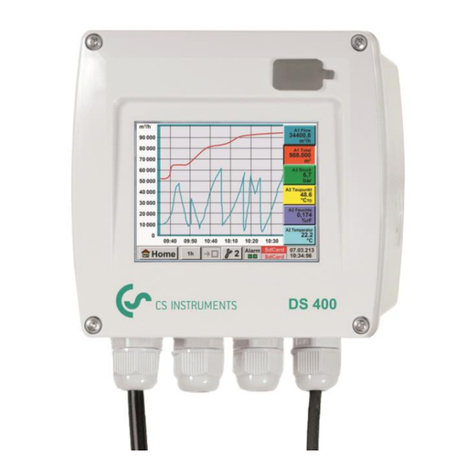

CS Instruments DS 350-P Installation manual

DS 350-P DS 350-P

DS 350-P English, V1.2, 13.09.13 DS 350-P English, V1.2, 13.09.13

0970 0065 0970 0065

24 1

DS 350-P

Operation manual

11A Floor, D3 Building, TCL International E City,

No. 1001 Zhongshanyuan Road,

Nanshan District, Shenzhen 518057, China

Tel: +86 (0)755 - 8619 3164

Fax: +86 (0)755 - 8619 3165

Email: sales@csinstrument.com

Website: http://www.csinstrument.com

CS Instruments (Shenzhen) Co. Ltd.

Room 1506, Hong Qiao Silver City Building,

No.933 Zhongshan Road(w),

Shanghai, China. 200051

Tel: +86 (0) 21-5111 3860

Fax: +86 (0) 21-5111 3861

Email: sales@csinstrument.com

Website: http://www.csinstrument.com

CS Instruments (Shanghai) branch

China

CS Instruments (Asia) Co. Ltd.

Shanghai officeHong Kong

Penang Office

303-2-22, Krystal Point, Jalan Sultan

Azlan Shah, Bayan Lepas,

11900 Penang, Malaysia

Tel: +60-4-643 1522

Fax: +60-4 643 1518

Website: http://www.csinstrument.com

Kuala Lumpur Office

No.1, Jalan TP3, UEP Subang Jaya Indus-

trial Estate, 47620 Subang Jaya, Selangor,

Malaysia

Tel: +603 5122 2082

Fax: +603 5122 5811

Website: http://www.csinstrument.com

CS Instruments (S.E.A.) Sdn. Bhd.

Malaysia

Werkstrasse 2,

D-79426 Buggingen,

Germany

Tel: +49 7631 9387 387

Fax: +49 7631 9387 388

Email: sales@cs-itec.com

Website: http://www.cs-itec.com

CS-iTEC GmbH

Germany

91/66 Suwintawong Road

Minburi, Bangkok 10510

Thailand

Tel: +66 2108 9658

Fax: +66 2108 9658

Website: http://www.csinstrument.com

CS Instruments (Thailand) Co., Ltd.

Thailand

ITC Cempaka Mas Office Tower8th

Floor, Room 8B, Jl. Letjend Suprapto,

Jakarta 10640, Indonesia

Tel: +6221 4452 7753

Fax: +6221 4280 3853

Email: sales@csinstrument.co.id

Website: http://www.csinstrument.com

PT. Solusi CS Instruments Indonesia

Indonesia

Room 31, Tower B, Cambridge Plaza,

188 San Wan Road,

Sheung Shui, N.T. , Hong Kong

Tel: +852 2328 9782

Fax: +852 2542 1310

Email: sales@csinstrument.com

Website: http://www.csinstrument.com

DS 350-P DS 350-P

DS 350-P English, V1.2, 13.09.13 DS 350-P English, V1.2, 13.09.13

0970 0065 0970 0065

2 23

Features

•

Connectable sensors for all required measurement tasks (air flow, air con sump-

tion, power consumption, pressure, temperature and many more)

•

Up to 24 inputs through extension boxes

•

Several loggers can be combined: no need to have long cables from the sensor

to the logger

•

Third party sensors can be easily connected

•

Up to 100 million records in SD card

•

Full software package includes:

- CSM-S for basic analyzes

- CAA for compressed air audit analyzes

•

No

time

consuming data transfer as data is stored on SD card and can be

moved to PC

The operating instructions must be read in full and carefully observed before starting

up the device. The manufacturer cannot be held liable for any damage which occurs

as a result of non-observance or non-compliance with this manual.

Should the device be tampered with in any manner other than a procedure which is

described and specified in the manual, the warranty is cancelled and the manufactur-

er is exempt from liability.

The device is destined exclusively for the described application.

CS Instruments offers no guarantee for the suitability for any other purpose and is not

liable for errors which may have slipped into this operating manual. They are also not

liable for consequential damage resulting from the delivery, capability or use of this

device.

Important information

DS 350-P DS 350-P

DS 350-P English, V1.2, 13.09.13 DS 350-P English, V1.2, 13.09.13

0970 0065 0970 0065

2. Overview

1 3

2 4 5

1

3

2

4

5

SD card slot

Keyboard for user interface operations

USB port

SD card ejector tool

Battery gauge

6

6

On/Off button

3

22

DS 350-P DS 350-P

DS 350-P English, V1.2, 13.09.13 DS 350-P English, V1.2, 13.09.13

0970 0065 0970 0065

Casing

Size: 265 x 220 x 150 mm

Sensor inputs

CS flow/dew point sensors

Modbus sensor modules

Process signal

Pulse

P4 P6 P8

2x 2x 2x

2x 2x 2x

2x 4x

2x

Interface

USB to PC

Keyboard

4 keys

Power supply 100 .… 240 VAC / 50 VA, 47-60 Hz

Display Graphic display, 220 x 140 pixels, with back light

Accuracy

Channel 1+2: see sensor specifications

Channel 7+8: see sensor specifications

Channel 3-6: see technical data process signales

Internal battery Rechargable for up to 8 hours operation.

