CTX KOMPACT Series User manual

EM00136493 Rev.1.0

EN

DE

ES

FR

IT

70692

BOMBA PH

INSTALLATION MANUAL

HANDBUCH

MANUAL DE INSTALACION

MANUEL D’INSTALLATION

MANUALE D’INSTALLAZIONE

EM00136493 Rev.1.0

EM00136493 rev. 1.0 EN

1

AB

E

C

G

I

F

D

H

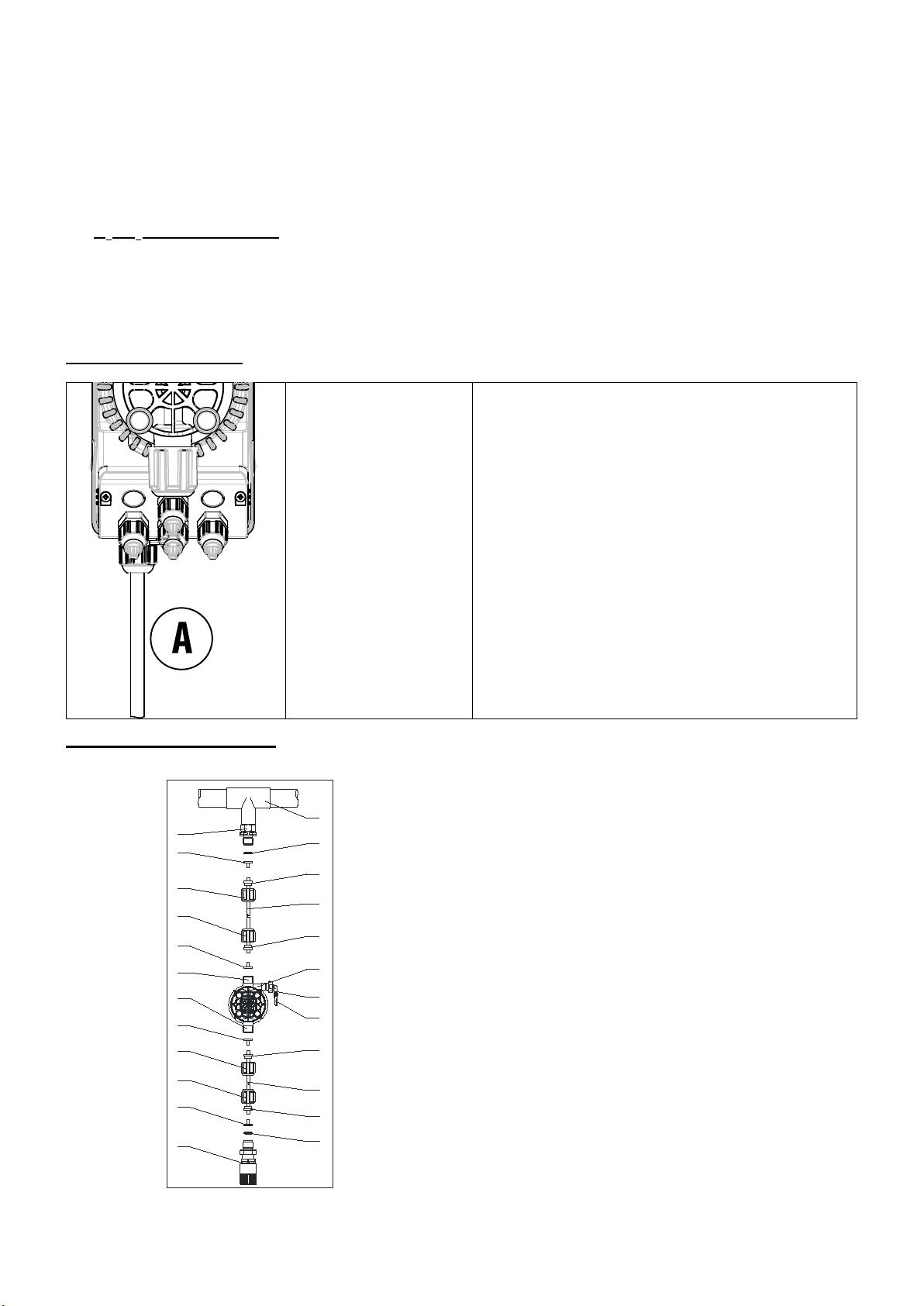

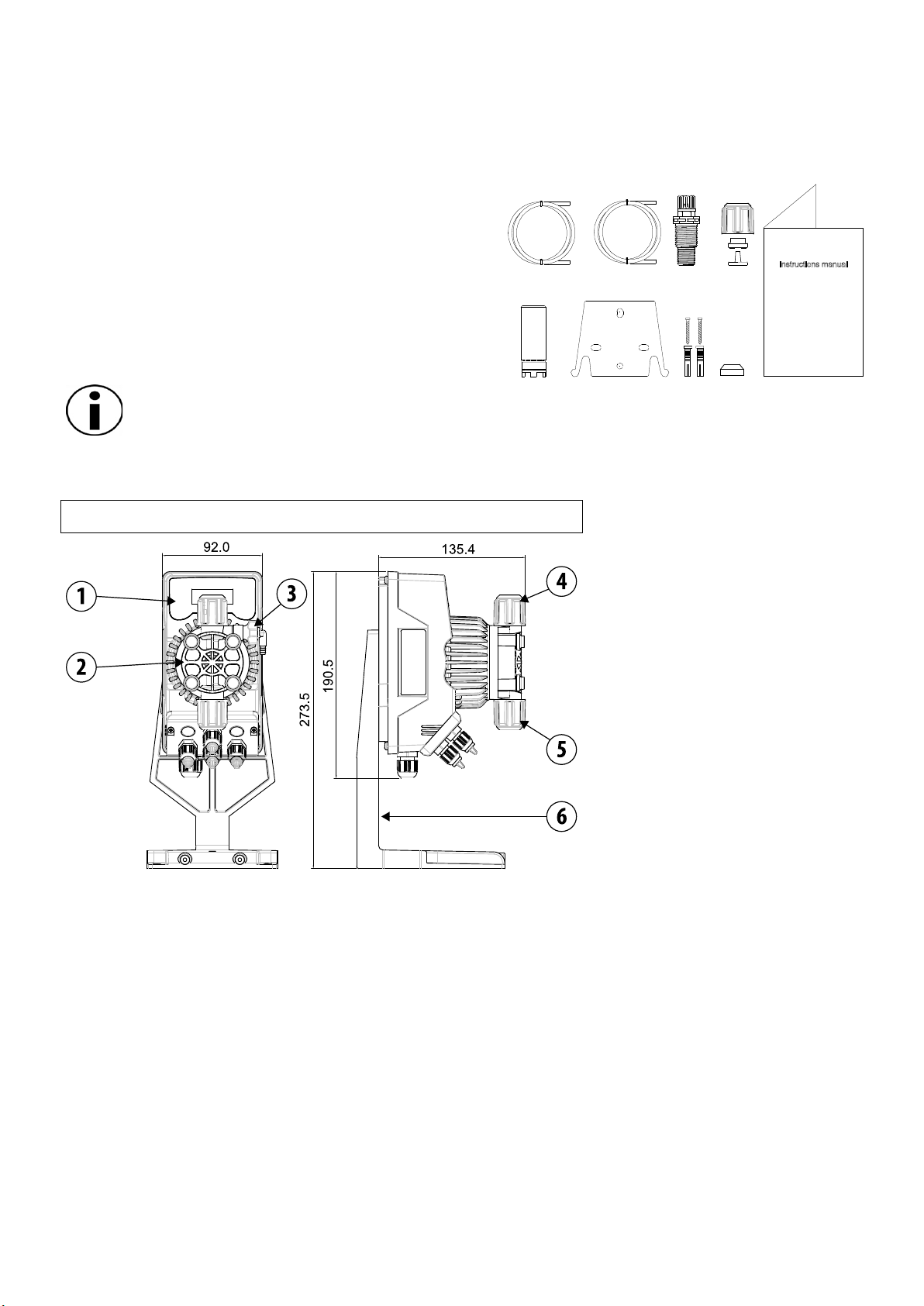

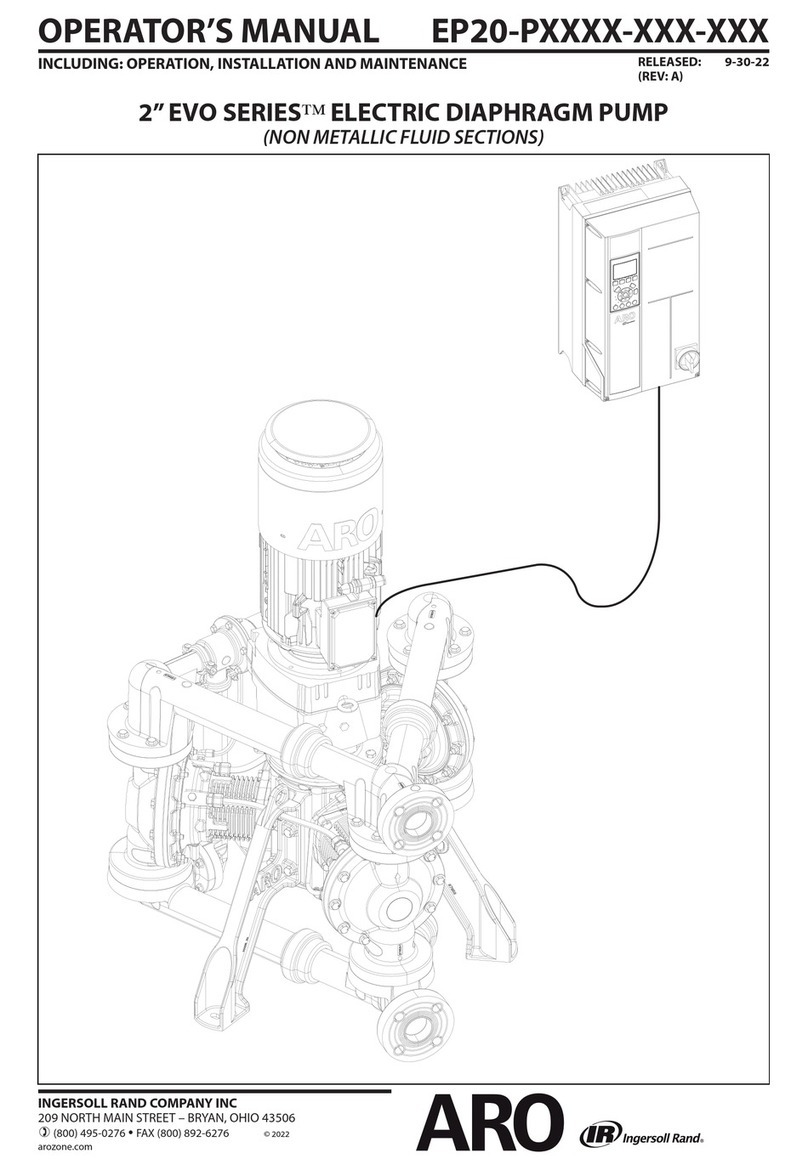

INSTALLATION MANUAL AND COMMISSIONING GUIDE FOR THE

KOMPACT SERIES DOSING PUMPS

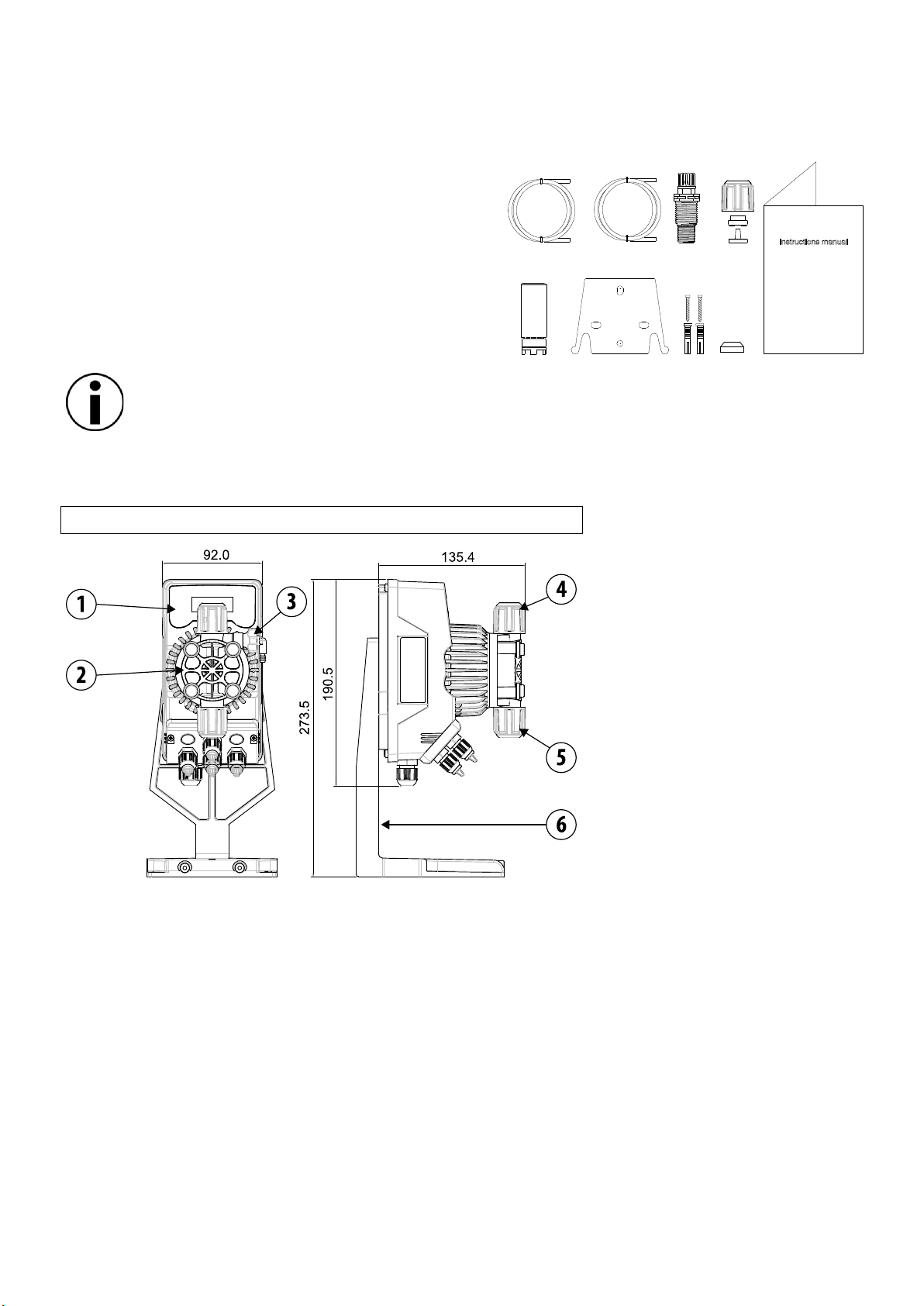

PACK CONTENTS:

A. Opaque tube for connecting the output from the pump

to the point of injection

B. Transparent tube for connecting the bleeder valve for

manual priming

C. Injection fitting

D. Tube connection kit

E. Foot filter

F. Wall fixing bracket

G. Anchor bolts for fixing the wall bracket

H. Pump body screws protection caps

I. Instruction Manual

FOR SPECIFIC HYDRAULIC FEATURES SEE THE LABEL ON THE PUMP

INTRODUCTION

The dosing pump consists of a control section containing the electronics and the magnet, and a hydraulic section, which

is always in contact with the liquid to be dosed.

Check the main specifications of your pump on the data plate

1Control panel

2Dosing head

3Valve for priming the pump

4Delivery connection

5Suction connection

6Support for base-plate (optional)

It is advisable to check the chemical compatibility between the product to be dosed and the materials with

which it will come into contact.

MATERIALS USED TO MAKE THE HEAD OF THE PUMP

•Casing: PVDF-T

•Valve: PVDF-T

•Balls: Ceramic

•Membrane: PTFE

TECHNICAL SPECIFICATIONS

•Weight: 1,5 Kg

•Power supply: 110 ÷ 230 Vac (50-60 Hz)

