CS Instruments PC 400 Specification sheet

EN - English

PC 400 EN V1.5_EN Page 1of 16

Operation and installation manual

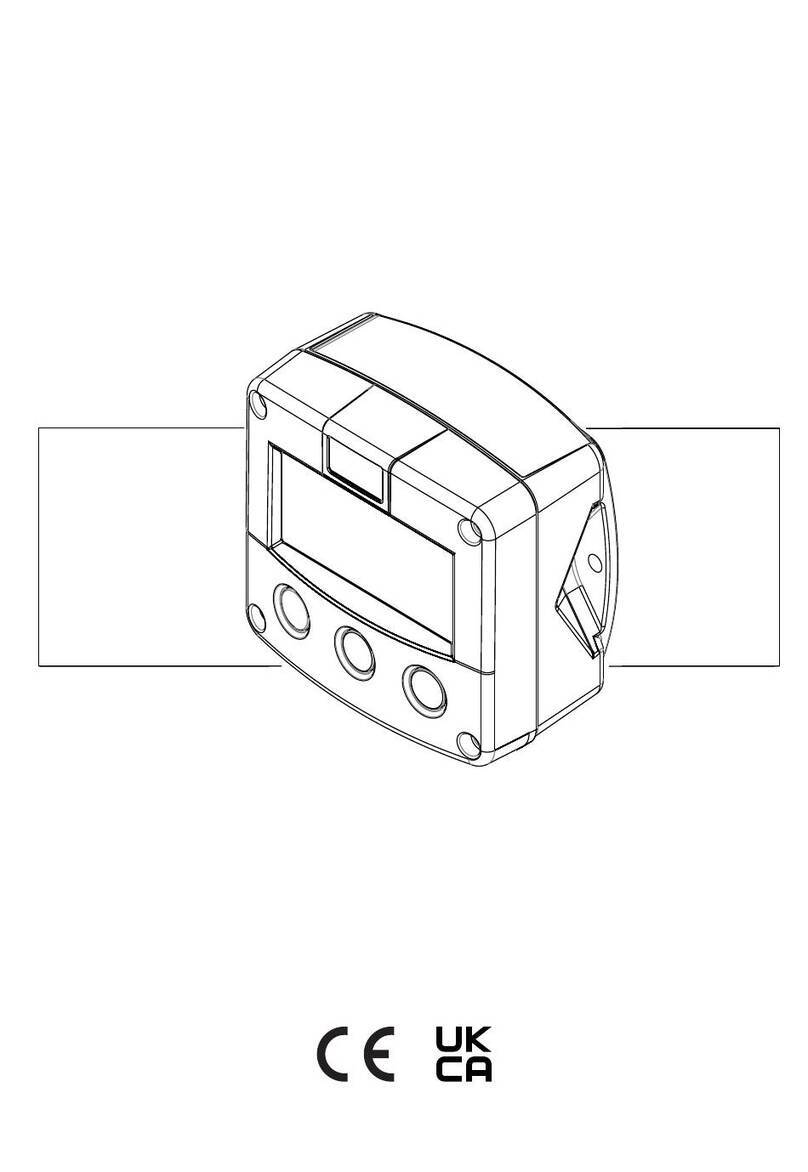

PC 400

Particle counter for compressed air and gases

Preamble

PC 400 EN V1.5_EN Page 2of 16

1 Preamble

Dear customer,

Thank you for deciding in favor of PC 400. Please read these operating and installation

instructions carefully before mounting and starting up the device and follow our

directions. Perfect functioning and thus safe operation of PC 400 can only be

guaranteed when the provisions and notes stipulated here are strictly adhered to.

Sales Office South Germany

Zindelsteiner Str. 15

D-78052 VS-Tannheim

Phone: +49 (0) 7705 978 99 0

Fax: +49 (0) 7705 978 99 20

Web: http://www.cs-instruments.com

Sales Office North Germany

Gewerbehof 14

D-24955 Harrislee

Phone: +49 (0) 461 807 150 -0

Fax: +49 (0) 461 807 150.15

Web: http://www.cs-instruments.com

Contents

PC 400 EN V1.5_EN Page 3of 16

2 Contents

1Preamble ....................................................................................................................... 2

2Contents........................................................................................................................ 3

3Safety advice................................................................................................................. 4

4General product information........................................................................................ 6

5Intended use.................................................................................................................. 6

5.1 Important notes...................................................................................................................... 6

