5

Q.A

MFG

APPV'D

CHK'D

DRAWN

COPYRIGHT PROPRIETOR

THIS DRAWING IS THE PROPERTY OF CROPLANDS PTY. LTD.

AND MUST BE TREATED AS CONFIDENTIAL.

REPRODUCTION OF THIS DRAWING (OR PART THEREOF) OR COMMUNICATION OF

ITS CONTENTS IS PROHIBITIED WITHOUT THE CONSENT OF CROPLANDS PTY. LTD.

CROPLANDS

A NUFARM LIMITED COMPANY

QUANTUM LINKAGE

A

RPJUCO

151220

REVISION

E

1726

1490

1440

4250

3154

2644.11

450

1750

D

E

F

C

1

2

3

4

B

A

3

2

1

5

C

D

4

6

7

8

A

B

2000LT QUANTUM MIST 6 HEAD

HTP2000QM-Q6 DIM

WEIGHT:

N/A

N/A

A3

SHEET 1 OF 1

SCALE: 1:30

DWG NO.

TITLE:

ISSUE

DO NOT SCALE DRAWING

MATERIAL:

DATE

SIGNATURE

NAME

DEBUR AND

BREAK SHARP

EDGES

FINISH:

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

0.2

TOLERANCES:

LINEAR:

0.5

ANGULAR:

0.5

Q.A

MFG

APPV'D

CHK'D

DRAWN

COPYRIGHT PROPRIETOR

THIS DRAWING IS THE PROPERTY OF CROPLANDS PTY. LTD.

AND MUST BE TREATED AS CONFIDENTIAL.

REPRODUCTION OF THIS DRAWING (OR PART THEREOF) OR COMMUNICATION OF

ITS CONTENTS IS PROHIBITIED WITHOUT THE CONSENT OF CROPLANDS PTY. LTD.

CROPLANDS

A NUFARM LIMITED COMPANY

QUANTUM MIST 420

A

RPJUCO

151220

REVISION

E

1726

1490

1440

4250

3154

2644.11

450

1750

D

E

F

C

1

2

3

4

B

A

3

2

1

5

C

D

4

6

7

8

A

B

2000LT QUANTUM MIST 6 HEAD

HTP2000QM-Q6 DIM

WEIGHT:

N/A

N/A

A3

SHEET 1 OF 1

SCALE: 1:30

DWG NO.

TITLE:

ISSUE

DO NOT SCALE DRAWING

MATERIAL:

DATE

SIGNATURE

NAME

DEBUR AND

BREAK SHARP

EDGES

FINISH:

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

0.2

TOLERANCES:

LINEAR:

0.5

ANGULAR:

0.5

Q.A

MFG

APPV'D

CHK'D

DRAWN

COPYRIGHT PROPRIETOR

THIS DRAWING IS THE PROPERTY OF CROPLANDS PTY. LTD.

AND MUST BE TREATED AS CONFIDENTIAL.

REPRODUCTION OF THIS DRAWING (OR PART THEREOF) OR COMMUNICATION OF

ITS CONTENTS IS PROHIBITIED WITHOUT THE CONSENT OF CROPLANDS PTY. LTD.

CROPLANDS

A NUFARM LIMITED COMPANY

QUANTUM MIST 420

A

RPJUCO

151220

REVISION

E

HT-OMQM420-A

10

SECTION 3

PRODUCT IDENTIFICATION, SHIPPING & SPECIFICATION

2700

4790 3000LT

5255 4000LT

3525 3000LT

3990 4000LT

685

3350

242.71

1940 3000LT

1975 4000LT

6

D

C

B

A

E

F

G

H

E

A

B

C

D

F

5

4

3

2

1

7

8

9

10

11

12

1

2

3

4

5

6

8

G

HTP3000QMQ18WT ASSEMBLY

HTP3000QMQ18WT DIM

WEIGHT:

N/A

N/A

A2

SHEET 1 OF 1

SCALE: 1:20

DWG NO.