Charging time ~ 3 hours

Data logger Data is stored in 4G SD card, up to 100 million values

Technical data

Sensor and mains connection at the side

CS flow/dew point sensors 1+2

Modbus sensor modules 7+8

Process signals 3-6

Pt100 3+4

Pulse 5+6

Sensor type Channel

4

Scope of delivery

•

DS 350-P x

•

CD with CSM-S and CAA software

•

USB cable

•

Operation manual

•

Sensors according to the order

•

Accessories according to the order

•

Delivery note

CS provides a warranty for this product of 24 months covering the material and work-

manship under the stated operating conditions from the date of delivery.

Please report any findings immediately and within the warranty time guaranteed by

us.

Excluded from this warranty is damage caused by improper use and non-adherence

to the instruction manual.

The warranty is also cancelled once the measuring instrument has been opened pro-

vided this is not described in the instruction manual for maintenance purposes. This is

also the case if the serial number has been changed, damaged or removed.

If in addition to the warranty service necessary repairs, adjustments or similar are

carried out, the warranty services are free of charge but there is a charge for other

services such as transport and packing costs. Other claims, especially those for dam-

age occurring outside the instrument are not included unless responsibility is legally

binding.

ATTENTION: Batteries have a reduced warranty time of 12 months.

Warranty

21

1 3 5 7 8

2 4 6

DS 350-P DS 350-P

DS 350-P English, V1.2, 13.09.13 DS 350-P English, V1.2, 13.09.13

0970 0065 0970 0065

20 5

Settings

Complete settings can be changed through user interface

at DS 350-P

Sensor connector

Round lockable connectors, 5 pole

Operating temperature

0 ... 50 ºC

Transport temperature

-20 ... 50 ºC

Weight

2400 g

Sensor inputs 0-1V, 0-10V

0-20 mA, 4-20 mA

Pt100/Pt1000

Pulse

Measuring range 0-20 mA: 0… 21 mA

0-1 V: 0...1.05 V

0-10 V: 0...10.5 V

Pt100: -200…+850 ºC

Pt1000: -200…+850 ºC

Pulse: 0...100 Hz, High > 5V, Low < 2 V

I < 5 mA, V < 30V

Accuracy 0-20 mA: 0.01 mA

0-1 V: 1 mV

0-10 V: 0.01 V

Pt100: 0.2 ºC

Pt1000: 0.2 ºC

Pulse 1 digit

Resolution 0-20 mA: 0.001 mA

0-1 V: 0.05 mV

0-10 V: 0.5 mV

Pt100: 0.1 ºC

Pt1000: 0.1 ºC

Pulse: 1 digit

Technical data process signals

0553 0103 Extension cable, 5m, male - female connectors

0553 0110 5 m connection cable with open wires

0554 0035

Probe case for sensors and accessories (internal compartment can be

arranged according to your sensor requirements individually)

0554 0062

Current clamp sensor, 1.8 m cable, 500/1 A, connectable to CS 110-P (1

pieces)

0554 0063

Current clamp sensor, 1.8 m cable, 1000/1 A, connectable to CS 110-P (1

pieces)

Liquid flow meter (clamp on ultra sound)

0554 0070

Ultrasonic controller for liquid flow sensor, connectable to DS 350-P, in-

cluding 5 m connection cable to DS 350-P and to the sensors, stretcher

(0554 0076) and coupling agent (0554 0075)

0554 0071

Ultra sound clamp-on sensor with installation device, DN 25...100

0554 0072

Ultra sound clamp-on sensor pair, DN 50...700

Other sensor / extensions

0554 0080

8 channel analog input extension, connectable to DS 350-P, including 5 m

cable with connector

Accessories

DS 350-P DS 350-P

DS 350-P English, V1.2, 13.09.13 DS 350-P English, V1.2, 13.09.13

0970 0065 0970 0065

Start DS 350-P

DS 350-P is equipped with an internal rechargeable battery. This battery is intended to

supply the system with power during power loss or for short term measurement where

a mains supply is inconvenient. However it‘s recommended to use the mains supply

whenever available to ensure a fully charged battery and to ensure a safe and long

term measurement.

Input impedance 0-20 mA: ~50 Ω

0-1 V: 60 MΩ

0-10 V: 1 MΩ

Pt100: N/A

Pt1000: N/A

Pulse: 1000R

Sensor excitation 24VDC / 20 W (total available power for sensor supply)

Probe connection and power supply

Please connect all sensors before switching on DS 350-P. CS flow / dew point sensors

are detected automatically when connected. The same applies to CS sensor extension

modules (power meter, us flow meter, analogue extension) which are connected to

channel 7 + 8.

Process signals can not be detected automatically. The user has to select the appro-

priate sensor type from the sensor selection menu (Sensors—Select sensor type).

The On/Off switch has following functions when powered off:

1. A short pressing of the button will activate the battery

gauge display and the charging status can be read.

2. Keep the button pressed for 2 seconds and the device

will start up

3. To switch off the device keep the button pressed for 2

seconds.