6Service........................................................................................................................... 6

7Principles of functioning.............................................................................................. 7

8Technical data............................................................................................................... 7

9Identification ................................................................................................................. 7

9.1 Name plate.............................................................................................................................. 7

10 Scope of delivery....................................................................................................... 8

11 Initiation ..................................................................................................................... 8

11.1 Voltage supply........................................................................................................................ 8

11.2 Connection to the compressed air system (gas supply system) ..................................... 8

11.2.1 Zero test............................................................................................................................. 8

11.3 Measurement procedure ....................................................................................................... 9

11.4 Status display......................................................................................................................... 9

12 Connection of the RS 485 interface.........................................................................10

12.1 Connection of the RS 485 interface to a DS 500............................................................... 10

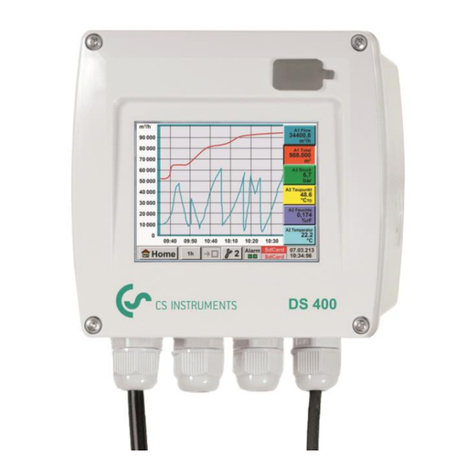

12.2 Connection of the RS 485 interface to a DS 400............................................................... 10

12.3 Modbus Interface Standard-Settings (Factory settings).................................................. 11

12.4 Registertable Device version 0,1µm ................................................................................ 11

12.5 Registertable Device version 0,3µm .................................................................................. 12

13 Analogue Output 4...20mA (Optional) .....................................................................13

14 Operation of the particle counter with the chart recorder DS 500.........................14

15 Operation of the particle counter with the multifunction measuring instrument

DS 400.................................................................................................................................15

16 Operation of the particle counter PC 400 with a DS 500 mobile in the mobile unit

for measurement of compressed air quality according to ISO 8573 –residual oil –

particles –moisture ...........................................................................................................16

Safety advice

PC 400 EN V1.5_EN Page 4of 16

3 Safety advice

Please check whether or not these instructions correspond to the device type.

Please adhere to all advice given in these operating instructions. They include basic information

which needs to be observed during installation, operation and maintenance. Therefore, it is vital

for the technician and the responsible operator/skilled personnel to read these operating

instructions prior to installation, start-up and maintenance.

The operating instructions must be accessible at all times at the place of application of PC 400.

In addition to these operating instructions, local and national regulations need to be observed

where required.

If you have any queries regarding these instructions, please contact CS Instruments GmbH.

Danger!

Supply voltage!

Contact with non-insulated parts carrying supply voltage involves the risk of an electric

shock resulting in injuries and death.

Measures:

•Observe all regulations in effect during electrical installation (e. g. VDE 0100)!

•Carry out maintenance works only when the device is de-energized!

•Any electrical works must only be carried out by authorized and skilled personnel.

Danger!

Inadmissible operating parameters!

Under-running or exceeding the limit values involves risks for persons and the material

and malfunction and service failures may occur.

Measures:

•Make sure that PC 400 is operated only within the permissible limit values indicated on the type

plate.

•Exact compliance with the performance data of PC 400 in connection with the case of application.

•Do not exceed the permissible storage and transport temperature.

Further important safety advice

•During installation and operation, the national regulations and safety instructions in force also need

to be observed.

•PC 400 must not be employed in hazardous areas.

Additional advice:

•Do not overheat the device!

Caution!

Malfunction in PC 400

Through incorrect installation and poor maintenance, a malfunction may occur in

PC 400, which may affect the measuring results and lead to misinterpretations.

The device may only be opened by authorised, trained service personnel!

Safety advice

PC 400 EN V1.4_US Page 5of 16

The device does not contain any components that can be serviced by the user. All repair and

maintenance work must be undertaken by an appropriately qualified service technician, authorised by

the manufacturer. All information in this user manual relating to such work is intended for qualified

technicians, authorised by the manufacturer.

!!! Laser radiation !!!