•Power consumption: 12 W

•Fuse: 2A 250V T 5x20

•Protection class: IP65

EM00136493 rev. 1.0 EN

2

READ CAREFULLY THE FOLLOWING WARNINGS BEFORE PROCEEDING

TO INSTALL OR CARRY OUT MAINTENANCE ON THE PUMP.

WARNING: ALWAYS DISCONNECT THE POWER SUPPLY BEFORE PROCEEDING TO INSTALL OR CARRY OUT

MAINTENANCE ON THE PUMP.

WARNING: WE RECOMMEND INSTALLING THE PUMP IN A VERTICAL POSITION TO ENSURE PROPER OPERATION.

WARNING: PRODUCT INTENDED FOR PROFESSIONAL USE ONLY, BY QUALIFIED PERSONNEL.

WARNING: THE MAINTENANCE OF THE PUMP MUST BE CARRIED OUT BY QUALIFIED AND AUTHORIZED

PERSONNEL.

-H2SO4SULPHURIC ACID Before dosing chemicals that could react with water it is necessary to dry all the internal

hydraulic parts.

-The ambient temperature must not exceed 40°C. The relative humidity must be lower than 90%. The pump protection

class is IP65. Do not install the pump in a place where it would be in direct sunlight.

-Secure the pump firmly into place in order to avoid excessive vibrations.

-The power-supply voltage available in the system and the working pressure must be compatible with those indicated on the

pump label.

WIRING CONNECTIONS

Input A

Power supply 110 ÷

230Vac (50 Hz)

The pump should be connected to a power supply

complying with the indications shown on the label on

the pump side. Failure to comply with the limits

indicated may cause damage to the pump.

These pumps have been designed to absorb minor

over voltages However, in order to prevent any

damage to the pump it is always preferable to avoid

connecting it to the same source of power as electrical

equipment that generates high voltages.

