2330102.fm

- 1 -

English (translated from the original language) user manual

title page title page

TABLE OF CONTENTS

IMPORTANT SAFETY NOTE

The information published in this booklet regards the

pointed out with relevant symbols in order to safe-

guard operational aspects of the operator unit instal-

led on the people from risks. Remember that

prudence is irreplaceable. machine. It is however

necessary that you carefully read the Safety is also

in the hands of all the operators who interact general

safety regulations published in Booklet 1 and those

with the machine.

TECHNICAL INFORMATION..................2

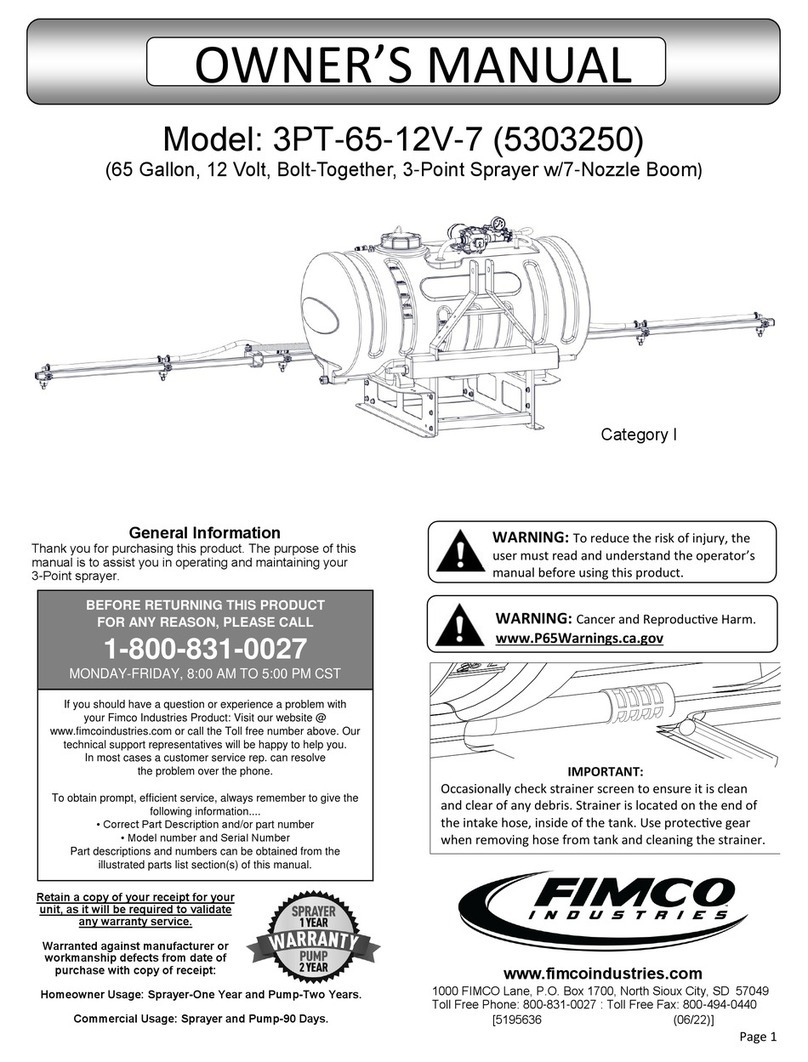

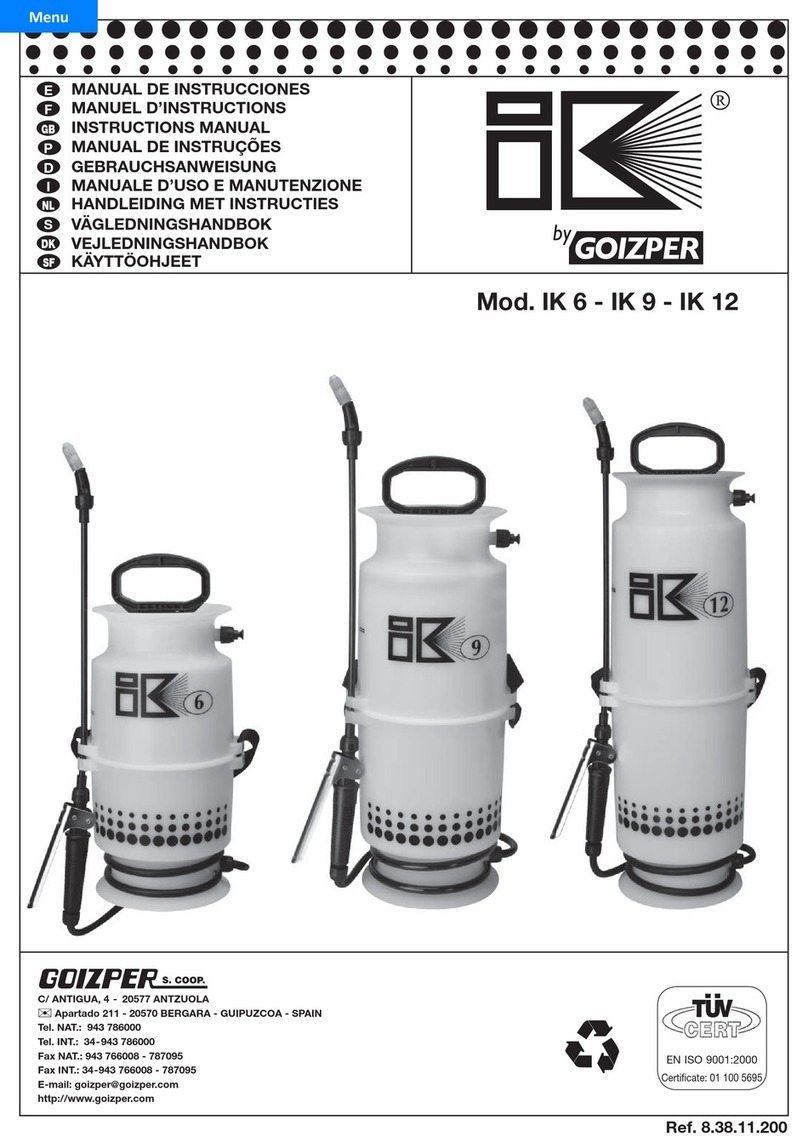

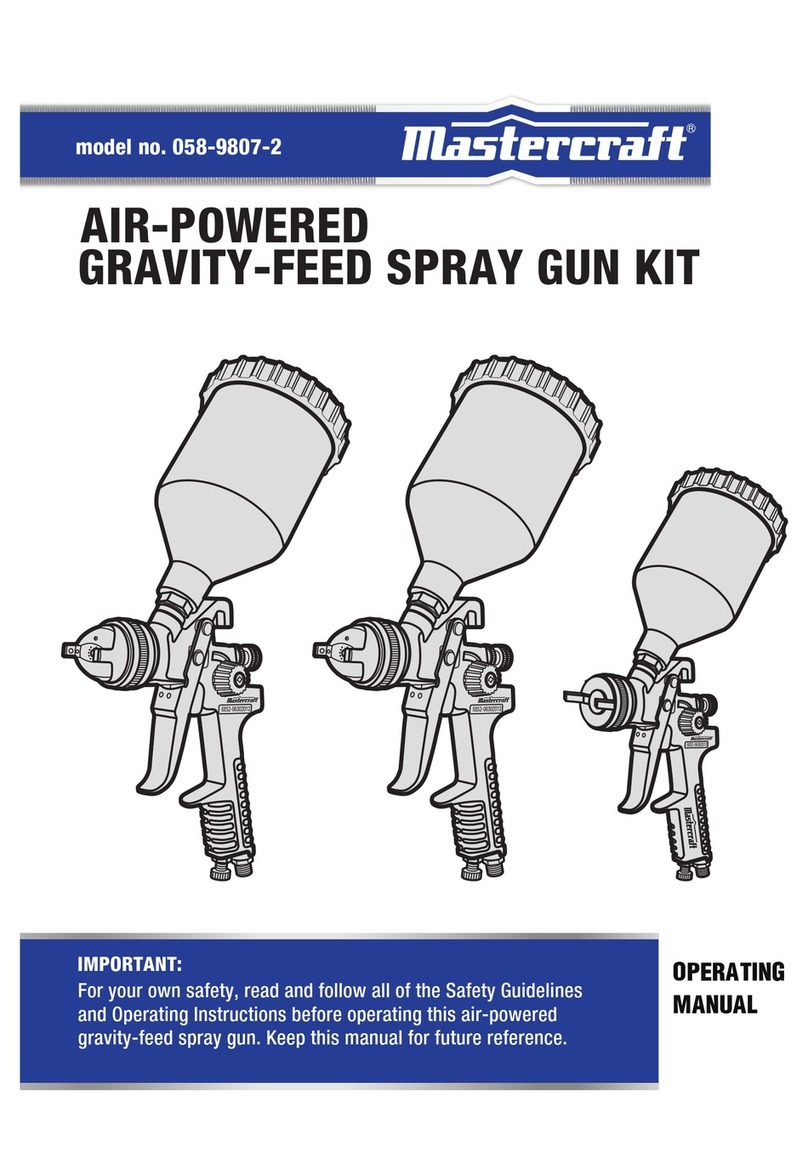

Equipment general description................2

Technical specifications...........................2