Corresponds to IEC 60825-1: 2014

•This air particle counter is a laser class I device

•The user is not exposed to laser radiation during normal operation

•Precautionary measures should nevertheless still be taken to avoid contact with hazardous

radiation in the form of intense, concentrated, visible light

•Such exposure may result in blindness

•UNDER NO CIRCUMSTANCES may you remove parts of the particle counter unless you are

expressly asked to do so in these operating instructions.

Caution! Laser radiation

The following precautionary measures must be observed:

•UNDER NO CIRCUMSTANCES may you remove parts of the particle counter unless you are

expressly asked to do so in these operating instructions

•UNDER NO CIRCUMSTANCES may you remove the housing. There are no components

inside the device that can be serviced by the user!

CAUTION –CLASS 3B LASER RADIATION,

WHEN OPENED, DO NOT COME INTO CONTACT WITH LIGHT BEAM

W A R N I N G !

Deviations from the settings specified in these operating instructions or

Procedures can lead to harmful optical radiation exposure.

Intended use

PC 400 EN V1.5_EN Page 6of 16

4 General product information

The device is a particle counter using an embedded laser, which is operated via internal electronics.

The laser radiation outside the device is below the radiation limits of a class 1 laser. The device itself

is powered by a power supply with external safety extra-low voltage (SELV). It consists of a metal

housing. The particle counter forms part of a measuring system for various applications.

5 Intended use

The particle counter PC 400 is used for determination of the particle concentration in gaseous carrier

media. It is equipped with a laser diode as a light source. The particle detection is effected sidewise

via a 90° optics. The transfer of the measured data is effected via the integrated RS 485 interface

(Modbus protocol).

It is designed and constructed exclusively for the intended use described here and may only be used

accordingly.

A check whether the device is suitable for the selected application must be carried out by the user.

The technical data listed in the data sheet are binding.

Improper handling or operation outside the technical specifications is not permitted. Claims of any kind

due to improper use are excluded.

5.1 Important notes

Our particle counters are highly sensitive optoelectronic devices which require a special and careful

handling. Therefore, please read through the following annotations and advices carefully. This will help

you to save unnecessary problems and costs.

Measuring media:

Suitable measuring media are: Air and all other non-explosive, non-corrosive, non-aggressive gases

whose temperature should not exceed 40 °C, as far as the maximum particle concentration (please

see technical data) is not exceeded (in case of doubt please use a dilution factor!!!).

Sensor system:

In case of a nonuse of the device the suction nozzle should be closed by means of a zero filter (HEPA

CAP) or a closing cap in order to avoid a soiling of the sensor system. This especially applies to the

transport and the storage of the instrument.

Please observe the following when putting the device into operation again:

The pump should only be switched on when the closing cap has been removed since this may lead to

damages at the pump. Furthermore, the instrument should not be exposed to any mechanical shock

since this may lead to a misalignment of the optics.

.

Location:

The instrument should be installed at a vibration-free location with a sufficient heat release, extreme

climate conditions (heat, moisture) should be avoided.

6 Service

Our products are thoroughly examined and tested after production. The primary calibration was

carried out with latex particles and the compliance of the calibration is confirmed on the calibration

label on the back side of the instrument.

The annual recalibration of the instruments with latex particles can be carried out either at the

premises of the customer or on our premises.

Initiation

PC 400 EN V1.5_EN Page 7of 16

7 Principles of functioning

The optical particle counters described in this manual use the scattered light effect for determination of

the particle size and the concentration of aerosol particles. The particles are illuminated with the laser

light. The intensity of the scattered light which is emitted by the particle under different angles is

measured and used as a parameter for determination of the particle diameter. As soon as an aerosol

particle passes through the measuring cell its scattered light gets to a photo element (photo diode) via

a collective lens system. The electronic pulse which is generated is strengthened and allocated to a

pre-selected size range in the microprocessor system. The pulses counted in a pre-selected time span

are related to the volume flow of air (28.3 l/min., or 2.83 l/min.).

When evaluating the counted particles mainly two terms are used which require a more detailed

explanation:

- cumulative (cumul.) = the number of particles which are bigger than the particle diameter given in

the respective channel.

- distributive (distr.) = the number of particles which are bigger than the particle diameter given in the

respective channel but smaller than the (bigger) particle diameter given in the next channel.

According to the factory setting PC 400 gives the measured values distributively.

