INDEX

1. PRODUCT SPECIFICATIONS ..................................................................................................................................3

1.1. DESCRIPTION......................................................................................................................................................3

1.2. DESIGNATION......................................................................................................................................................4

1.3. OPERATING LIMITS.............................................................................................................................................4

1.4. TECHNICAL CHARACTERISTICS AND DIMENSIONS .......................................................................................4

1.5. EQUIPMENT DESIGN ..........................................................................................................................................5

2. UNIT PREPARATION FOR USE...............................................................................................................................5

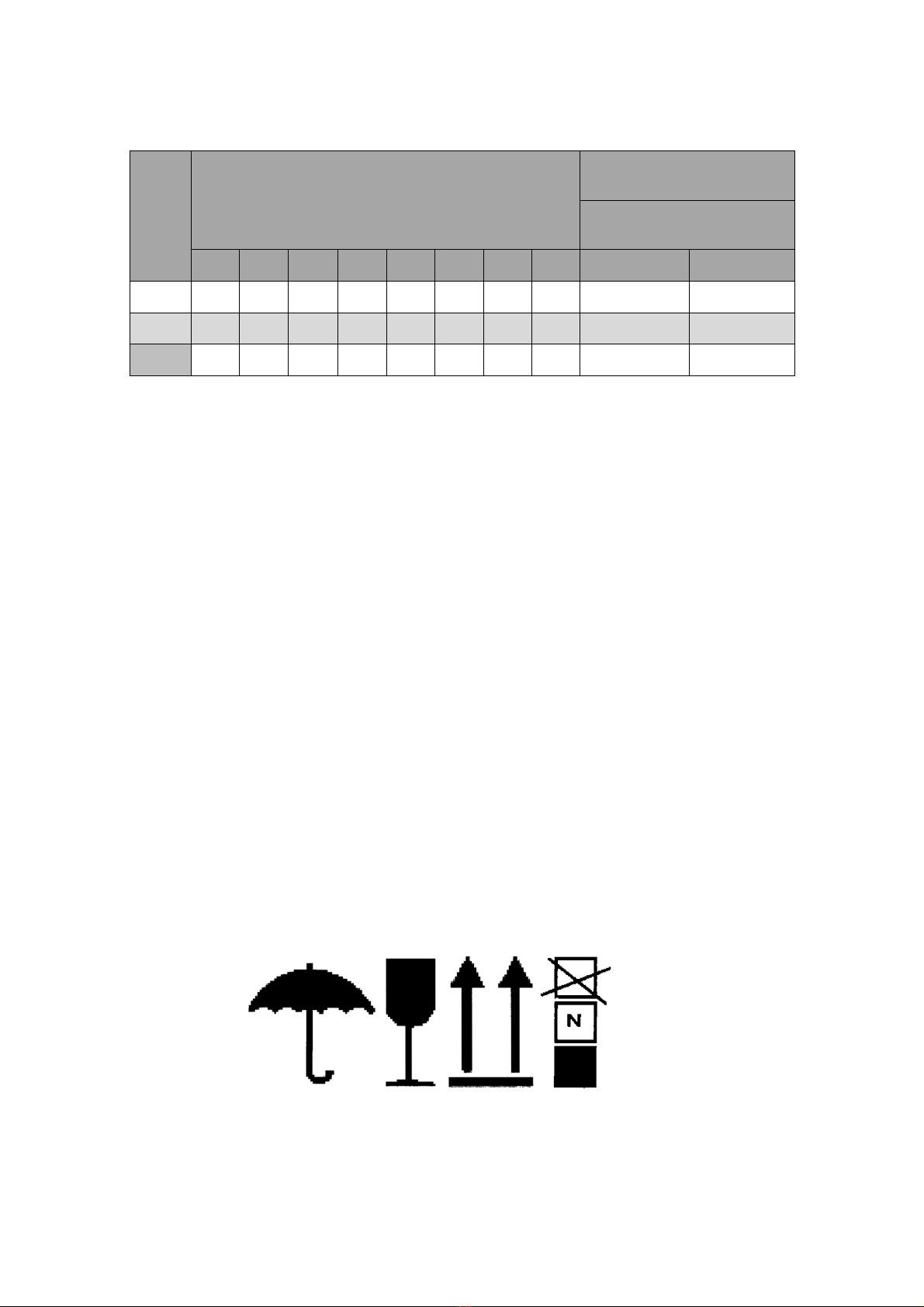

2.1. TRANSPORT........................................................................................................................................................5

2.2. IMPORTANT SAFETY WARNINGS......................................................................................................................6