TITLE:

ISSUE

DO NOT SCALE DRAWING

MATERIAL:

DATE

SIGNATURE

NAME

DEBUR AND

BREAK SHARP

EDGES

FINISH:

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN MILLIMETERS

SURFACE FINISH:

0.2

TOLERANCES:

LINEAR:

0.5

ANGULAR:

0.5

Q.A

MFG

APPV'D

CHK'D

DRAWN

COPYRIGHT PROPRIETOR

THIS DRAWING IS THE PROPERTY OF CROPLANDS PTY. LTD.

AND MUST BE TREATED AS CONFIDENTIAL.

REPRODUCTION OF THIS DRAWING (OR PART THEROF) OR COMMUNICATION OF ITS

CONTENTS IS PROHIBITIED WITHOUT THE CONSENT OR AUTHORITY OF CROPLANDS PTY. LTD.

CROPLANDS

A NUFARM LIMITED COMPANY

A

RPJUCO

161220

QUANTUM MIST 420

REVISION

7

DIMENSIONS 3000 / 4000 LT 3ROW TERRACING

11

SECTION 3

PRODUCT IDENTIFICATION, SHIPPING & SPECIFICATION

GENERAL SPECIFICATION

The QM-420 Sprayer is Croplands latest vineyard sprayer

range to feature the patent pending QM-420 spray fans

with dual spray rings. The sprayers are available in single

row (linkage and trailed), double row and triple row

configurations with optional Micro Power Pack.

The Quantum Mist™ system uses a combination of

individual hydraulically driven spray fans with 5-blade

fans to give the maximum possible spray coverage in

grapes and dwarf tree crops.

The sprayers are available with a wide selection of options

for booms, towers, and controllers.

For more detailed specification, see Section 4,

Product Features / Familiarisation

Controls

A wide variety of controllers are available. Basic

manual controls, standard electric controls & auto-rate

controllers. A separate manual will be provided for

your Spray controller option.

Tank Sizes

600, 800, 1000, 1500, 2000, 3000, and 4000 litre

tank options are available and are constructed of impact-

resistant polyethylene and UV stabilized. Each unit has

a separate flushing tank with additional separate or

integrated fresh water tank and a calibrated sight tube for

filling level indication.

All main tanks drain completely via a large drain valve

and sump.

Chemical Handling

Quick fill system and chemical suction probe standard on

all trailed models.

Filtration

Lid-strainers & chemical mixing baskets are standard on

all models.

Large suction filter, and self-cleaning pressure filter fitted.

Pumps

All QM-420 Sprayers are fitted with an Annovi Reverberi

positive displacement diaphragm pumps with a capacity

of 80 to 250 L/min - depending on the sprayer model.

A heavy-duty PTO shaft is supplied to drive the pump.

This will be supplied specific to the sprayer model.

Hydraulic-driven pumps (in lieu of PTO) are installed

when a Micro Power Pack is fitted to the sprayer.

Agitation

The agitation system is driven by the pump via twin supa-

flow venturi tank agitators & bypass agitation. Single

agitator for the 1,500 model and linkage units.

Hydraulic System

Standard hydraulic oil supply is from the tractor hydraulics

for fan operation, boom operations and optional

pump operation.

Optional (and highly recommended) is the Micro Power

Pack for fan drive hydraulics.

The “standard” fan drive oil system uses a soft start/fan

speed control manifold (with test ports for pressure and

return) mounted at the front of the sprayer which then feeds

a distribution block at the rear of the sprayer with separate

hose circuits to the hydraulic driven fans.

The optional WindComp fan function uses a single manifold

block which incorporates all the above functions in the one

block at the rear of the sprayer.

All models with 6 or more fans are fitted with a hydraulic oil

radiator with thermostat switching of an electric fan cooler.

Boom and tower control functions are separate hydraulic

functions direct to tractor remotes.