The connection to the three-phase 380V line MUST

always be made solely between phase and

neutral. No connections should

be made between phase and earth.

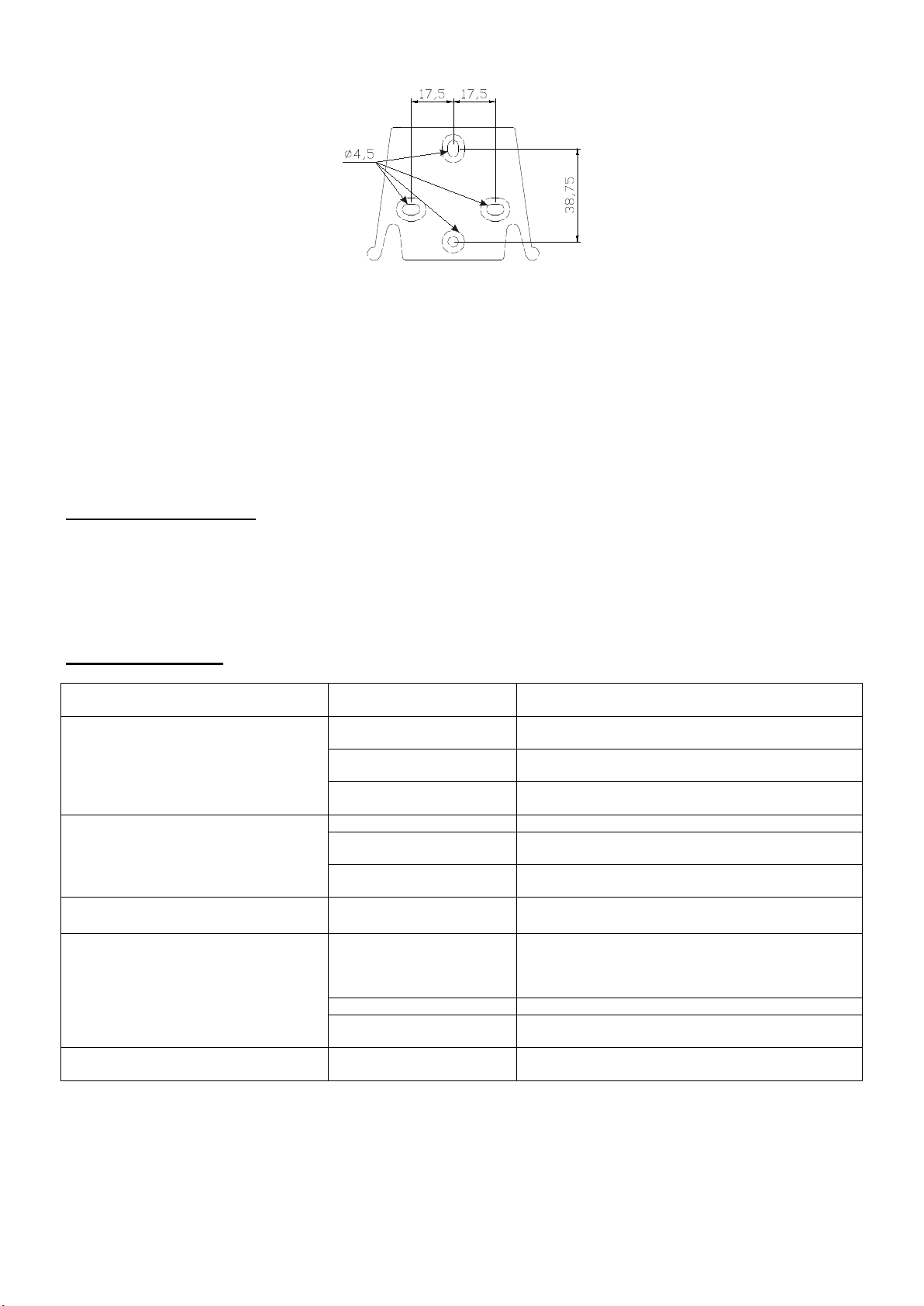

HYDRAULIC CONNECTIONS

13

4

6

3

12

5

2

11

6

4

8

4

6

6

43

14

5

10

9

7

5

5

1

1. Injection point

2. Injection coupling

3. Gasket

4. Washer holder

5. Pipe clamp

6. Ring nut

7. Delivery pipe (rigid)

8. Delivery coupling

9. Pumping body

10. Bleeding valve

11. Suction coupling

12. Suction hose (soft)

13. Foot filter

14. Bleeding valve coupling

EM00136493 rev. 1.0 EN

3

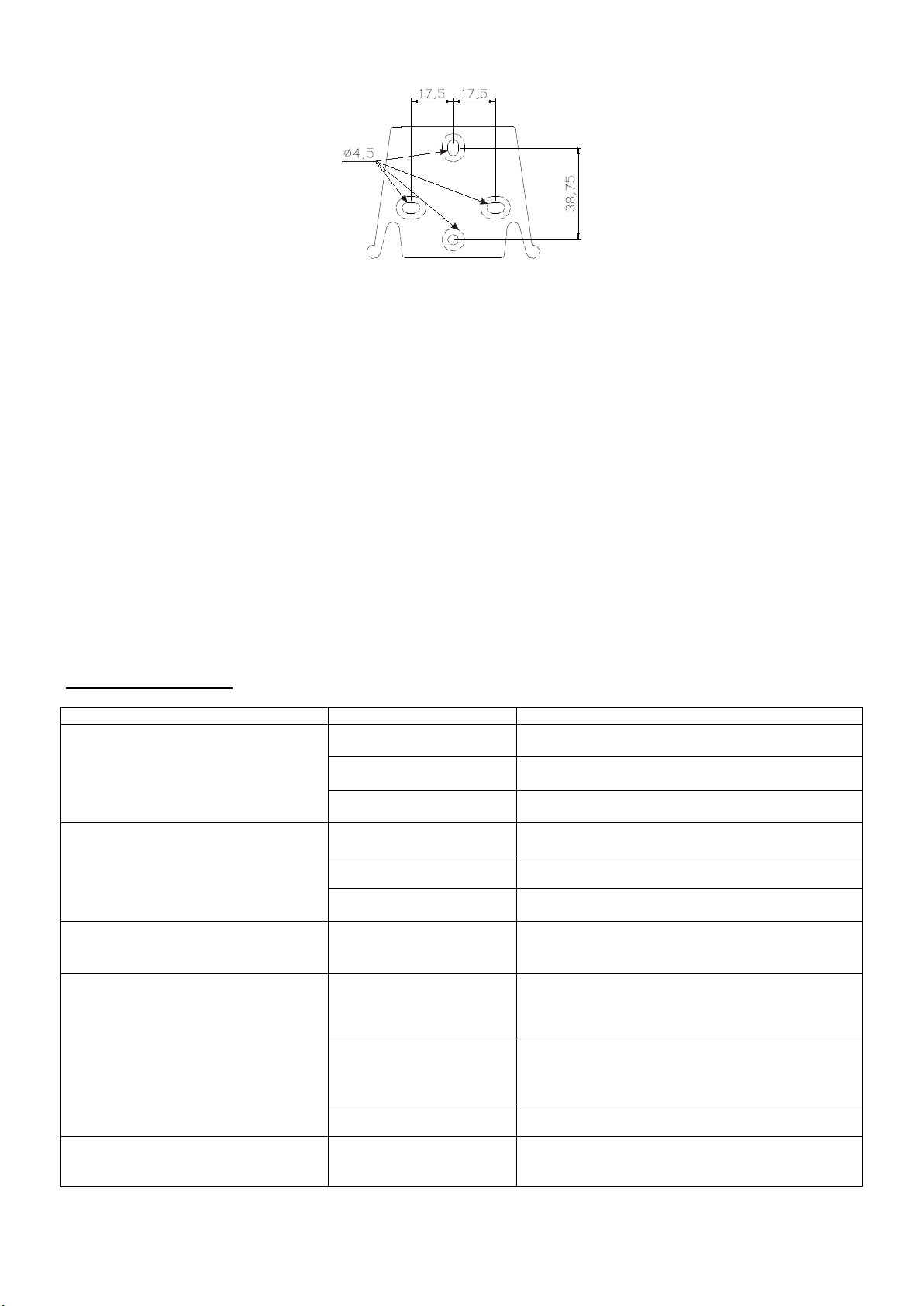

Drilling template for the wall bracket

After about 800 hours of operation, tighten the bolts of the pump body by using a tightening torque of 3 Nm.

In making the hydraulic connections it is necessary to comply with the following instructions:

-The BOTTOM FILTER should be installed at a distance of about 5-10 cm from the bottom, in order to avoid clogging;

-The installation with the pump below the liquid level is recommended for pumps with very low flow rates. In particular when

dosing products that have a tendency to develop gases (ex: sodium hypochlorite, hydrazine, hydrogen peroxide...)

-If it is necessary to use tubes longer than those supplied with the installation kit, they must always have the same

dimensions as those supplied with the pump. If the DELIVERY PIPE is exposed to direct sunlight, it is recommended the

use of a black UV-resistant pipe;

-It is advisable for the INJECTION POINT to be placed higher than the pump or the tank.;

-The INJECTION VALVE supplied with the pump, should always be installed at the end of the dosing-flow delivery line.