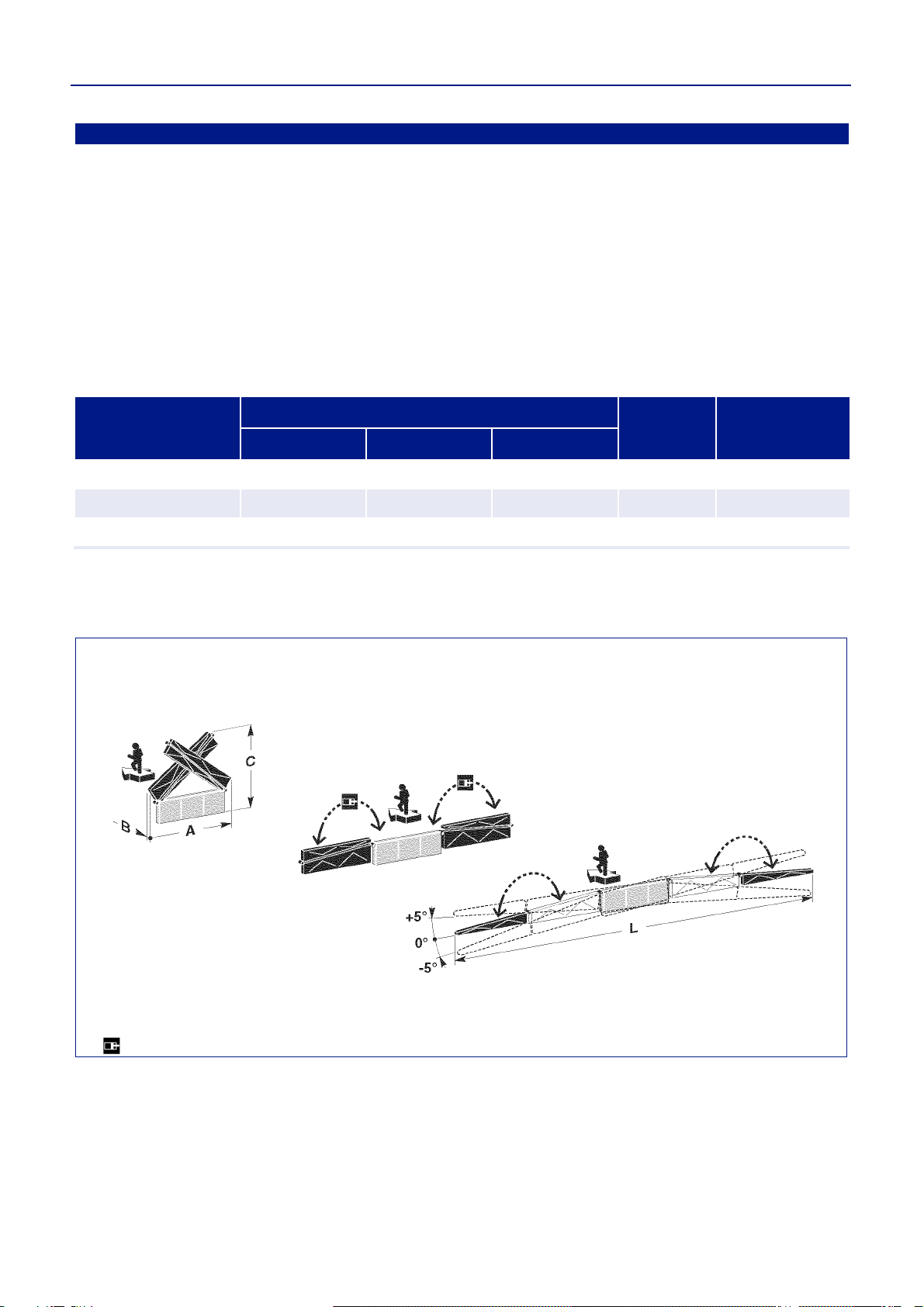

Technical specification diagram....................2

Fittings on demand..................................2

Safety devices .........................................3

Safety distance diagram................................3

Identification plate position ......................4

Position of signals....................................4

INFORMATION ABOUT HANDLING

AND INSTALLATION..............................4

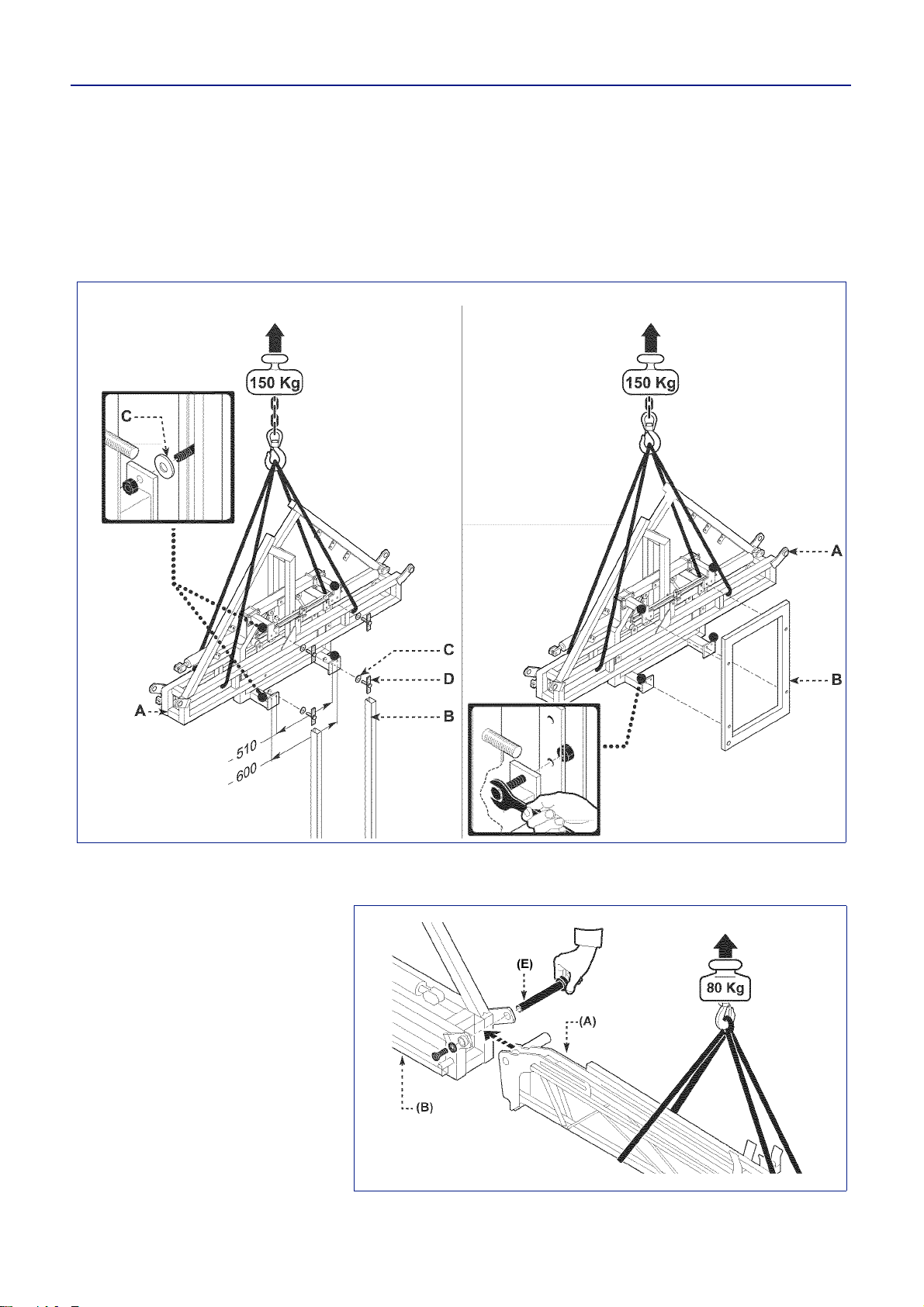

Handling instructions ...............................4

Packing and unpacking............................4

Loading and transportation......................5

Handling and lifting..................................5

Installation instructions ............................5

Installation of disassembled parts............5

Equipment installation..............................6