8 Technical data

PC 400 (0.1µm…5 µm)

PC 400 (0.3 µm…5 µm)

Measuring range

0.1 µm…5 µm

0.3 µm…5 µm

Channels

0.1…0.5 µm

0.5…1 µm

1…5 µm

0.3…0.5 µm

0.5…1 µm

1…5 µm

Counting accuracy acc.

to ISO 21501-4

50% at 0.1 µm

100 at > 0.15 µm

50 % at 0.3 µm

100 % at > 0.45 µm

Max. concentration

1 million. / 1 CFM

Light source

Laser diode

Zero counting

According to ISO 21501-4: < 1 counting / 5 min.

Flow rate

1 CFM / 28.3 L/min

Flow generator

Overpressure in compressed air system / pressure reducer

Calibration

According to ISO 21501-4: Latex-Aerosol

Interface

RS 485 (Modbus protocol)

Dimensions D x W x H

[cm]

15 x 20 x 30

Weight [kg]

8

Power Supply

24 VDC / 30W

9 Identification

9.1 Name plate

Type: LDPC-1-5-P0-DR-RTU

Seriennr.: 1307128

Power: 24VDC 30W

Telefon: +49 (0) 7705-97899-0 www.cs-instruments. com

Zindelsteiner Straße 15

D-78052 VS-Tannheim

Initiation

PC 400 EN V1.4_US Page 8of 16

10 Scope of delivery

1x PC 400

1x Pressure regulator

1x Power supply

1x calibration certificate

1x User manual

11 Initiation

After removing the transportation packaging please place the particle counter PC 400 at first

horizontally onto a vibration-free surface near a mains socket. However, please avoid lines at which

large electric motors or devices with strong electrical interferences are operated. Please use the

instrument in no case near devices with stray radiances or heat radiation (e. g. blowers and heating

devices).

11.1 Voltage supply

The voltage supply is effected via the mains unit which is included in the shipment.

In case of any voltage supply via third-party mains units please observe the following

requirements: 18…36 VDC / 0,75 A

11.2 Connection to the compressed air system (gas supply system)

The particle counter PC 400 is connected to the compressed air system/gas supply system via the

supplied pressure controller (please see photo below).

11.2.1 Zero test

If a zero test should be carried out before starting the measurement the zero filter has to be inserted

behind the pressure controller before connecting PC 400 to the compressed air system/gas supply

system. This serves for a zero test of the sensor and avoids a pollution of the optics.

Important: The pressure at the particle counter PC 400 is not allowed to exceed 1.6 bar over-

pressure. The pressure has to be reduced correspondingly by means of the supplied pressure

controller.

Compressed air system /

gas supply system

Initiation

PC 400 EN V1.4_US Page 9of 16

11.3 Measurement procedure

Before starting the measuring procedure, the zero filter which possibly has been inserted in front of the

PC 400 for zero test has to be removed.

Please observe that no rough objects, smoke (also testing tubes from flow meters) or liquids get into

the optics. The optical system is the most sensitive part of the instrument and has to be disassembled,

cleaned, mounted, adjusted and calibrated completely after the entry of the above mentioned

materials. This time expenditure can be avoided by careful handling. Please avoid an impact of the

instrument by cigarette smoke. Furthermore, please avoid air resp. gas samples which contain more

particles than the specified maximum particle concentration (please see technical data).

The measurement procedure starts immediately after connecting PC 400 to the power supply.

The LED „Power“ (red) and „Laser“ (green) show the proper condition of PC 400.

11.4 Status display

Power: Lightens up if supply voltage is connected

Meas.: Lightens up of the instruments is in measuring mode (counter is active).

If this light expires the particle counter is in the rinsing stage.

Laser: Lightens up if the laser power is within the tolerance.

Flow: The green LED of the three colors luminous row display shows the correctly adjusted

flow (sampling) and the following indications:

green = OK

yellow = within tolerance

red = out of tolerance

RS 485 Interface

PC 400 EN V1.5_EN Page 10 of 16

12 Connection of the RS 485 interface

The particle counter PC 400 disposes of a M12 connector for communication( M12 , 4pole, A-coded)

If no connection cable is ordered the

sensor will be supplied with a M12

connector plug. The user can

connect the supply and signal

cables as indicated in the

connection diagram.