STARTING UP THE PUMP

Once you have checked all the above operations, you are ready to start the pump.

Priming

-Start the pump

-Open the priming coupling by turning the knob anticlockwise and wait for the liquid to flow out of the hose connected to it.

-Once you are sure that the pump is completely filled with liquid you can close the coupling and the pump begins to dose.

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

The pump is running regularly but the

dosage was interrupted

The valves are clogged

Clean the valves or replace them if it’s not possible

to remove the deposits

Eccessive intake height

Position the pump or the tank so as to reduce the

intake height

The liquid is too viscous

Reduce the intake height or use a pump with a

higher flow rate

Insufficient flow rate

Leaky valves

Check the tightness of the nuts

The liquid is too viscous

Reduce the intake height or use a pump with a

higher flow rate

Partial clogging of the

valves

Clean the valves or replace them if it’s not possible

to remove the deposits

Irregular pump flow rate

Transparent PVC tube for

delivery

Use the opaque PE tube for delivery

The diaphragm is breaking

Excessive back pressure

Check the system pressure. Check if the injection

valve is clogged. Check if there is a clogging

between the discharge valves and the injection

point.

Operation without liquid

Check the presence of the foot filter (valve)

The diaphragm is not fixed

properly

If the diaphragm has been replaced, check its

proper tightening

The pump does not turn on

Insufficient power supply

Check if the values on the plate of the pump

correspond to those of the electrical network.

EM00136493 rev. 1.0 EN

4

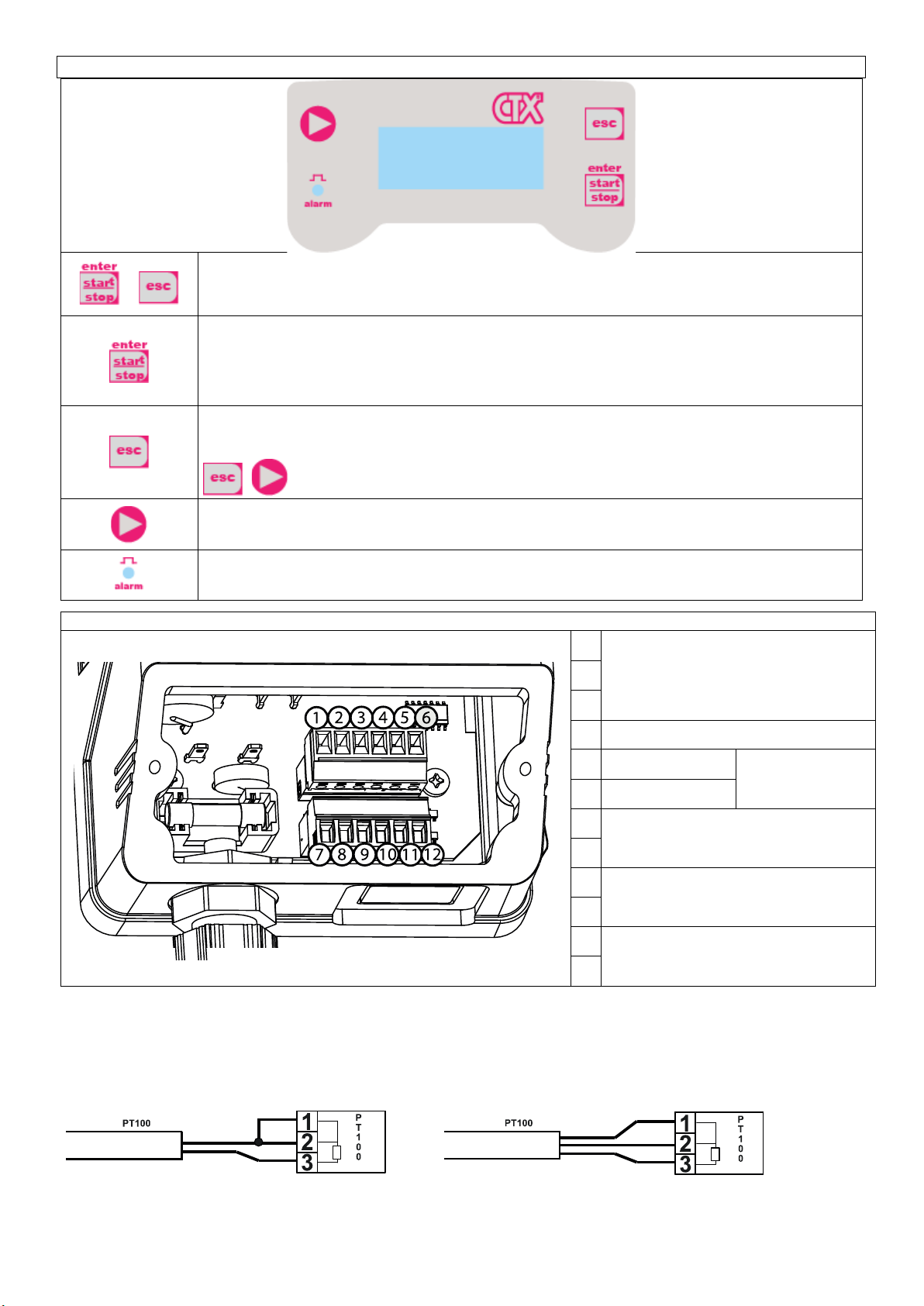

Control panel – KOMPACT DRP

+

To access the programming menu. (Press and hold down simultaneously for at least 3

seconds).

To start and stop the pump.

To disable the display notification in case of active level alarm condition (only alarm function),

flow alarm condition and memory.

In programming mode it functions as “enter”, to confirm the access and the changes to the

various menu levels.

To “escape” the various menu levels. Before exiting the programming mode you will be

prompted to save the changes.

Prolonged pressure displays the screen for the flow sensor calibration.

+ to change the contrast.

To scroll the menus or change the parameters in programming mode.

Prolonged pressure enables the priming.

Green LED flashes while dosing.

Red LED turns on in case of various alarm conditions.

CONNECTIONS DIAGRAM

Electrical connections

1 PT100 temperature probe input (see

the connection diagram)

2

3

4 Not Used

5 Pole - pH or Redox

probe input (pre-

wired with BNC )

6 Pole +

7 Level control probe input

8

9

Remote control input (start-stop)