Micro Power Pack

A compact, self-contained, independent hydraulic

oil supply system incorporated into a 3 point linkage,

self-steering drawbar. Driven by the tractor PTO shaft,

the Micro Power Pack is available in a variety of pump

configurations depending on Sprayer model specifications.

See the separate manual for this option.

QM-420 Spray fans

The new QM-420 Spray Fans “Fans”, comprised of

a Polyethylene Rotomoulded cowling which includes

mounting points on either side, into which there installed

dual spray rings, front and rear safety guards and drive

body & fan.

The 5-blade 420mm diameter fan has been designed for

maximum air efficiency in the agricultural environment with

excellent characteristics for canopy spraying.

The fans are hydraulically driven by a case drained 6.5cc

or 9.8cc motor, driving via a double bearing “drive body”

and shaft with well-proven rubber coupling to smoothly

drive the fan.

QM-420

P

A

T

E

N

T

P

E

N

D

I

N

G

HT-OMQM420-A

12

SECTION 3

PRODUCT IDENTIFICATION, SHIPPING & SPECIFICATION

Nozzles

Each QM-420 spray fan comes with 2 spray rings with

5 nozzles per ring, for a total of 10 nozzles per fan. The

nozzles are used in a 3 tier system, with low, medium, and

high settings which are manually adjusted from the ground.

Standard nozzles are ALBUZ 80-degree ceramic hollow

cone nozzles (brown and yellow). Alternative size

nozzles may be selected at the time of order (e.g. yellow

and orange).

The feed to all spray rings is fitted with a “non-drip”

diaphragm check valve with an integral stop cock.

Spray rate capability for the Quantum Mist™ QM-420

Sprayer ranges from 150 to 2000+ L/ha.

Boom & Fan Frame

Rugged powder-coated, heavy-duty steel booms support

the galvanised “fan frames” The spray fans are well

protected within the galvanized fan frames.

The fans can be moved vertically and / or angle adjusted

up or down to ensure optimum spray coverage.

Boom folding is controlled via tractor remotes.

Spray fans in the boom open position are at right angles to

the sprayer. The fan (frames) can be manually rotated to be

flat against the sprayer for transport.

Rear (inner) booms are manually adjusted.

All boom side fan frames feature a breakaway system.

2-Row and 3-Row

2-Row and 3-Row configurations use a common boom

arm. Each set of (fan frame) fans can be manually adjusted

for row width via a sliding carriage. Optional hydraulic row

width adjustment enables adjusted from the tractor cab.

Chassis

Hot-dipped galvanised full-length heavy-duty chassis

slide-out step & jockey stand.

Suspension

Walking beam tandem axle is fitted as standard on all 2

and 3-row sprayers. All trailed single row sprayers are

fitted with a single fixed axle as standard.

Wheels & Tyres

11.5/80 x15.3 wheels with tubeless tyres are fitted as

standard. Flotation tyres available as an option for most

axle options.

Speed Sensors

Proximity sensors are used for Fan speed, Pump speed,

and Wheel (travel) speed.

Self-Steer Drawbar

2-point hitch, self-steer drawbar is standard on all trailed

QM-420 sprayers 3-point is standard on all 3,000 &

4,000 Lt models.

Tractor required

Power required at the PTO on flat terrain:

• Linkage models - approx. 40-50 HP.

• Single row trailed - approx. 50-70 HP

• 2-row trailed - approx. 70-90 HP.

• 3-row trailed - approx. 80 -110 HP

If not using a Micro Power Pack, hydraulic oil required

will be dependent on sprayer model & configuration,

ranging from 36 to 108 litres per minute at pressures up

to a maximum of 2,750 psi.

Category 2 linkage connections required.

Factory Fitted Options

• Wide Tower – is recommended for use in row widths

greater than 3.0 metres (3.3 - 3.75)

• Nozzles- Albuz 60-degree nozzles can be used in

lieu of 80-degree.