6

Order information

P/N

Describtion

0560 0550 DS 350-P4, 4 channel data recorder, incl. Software, SD card, power cord,

USB cable

0560 0551

DS 350-P6, 6 channel data recorder, incl. Software, SD card, power cord,

USB cable

0560 0552 DS 350-P8, 8 channel data recorder, incl. Software, SD card, power cord,

USB cable

Flow sensors

0695 0122

VA 400-M, insertion type flow sensor, DN15 ... DN300, 5m cable with con-

nector

0695 0453

VA 450-M, insertion type flow sensor, DN15 ... DN300, wet & dirty appli-

cations

Dew point sensors

0699 0419

FA 410, -80 ... +20 ºCtd, measuring chamber, 5m cable with connector

Pressure sensors

0694 1886

0 ... 1.6 MPa, quick connector, 5 m cable with connector

0694 0356

0 ... 4 MPa, quick connector, 5 m cable with connector

Amp sensors

0554 0504 Clamp on amp sensor, 1000 A, 5 m cable with connector

Temperature sensor

0604 0100

Pt100 probe, class A, 5 m cable with connector

0554 6003 Compression fitting, 6 mm, G ½" thread, 0.6 MPa

0554 6004 Compression fitting, 6 mm, G ½" thread, 1.6 MPa

Power meter

0554 0034 Portable power meter CS 110-P, Modbus/RTU, including 4 test leads, 4

test clips, 5 m cable with connector to DS 350-P

0554 0061 Current clamp sensor, 1.8 m cable, 200/1 A, connectable to CS 110-P (1

pieces)

19

DS 350-P DS 350-P

DS 350-P English, V1.2, 13.09.13 DS 350-P English, V1.2, 13.09.13

0970 0065 0970 0065

18 7

Operation

Description of display icons

One page of measurement value will be shown at a time. User

can use or key to scroll through all

available value.

Page view indication: This “ Page view indication ” shows

the current display measurement value page no., and the total

measurement value page count available .

Indicate there are totally 8 page

measurement value available.

Indicate the measurement value

display page 1 of 8 .

Status icon detail description:

Status icon shows different status of the system.

Low battery icon: it shows when internal battery low.

(Please contact service.)

USB connection icon: icon shows when DS 350-P connected to PC via USB .

When DS 350-P starts up it will display the

start-up screen for a few seconds. During this

time the sensor connections are established

and a few other initialisation tasks are per-

formed.

If there are any sensors connected, DS 350-P

will connect to them automatically and start to

display real time measurement values acquired

from those sensors. The measurement values

may be displayed on more than one page. To

see another page, just press the arrow buttons

on the key board .

CS is offering a 5 m connection cable with open wires

(P/N: 0553 0110) which has 5 cores. These 5 cores

match with the pins of DS 300-P plug one-to-one, ac-

cording to the table below.

Pin

1 2 3 4 5

Color code

Brown White Blue Black Grey

Sensors powered through DS 350-P

DS 350-P can supply 24 VDC to the external sensors and a total power of 20 W. All

sensors connected to DS 350-P and supplied by DS 350-P must not exceed this power

limit. To determine the power consumption please use the table below:

Sensor

P/N

Power [W]

VA 450 / 452 0695 0453 5.0

VA 400 / 420 0695 4XXX 3.0

CS dew point sensor 0699 0419 1.0

CS Pressure sensor 0694 XXXX 0.5

Analog input extension (8 Ch.) 0554 0080 1.3

Power meter CS 110-P 0554 0034 0.5

US flow meter controller CS 460-P 0554 0070 1.5

Connector pinning, view to the plug at DS 350-P

DS 350-P DS 350-P

DS 350-P English, V1.2, 13.09.13 DS 350-P English, V1.2, 13.09.13

0970 0065 0970 0065

5.2 Basic key operation

Basic concept for MENU mode key operation

The number indicates the sensor terminal connection. If it’s inverse this chan-

nel is set to be logged. It will start blinking as soon the logger is activated.

1

The calibration is expired. It‘s recommended to re-calibrate the sensor unit.

Contact CS Service

General error indication. Please note down the error codes and contact CS

Service

8

LOG

100%

Logger module status:

- WAIT: Time start condition set, and wait for start logging

- LOG: Logger module is doing data logging

- STOP: Logging is stopped

- DEL: Logger is deleting protocol data

- ERR: Error occur during data logging.

Logger module free memory in percentage , or CYCLE when logger memory

in circular mode.

SD card is inserted. Please ensure that this symbol is shown before sarting

data logging.

Connecting analogue sensors

All CS sensors will fit to the designated terminal.

In case the user want to connect other analogue sensors such as Pt100, Pt1000 (3-

wire), 0-20 mA, 4-20 mA, 0-1 V and 0-10 V, Pulse types, this can be done through con-

nector 3—6 according to the pinning shown in the table above.

DS 350-P can also supply the external sensor with 24 VDC. Please ensure that the

power drawn is within the allowed limits (see next chapter for more details).

If an analogue sensor is not in the selection list found when assigning the sensor type

in the sensor setting menu, it’s required to use the software CSC-350. The software

can be downloaded from www.csinstrument.com.

Through this software further analogue sensors which are not included in the standard

package can be added into the selection list.

17

DS 350-P DS 350-P

DS 350-P English, V1.2, 13.09.13 DS 350-P English, V1.2, 13.09.13

0970 0065 0970 0065

Typical display layout for option selection:

The radio button for selecting the option

.

- Radio button style for de-selected item

- Radio button style for selected item

Procedure to select and enable new option

1) Use or key to select the desired option being

enable

2) Use the key to enable the new selected

For leaving the exist option:

1) Use the key to go back to last menu level without enable

the selected option.

Typical menu display layout and keys description :

The current select menu item

will be shown in negative color.

If there is a “ < ” sign, it

means we can exit the current

menu or go up one level from

the current menu level.

If there is a “ > ” sign, it

means we can go into the

submenu

Selectable menu item, it shows

5 items at a time. If the total

items in the current menu level

is more then 4 items, the menu

item should scroll over.