10

11 Flow sensor input

12

2-wire PT100 connection diagram

3-wire PT100 connection diagram

EM00136493 rev. 1.0 EN

5

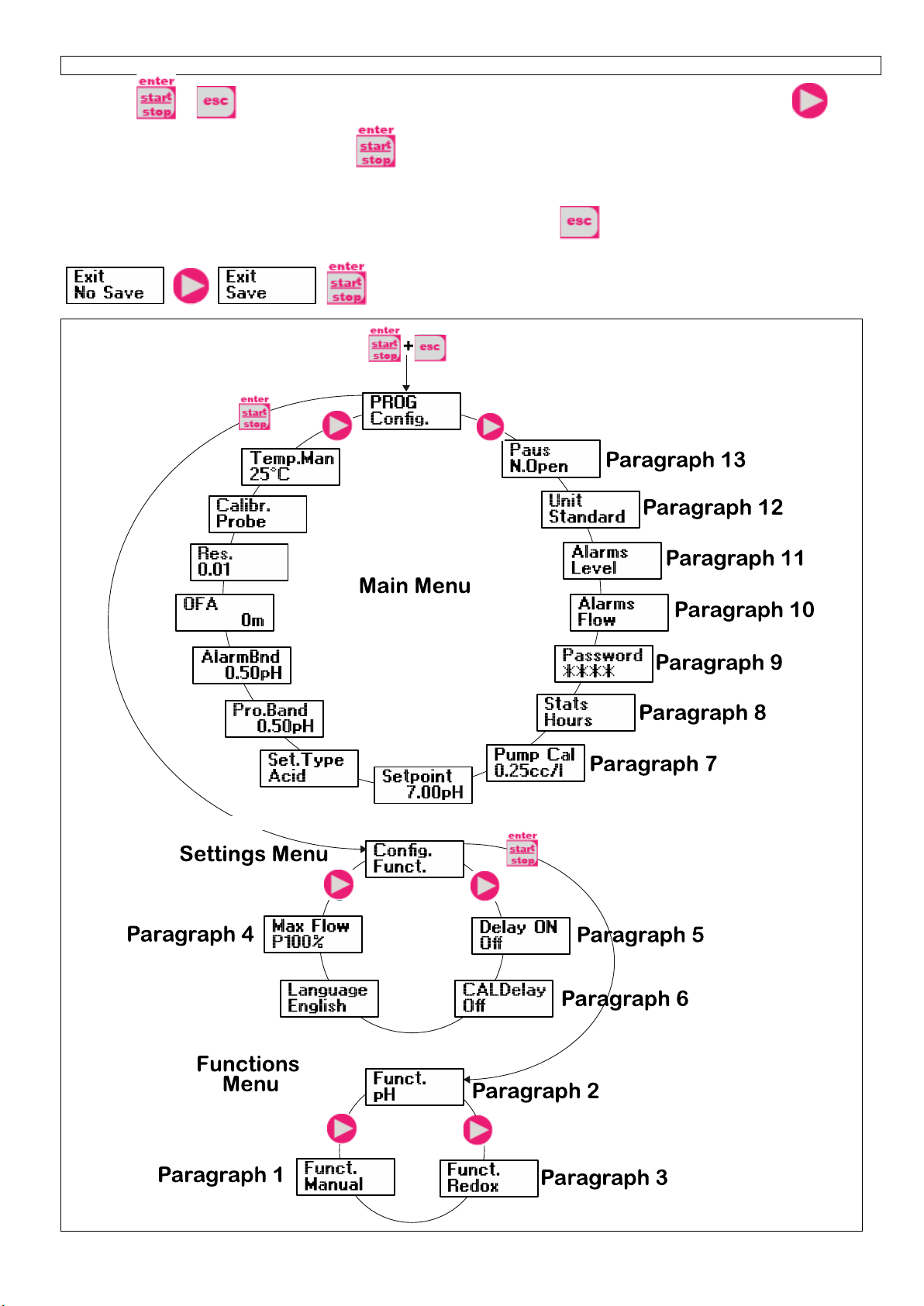

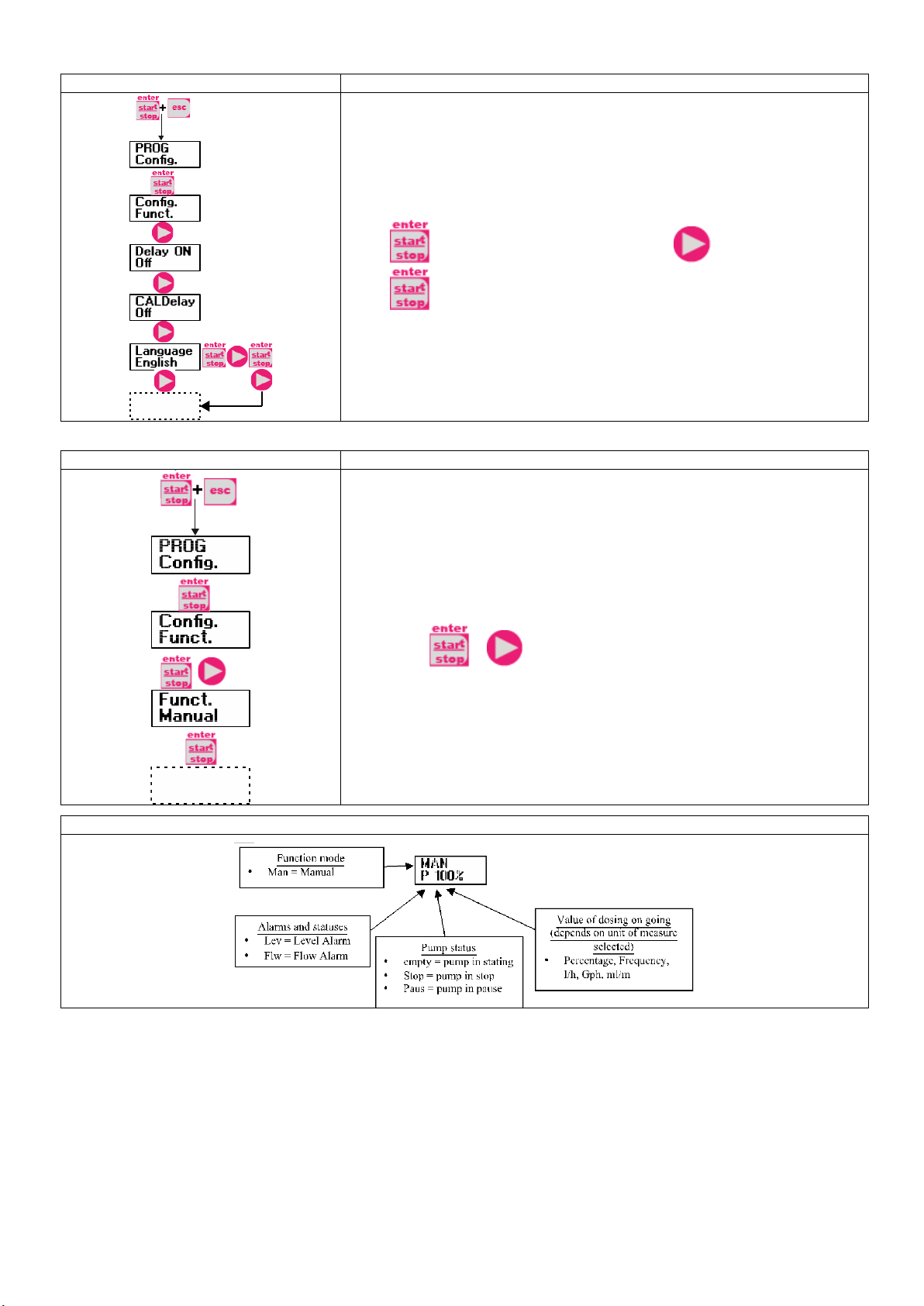

Kompact DRP Programming Menu

Press the + keys for more than three seconds to access the programming mode. Press the key

to scroll the menu items, then press the key to access the options. Whenever a menu item is editable, it

flashes.

By default the pump is set for constant mode. The pump automatically returns to operating mode after 1 minute of

inactivity. In this case, the data entered will not be saved. Press the key to exit the programming levels.

When you exit the programming mode, the display shows:

to confirm your choice.

EM00136493 rev. 1.0 EN

6

Setting the language

Programming

Operation

Allows you to set the language. By default the pump is set to English.

Press to access the item, and then press to set the language.

Press to confirm and return to the main menu.

Paragraph 1 –Manual dosing

Programming

Operation

The pump works in constant mode. The flow rate can be

adjusted manually

by pressing + simultaneously.

Display during operation

EM00136493 rev. 1.0 EN

7

Paragraph 2 – Proportional dosing for the pH measurement (factory default)

Programming

Operation

The pump measures and controls the pH value of a solution, by

programming the following parameters: set-point, set-point type

,

proportional band and alarm band.

Set-point type: acid

014

pH

s/m

max

flow-rate

Ala rm Ba nd Ala rm Ba nd

Proportional

Ba nd

set-point

AlarmOn

AlarmOn

Pump Off

PumpOn

Set-point type: alkaline

014

pH

s/m

max

flow-rate

Ala rm Ba nd Ala rm Ba nd

Proportional

Ba nd

set-point

AlarmOn

AlarmOn

Pump Off

PumpOn

Can also be programmed:

-The O.F.A. (Over Feed Alarm) time in minutes, a set period of time

after

which, if the measured pH does not reach the set-

point, an alarm signal

is activated.

-The resolution of the measurement (1 or 2 digits)

-Activation / deactivation of the calibration procedure

-Manual temperature value in °C (default) or °F

The maximum frequency can be changed during the operation by

pressing + simultaneously.

Display during operation

EM00136493 rev. 1.0 EN

8

Paragraph 3 – Proportional dosing for the Redox (O.R.P.) measurement

Programming

Operation

The pump measures and controls the Redox value of a solution, by

programming the following parameters: set-point, set-point type

,

proportional band and alarm band.

Set-point type: maximum

0

mV

s/m

max

flow-rate

Ala rm Ba nd Ala rm Ba nd

Proportional

Ba nd

set-point

AlarmOn

AlarmOn

Pump Off

P

umpOn

Set-point type: minimum

0

mV

s/m

max

flow-rate

Ala rm Ba nd Ala rm Ba nd

Proportional

Ba nd

set-point

AlarmOn

AlarmOn

Pump Off

PumpOn

Can also be programmed:

-The O.F.A. (Over Feed Alarm) time in minutes, a set period of

time after

which, if the measured Redox value does not reach the set-

point, an

alarm signal is activated.

-The resolution of the measurement (1 or 2 digits)

-Activation / deactivation of the calibration procedure

The maximum frequency can be changed during the operation by

pressing + simultaneously.