M12 Connector plug

View from back side

(terminal side)

12.1 Connection of the RS 485 interface to a DS 500

1

2

3

4

5

6

7

8

+RS 485

- RS 485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

9

Ext. Anzeige

Weiss / White

Schwarz / Black

Blau / Blue

V Pt

DS 500

Kanal / Channel

12.2 Connection of the RS 485 interface to a DS 400

interneLoop

- RS485(B)

+ RS485 (A)

Pulse Input

4 5 6 7 8

+24Vdc

Loop

SDI

2

-Vb Gnd

13

Loop

Weiss / White

Schwarz / Black

Blau / Blue

DS 400

Kanal / Channel

Pin 1

Pin 2

Pin 3

Pin 4

RS 485 (A)

RS 485 (+)

GND

RS 485 (B)

RS 485 (-)

RS 485 (A)

RS 485 (B)

Modbus RTU A / Modbus RTU (+)

Modbus RTU B / Modbus RTU (-)

RS485

Power

24VDC

PC 400

M12 Stecker Vorderansicht

M12 Connector Front view

PC 400

M12 Stecker Vorderansicht

M12 Connector Front view

RS 485 Interface

PC 400 EN V1.4_US Page 11 of 16

12.3 Modbus Interface Standard-Settings (Factory settings)

Baud Rate 19200

Data bits 8

Parity EVEN

Stop bits 1

Handshake NONE

12.4 Registertable Device version 0,1µm

Address

Pswd Level

dec

Hex

R

W

Data type

Count per f3

1

0x01

0

-

U_Int32

Last measurement

1. Channel to 3. Channel (0,1 < d ≤ 0,5 µm)

2

0x02

3

0x03

0

-

U_Int32

Last measurement

4. Channel to 5. Channel (0,5 < d ≤ 1,0 µm)

4

0x04

5

0x05

0

-

U_Int32

Last measurement

6. Channel to 7. Channel (1,0 < d ≤ 5,0 µm)

6

0x06

7

0x07

0

-

U_Int32

Current measurement (counting)

1. Channel to 3. Channel (0,1 < d ≤ 0,5 µm)

8

0x08

9

0x09

0

-

U_Int32

Current measurement (counting)

4. Channel to 5. Channel (0,5 < d ≤ 1,0 µm)

10

0x0A

11

0x0B

0

-

U_Int32

Current measurement (counting)

6. Channel to 7. Channel (1,0 < d ≤ 5,0 µm)

12

0x0C

13

0x0D

0

-

U_int16

State of laser power (0..100%)

14

0x0E

0

-

U_int16

State of flow rate(80.. 120%)

Address

Pswd Level

dec

Hex

R

W

Data type

Count per m3

40

0x028

0

-

float

Last measurement

1. Channel to 3. Channel (0,1 < d ≤ 0,5 µm)

41

0x029

42

0x02A

0

-

float

Last measurement

4. Channel to 5. Channel (0,5 < d ≤ 1,0 µm)

43

0x02B

44

0x02C

0

-

float

Last measurement

6. Channel to 7. Channel (1,0 < d ≤ 5,0 µm)

45

0x02D

46

0x02E

0

-

float

Current measurement (counting)

1. Channel to 3. Channel (0,1 < d ≤ 0,5 µm)

47

0x02F

48

0x030

0

-

float

Current measurement (counting)

4. Channel to 5. Channel (0,5 < d ≤ 1,0 µm)

49

0x031

50

0x032

0

-

float

Current measurement (counting)

6. Channel to 7. Channel (1,0 < d ≤ 5,0 µm)

51

0x033

13

0x0D

0

-

U_int16

State of laser power (0..100%)

14

0x0E

0

-

U_int16

State of flow rate(80.. 120%)

RS 485 Interface

PC 400 EN V1.4_US Page 12 of 16

12.5 Registertable Device version 0,3µm

Address

Pswd Level

dec

Hex

R

W

Data type

Count per f3

21

0x015

0

-

U_Int32

Last measurement

1. Channel to 3. Channel (0,3 < d ≤ 0,5 µm)

22

0x016

23

0x017

0

-

U_Int32

Last measurement

4. Channel to 5. Channel (0,5 < d ≤ 1,0 µm)

24

0x018

25

0x019

0

-

U_Int32

Last measurement

6. Channel to 7. Channel (1,0 < d ≤ 10,0 µm)

26

0x01A

27

0x01B

0

-

U_Int32

Current measurement (counting)

1. Channel to 3. Channel (0,3 < d ≤ 0,5 µm)

28

0x01C

29

0x01D

0

-

U_Int32

Current measurement (counting)

4. Channel to 5. Channel (0,5 < d ≤ 1,0 µm)

30

0x01E

31

0x01F

0

-

U_Int32

Current measurement (counting)