It tells how many item exist in the

current menu, and which no. of item

is currently selected

9

- use these keys to

- browse and select different items in menu, and scroll

through different pages of measurement value display

- use these keys to alter or adjust the setting option or number

ing

- use this key to

- exit the current menu level

- leave setting state, without saving the changes

- use this key

- to enter to submenu or next menu level of the current

selected menu item

- use it to confirm the setting change or enable an option in all

setting state

This is a information about the Modbus communication settings. To connect third par-

ty sensors, this parameters need to be set at the sensor.

Communication

System

•

Setup time/date: The internal clock can be set

•

Device info: shows software and hardware version as well as some other de

vice information.

•

LCD contrast: Contrast of display can be changed

•

Reset: does a restart of the whole system

•

Language: The user interface language can be selected here.

16

There is a separate instruction manual for the operation and installation of the ultra-

sonic flow meter CS 460. Please refer to manual number 0970 0069.

CS 460 Ultrasound liquid flow meter

The analogue extension module offers additional 8 X 0-20 mA channels. Similar to the

analogue input channels on connector 3-6, the sensor type can be assigned through

the user interface in the menu “Sensors” .

These settings are stored permanently inside DS 350-P and need only to be changed

if there is a change in these parameters.

The connection pinning is the same as of the 0-20 mA Signal of connector 3-6.

Analogue extension module

DS 350-P DS 350-P

DS 350-P English, V1.2, 13.09.13 DS 350-P English, V1.2, 13.09.13

0970 0065 0970 0065

10 15

Operation in detail

By pressing the <Enter> key the menu can be accessed. DS 350-P has following main

menus:

Logger

Files

Sensors

Communication

System

Typical display layout for altering or adjusting the number setting :

Example: Time and data setting

1) Use and key adjust the time

2) Use key to move from HOUR -> MINUTE -> SEC

OND setup

3) After the SECOND setting and press the key to finalize

the setup, or press to exit from the “Time and date set

ting” menu and without saving the new setting

CS 110-P requires a few selections in order to measure. In the sensor menu please

select CS 110-P and make following settings.

Sensor type: choose the the right CT type (200A, 500 A, 1000 A)

Sensor status: This menu will provide sensor information about the connection.

Please check here for details in case the displayed values are

shown as “—-.-”. Most likely it’s caused by a wrong connection of

the CTs or Voltages.

These settings are stored permanently inside DS 350-P and need only to be changed

if there is a change in these parameters.

CS power meter CS 110-P

DS 350-P can support up to two Modbus sensors connected to connector 7 and 8.

For the communication there is a fixed parameter setting which can be viewed in the

communication menu. Any third party sensor connected to these inputs need to have

it’s communication parameters set like that.

CS provides following Modbus sensors:

- Power meter CS 110-P

- Liquid flow (US clamp meter) CS 460-P

- 8 channel analogue extension module

CS Modbus sensors are detected automatically (plug & play).

For third party sensors its required to use the configuration software CSC-350 to cre-

ate the sensor and download it into DS 350-P. After the download this sensor is then

available for selection from the menu.

Modbus sensors

•

One point calibration: The instrument provides a one-point system calibration,

which can eliminate accuracy failures of instrument and sensor. If an accurate

reference is available (i.e. Calibration Lab), the system can be calibrated at one

point to this reference. The calibration is stored inside the DS 350-P. However this

calibration offset is applied to every sensor connected to this particular terminal. If

the sensor type is changed, DS 350-P will delete the stored calibration offset.

•

Remove one-point calibration: is used to delete the calibration offset.

DS 350-P DS 350-P

DS 350-P English, V1.2, 13.09.13 DS 350-P English, V1.2, 13.09.13

0970 0065 0970 0065

14 11

Logger

DS 350-P includes a data logger that can record up to 100,000,000 measurement

values. In order to configure the logger function and to activate/deactivate it, there

are several functions available which are explained below:

Key start/stop log-

ging Starts or stops the data recording. Whenever a new recording

is started a new file is created in the memory.

Select logging

channel Those channels which should be recorded with the data logger

must be selected first. For example, if Flow is selected to be

recorded the flow value of all connected flow sensors will be

recorded. Attention: sensors connectable on connector 3...6

are shown as they have been selected in the sensor setting

menu.

Set logger memory

mode It can be selected to stop logging when memory is full, or the

“wrap around mode” can be chosen, which then will overwrite

the oldest values as soon the memory is full.

Set logging rate and

averaging The logging rate defines the interval data should be recorded in

the memory. It will record from every activated channel a sam-

ple. The averaging option can be used to calculate an average

value. I.e. DS 350-P is measuring every 1 second and if the

logging rate is 10 seconds, it will calculate an average value

out of the last 10 measurement values and store it as a record-

ed sample.

Logger status Shows the start time and the number of samples recorded up

to now. Can only be entered if a logging has been started.

Set time start

condition DS 300-P can be programmed to start at a certain time. Pro-

grammed time must be 10 seconds later than the system time.

DS 350-P has up to 4 analogue input channels at connector 3 to 6. These channels

don’t have an automatic sensor detection, the sensors need to be manually selected.

Following settings are available:

•

Select sensor type: Ds 350-P stores up to 15 different analogue sensors which

can be selected from the list

•

Show sensor setting: the details of the sensor settings such as: sensor type,

unit, resolution, input scaling and calibration offset can be viewed.

Analogue sensor settings

To ensure a reliable logger operation please ensure following:

- Don't remove the SD card during logging

- Format a NEW SD card before using it

- SD cards with more than 4 GB size should be partitioned to reduce the size to 4 GB.

For CS dew point sensors following settings are available:

•

Set moisture unit: (ºCtd, g/m3, g/kg, ppm etc.). Attention: g/m

3

, mg/m

3

, ppm[V]

and atmospheric dew point require to enter a reference pressure.

•

Set reference pressure: required for g/m

3

, mg/m

3

, ppm[V] and atmospheric

dew point calculation. The pressure has to be entered as absolute pressure (not

gauge pressure!)