13

SECTION 3

PRODUCT IDENTIFICATION, SHIPPING & SPECIFICATION

Options (not applicable to all models)

• HV4000 auto rate controller

• Bravo 180 auto rate controller

• WindComp (variable fan speed to left and right).

This also includes the Opus A3 controller and dual

fan speed sensors.

• Fan rpm sensors.

• Visio Multi-function display

• Electric fan speed control

• Atlas 100 GPS speed sensor

• Wide tower – a “standard” option when used in row

spacing greater than 3.0 metres

• Terracing tower, including wide terracing tower option

• Hydraulic row width adjustment

• Flotation tyres (31 x 13.5 – 15”) – not compatible with

the 2,000 Lt model

• Heavy-duty, 3-point self-steer drawbar (as shown).

• Micro Power Pack (standard on all 18 fan models)

(includes 3-point drawbar as standard).

• Bio oil (for Micro Power Pack)

• Light kit

• Electric brakes

• Alternative nozzles, Albuz 60-degree or 40-degree

nozzles can be used in lieu of 80-degree.

• NuPoint GPS tracking, mapping and data reporting

system

Sprayer specifications are subject to

change without prior notification.

HT-OMQM420-A

14

QUANTUM MIST QM420 SPRAY FAN “FAN” 15

FAN FRAMES, BOOM ARMS & TIE RODS 17

BOOM CONTROLS 20

FAN HYDRAULIC SYSTEM 20

SPRAY PUMP & SELFSTEER LINKAGE 22

SPRAY CONTROLLERS & CONNECTION 23

LIQUID SYSTEM OVERVIEW 26

TANKS & SUCTION PLUMBING 26

PUMP & PRESSURE PLUMBING 29

SECTION CONTROLS 30

TIERED SPRAYING 30

CHASSIS ETC. 31

LINKAGE 33

SECTION 4

PRODUCT FEATURES / FAMILIARISATION

15

SECTION 4

PRODUCT FEATURES / FAMILIARISATION

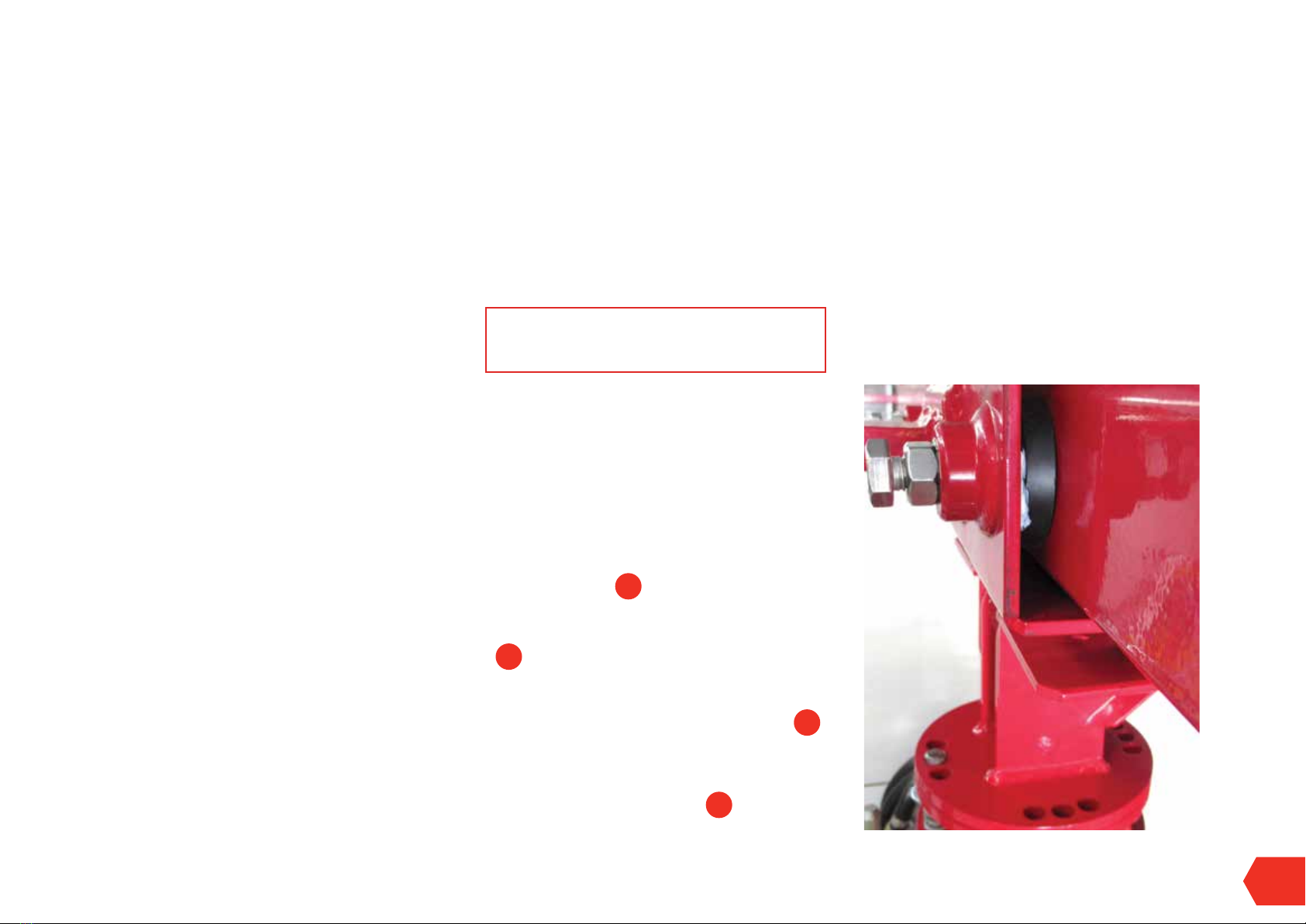

QUANTUM MIST QM420 SPRAY “FAN”

Standard on all QM-420 models is the new extremely

efficient 420 mm diameter “QM-420” fan and the “Fan

Frame” mounting system.

Fan / Cap / Cover

The robust 5 bladed fan also features a separate