6. Channel to 7. Channel (1,0 < d ≤ 1,0 µm)

32

0x020

13

0x0D

0

-

U_int16

State of laser power (0..100%)

14

0x0E

0

-

U_int16

State of flow rate(80.. 120%)

Address

Pswd Level

dec

Hex

R

W

Data type

Count per m3

60

0x03C

0

-

float

Last measurement

1. Channel to 3. Channel (0,3 < d ≤ 0,5 µm)

61

0x03D

62

0x03E

0

-

float

Last measurement

4. Channel to 5. Channel (0,5 < d ≤ 1,0 µm)

63

0x03F

64

0x040

0

-

float

Last measurement

6. Channel to 7. Channel (1,0 < d ≤ 10,0

µm)

65

0x041

66

0x042

0

-

float

Current measurement (counting)

1. Channel to 3. Channel (0,3 < d ≤ 0,5 µm)

67

0x043

68

0x044

0

-

float

Current measurement (counting)

4. Channel to 5. Channel (0,5 < d ≤ 1,0 µm)

69

0x045

70

0x046

0

-

float

Current measurement (counting)

6. Channel to 7. Channel (1,0 < d ≤ 1,0 µm)

71

0x047

13

0x0D

0

-

U_int16

State of laser power (0..100%)

14

0x0E

0

-

U_int16

State of flow rate(80.. 120%)

Analogue output 4..20mA

PC 400 EN V1.5_EN Page 13 of 16

13 Analogue Output 4...20mA (Optional)

The particle counter PC 400 can optionally be ordered/delivered with 4x analogue outputs 4...20mA.

The particle counter then has a 9-pin Sub-D socket.

Analogue Output: PIN 1: CH1

PIN 2: CH2

PIN 3: CH3

PIN 4: CH4

PIN 5: GND

Remark:

Channel assignment (value assignment) as well as scaling of the outputs is done at the factory.

D-Sub

Power

24VDC

Operation with evaluation instruments DS 500 / DS 400

PC 400 EN V1.5_EN Page 14 of 16

14 Operation of the particle counter with the chart recorder DS 500

The data transfer of the measured data between particle counter PC 400 and DS 500 is effected via a

digital RS 485 interface (Modbus protocol).

The particle counter PC 400 is stored as a sensor in the sensor selection list in DS 500.

For sensor selection in DS 500 please proceed as follows:

Select sensor type “PC 400“ or “Particle” in the selection list, depending on the Version of DS 500.

For detailed information please see instruction manual DS 500.

Operation with evaluation instruments DS 500 / DS 400

PC 400 EN V1.4_US Page 15 of 16

15 Operation of the particle counter with the multifunction measuring

instrument DS 400

The data transfer of the measured values between PC 400 particle counter and DS 400 is effected via

a digital RS 485 interface (Modbus protocol).

The particle counter PC 400 is stored as a sensor in the sensor selection list in DS 400.

For sensor selection in DS 400 please proceed as follows:

Select sensor type “PC400“ or “Particle“ in the selection list, depending on the DS 400 version..

For detailed information please see instruction manual DS 400.

Operation with evaluation instruments DS 500 / DS 400

PC 400 EN V1.5_EN Page 16 of 16

16 Operation of the particle counter PC 400 with a DS 500 mobile in the

mobile unit for measurement of compressed air quality according to

ISO 8573 –residual oil –particles –moisture

The connection of PC 400 to DS 500 mobile is effected via the 5 meters connection cable (order no.

0553.0501).

1

2

3

4

5

6

7

8

+RS 485

- RS 485

SDI

Analog IN +

+VB 24Vdc

-VB GND

Analog IN -

Weiss / White

Schwarz / Black

Rot / Red

V Pt

DS 400

Kanal / Channel

Cable length 5 / 10 m

PC 400

M12 Stecker Vorderansicht

M12 Connector Front view

Table of contents

Other CS Instruments Measuring Instrument manuals

CS Instruments

CS Instruments DS 300-P User manual

CS Instruments

CS Instruments DS 500 User manual

CS Instruments

CS Instruments DP 400 mobil User manual

CS Instruments

CS Instruments VA 520 User manual

CS Instruments

CS Instruments LD 500 User manual

CS Instruments

CS Instruments LD 510 User manual

CS Instruments

CS Instruments 0554 0504 User manual

CS Instruments

CS Instruments DS400 User manual

CS Instruments

CS Instruments VA 550 Ex User manual

CS Instruments

CS Instruments DS 350-P Installation manual