For the unit atmospheric dew point and ppm[V], the line pressure (absolute)

has to be entered.

For the unit g/m

3

, mg/m

3

, if the calculate should be done under line pressure

conditions, a reference pressure of 1013 hPa has to be entered.

If the calculation should be done for atmospheric conditions, the line pres

sure (absolute) has to be entered.

Dew point sensor settings

In case the destination port is 5 or 6 an additional channel for the counter is added to

the channel list.

Through these steps up to 6 CS flow sensor can be configured and operated at one

DS 350-P8.

DS 350-P DS 350-P

DS 350-P English, V1.2, 13.09.13 DS 350-P English, V1.2, 13.09.13

0970 0065 0970 0065

12 13

Sensors

The following chapter describes the settings related to the sensor itself, which can be

changed on the DS 350-P menu. For that purpose select in the menu the function

“Sensors”.

The next screen will show all detected flow/dew point sensors of connector 1 and 2.

Sensors of connector 7+8 are also auto-detected as long it’s a CS sensor (power

meter, US flow meter, analogue extension), but other Modbus sensors are shown as

selected from the menu. Connector 3 to 6 show also the selected analogue sensors.

The next chapters describe the available settings of the different sensors.

For CS flows sensors following settings can be made:

•

Set tube diameter: for flow calculation

•

Set total consumption: counter can be set to any value

•

Set flow unit: Selection of the desired flow unit

•

Set consumption unit: selection of the desired consumption unit

•

Set reference pressure: in order to calculate the standard flow

•

Set reference temperature: in order to calculate the standard flow

•

Set gas type: Select the gas which is measured with the flow sensor.

Note:

Reference pressure and reference temperature are not related to the actual process

pressure or temperature. They are used to calculate the standard flow at standard

conditions, for example: 1000 hPa, 20 ºC.

Changes on the sensor settings are downloaded immediately into the sensor as soon

the changes are confirmed by pressing <Enter>.

The gas type can not be changed if the connected sensor was calibrated in “real gas”

Flow sensor settings

Files

DS 350-P stores the recorded measurement values on a SD card which is accessible

at the front side. In this menu the available functions are as follows:

Recorded files Lists all recorded files on the SD card. After selecting a particu-

lar file, the file information such as start time, location name

and samples recorded can be shown.

It also allows the deletion of recorded files.

SD card status Displays the available memory and total memory size

Format SD card Is used to format the SD card. ATTENTION: formatting will

delete the contents on the card completely and it can not be

recovered!

CS Flow sensors connected to port 3-6

Flow sensors connectable to the ports 3 … 6 must be configured first by connecting

them to either port 1 or 2. Only these 2 ports a capable to write sensor settings into

the sensor. Port 3 and 4 can measure flow only and ports 5 and 6 can measure flow

and consumption. To do the settings follow these steps:

•

Connect the sensor to port 1 or 2 and perform the settings in the menu as it

would remain connected to this port (diameter, units, etc.)

•

When finished, select in the menu “copy settings” together with the desired

port or terminal (3...6)

•

Switch off DS 350-P and move the flow sensor connection to the selected

port.

•

Done! You will see a “CS flow sensor “ then in the sensor channel list at the

selected port with the correct unit and scaling.

DS 350-P DS 350-P

DS 350-P English, V1.2, 13.09.13 DS 350-P English, V1.2, 13.09.13

0970 0065 0970 0065

12 13

Sensors

The following chapter describes the settings related to the sensor itself, which can be

changed on the DS 350-P menu. For that purpose select in the menu the function

“Sensors”.

The next screen will show all detected flow/dew point sensors of connector 1 and 2.

Sensors of connector 7+8 are also auto-detected as long it’s a CS sensor (power

meter, US flow meter, analogue extension), but other Modbus sensors are shown as

selected from the menu. Connector 3 to 6 show also the selected analogue sensors.

The next chapters describe the available settings of the different sensors.

For CS flows sensors following settings can be made:

•

Set tube diameter: for flow calculation

•

Set total consumption: counter can be set to any value

•

Set flow unit: Selection of the desired flow unit

•

Set consumption unit: selection of the desired consumption unit

•

Set reference pressure: in order to calculate the standard flow

•

Set reference temperature: in order to calculate the standard flow

•

Set gas type: Select the gas which is measured with the flow sensor.

Note:

Reference pressure and reference temperature are not related to the actual process

pressure or temperature. They are used to calculate the standard flow at standard

conditions, for example: 1000 hPa, 20 ºC.

Changes on the sensor settings are downloaded immediately into the sensor as soon

the changes are confirmed by pressing <Enter>.

The gas type can not be changed if the connected sensor was calibrated in “real gas”

Flow sensor settings

Files

DS 350-P stores the recorded measurement values on a SD card which is accessible

at the front side. In this menu the available functions are as follows:

Recorded files Lists all recorded files on the SD card. After selecting a particu-

lar file, the file information such as start time, location name

and samples recorded can be shown.

It also allows the deletion of recorded files.

SD card status Displays the available memory and total memory size

Format SD card Is used to format the SD card. ATTENTION: formatting will

delete the contents on the card completely and it can not be

recovered!

CS Flow sensors connected to port 3-6

Flow sensors connectable to the ports 3 … 6 must be configured first by connecting

them to either port 1 or 2. Only these 2 ports a capable to write sensor settings into

the sensor. Port 3 and 4 can measure flow only and ports 5 and 6 can measure flow

and consumption. To do the settings follow these steps:

•

Connect the sensor to port 1 or 2 and perform the settings in the menu as it

would remain connected to this port (diameter, units, etc.)