moulded front cap designed to prevent the build-up of

detritus so common in other fans, and the same cap, with

the “knockout” removed, is used at the rear to further

streamline the airflow.

Drive Body

The drive body differs from the “original” and very reliable

QM-380 drive body in that it has a further 4 tapped holes

to accept the rear cover. Note the rear cover (which is

the same moulding as the front cap, with a knock out for

the hydraulic motor) has positions for 5 screws, but only

4 screws are used. The “5th screw” position aligns with a

casting cutaway for either a speed sensor or case drain

connection (see photo above).

Cowl Orientation / Speed Sensor / Case drain

The cowling should always be mounted with the cutaway

for speed sensor or case drain facing downwards (to

enable drainage). The case drain is there for the unlikely

event of blowing oil seals in the hydraulic motor.

Sprayers fitted with the optional Wind Compensation

feature will use two speed sensors (left and right).

Note the rear guard needs to be removed to fit or access

the speed sensor. Replace the guard once done.

Dual Spray Rings

The fan also features twin spray rings, with 5 nozzles

per ring. This allows unprecedented control over spray

coverage rates and droplet spectrums.

As supplied ”standard”, it’s set up as a 3-tier system. The

inner / smaller diameter spray ring is fitted with a smaller

(brown) nozzle, and the outer / larger diameter spray ring

is fitted with a larger (yellow) nozzles.

• Inner spray ring only is Tier 1 / lowest volume rate.

• Outer spray ring only is Tier 2 / medium volume rate.

• Both spray rings together are Tier 3 / for high volume rate.

There are many other ways to use the dual ring system such

as using one of the rings for special purpose nozzles.