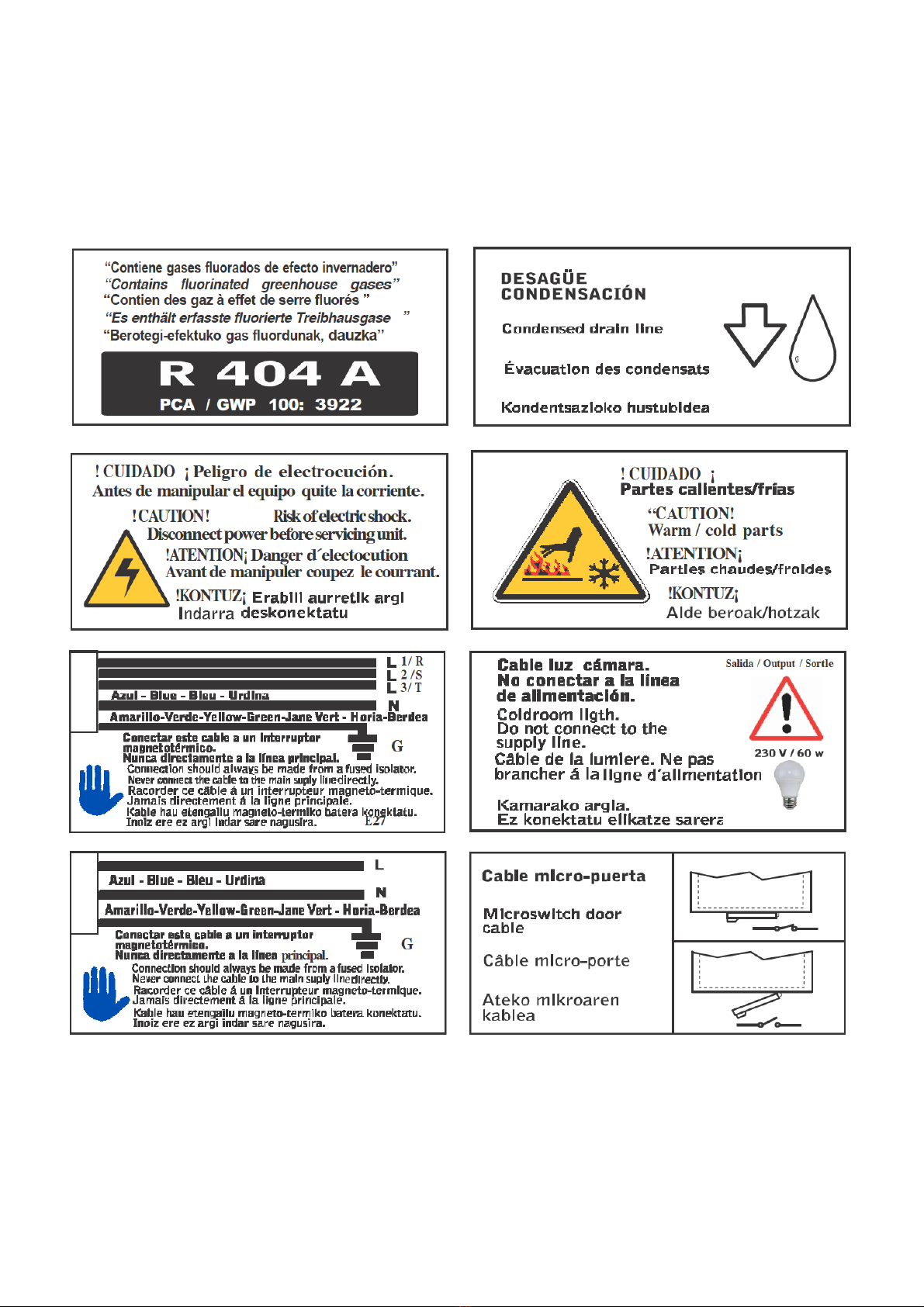

2.3. INDICATIONS.......................................................................................................................................................7

2.4. INSTALLING THE UNIT........................................................................................................................................9

2.5. COMPULSORY SPACE TO BE LEFT AROUND THE UNIT ................................................................................9

2.6. ASSEMBLY...........................................................................................................................................................9

2.7. PROTECTIVE DEVICES AND SAFETY MEASURES ........................................................................................11

2.8. DISPOSING OF PACKAGING ............................................................................................................................11

2.9. CONTROLS, ADJUSTMENTS AND CHECKS TO BE MADE.............................................................................11

3. OPERATING INSTRUCTIONS................................................................................................................................11

3.1. CONNECTING THE UNIT TO EXTERNAL POWER SOURCES........................................................................11

3.2. ELECTRICAL POWER CONNECTION...............................................................................................................11

3.3. ADJUSTMENT AND CONTROL .........................................................................................................................12

3.4. COLD ROOM LIGHT...........................................................................................................................................13

3.5. CONTROL DEVICE ............................................................................................................................................13

3.6. CONTROL FUNCTIONS.....................................................................................................................................14

3.7. INDICATOR LIGHTS...........................................................................................................................................15

3.8. ALARM SIGNALS ...............................................................................................................................................15

3.9. RESETTING THE ALARMS ................................................................................................................................15

3.10. PAL/CA ALARM ..................................................................................................................................................16

3.11. P1, P2, P3, P4 ALARM .......................................................................................................................................18

3.12. dA ALARM...........................................................................................................................................................19

3.13. COMPRESSOR ALARM DOES NOT START.....................................................................................................19

3.14. PARAMETER LIST .............................................................................................................................................20