•

When finished, select in the menu “copy settings” together with the desired

port or terminal (3...6)

•

Switch off DS 350-P and move the flow sensor connection to the selected

port.

•

Done! You will see a “CS flow sensor “ then in the sensor channel list at the

selected port with the correct unit and scaling.

DS 350-P DS 350-P

DS 350-P English, V1.2, 13.09.13 DS 350-P English, V1.2, 13.09.13

0970 0065 0970 0065

14 11

Logger

DS 350-P includes a data logger that can record up to 100,000,000 measurement

values. In order to configure the logger function and to activate/deactivate it, there

are several functions available which are explained below:

Key start/stop log-

ging Starts or stops the data recording. Whenever a new recording

is started a new file is created in the memory.

Select logging

channel Those channels which should be recorded with the data logger

must be selected first. For example, if Flow is selected to be

recorded the flow value of all connected flow sensors will be

recorded. Attention: sensors connectable on connector 3...6

are shown as they have been selected in the sensor setting

menu.

Set logger memory

mode It can be selected to stop logging when memory is full, or the

“wrap around mode” can be chosen, which then will overwrite

the oldest values as soon the memory is full.

Set logging rate and

averaging The logging rate defines the interval data should be recorded in

the memory. It will record from every activated channel a sam-

ple. The averaging option can be used to calculate an average

value. I.e. DS 350-P is measuring every 1 second and if the

logging rate is 10 seconds, it will calculate an average value

out of the last 10 measurement values and store it as a record-

ed sample.

Logger status Shows the start time and the number of samples recorded up

to now. Can only be entered if a logging has been started.

Set time start

condition DS 300-P can be programmed to start at a certain time. Pro-

grammed time must be 10 seconds later than the system time.

DS 350-P has up to 4 analogue input channels at connector 3 to 6. These channels

don’t have an automatic sensor detection, the sensors need to be manually selected.

Following settings are available:

•

Select sensor type: Ds 350-P stores up to 15 different analogue sensors which

can be selected from the list

•

Show sensor setting: the details of the sensor settings such as: sensor type,

unit, resolution, input scaling and calibration offset can be viewed.

Analogue sensor settings

To ensure a reliable logger operation please ensure following:

- Don't remove the SD card during logging

- Format a NEW SD card before using it

- SD cards with more than 4 GB size should be partitioned to reduce the size to 4 GB.

For CS dew point sensors following settings are available:

•

Set moisture unit: (ºCtd, g/m3, g/kg, ppm etc.). Attention: g/m

3

, mg/m

3

, ppm[V]

and atmospheric dew point require to enter a reference pressure.

•

Set reference pressure: required for g/m

3

, mg/m

3

, ppm[V] and atmospheric

dew point calculation. The pressure has to be entered as absolute pressure (not

gauge pressure!)

For the unit atmospheric dew point and ppm[V], the line pressure (absolute)

has to be entered.

For the unit g/m

3

, mg/m

3

, if the calculate should be done under line pressure

conditions, a reference pressure of 1013 hPa has to be entered.

If the calculation should be done for atmospheric conditions, the line pres

sure (absolute) has to be entered.

Dew point sensor settings

In case the destination port is 5 or 6 an additional channel for the counter is added to

the channel list.

Through these steps up to 6 CS flow sensor can be configured and operated at one

DS 350-P8.

DS 350-P DS 350-P

DS 350-P English, V1.2, 13.09.13 DS 350-P English, V1.2, 13.09.13

0970 0065 0970 0065

10 15

Operation in detail

By pressing the <Enter> key the menu can be accessed. DS 350-P has following main

menus:

Logger

Files

Sensors

Communication

System

Typical display layout for altering or adjusting the number setting :

Example: Time and data setting

1) Use and key adjust the time

2) Use key to move from HOUR -> MINUTE -> SEC

OND setup

3) After the SECOND setting and press the key to finalize

the setup, or press to exit from the “Time and date set

ting” menu and without saving the new setting

CS 110-P requires a few selections in order to measure. In the sensor menu please

select CS 110-P and make following settings.

Sensor type: choose the the right CT type (200A, 500 A, 1000 A)

Sensor status: This menu will provide sensor information about the connection.

Please check here for details in case the displayed values are

shown as “—-.-”. Most likely it’s caused by a wrong connection of

the CTs or Voltages.

These settings are stored permanently inside DS 350-P and need only to be changed

if there is a change in these parameters.

CS power meter CS 110-P

DS 350-P can support up to two Modbus sensors connected to connector 7 and 8.

For the communication there is a fixed parameter setting which can be viewed in the

communication menu. Any third party sensor connected to these inputs need to have

it’s communication parameters set like that.

CS provides following Modbus sensors:

- Power meter CS 110-P

- Liquid flow (US clamp meter) CS 460-P

- 8 channel analogue extension module

CS Modbus sensors are detected automatically (plug & play).

For third party sensors its required to use the configuration software CSC-350 to cre-

ate the sensor and download it into DS 350-P. After the download this sensor is then

available for selection from the menu.

Modbus sensors

•

One point calibration: The instrument provides a one-point system calibration,

which can eliminate accuracy failures of instrument and sensor. If an accurate

reference is available (i.e. Calibration Lab), the system can be calibrated at one

point to this reference. The calibration is stored inside the DS 350-P. However this

calibration offset is applied to every sensor connected to this particular terminal. If

the sensor type is changed, DS 350-P will delete the stored calibration offset.

•

Remove one-point calibration: is used to delete the calibration offset.

DS 350-P DS 350-P

DS 350-P English, V1.2, 13.09.13 DS 350-P English, V1.2, 13.09.13

0970 0065 0970 0065

Typical display layout for option selection:

The radio button for selecting the option

.