See pages 30 & 31 for more information on Tiered plumbing.

HT-OMQM420-A

16

SECTION 4

PRODUCT FEATURES / FAMILIARISATION

Hydraulic Drive

All QM-420 fans are driven by hydraulic motors built to a

special heavy-duty specification and with case drain port.

Most QM-420 models are fitted with 6.5 cc hydraulic

motors. In some instances (if required) 9.8 cc motors

are used.

Guards

The QM-420 must never be used without the front and rear

guards installed.

Operational limits

The nominated maximum operating speed of the fan is

3,000 rpm. Normal delivered maximum operating speed

of 2,500 rpm. Exceptions apply.

DANGER, Stay well away from rotating fans.

Whilst the front (downwind) side may appear to be the

more dangerous side, it’s the back side that holds greater

danger as it can suddenly suck body parts or objects in.

Fan Frame Mounting

Each spray fan is mounted via dual M12 brass inserts

moulded into each side of the cowling.

The normal spray fan mounting method is via special

stainless-steel clamps into the “Fan Frame”.

The bracket is reversible and can be used to adjust fan

positioning (see more on page 50).

U-Bracket Mounting

As used on the 1000 Lt trailed sprayer and….

• where the QM-420 is being retrofitted to replace older

QM-380 fans (now discontinued)

• the fan is being fitted to a “Classic” style sprayer which

uses hook brackets rather than fan frames...

… the fan can be mounted via a fabricated, black powder-

coated steel U-bracket (HP-319-8) to the HP-275C scissor

action clamp.

Also requires the HP-275C-1 clamp plate.

Leaf Guard

A moulded leaf guard is fitted as standard to all bottom fans.

Check Valve/stop cock/drain

The feed to each spray ring is fitted with a “non-drip”

diaphragm check valve with an integral stop cock

which allows individual spray rings to be manually shut off

as required.

Screw the red cap in for stop, out for normal diaphragm

“non-drip”.

Each spray ring has a draining/flush tap on the exit.

17

SECTION 4

PRODUCT FEATURES / FAMILIARISATION

FAN FRAMES, BOOM ARMS & TIE RODS

Fan Frames

Mounting the spray fans into the fan frames has many

advantages, including the ability to specify the exact

positioning of fan heights and angles. The fans remain well

protected and fixed until a change is required.

Up to 3 fans can be installed in each fan frame – with the

lower fan also using a leaf guard.

All outer row fan frames incorporate a breakaway system.

Detailed information regarding setting up and

operating the fans (and booms) in Section 5.

Over-row Boom

Over row booms use a sliding carriage (A) connection to

the fan frames and incorporate a breakaway system.

The outer underside of each boom arm has 3 holes (B) set

at 300m intervals into which the sprung loaded pin (C)

can be engaged. This sets the row width.

NOTE - If fitted with Optional Hydraulic outer row width

adjustment the manual locking in is not used.

The optional hydraulic outer row width function does not

require the slide locking mechanism.

The slide has several nylon buttons within the carriage to

aid smooth operation. The buttons are adjustable to allow

for wear – the buttons and adjustment bolt with lock nut

can be seen in the photo below.

A

C

D

B

HT-OMQM420-A

18

SECTION 4

PRODUCT FEATURES / FAMILIARISATION

Spray fans in the boom open position are at right angles

to the sprayer. For parking, the fans can be manually

rotated via the connection swivel (D) to one of 3 positions

(nominally 74, 90 or 104 degrees) so that the fans can

park flat against the sprayer for transport. The 3 positions

can be seen in the last photo previous page.

3-Row sprayers use the same sliding carriage

arrangement. Only the outermost carriage is locked into

place with a tie rod connection between both slides. This

ensures both frames remain sufficiently separated (when

rotated for parking) and will move together when row

width adjusted.

The optional hydraulic outer row width function also

requires the tie rod between both slides to ensure both

frames move together.