Installation of arm ....................................6

Installation of the hydraulic system..........7

2-function hydraulic system (with electric

switch and control panel) ..............................8

Boom folding and unfolding...........................9

4-function hydraulic system (with electric

switch and control panel) ............................10

Boom folding and unfolding.........................11

4-function hydraulic system (with double

effect solenoid valves).................................12

Boom folding and unfolding.........................13

Installation of line filters (if required)

and jets..................................................14

Number of jets on each boom section...15

Jet number diagram for each boom

section (500 mm pitch)................................16

Installation of water hoses.....................16

5-supply water connection diagram ............18

Installation of rear light kit .....................19

Installation of the locking piston

(on request)........................................... 20

INFORMATION ABOUT

ADJUSTMENTS................................... 21

Instructions for adjustments..................21

Adjustment of the swinging sliding

shoes.....................................................21

Adjustment of the automatic blocking

device....................................................21

Adjustment of arm alignment ................22

Boom folding support adjustment..........23

INFORMATION ABOUT USE............... 23

Recommendations for use with

self-levelling device automatic locking..23

Recommendations for use with

self-levelling device hydraulic locking ... 24

Boom folding and unfolding...................25

Adjustment of tilt....................................25

Adjust the hydraulic locking device.......26

INFORMATION ABOUT

MAINTENANCE....................................27

Maintenance schedule table .................27

Lubrication points diagram.................... 28

Cleaning nozzles................................... 28

Long period of inactivity ........................29

TROUBLESHOOTING.......................... 29

Troubles, causes, remedies..................29

INFORMATION ABOUT

REPLACEMENTS ................................31

Replacement of spring and terminal

joint pin.................................................. 31

Replacement of corrector of position

spring ....................................................32

Disposing of the equipment...................32

Spraying boom

user manual

Serial number Edition 2

07 - 2013

Booklet

9