3.15. EXTERNAL COMMUNICATION .........................................................................................................................20

3.16. STARTING UP THE UNIT...................................................................................................................................21

3.17. DIAGRAM OF THE UNIT ELECTRICAL SYSTEM .............................................................................................21

4. MAINTENANCE AND CLEANING...........................................................................................................................21

4.1. MAINTENANCE AND REPAIR OF THE UNIT ....................................................................................................21

4.2. ORDINARY MAINTENANCE ..............................................................................................................................21

4.3. PERIODIC AND PREVENTIVE MAINTENANCE................................................................................................22

4.4. SERVICING TO BE CARRIED OUT BY QUALIFIED STAFF .............................................................................22

4.5. TECHNICAL PROBLEMS ...................................................................................................................................22

4.6. FAILURE ANALYSIS...........................................................................................................................................24

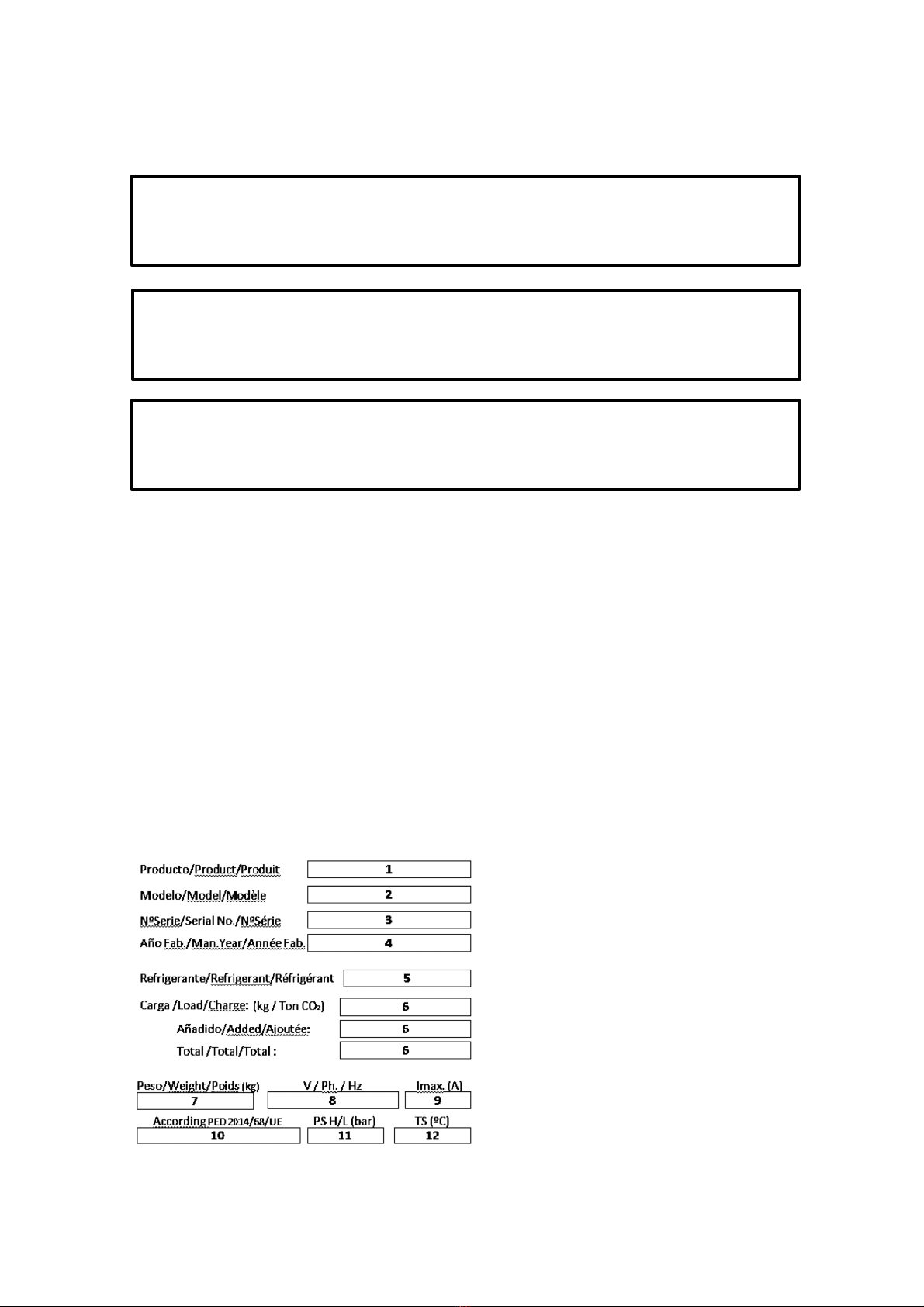

4.7. HOW TO ORDER SPARE PARTS......................................................................................................................25

4.8. SCRAPPING THE UNIT......................................................................................................................................25

3

3

4

4

4

5

5

5

6

7

9

9

9

11

11

11

11

11

11

12

13

13

14

15

15

15

16

18

19

19

20

20

21

21

21

21

21

22

22

22

24

25

25

2