Single row/Rear Fans

Most models of the QM-420 Sprayers connect the rear fan

frames to the main tower via a pair of “standoff” brackets

and saddle clamps.

The standoff brackets can be moved in both height and

rotation by loosening the saddle clamps at (A) and rotate

the required width – retighten. Then adjust the fan frames at (B) to spray to the required

direction (normally square to the canopy.

A

B

A

B

19

SECTION 4

PRODUCT FEATURES / FAMILIARISATION

Tower options

All boom arms connect to a Tower, of which there are

multiple variations.

• Standard Tower (the standard tower is recommended for

use in vineyards with row widths from 2.5 to 3.0 metres).

• Wide Tower, has an extra 400mm each side.

The wide tower option (shown by yellow arrow) is

recommended for use in vineyards with row widths

from 3.3 -3.6 metres. This design reduces the boom

arm length thus aiding more clearance for 3-row

sprayers in the parked position.

• Tall Tower (400 higher and uses longer fan frames).

• Tall (wide) Tower.

• Terracing Tower. The terracing tower has 600mm

of movement. Both the left and right sides can be

moved independently. All fans on one side move

at the same time.

• Wide Terracing Tower.

• Tall versions of both terracing towers are also available

as special builds.

HT-OMQM420-A

20

SECTION 4

PRODUCT FEATURES / FAMILIARISATION

BOOM CONTROLS/HYDRAULICS

All boom fold functions are (standard) via tractor hydraulic

remotes.

However, a fully optioned sprayer will have too many

boom functions for operation via the available tractor

remotes. Tractor remotes #1 will often be for fan

hydraulics.

Possible boom functions are (also see photo previous

page):

• Left arm fold

• Right arm fold

• Left terracing lift

• Right terracing lift

• Left row width adjustment

• Right row width adjustment

If the diverter (HT-EDV option) is available where only one

remote is available for 2 functions

Eg. say left and right fold, to flick between these operations.

If the diverter valve option is not sufficient, the only choice

is to use the multi-function electric/hydraulic switch box to

control boom functions via multi-function Cetop valve block

at the rear of the sprayer.

Hydraulic Identification

All hydraulic hose circuits are identified as per below.

Some exceptions apply for special builds.

(A) Pressure hoses to have two colour bands

(B) Return lines to have one colour band

Hydraulic hose identification

BLUE RIGHT FOLD

RED LEFT FOLD OR ELEC/HYD

YELLOW FANS

WHITE PRODUCT PUMP

GREEN AXLE/SPARE

FAN HYDRAULIC SYSTEM

There are 2 different fan hydraulic systems available.

(a) The Standard conventional hydraulic system as

used on Quantum Mist sprayers for many years, with

several improvements, and …

(b) The “A3 WindComp” system. The A3 system is

only used on the QM-420 sprayers with the optional

WindComp feature.

In both systems, the general fan motor plumbing is the

same. The fan hydraulic motors are plumbed in series of 2,

3 or 4 fans per circuit. As well as pressure in and out, each

motor is plumbed with a case drain, also plumbed in series.

In some cases, each set of fans per fan frame is a

separate circuit.

Oil returns from the fans go via the distribution block, then

via the oil cooler (if fitted), and finally back to the tank (be

it the tractor or power pack).

1 Band for Return

2 Bands for Pressure

Other manuals for Quantum Mist Smart Spray QM-420

1

Table of contents

Other Croplands Paint Sprayer manuals

Croplands

Croplands PEGASUS WEED-IT 4000 User manual

Croplands

Croplands MHL12 User manual

Croplands

Croplands RSRL3-100RC REEL User manual

Croplands

Croplands CROPPAK US200F User manual

Croplands

Croplands AgriPak LA300 User manual

Croplands

Croplands Quantum Mist Smart Spray QM-420 User manual

Croplands

Croplands Pinto 2000 User manual

Croplands

Croplands GEX Series User manual

Croplands

Croplands WEED-IT User manual