- Radio button style for de-selected item

- Radio button style for selected item

Procedure to select and enable new option

1) Use or key to select the desired option being

enable

2) Use the key to enable the new selected

For leaving the exist option:

1) Use the key to go back to last menu level without enable

the selected option.

Typical menu display layout and keys description :

The current select menu item

will be shown in negative color.

If there is a “ < ” sign, it

means we can exit the current

menu or go up one level from

the current menu level.

If there is a “ > ” sign, it

means we can go into the

submenu

Selectable menu item, it shows

5 items at a time. If the total

items in the current menu level

is more then 4 items, the menu

item should scroll over.

It tells how many item exist in the

current menu, and which no. of item

is currently selected

9

- use these keys to

- browse and select different items in menu, and scroll

through different pages of measurement value display

- use these keys to alter or adjust the setting option or number

ing

- use this key to

- exit the current menu level

- leave setting state, without saving the changes

- use this key

- to enter to submenu or next menu level of the current

selected menu item

- use it to confirm the setting change or enable an option in all

setting state

This is a information about the Modbus communication settings. To connect third par-

ty sensors, this parameters need to be set at the sensor.

Communication

System

•

Setup time/date: The internal clock can be set

•

Device info: shows software and hardware version as well as some other de

vice information.

•

LCD contrast: Contrast of display can be changed

•

Reset: does a restart of the whole system

•

Language: The user interface language can be selected here.

16

There is a separate instruction manual for the operation and installation of the ultra-

sonic flow meter CS 460. Please refer to manual number 0970 0069.

CS 460 Ultrasound liquid flow meter

The analogue extension module offers additional 8 X 0-20 mA channels. Similar to the

analogue input channels on connector 3-6, the sensor type can be assigned through

the user interface in the menu “Sensors” .

These settings are stored permanently inside DS 350-P and need only to be changed

if there is a change in these parameters.

The connection pinning is the same as of the 0-20 mA Signal of connector 3-6.

Analogue extension module

DS 350-P DS 350-P

DS 350-P English, V1.2, 13.09.13 DS 350-P English, V1.2, 13.09.13

0970 0065 0970 0065

5.2 Basic key operation

Basic concept for MENU mode key operation

The number indicates the sensor terminal connection. If it’s inverse this chan-

nel is set to be logged. It will start blinking as soon the logger is activated.

1

The calibration is expired. It‘s recommended to re-calibrate the sensor unit.

Contact CS Service

General error indication. Please note down the error codes and contact CS

Service

8

LOG

100%

Logger module status:

- WAIT: Time start condition set, and wait for start logging

- LOG: Logger module is doing data logging

- STOP: Logging is stopped

- DEL: Logger is deleting protocol data

- ERR: Error occur during data logging.

Logger module free memory in percentage , or CYCLE when logger memory

in circular mode.

SD card is inserted. Please ensure that this symbol is shown before sarting

data logging.

Connecting analogue sensors

All CS sensors will fit to the designated terminal.

In case the user want to connect other analogue sensors such as Pt100, Pt1000 (3-

wire), 0-20 mA, 4-20 mA, 0-1 V and 0-10 V, Pulse types, this can be done through con-

nector 3—6 according to the pinning shown in the table above.

DS 350-P can also supply the external sensor with 24 VDC. Please ensure that the

power drawn is within the allowed limits (see next chapter for more details).

If an analogue sensor is not in the selection list found when assigning the sensor type

in the sensor setting menu, it’s required to use the software CSC-350. The software

can be downloaded from www.csinstrument.com.

Through this software further analogue sensors which are not included in the standard

package can be added into the selection list.

17

DS 350-P DS 350-P

DS 350-P English, V1.2, 13.09.13 DS 350-P English, V1.2, 13.09.13

0970 0065 0970 0065

18 7

Operation

Description of display icons

One page of measurement value will be shown at a time. User

can use or key to scroll through all

available value.

Page view indication: This “ Page view indication ” shows

the current display measurement value page no., and the total

measurement value page count available .

Indicate there are totally 8 page

measurement value available.

Indicate the measurement value

display page 1 of 8 .

Status icon detail description:

Status icon shows different status of the system.

Low battery icon: it shows when internal battery low.

(Please contact service.)

USB connection icon: icon shows when DS 350-P connected to PC via USB .

When DS 350-P starts up it will display the

start-up screen for a few seconds. During this

time the sensor connections are established

and a few other initialisation tasks are per-

formed.

If there are any sensors connected, DS 350-P

will connect to them automatically and start to

display real time measurement values acquired

from those sensors. The measurement values

may be displayed on more than one page. To

see another page, just press the arrow buttons

on the key board .

CS is offering a 5 m connection cable with open wires

(P/N: 0553 0110) which has 5 cores. These 5 cores

match with the pins of DS 300-P plug one-to-one, ac-

cording to the table below.

Pin

1 2 3 4 5

Color code

Brown White Blue Black Grey

Sensors powered through DS 350-P

DS 350-P can supply 24 VDC to the external sensors and a total power of 20 W. All

sensors connected to DS 350-P and supplied by DS 350-P must not exceed this power

limit. To determine the power consumption please use the table below:

Sensor

P/N

Power [W]

VA 450 / 452 0695 0453 5.0

VA 400 / 420 0695 4XXX 3.0

CS dew point sensor 0699 0419 1.0

CS Pressure sensor 0694 XXXX 0.5

Analog input extension (8 Ch.) 0554 0080 1.3

Power meter CS 110-P 0554 0034 0.5

US flow meter controller CS 460-P 0554 0070 1.5

Connector pinning, view to the plug at DS 350-P

DS 350-P DS 350-P

DS 350-P English, V1.2, 13.09.13 DS 350-P English, V1.2, 13.09.13

0970 0065 0970 0065

Start DS 350-P

DS 350-P is equipped with an internal rechargeable battery. This battery is intended to

supply the system with power during power loss or for short term measurement where

a mains supply is inconvenient. However it‘s recommended to use the mains supply

whenever available to ensure a fully charged battery and to ensure a safe and long

term measurement.