Display during operation

EM00136493 rev. 1.0 EN

9

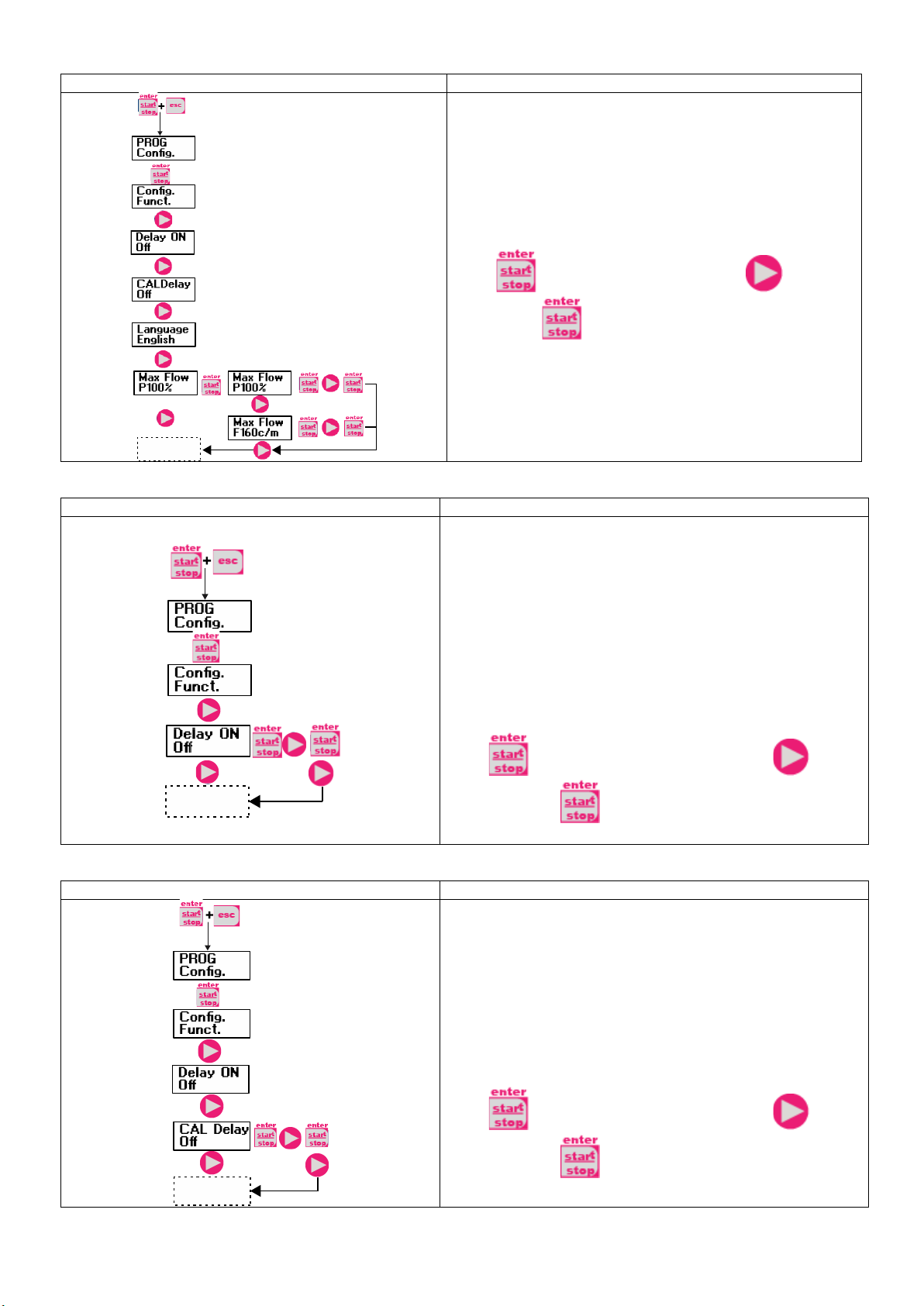

Paragraph 4 – Setting the Maximum Flow Rate

Programming

Operation

Allows you to set the maximum flow rate of the pump and

the programmed mode (% or frequency) is used as the

standard measurement unit when displaying the flow rate.

Press to access the item then press to set the

value. Press to confirm and return to the main

menu.

Paragraph 5 – Setting the Power On Delay

Programming

Operation

Allows you to set a pump operation delay at the start up of

the pump. This delay takes effect only if the pump is

switched off and then switched on by disconnecting the

power supply.

The delay can be disabled, Off (default) or can be set from 1

to 60 minutes.

With the delay enabled, during the set time the LED flashes

(1 sec On – 1 sec Off) and the display shows the countdown

in seconds. If the pump is in Stop mode the display shows

only the flashing LED. During the delay time the function can

be disabled by accessing the menu and setting the time to

Off.

Press to access the item, and then press to set

the value. Press to confirm and return to the main

menu.

Paragraph 6 – Setting the Calibration Delay

Programming

Operation

Allows you to set a pump operation delay after the probe

(Redox or pH) calibration

The delay can be disabled, Off (default) or can be set from 1

to 60 minutes.

With the delay enabled, during the set time the LED flashes

(1 sec On – 1 sec Off) and the display shows the countdown

in seconds. If the pump is in Stop mode the display shows

only the flashing LED. During the delay time the function can

be disabled by accessing the menu and setting the time to

Off.

Press to access the item, and then press to set

the value. Press to confirm and return to the main

menu.

EM00136493 rev. 1.0 EN

10

Paragraph 7 – Flow Rate Calibration

Programming

Operation

On the main menu appears the memorized cc/stroke value

.

You can perform the calibration in two modes:

MANUAL – insert manually the cc/stroke value using the

key and then confirm with the key.

AUTOMATIC – the pump runs 100 strokes,

which are

started by pressing the key, and at the end of the

strokes insert the amount aspirated by the pump using

the

key and confirm with the key.

The data entered will be used for

the calculation of the flow

rates.

Paragraph 8 – Statistics

Programming

Operation

On the main menu is displayed, in hours,

the operating time

of the pump; press to access other statistics:

- Strokes = the number of strokes performed by the pump

- Q.ta (L) = the quantity dosed from the pump expressed

in

liters; this information is calculated based on the

memorized

cc/stroke value

- Power = the number of pump activations

- Reset = press to reset the counters, select

(YES) or

(NO), then press to confirm.

Press to return to the main menu.

EM00136493 rev. 1.0 EN

11

Paragraph 9 – Password

Programming

Operation

By setting the password, the programming section can be

accessed to view all the setup parameters, but every time

you try to change the settings you will be prompted for the

password.

The flashing line indicates the editable number; press

to select the number (from 1 to 9), then press to select

the number to modify, and then press to confirm.

By setting “0000” (default), the password will be eliminated.

Paragraph 10 – Flow Alarm

Programming

Operation

Allows you to activate (deactivate) the flow sensor.

Once activated (On) by pressing the key,

you can set

the number of signals

the pump requires before starting the

alarm. Press and the number will start to flash; press

to set the value. Press to confirm. Press

to return to the main menu.

Paragraph 11 – Level Alarm

Programming

Operation

Allows you to set the pump for the level alarm activation,

with dosage operation interruption (Stop), or simple

activation of the alarm signal without dosage operation

interruption.

Press to access the item then press to set the

alarm type. Press to confirm. Press to return to

the main menu.

EM00136493 rev. 1.0 EN

12

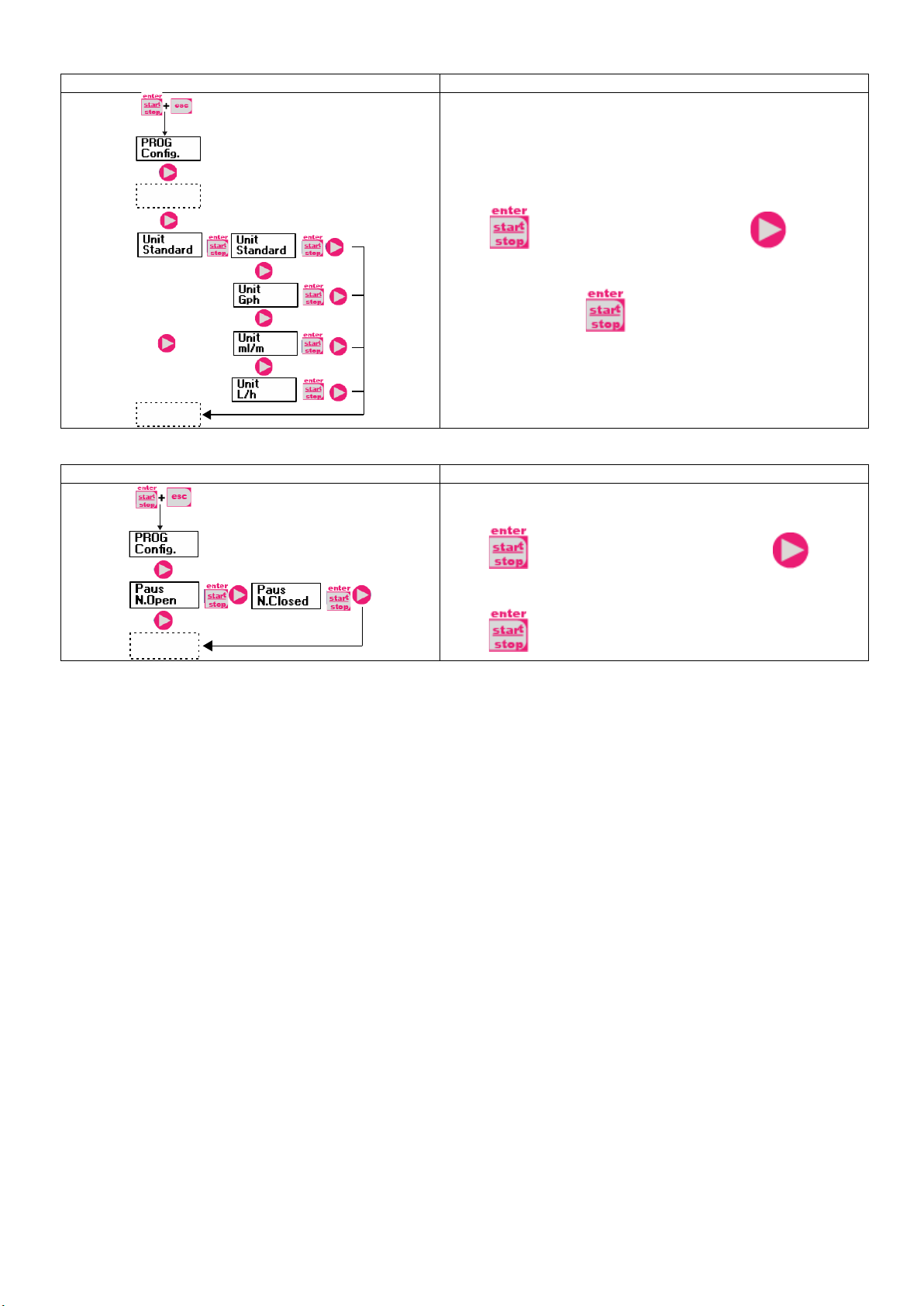

Paragraph 12 – Flow Rate Measurement Unit Display

Programming

Operation

Allows you to set the measurement unit of the displayed

dosage.

Press to access the item, then press

to set the

type of unit, L/h (Liter/hour), Gph (Gallons/hour), mL

/m

(milliliters/minute) or standard (% or frequency, according

to

the settings). Press

to confirm and return to the main

menu.

Paragraph 13 – Setting the Pause

Programming

Operation

Remote input to pause the pump.

By default, the system is set to Normally Open.

Press to access the item, and then press to set

the value (N. OPEN or N. CLOSED).

Press to confirm and return to the main menu.

EM00136493 rev. 1.0 EN

13

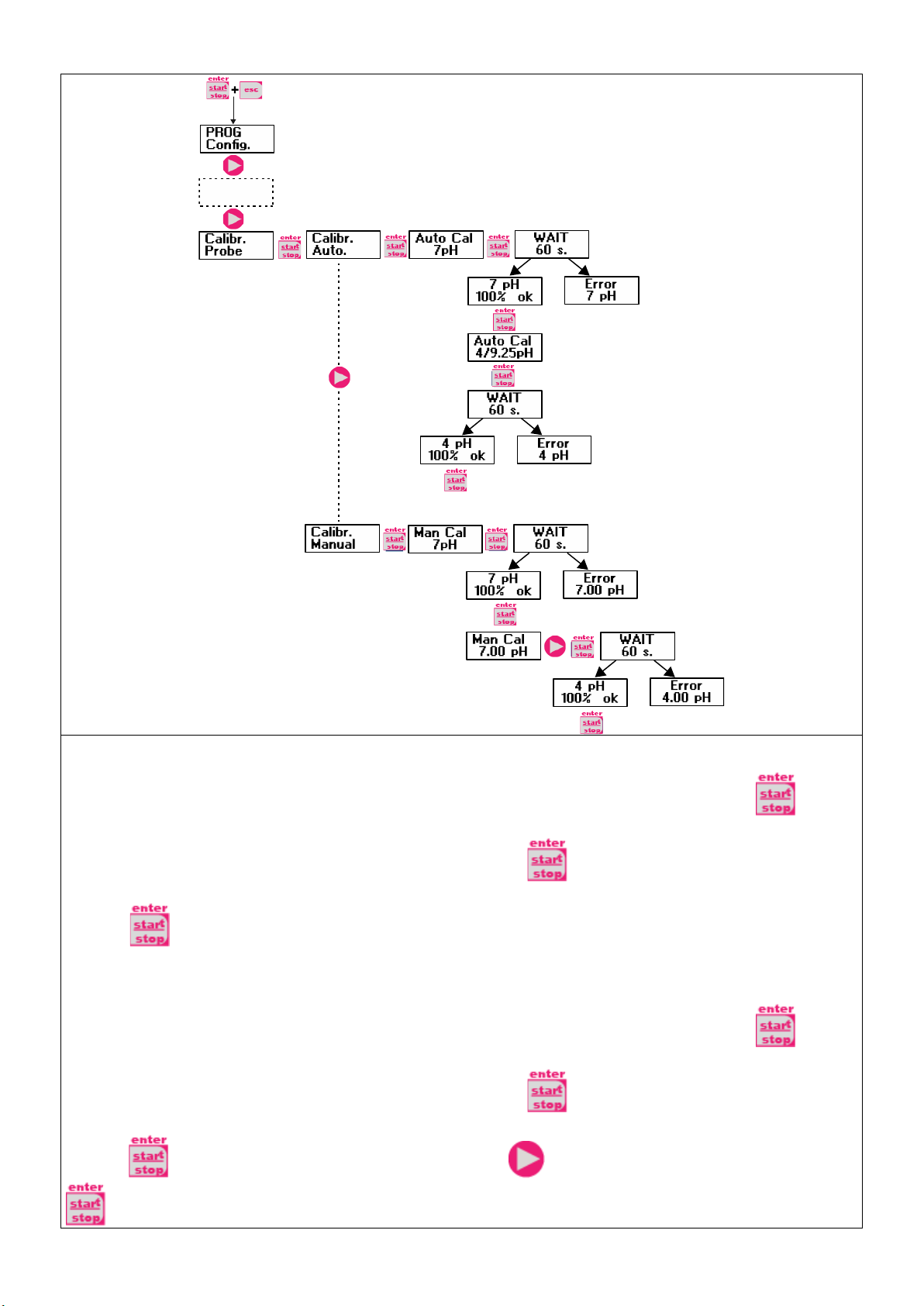

Calibration Menu

You can choose the automatic or manual calibration mode, in both cases the calibration at pH 7 is automatic.

-Automatic calibration:

When the display shows the value of the buffer solution, insert the probe into the bottle, press a

nd the

display will show the countdown of the 60 seconds required to complete the calibration.

If the quality of the

alignment is less than 50%, an error appears on the display; press

to exit the calibration (after 4 seconds the

pump will automatically exit the calibration); if the quality is higher than 50%, the value appears on the display;

pressing you will be prompted for the pH 4 or 9 buffer solution;

at this point the procedure is similar to the

previous calibration.

-Manual calibration:

When the display shows the value of the buffer solution, insert the probe into the bottle, press

and the

display will show the countdown of the 60 seconds required to complete the calibration.

If the quality of the

alignment is less than 50%, an error appears on the display; press to exi

t the calibration (after 4 seconds the

pump will automatically exit the calibration); if the quality is higher than 50%, the value appears on the display;

pressing on the display will flash the pH 7.00 value; press to insert the value of my solution, then press

to confirm and start the calibration procedure as described previously.

EM00136493 rev. 1.0 EN

14

Redox (O.R.P.) Calibration Menu

You can choose the automatic or manual mode.

-Automatic calibration:

When the display shows the value of the buffer solution, insert the probe into the bottle, press

and the

display will show the countdown of the 60 seconds required to complete the calibration.

If the quality of the

alignment is less than 50%, an error appears on the display; press

to exit the calibration (after 4 seconds the

pump will automatically exit the calibration); if the quality is higher than 50%, the value appears on the display;

press and the procedure is completed.

-Manual calibration:

When the display shows the value of the buffer solution, insert the probe into the bottle, press and the

display will show the value 465mV flashing, insert the probe into my solution, press to display the value of my

solution, then press to confirm and start the calibration procedure as described previously.

EM00136493 rev. 1.0 EN

15

Alarms

Dislay

Cause

Remedy

Alarm LED on

“Lev” icon flashing

End level alarm, without pump

operation interruption.

Restore the liquid level.

Alarm LED on

“Lev” and “Stop” icons flashing

End level alarm, with pump

operation interruption.

Restore the liquid level.

Alarm LED on

“Flw” icon flashing

Flow alarm activated, the pump has

not received from the flow sensor

the programmed number of signals. Press the key.

“OFA” icon flashing

“Stop” icon flashing

O.F.A. alarm

Press the key to stop the

flashing of the “Stop” icon, press

the key again to restart the pump.

“Alm” icon flashing

The value read by the probe is out

of the alarm band set

Check the "Alarm Band" parameter

for the correct settings in

programming mode.

“Cal” icon flashing

Probe not calibrated alarm

Perform the probe calibration

procedure.

EM00136493 rev. 1.0 DE

1

AB

E

C

G

I

F

D

H

INSTALLATIONS- UND INBETRIEBNAHMEANLEITUNG FÜR DIE

DOSIERPUMPE SERIE KOMPACT

Packungsinhalt:

A. Undurchsichtiger Schlauch für den Anschluss des

Pumpenausgangs an den Einspritzpunkt

B. Transparenter Schlauch für die Ansaugung, für den

Anschluss des Auslassventils und für die manuelle

Befüllung

C. Anschluss Einspitzung

D. Satz Schlauchanschlüsse

E. Bodenfilter

F. Bügel für Wandmontage

G. Dübel für die Montage des Wandbügels

H. Schraubenschutzkappen

I. Anleitung

HYDRAULISCHE BESONDERHEITEN FINDEN SIE UNTER DER BEZEICHNUNG AUF DER PUMPE

EINLEITUNG

Die Dosierpumpe besteht aus einer Steuereinheit, in der die Elektronik und der Magnet sowie ein Teil der Hydraulik

untergebracht sind, immer in Kontakt mit der zu dosierenden Flüssigkeit.