Input impedance 0-20 mA: ~50 Ω

0-1 V: 60 MΩ

0-10 V: 1 MΩ

Pt100: N/A

Pt1000: N/A

Pulse: 1000R

Sensor excitation 24VDC / 20 W (total available power for sensor supply)

Probe connection and power supply

Please connect all sensors before switching on DS 350-P. CS flow / dew point sensors

are detected automatically when connected. The same applies to CS sensor extension

modules (power meter, us flow meter, analogue extension) which are connected to

channel 7 + 8.

Process signals can not be detected automatically. The user has to select the appro-

priate sensor type from the sensor selection menu (Sensors—Select sensor type).

The On/Off switch has following functions when powered off:

1. A short pressing of the button will activate the battery

gauge display and the charging status can be read.

2. Keep the button pressed for 2 seconds and the device

will start up

3. To switch off the device keep the button pressed for 2

seconds.

6

Order information

P/N

Describtion

0560 0550 DS 350-P4, 4 channel data recorder, incl. Software, SD card, power cord,

USB cable

0560 0551

DS 350-P6, 6 channel data recorder, incl. Software, SD card, power cord,

USB cable

0560 0552 DS 350-P8, 8 channel data recorder, incl. Software, SD card, power cord,

USB cable

Flow sensors

0695 0122

VA 400-M, insertion type flow sensor, DN15 ... DN300, 5m cable with con-

nector

0695 0453

VA 450-M, insertion type flow sensor, DN15 ... DN300, wet & dirty appli-

cations

Dew point sensors

0699 0419

FA 410, -80 ... +20 ºCtd, measuring chamber, 5m cable with connector

Pressure sensors

0694 1886

0 ... 1.6 MPa, quick connector, 5 m cable with connector

0694 0356

0 ... 4 MPa, quick connector, 5 m cable with connector

Amp sensors

0554 0504 Clamp on amp sensor, 1000 A, 5 m cable with connector

Temperature sensor

0604 0100

Pt100 probe, class A, 5 m cable with connector

0554 6003 Compression fitting, 6 mm, G ½" thread, 0.6 MPa

0554 6004 Compression fitting, 6 mm, G ½" thread, 1.6 MPa

Power meter

0554 0034 Portable power meter CS 110-P, Modbus/RTU, including 4 test leads, 4

test clips, 5 m cable with connector to DS 350-P

0554 0061 Current clamp sensor, 1.8 m cable, 200/1 A, connectable to CS 110-P (1

pieces)

19

DS 350-P DS 350-P

DS 350-P English, V1.2, 13.09.13 DS 350-P English, V1.2, 13.09.13

0970 0065 0970 0065

20 5

Settings

Complete settings can be changed through user interface

at DS 350-P

Sensor connector

Round lockable connectors, 5 pole

Operating temperature

0 ... 50 ºC

Transport temperature

-20 ... 50 ºC

Weight

2400 g

Sensor inputs 0-1V, 0-10V

0-20 mA, 4-20 mA

Pt100/Pt1000

Pulse

Measuring range 0-20 mA: 0… 21 mA

0-1 V: 0...1.05 V

0-10 V: 0...10.5 V

Pt100: -200…+850 ºC

Pt1000: -200…+850 ºC

Pulse: 0...100 Hz, High > 5V, Low < 2 V

I < 5 mA, V < 30V

Accuracy 0-20 mA: 0.01 mA

0-1 V: 1 mV

0-10 V: 0.01 V

Pt100: 0.2 ºC

Pt1000: 0.2 ºC

Pulse 1 digit

Resolution 0-20 mA: 0.001 mA

0-1 V: 0.05 mV

0-10 V: 0.5 mV

Pt100: 0.1 ºC

Pt1000: 0.1 ºC

Pulse: 1 digit

Technical data process signals

0553 0103 Extension cable, 5m, male - female connectors

0553 0110 5 m connection cable with open wires

0554 0035

Probe case for sensors and accessories (internal compartment can be

arranged according to your sensor requirements individually)

0554 0062

Current clamp sensor, 1.8 m cable, 500/1 A, connectable to CS 110-P (1

pieces)

0554 0063

Current clamp sensor, 1.8 m cable, 1000/1 A, connectable to CS 110-P (1

pieces)

Liquid flow meter (clamp on ultra sound)

0554 0070

Ultrasonic controller for liquid flow sensor, connectable to DS 350-P, in-

cluding 5 m connection cable to DS 350-P and to the sensors, stretcher

(0554 0076) and coupling agent (0554 0075)

0554 0071

Ultra sound clamp-on sensor with installation device, DN 25...100

0554 0072

Ultra sound clamp-on sensor pair, DN 50...700

Other sensor / extensions

0554 0080

8 channel analog input extension, connectable to DS 350-P, including 5 m

cable with connector

Accessories

Table of contents

Other CS Instruments Measuring Instrument manuals

CS Instruments

CS Instruments VA 550 Ex User manual

CS Instruments

CS Instruments DS 300-P User manual

CS Instruments

CS Instruments VA 520 User manual

CS Instruments

CS Instruments DP 500 Instruction manual

CS Instruments

CS Instruments FA 400 User manual

CS Instruments

CS Instruments DS400 User manual

CS Instruments

CS Instruments 0554 0504 User manual

CS Instruments

CS Instruments LD 500 User manual

CS Instruments

CS Instruments FA 300-2 Ex User manual

CS Instruments

CS Instruments VA 452 Operator's manual