Prüfen Sie anhand der Angaben auf dem Typenschild die Haupteigenschaften

Ihrer Pumpe

1. Einstellbereich

2. Dosierkopf

3. Befüllventil

4. Druckanschluss

5. Ansauganschluss

6. Gestell für Unterbau (optional)

Wir empfehlen eine Prüfung der chemischen Kompatibilität zwischen dem dosierten Produkt und den

Kontaktmaterialien.

MATERIALIEN DES PUMPENKOPFES

•Pumpengehäuse: PVDF-T

•Ventile: PVDF-T

•Kugeln: Keramik

•Membran: PTFE

TECHNISCHE MERKMALE

•Gewicht: 1,5 Kg

•Stromversorgung: 110 ÷ 230 Vac (50-60 Hz)

•Leistungsaufnahme: 12 W

•Sicherung: 2A 250V T 5x20

•Schutzgrad: IP65

•Eingang Füllstandskontrolle: Trockenkontakt (on-off)

•Impulseingang: Trockenkontakt (on-off) Höchstfrequenz 80Hz

EM00136493 rev. 1.0 DE

2

VOR DER INSTALLATION ODER

WARTUNGSARBEITEN AN DER PUMPE AUFMERKSAM LESEN

ACHTUNG: VOR DER INSTALLATION ODER DER WARTUNG DER PUMPE IMMER ZUNÄCHST DIE VERSORGUNG

TRENNEN.

ACHTUNG: WIR EMPFEHLEN DIE INSTALLATION DER PUMPE IN EINER VERTIKALEN POSITION UM EINEN

ORDNUNGSGEMÄSSEN BETRIEB ZU GEWÄHRLEISTEN.

ACHTUNG: DAS PRODUKT IST AUSSCHLIESSLICH FÜR DEN PROFESSIONELLEN GEBRAUCH DURCH

QUALIFIZIERTES PERSONAL BESTIMMT.

ACHTUNG: DIE WARTUNG DER PUMPE DARF AUSSCHLIESSLICH DURCH QUALIFIZIERTES UND AUTORISIERTES

PERSONAL DURCHGEFÜHRT WERDEN.

-H2SO4SCHEFELSÄURE Vor der Dosierung chemischer Produkte, die mit Wasser reagieren können, müssen alle

internen Komponenten der Hydraulik getrocknet werden.

-Umgebungstemperatur unter 40°C. Relative Luftfeuchte unter 90%. Schutzgrad: IP65 Die Pumpe nicht so installieren, dass

sie direkt Sonnenstrahlen ausgesetzt ist.

-Die Pumpe gut befestigen, damit übermäßige Vibrationen vermieden werden.

-Versorgungsspannung und -druck der Anlage müssen mit den Angaben auf dem Etikett der Pumpe übereinstimmen.

ELEKTRISCHE ANSCHLÜSSE

Eingang A = Versorgung

110 ÷ 230 Vac (50-60

Hz)

Die Pumpe muss an eine Versorgung

angeschlossen werden, die mit den

Angaben auf dem Etikett an der Seite der

Pumpe übereinstimmen. Die

Nichtbeachtung dieser Vorschrift kann zu

Schäden an der Pumpe führen.

Die Pumpen wurden geplant, um geringe

Überspannungen absorbieren zu können.

Um Schäden an der Pumpe zu vermeiden,

sollte daher immer sicher gestellt werden,

dass sie keine Energiequelle zusammen mit

anderen elektrischen Apparaten nutzt, die

hohe Spannungen erzeugen.

Die Verbindung mit der 380V-

Dreiphasenleitung darf NUR zwischen

Phase und Neutralleiter vorgenommen

werden. Die Anschlüsse DÜRFEN NICHT

zwischen Phase und Erde erfolgen.

HYDRAULIKANSCHLÜSSE

13

4

6

3

12

5

2

11

6

4

8

4

6

6

43

14

5

10

9

7

5

5

1

1. Einspritzpunkt

2. Anschluss Einspritzung

3. Dichtung

4. Schlauchhalterung

5. Schlauchdurchführung

6. Gewindering

7. Druckschlauch (starr)

8. Druckventil

9. Pumpengehäuse

10. Ablassventil

11. Ansaugventil

12. Ansaugschlauch (weich)

13. Bodenfilter

14. Anschluss Ablassventil

EM00136493 rev. 1.0 DE

3

Bohrschablonen Wandbügel

Nach etwa 800 Betriebsstunden die Bolzen des Pumpengehäuses mit einem Anzugsmoment von 3 Nm anziehen.

Zum Durchführen derWasseranschlüsse müssen folgende Hinweise beachtet werden:

-Den BODENFILTER etwa 5-10cm über dem Boden installieren, um eventuelle Ablagerungen zu vermeiden

-Die Installation unter dem Flüssigkeitsstand wird bei Pumpen mit sehr geringer Fördermenge empfohlen. Insbesondere für

die Dosierung von Produkten, die Gase entwickeln (z.B. Natriumhypochlorit, Hydrazin, Wasserstoffperoxid,...).

-Bei Schläuchen, die länger als die im Installationssatz enthaltenen sind, ist es wichtig, dass diese dieselben Maße wie die

mit der Pumpe gelieferten aufweisen. Wenn die DRUCKLEITUNG Sonnenstrahlung ausgesetzt ist, empfiehlt sich der

Einsatz eines schwarzen, UV-beständigen Schlauchs;

-Der EINSPRITZPUNKT sollte höher als die Pumpe oder der Tank liegen;

-Das EINSPRITZVENTIL, das mit der Pumpe geliefert wird, muss immer am Ende der Druckleitung des Dosierungsflusses

installiert werden.

START

Nach der Durchführung aller zuvor beschriebenen Schritte ist die Pumpe für den Start bereit.

Befüllen

-Die Pumpe starten

-Den Befüllanschluss durch Drehen des Knaufs entgegen dem Uhrzeigersinn öffnen und warten, bis die Flüssigkeit aus der

angeschlossenen Leitung tritt.

-Nachdem sicher gestellt wurde, dass die Pumpe ganz gefüllt ist, kann der Anschluss wieder geschlossen werden und die

Pumpe beginnt mit der Dosierung.

PROBLEMBEHEBUNG

Störung

Mögliche Ursache

Lösung

Die Pumpe funktioniert normal, aber die

Dosierung wurde unterbrochen.

Verstopfung der Ventile

Die Ventile reinigen oder, wenn es nicht möglich ist,

die Verkrustungen zu entfernen, ersetzen

Übermäßige Ansaughöhe

Die Pumpe oder den Tank so positionieren, dass die

Ansaughöhe reduziert wird

Flüssigkeit zu viskos

Die Ansaughöhe reduzieren oder eine Pumpe mit

höherer Fördermenge nutzen

Unzureichende Fördermenge

Leckage der Ventile

Kontrollieren, ob die Gewinderinge korrekt

angezogen sind

Flüssigkeit zu viskos

Eine Pumpe mit höherer Fördermenge nutzen oder

die Ansaughöhe reduzieren

Teilweise Verstopfung der

Ventile

Die Ventile reinigen oder, wenn es nicht möglich ist,

die Verkrustungen zu entfernen, ersetzen

Unregelmäßige Fördermenge der

Pumpe

Für die Druckleitung wird

ein transparenter PVC-

Schlauch genutzt

Einen undurchsichtigen PE-Schlauch für die

Druckleitung nutzen

Membran ist kaputt

Zu hoher Gegendruck

Den Druck der Anlage prüfen. Prüfen, ob das

Einspritzventil verstopft ist. Prüfen, ob zwischen den

Druckventilen und dem Einspritzpunkt

Verstopfungen vorhanden sind.

Betrieb ohne Flüssigkeit

Prüfen, ob der Bodenfilter (das Ventil) vorhanden

ist. Eine Füllstandssonde verwendet, die die Pumpe

blockiert, wenn das chemische Produkt im Tank zu

Ende geht

Membran nicht richtig

befestigt

Bei Ersatz der Membran prüfen, dass diese wieder

richtig befestigt wird.

Die Pumpe geht nicht an

Unzureichende Versorgung

Prüfen, ob die Werte auf dem Typenschild der

Pumpe mit denen des Stromnetzes

übereinstimmen.

This manual suits for next models

3

Table of contents

Languages:

Other CTX Water Pump manuals

Popular Water Pump manuals by other brands

Xylem

Xylem LOWARA e-SV Series Additional Installation, Operation and Maintenance Instructions

Grundfos

Grundfos CR 1 instructions

Pacific hydrostar

Pacific hydrostar PacificHydrostar 2" Gasoline Powered Clear Water... manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 0 Series Installation, operation, and maintenance manual with parts list

Graco

Graco Series A Repair

Ingersoll-Rand

Ingersoll-Rand ARO EVO EP20-P Series Operator's manual